Conductive agent for lithium battery and preparation method thereof

A conductive agent, lithium battery technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve problems such as difficulty in ensuring good contact of conductive agents, inability to achieve conductive effects, and increased costs, to achieve reliable long-distance conductivity and improve charge and discharge Rate and cycle performance, effects of reducing internal resistance and temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Wash and dry carbon black particles with a particle size of 50 nm with sodium hydroxide, hydrochloric acid and deionized water;

[0025] (2) The carbon black particles obtained in step (1) are soaked in a toluene solvent containing 0.1 mol / L of ferrocene for 1 hour, taken out and dried.

[0026] (3) Put the carbon black particles obtained in step (2) into a microwave device, turn on the microwave, and grow for 90 seconds to grow multiple multi-walled carbon nanotubes on the surface of the carbon black particles to obtain carbon nanotubes / carbon black particles In the conductive particles, the growth direction of the carbon nanotubes is radiating outward from the surface of the carbon black particles. The diameter of the carbon nanotubes is 20nm and the length is 10μm.

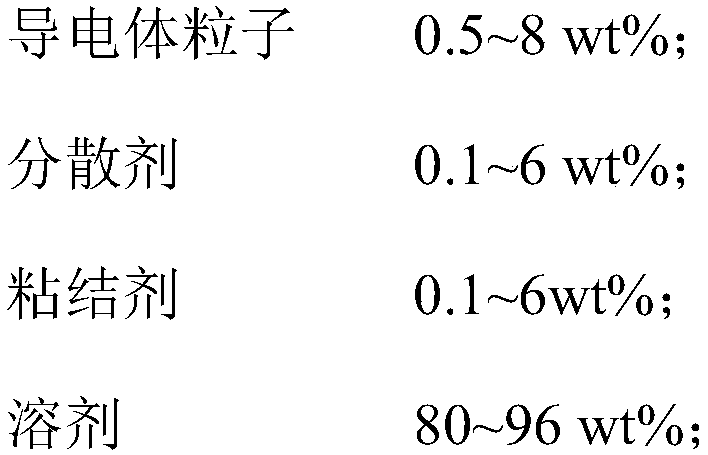

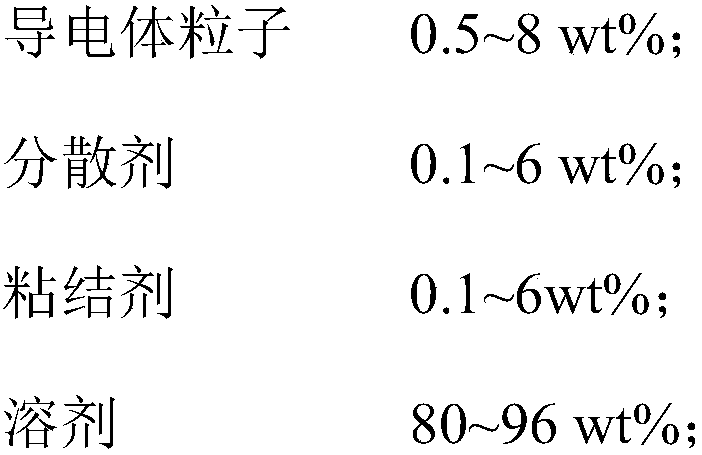

[0027] (4) The conductor particle powder, polyvinylpyrrolidone (PVP), polyvinylidene fluoride (PVDF) and nitrogen methyl pyrrolidone (NMP) obtained in step (3) are respectively 2wt%, 1wt%, 2wt%, 95wt% % By...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com