Method and apparatus for repair of wells utilizing meltable repair materials and exothermic reactants as heating agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention provides apparatus and methods for repairing fluid seal defects in subterranean structures of wells using meltable repair materials which are melted using exothermic reactant materials. By way of example and not limitation, the method and apparatus can be used to repair leaking cemented annuli, cement, mechanical or other fluid sealing plugs, unwanted perforations in wells which are to be abandoned or to temporarily or permanently isolate high pressure intervals, or shut-off water influx in gravel-packed production intervals. Defects may include seals, while currently integral, are to be reinforced to further enhance the structural integrity of the seal.

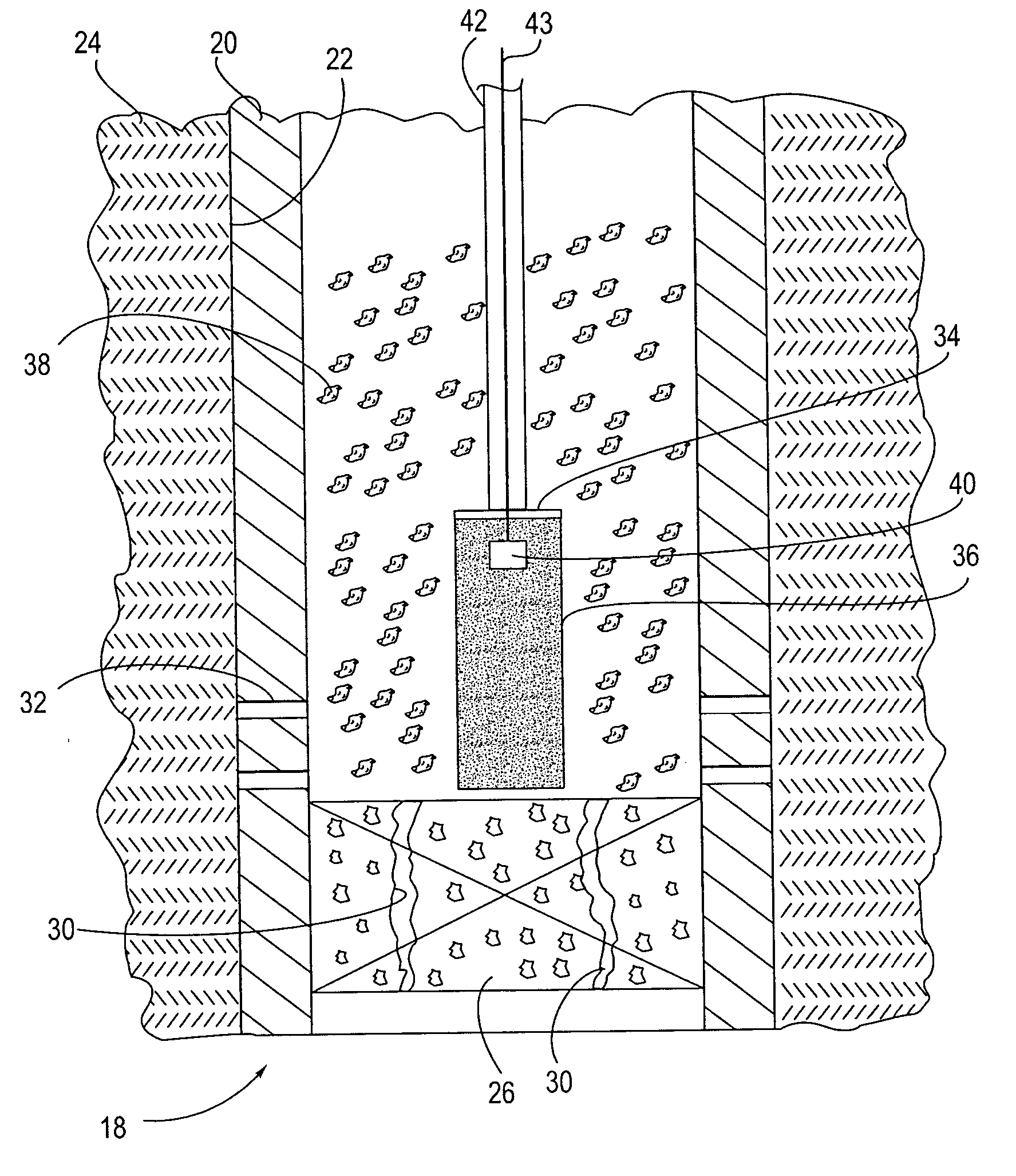

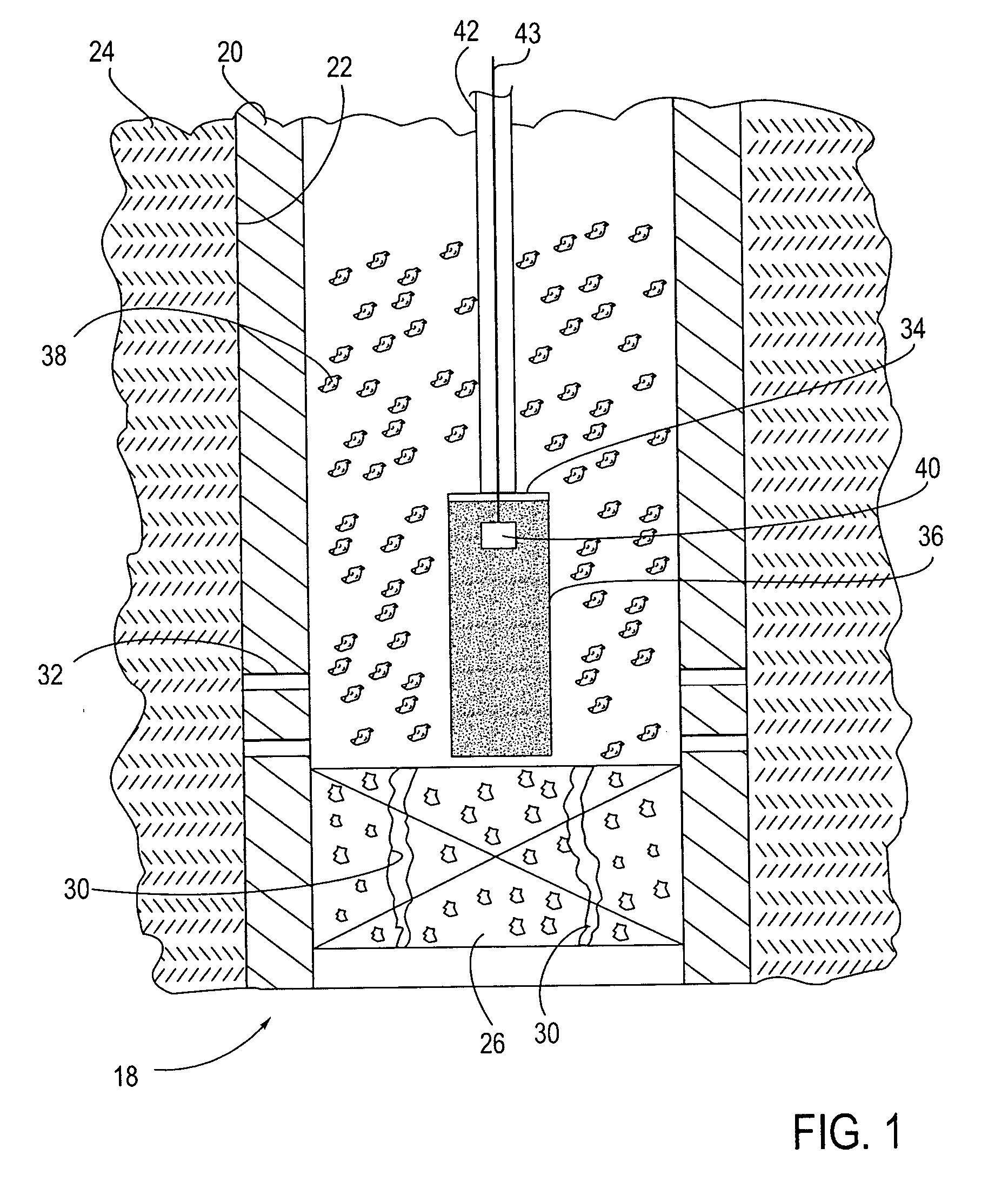

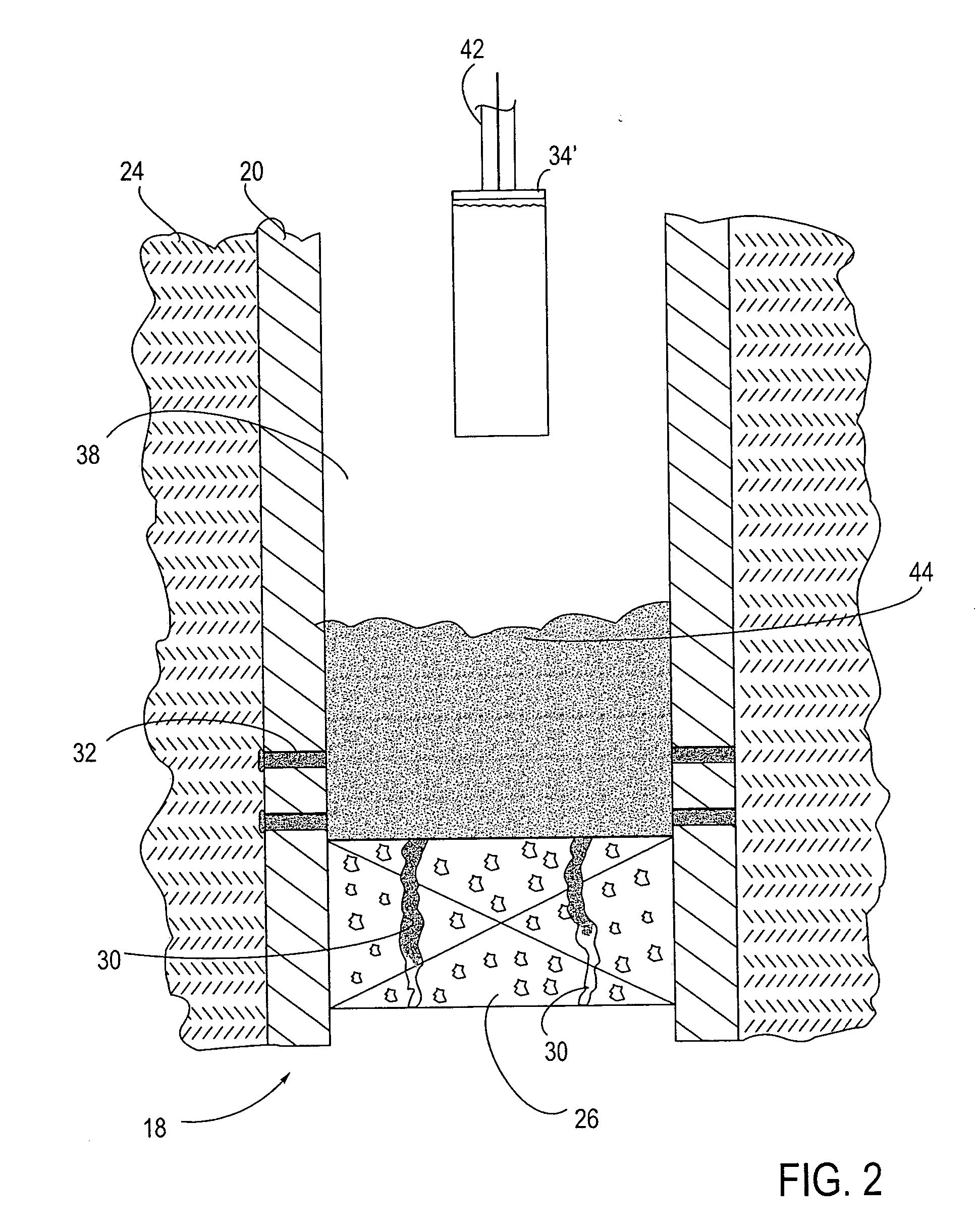

[0018] As a first example, FIG. 1 shows a casing 20 lining a wellbore 22 formed in an earth formation 24. Located within casing 20 is a cement or mechanical bridge plug 26. Cracks 30 in cement plug 26 and perforations 32 in casing 20 allow fluids to pass through cement plug 26 and casing 20 or the plug m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com