Patents

Literature

76 results about "Selective stimulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

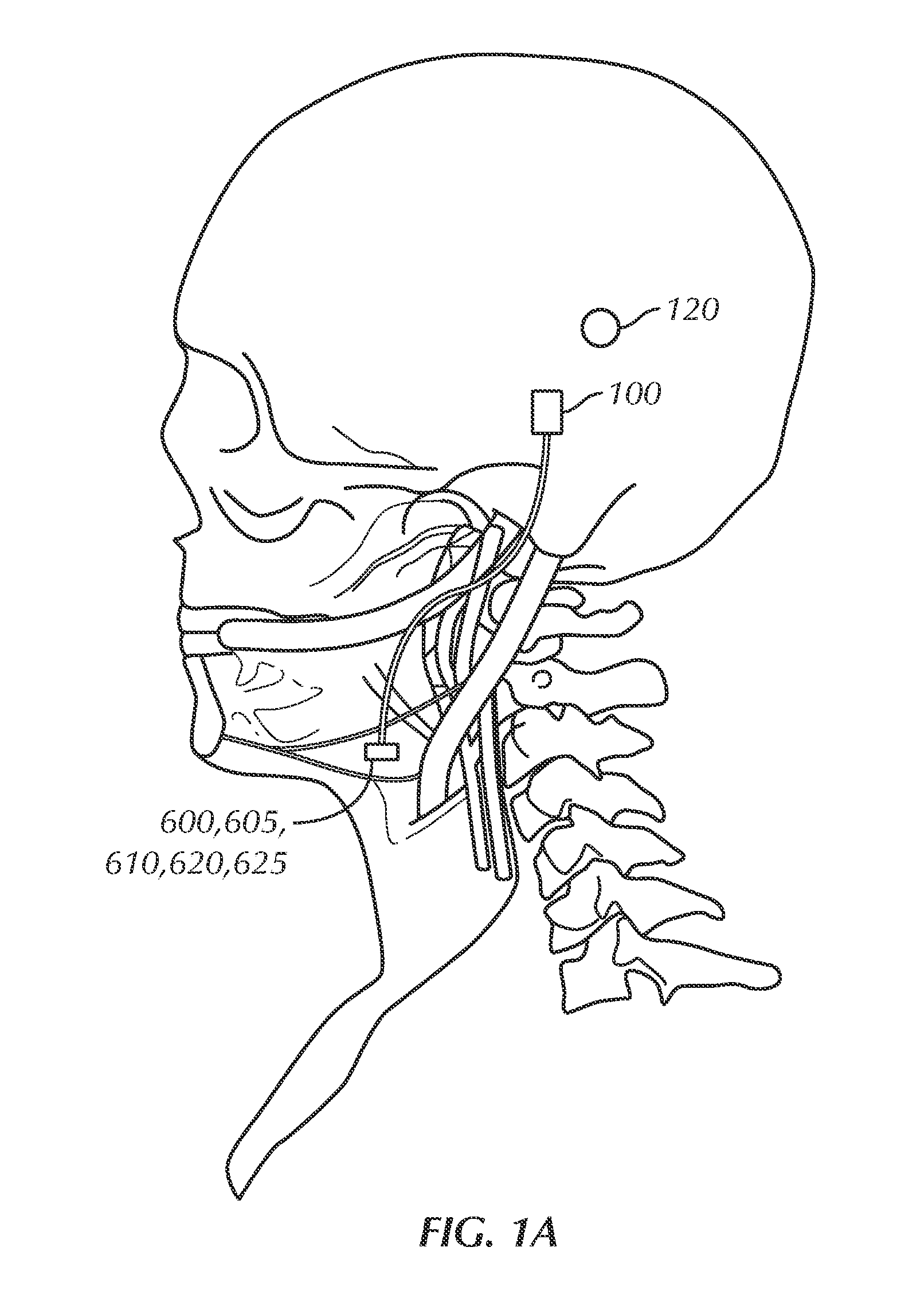

Methods for stimulating a nerve root ganglion

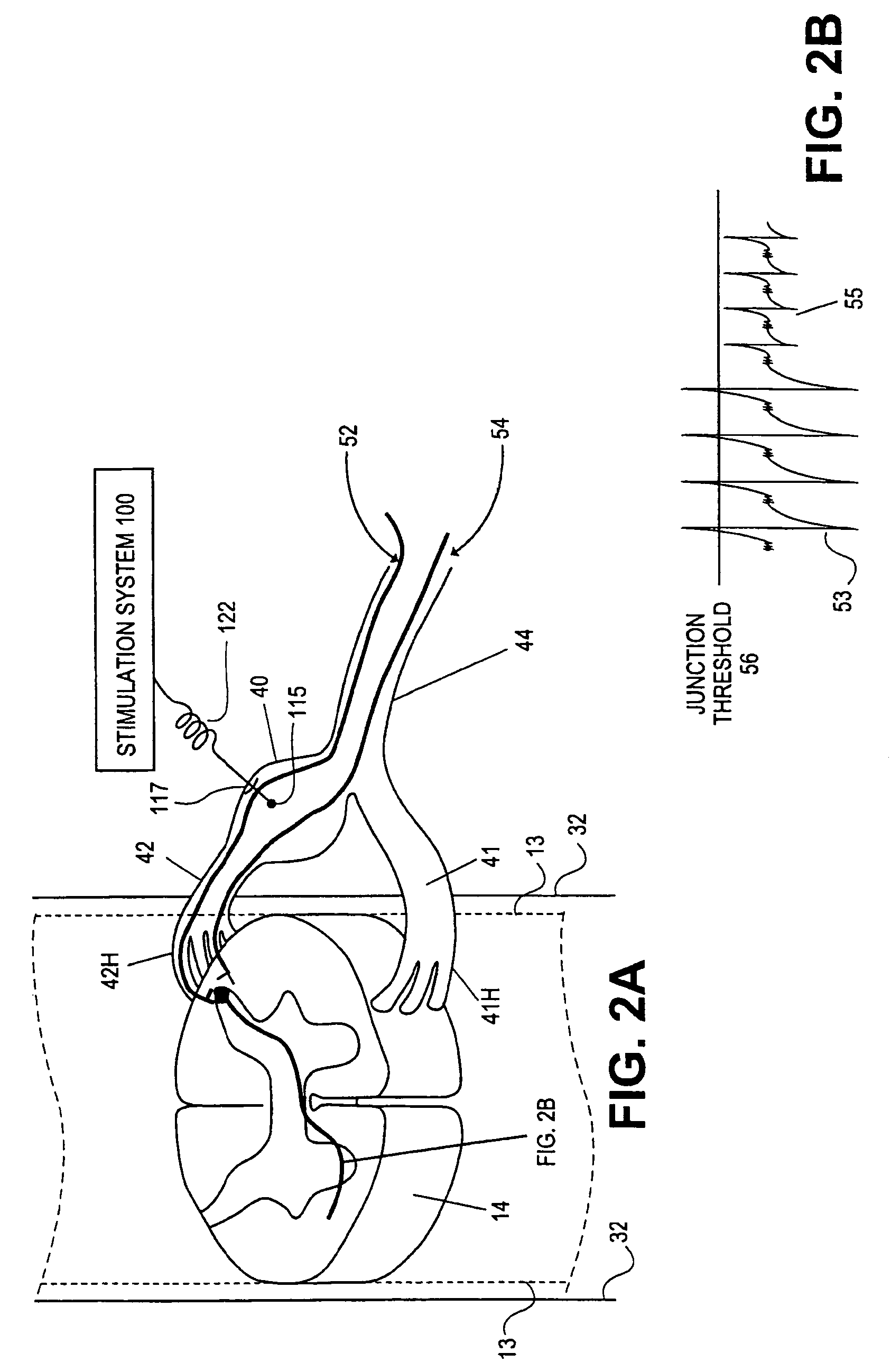

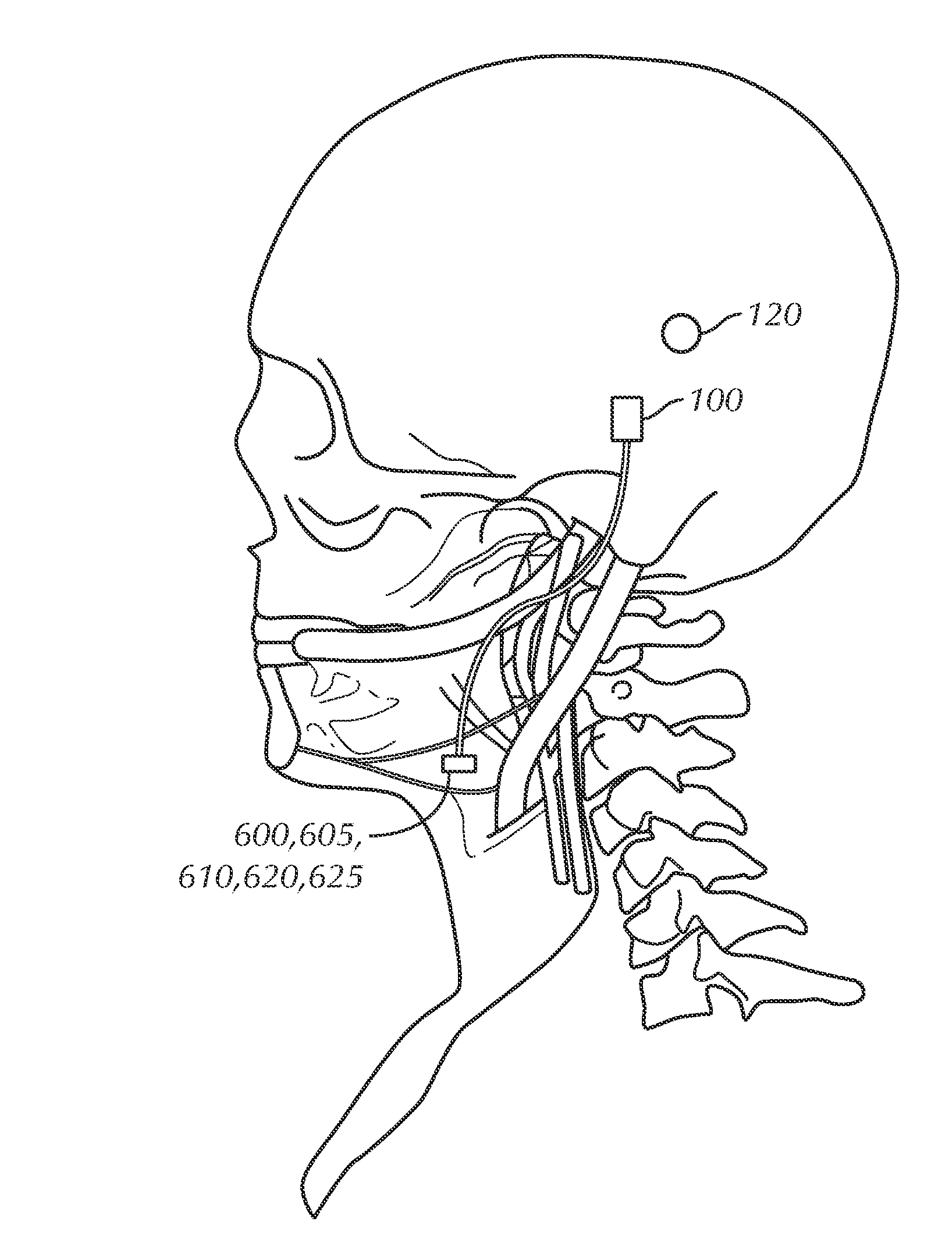

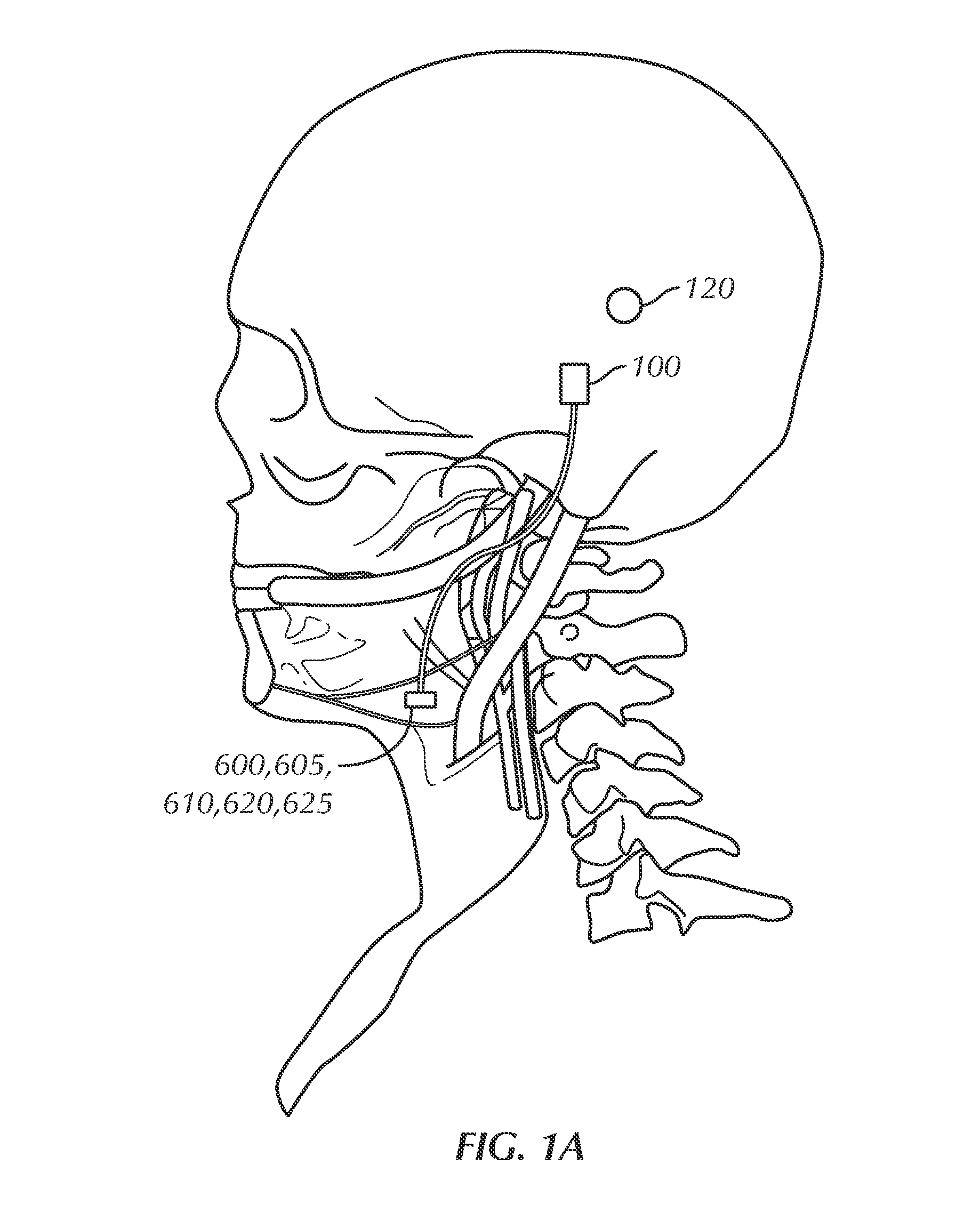

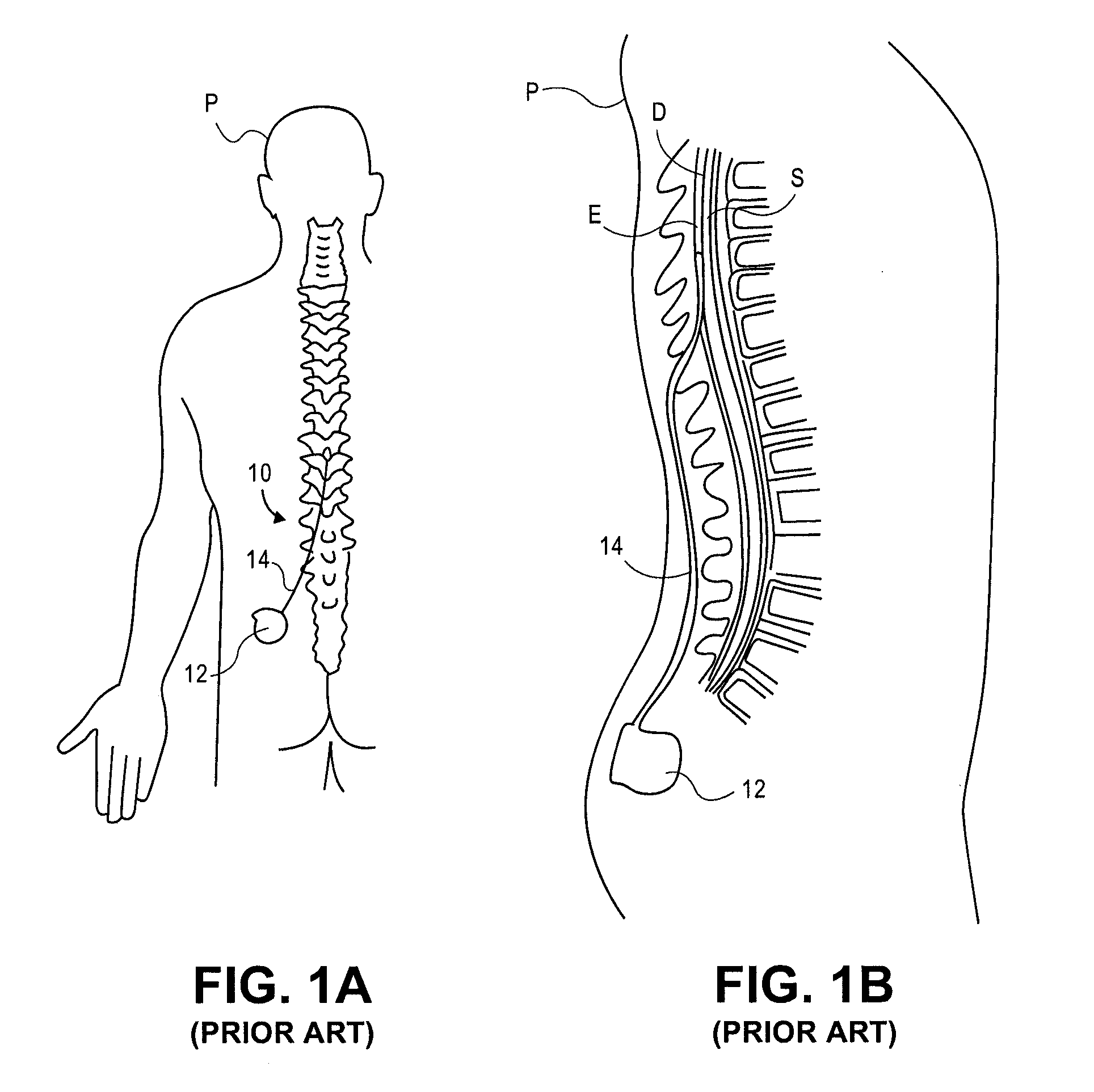

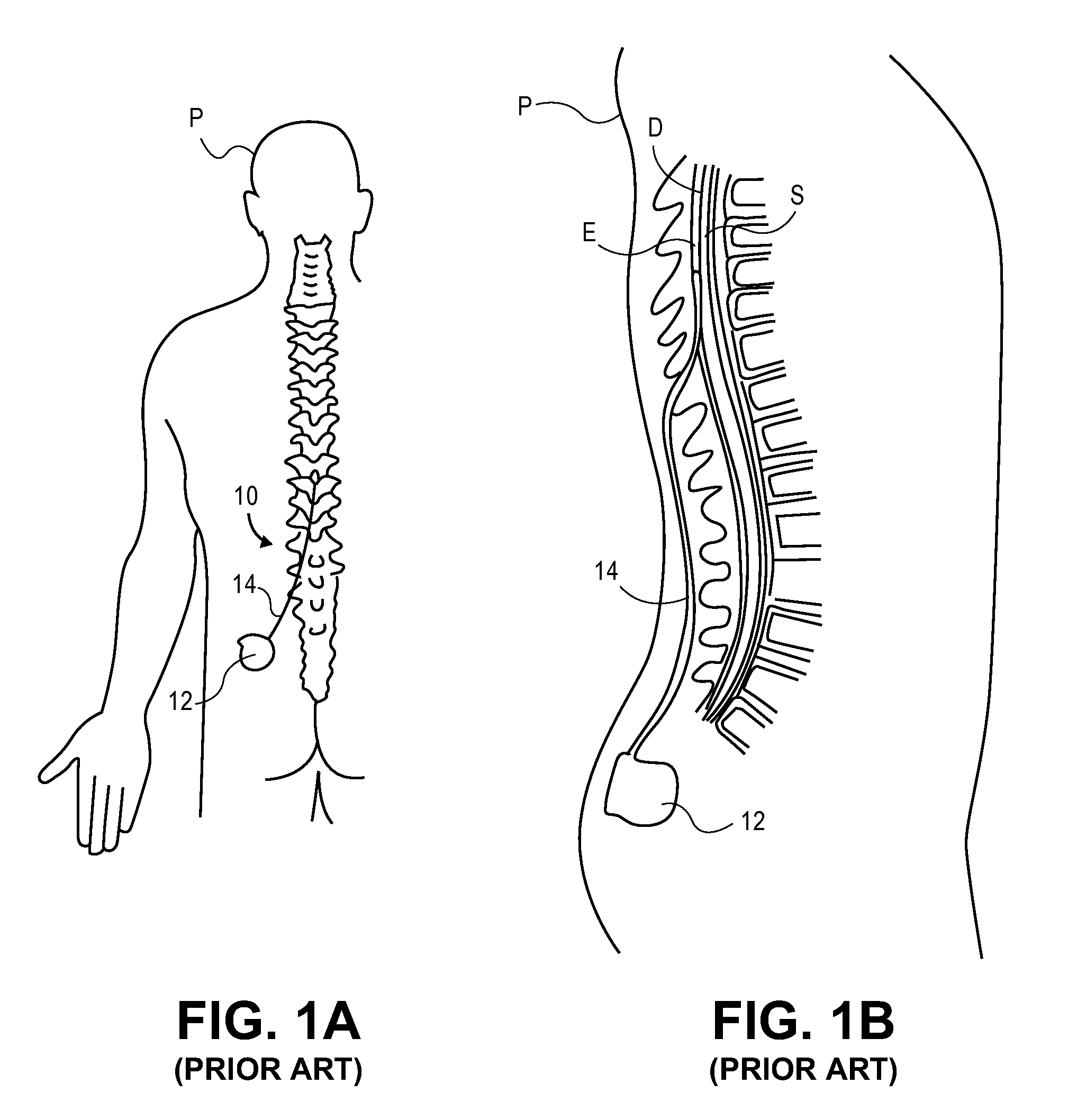

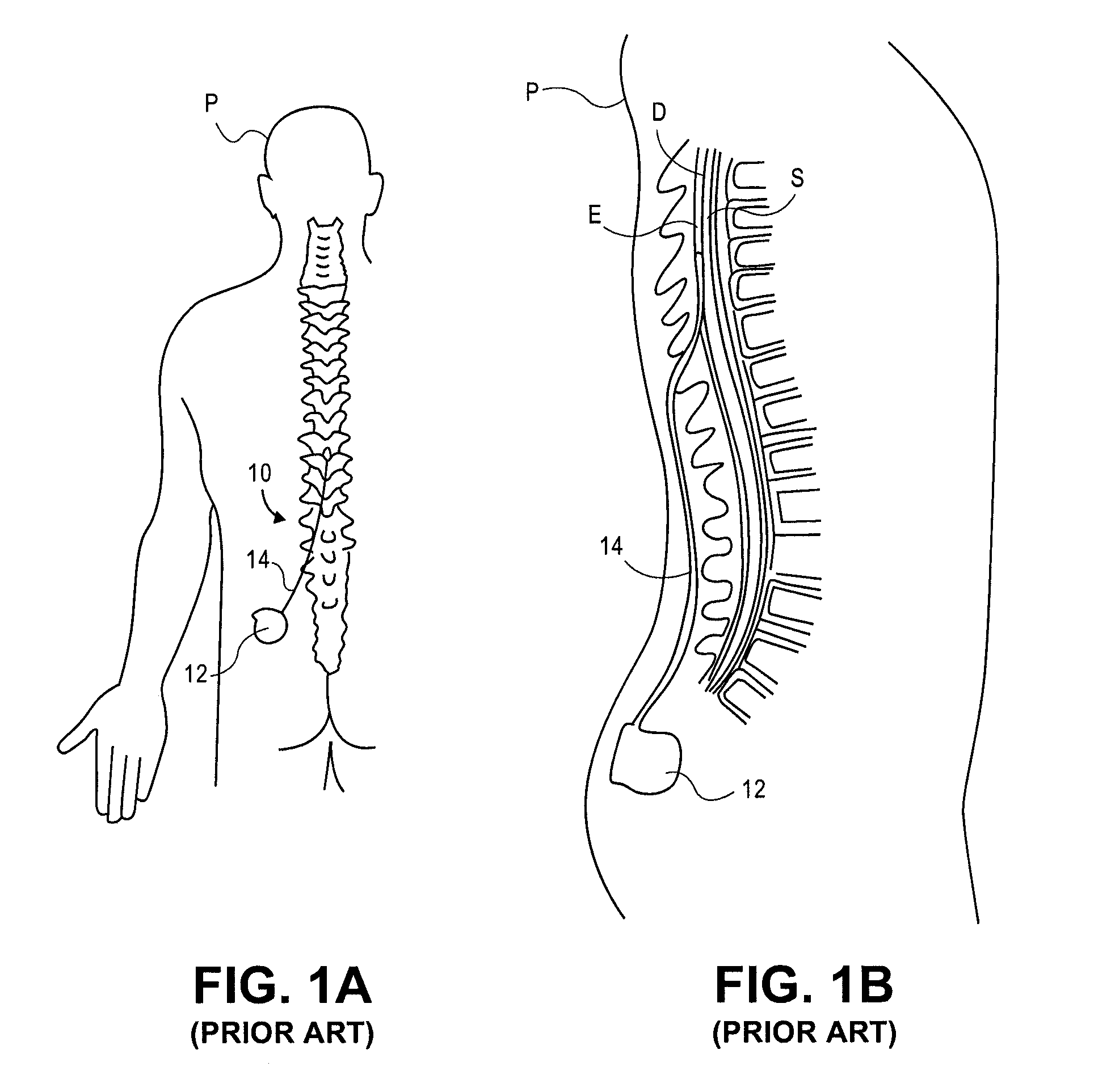

Some embodiments of the present invention provide stimulation systems and components for selective stimulation and / or neuromodulation of one or more nerve root ganglia through implantation of an electrode on, in or around a nerve root ganglia. Some other embodiments of the present invention provide methods for selective neurostimulation of one or more dorsal root ganglia as well as techniques for applying neurostimulation to the spinal cord. Still other embodiments of the present invention provide stimulation systems and components for selective stimulation and / or neuromodulation of one or more nerve root ganglia through implantation of an electrode on, in or around a nerve root ganglia in combination with a pharmacological agent.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV +2

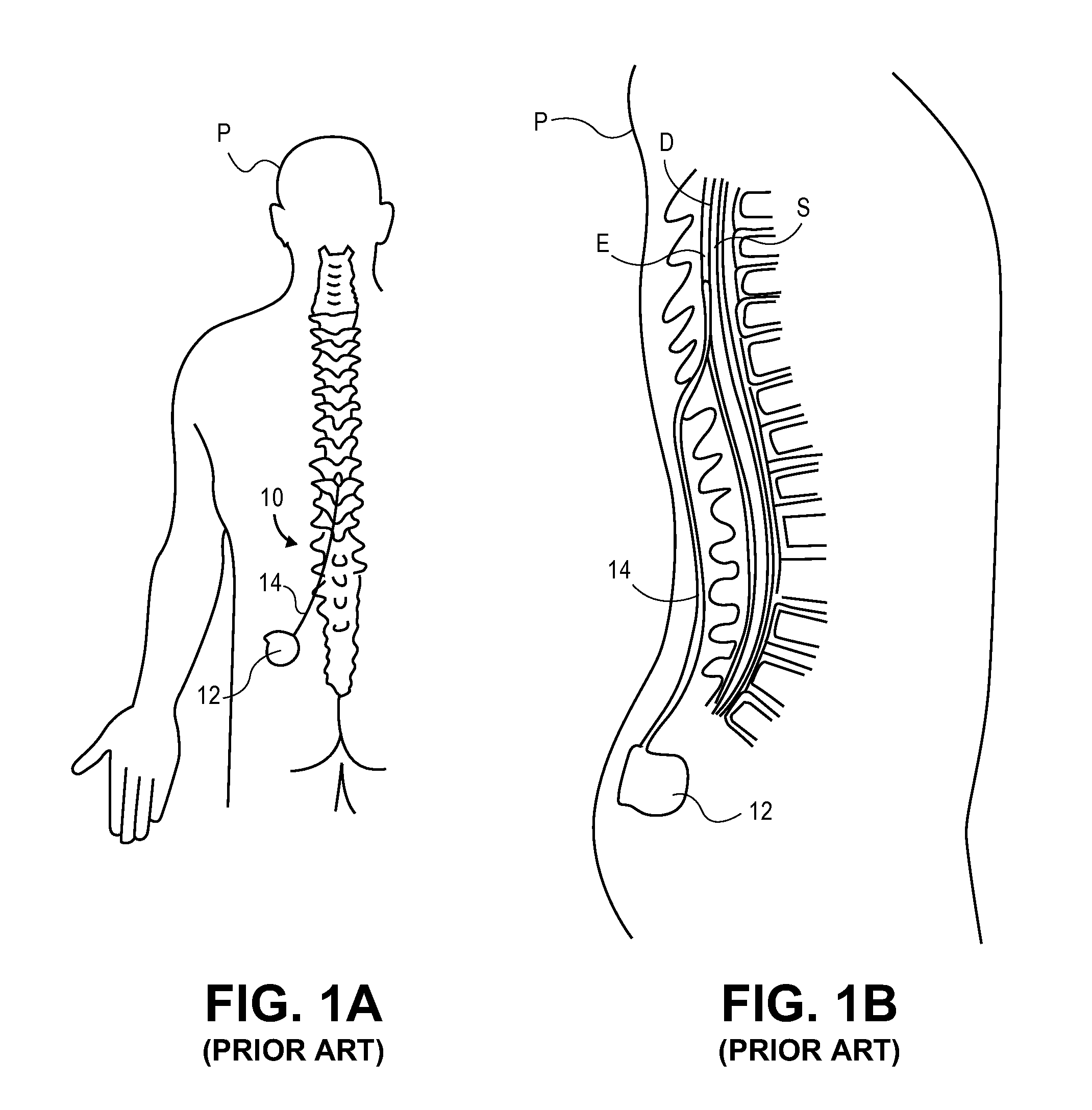

Apparatus and methods for treating congestive heart failure

InactiveUS6076013AImprove efficiencyImproved ventricular functionEpicardial electrodesHeart valvesCardiac muscleVentricular function

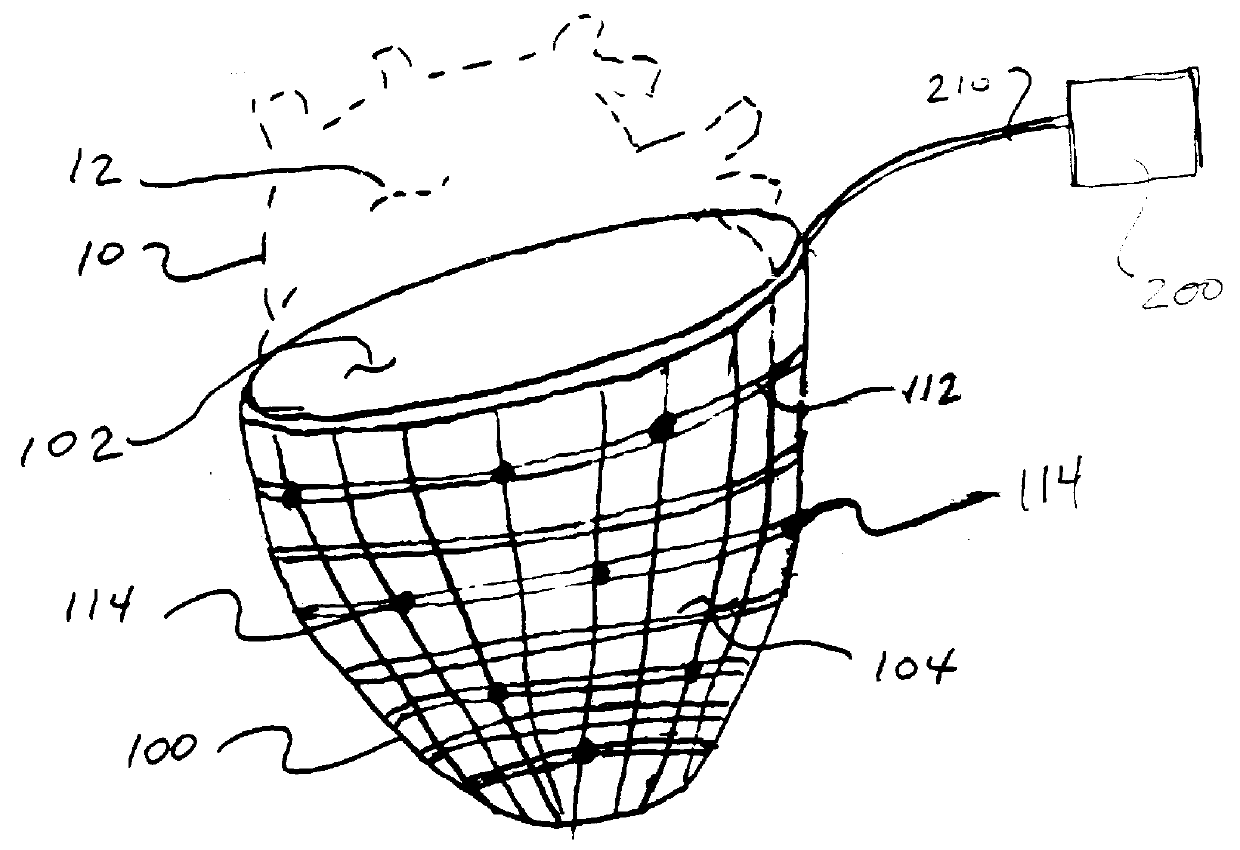

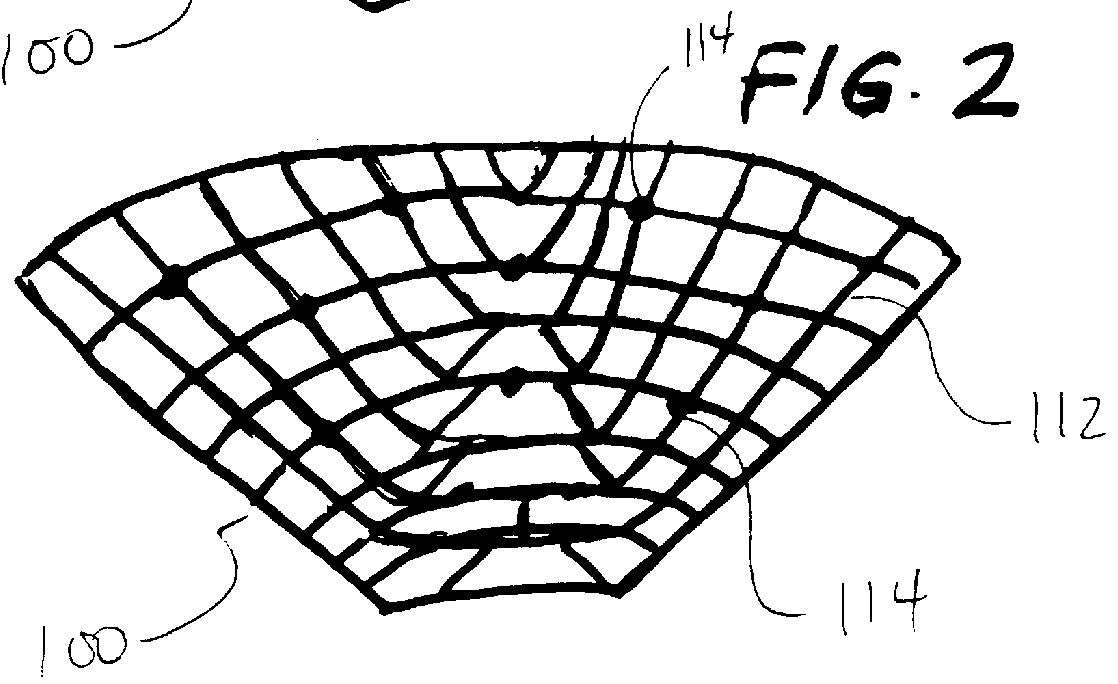

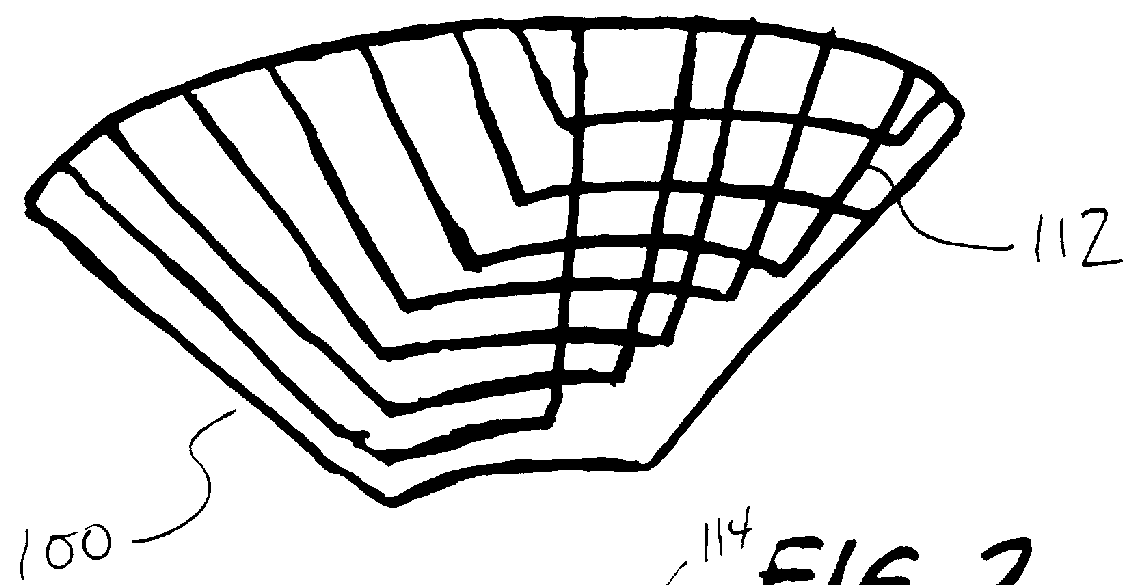

Apparatus and method for the treatment of congestive heart failure are disclosed that utilize a cuff that surrounds the heart and constrains cardiac dilation, while electrodes embedded in the cuff stimulate the myocardium to contractile function. An EKG signal can be processed to create an optimal pattern of selective stimulation of different areas of the heart at different times. An implantable circuit contains a power source and stimulation circuits. In some embodiments, a telemetry unit and an EKG collection circuit are also included. In accordance with the present disclosure, cuff limits the dilation of the heart and the stimulation electrodes enhance ventricular function by optimizing ventricular contractility.

Owner:BRENNAN EDWARD F +1

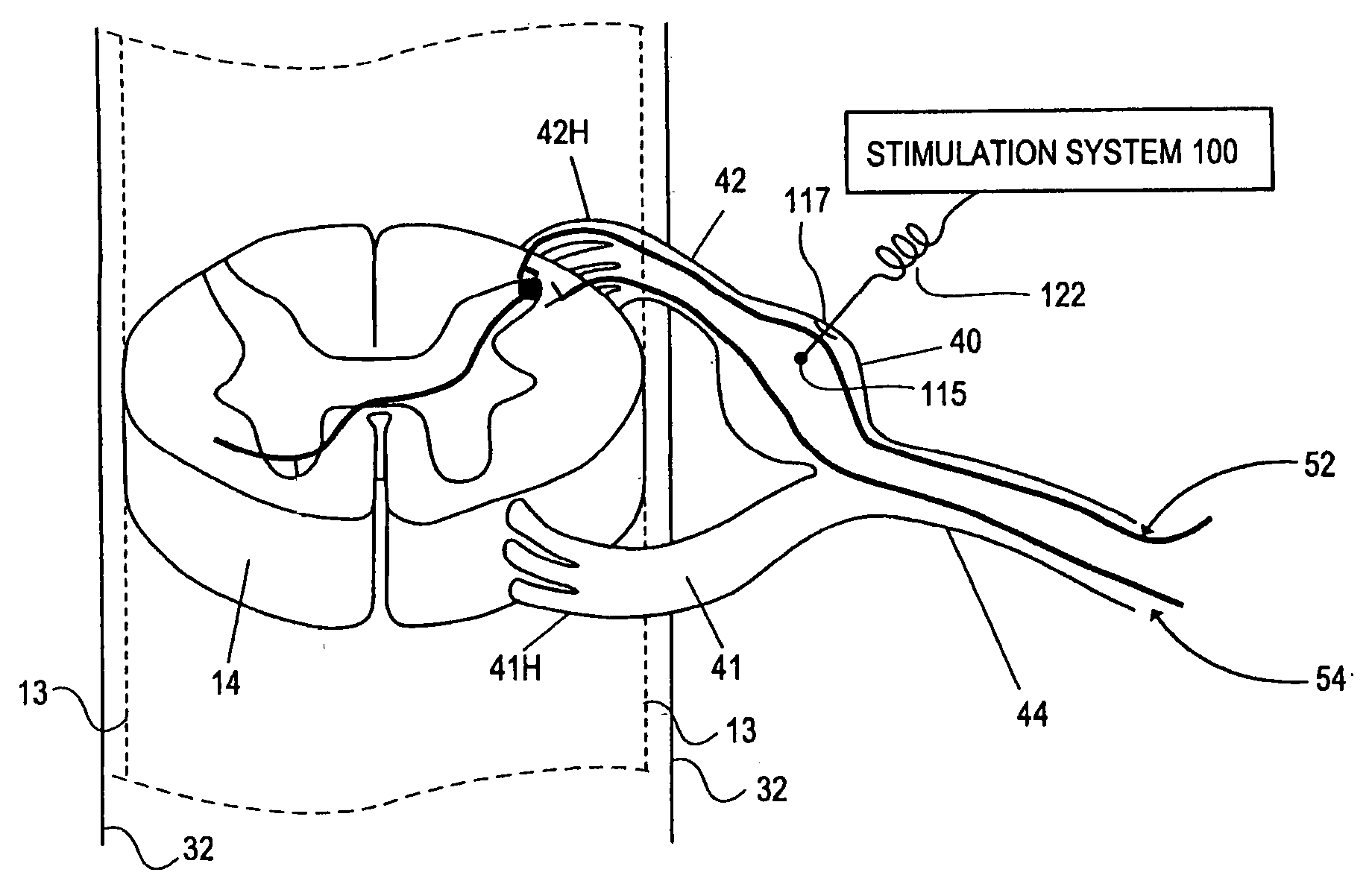

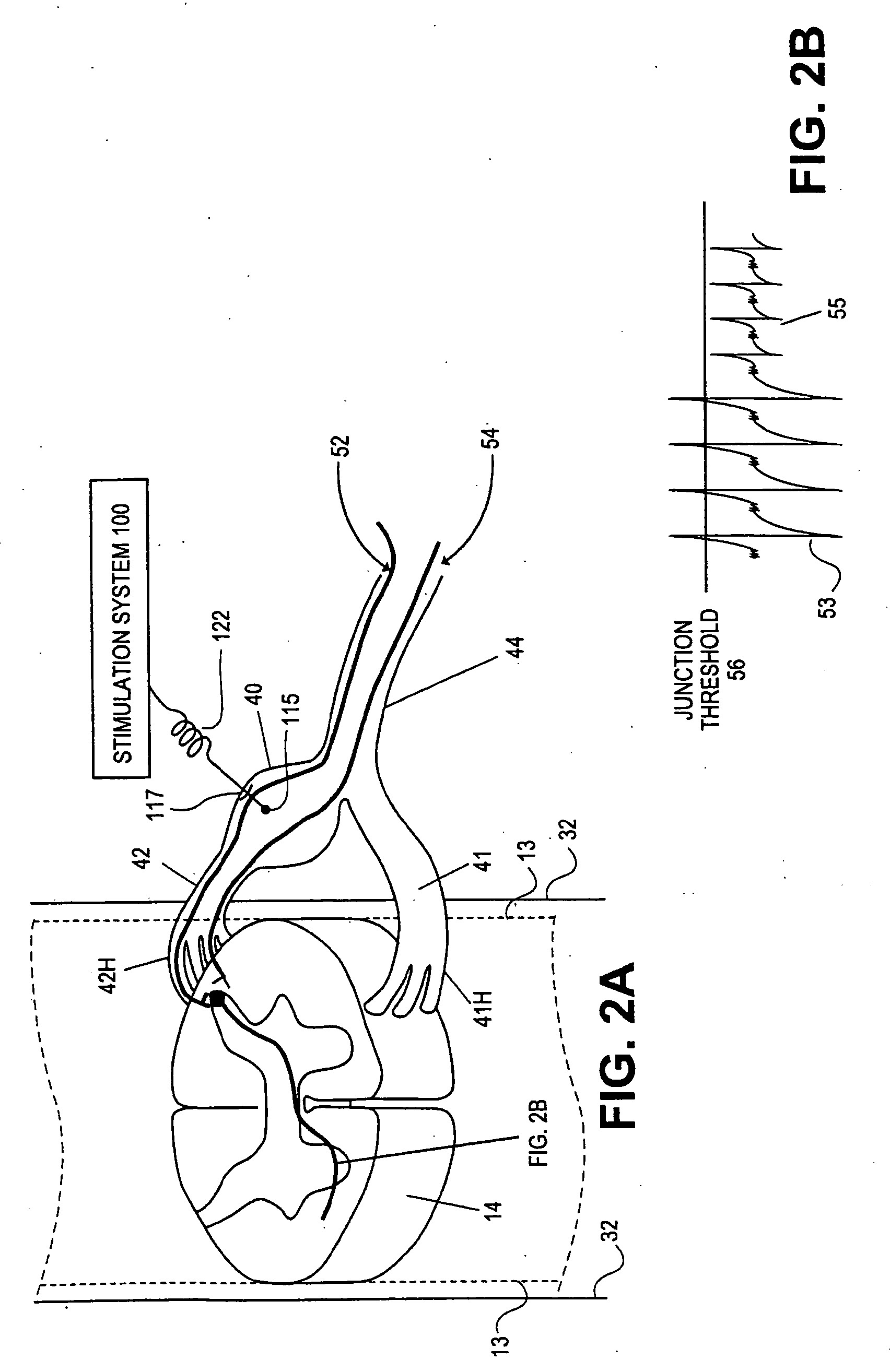

Methods and systems for modulating neural tissue

Some embodiments of the present invention provide methods and systems for modulating neural tissue including systems and components for selective stimulation and / or neuromodulation of targeted neural tissue. Targeted neural tissue may include one or more ganglia including those of the spinal nerves in the dorsal root and the sympathetic chain. Methods also include implantation of an electrode on, in or around a dorsal root ganglia. Some other embodiments of the present invention provide methods for selective neurostimulation of one or more dorsal root ganglia as well as techniques for applying neurostimulation to the spinal cord. Still other embodiments of the present invention provide stimulation systems and components for selective stimulation and / or neuromodulation of one or more dorsal root ganglia through implantation of an electrode on, in or around a dorsal root ganglia in combination with a pharmacological agent.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV +2

Selective stimulation systems and signal parameters for medical conditions

Devices, systems and methods are provided for targeted treatment of a variety of conditions, particularly conditions that are associated with or influenced by the nervous system, such as pain. Targeted treatment of such conditions is provided with minimal deleterious side effects, such as undesired motor responses or undesired stimulation of unaffected body regions. This is achieved by directly neuromodulating a target anatomy associated with the condition while minimizing or excluding undesired neuromodulation of other anatomies.

Owner:TC1 LLC

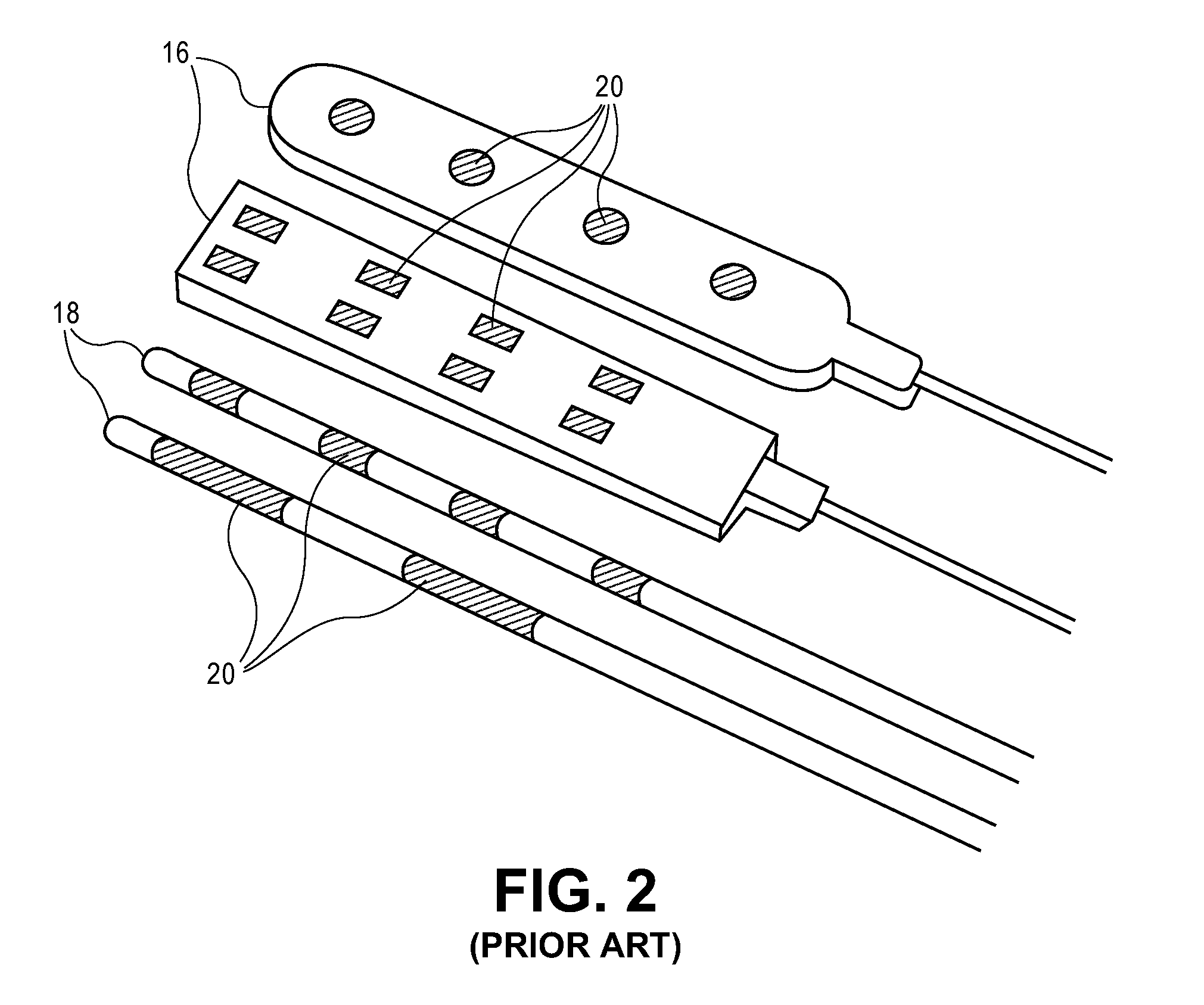

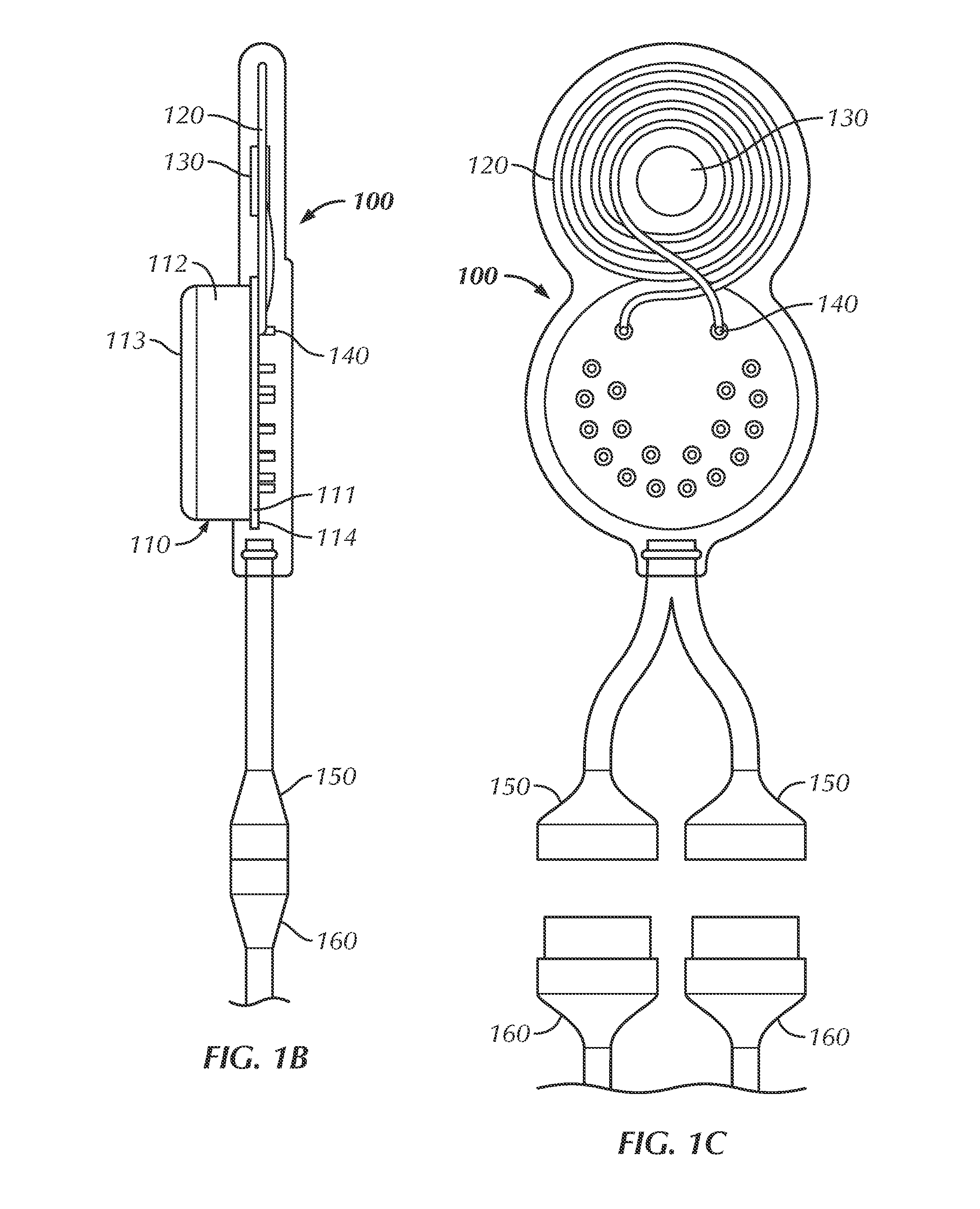

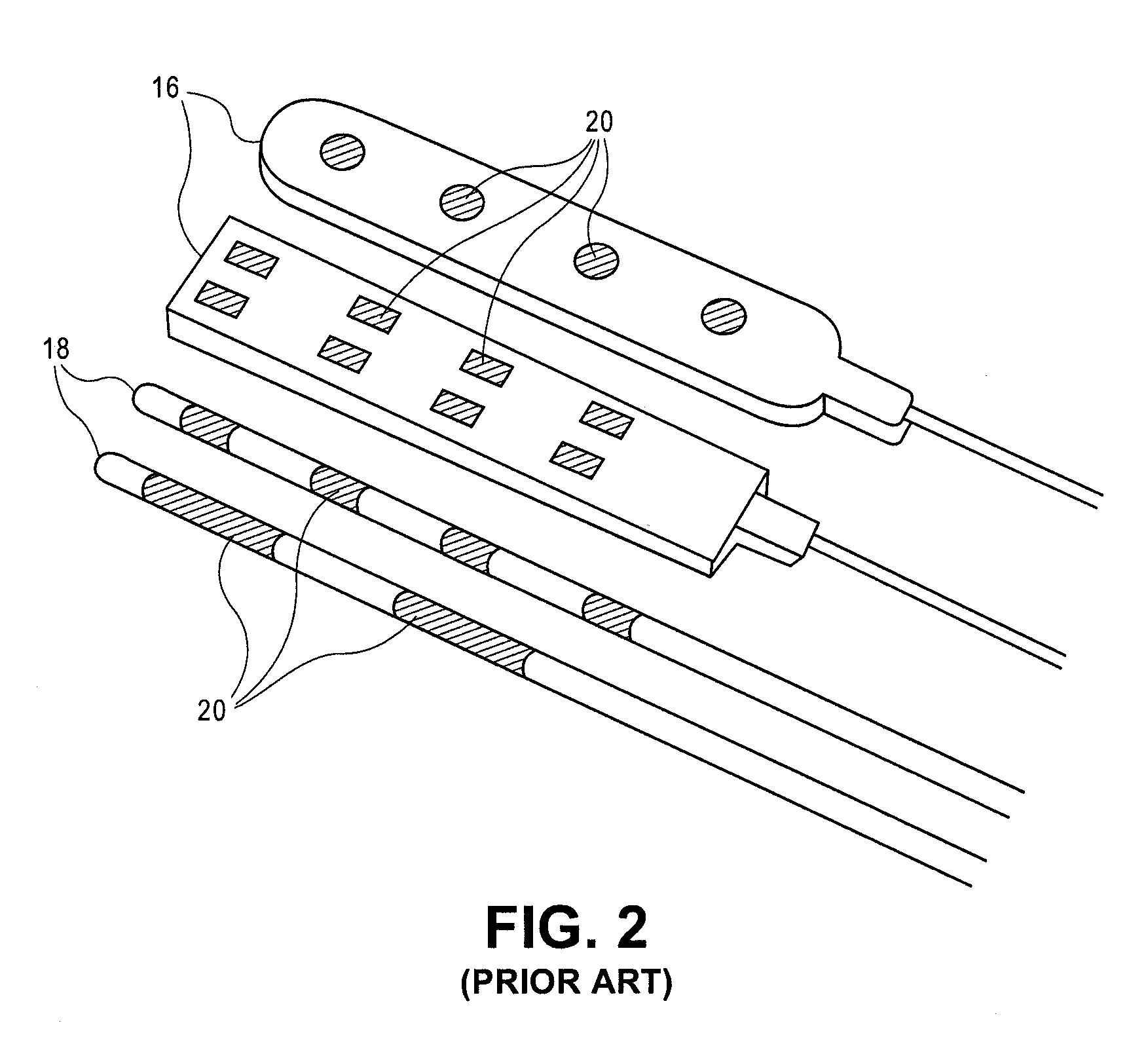

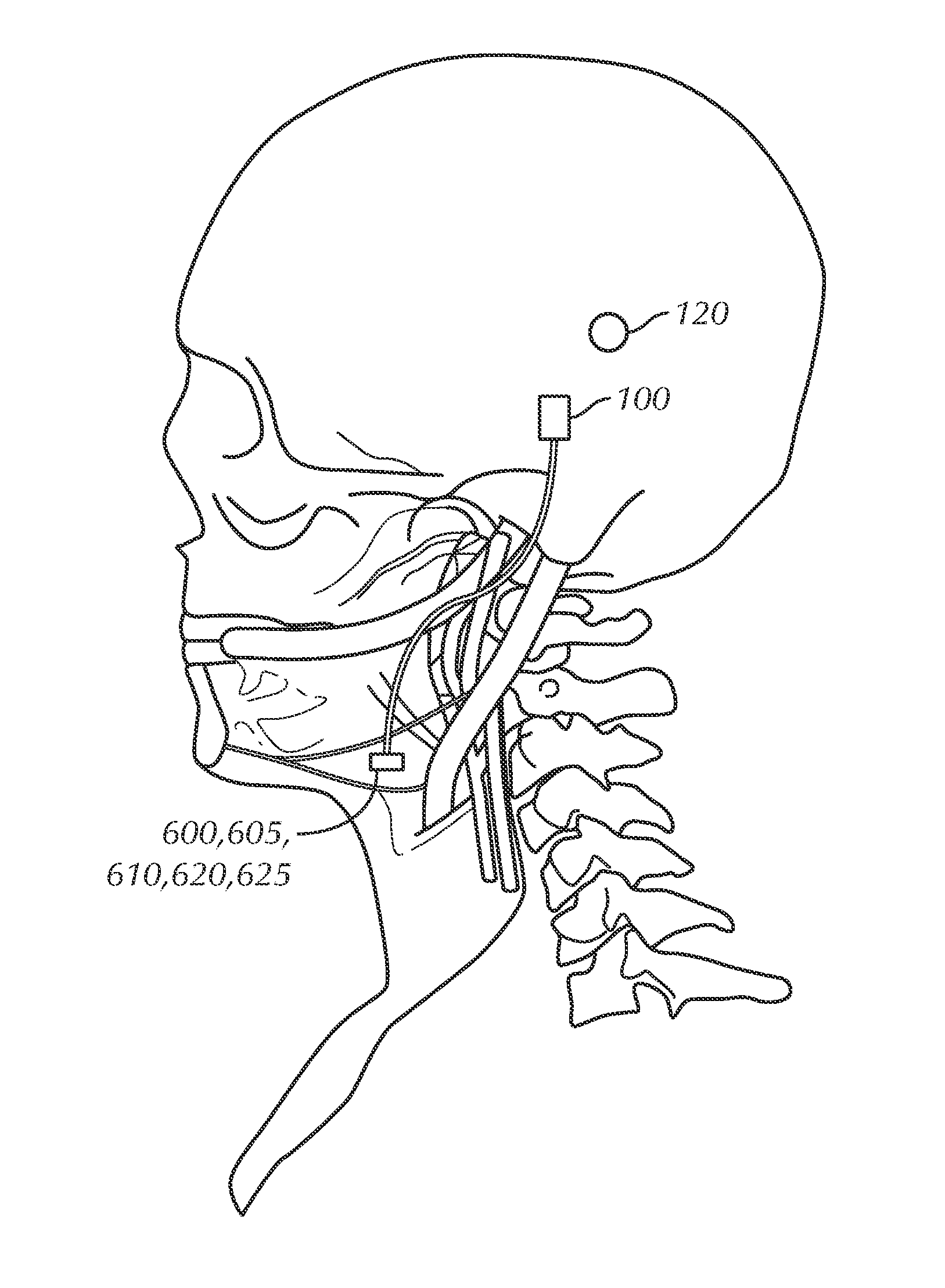

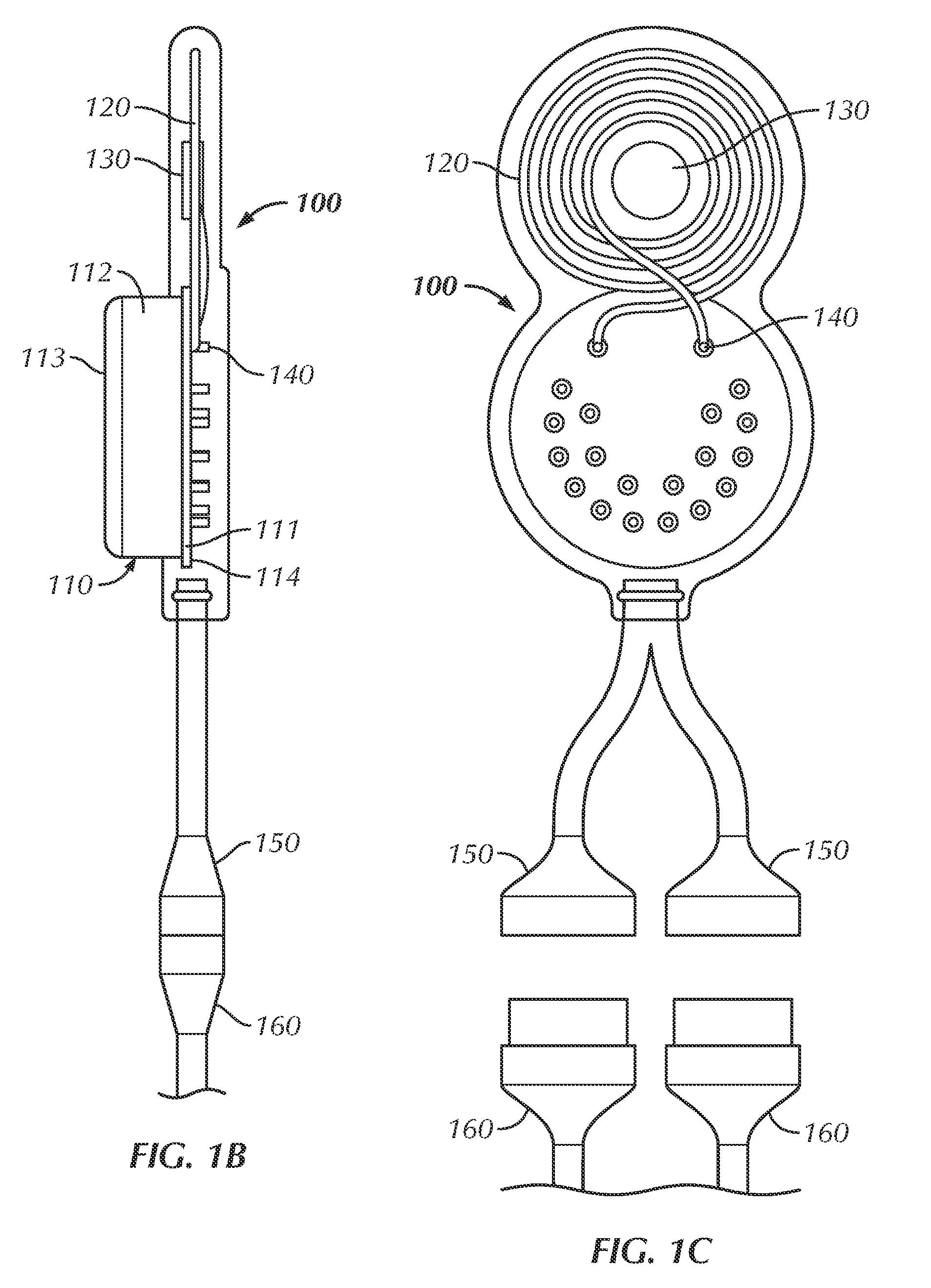

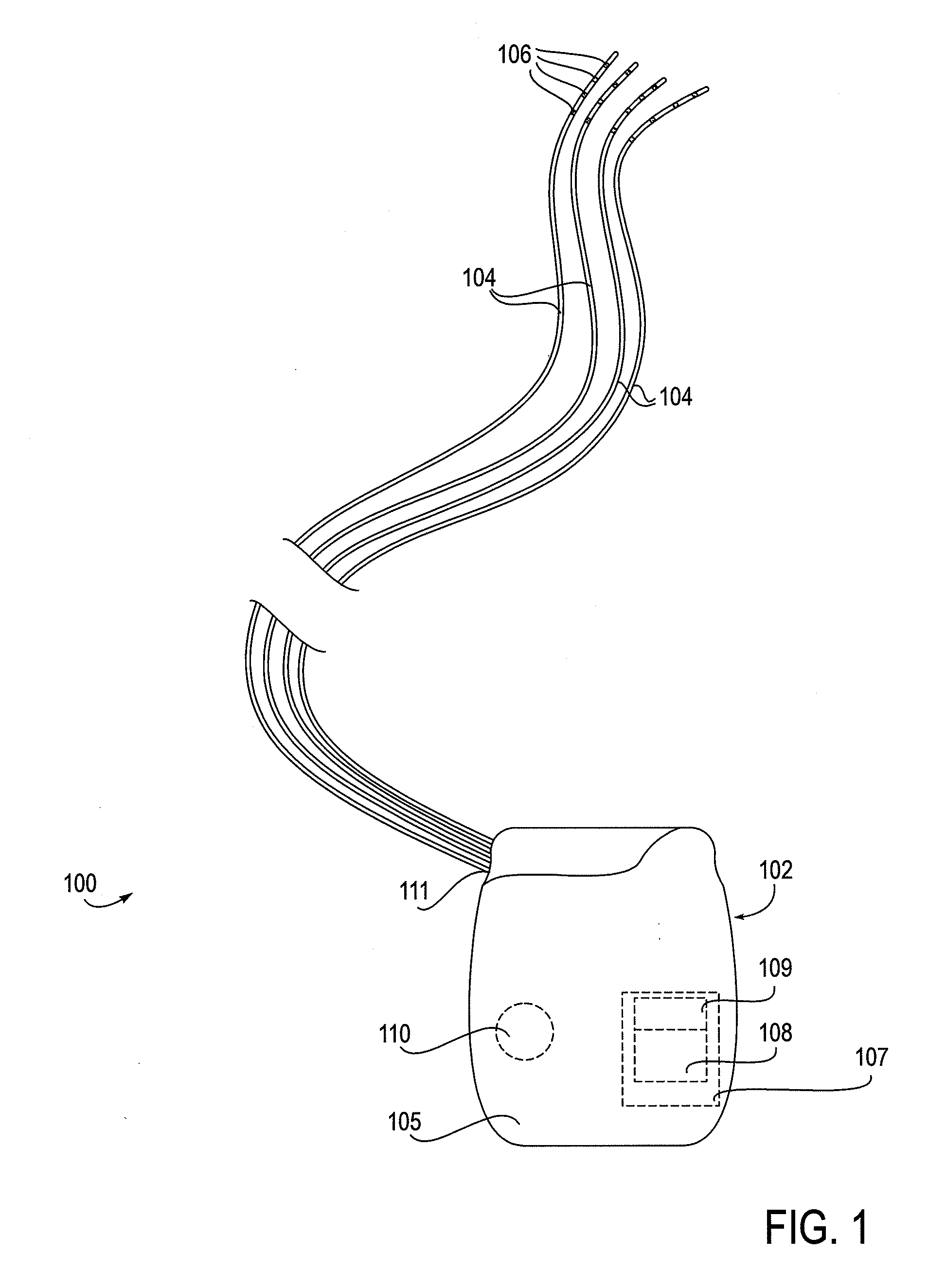

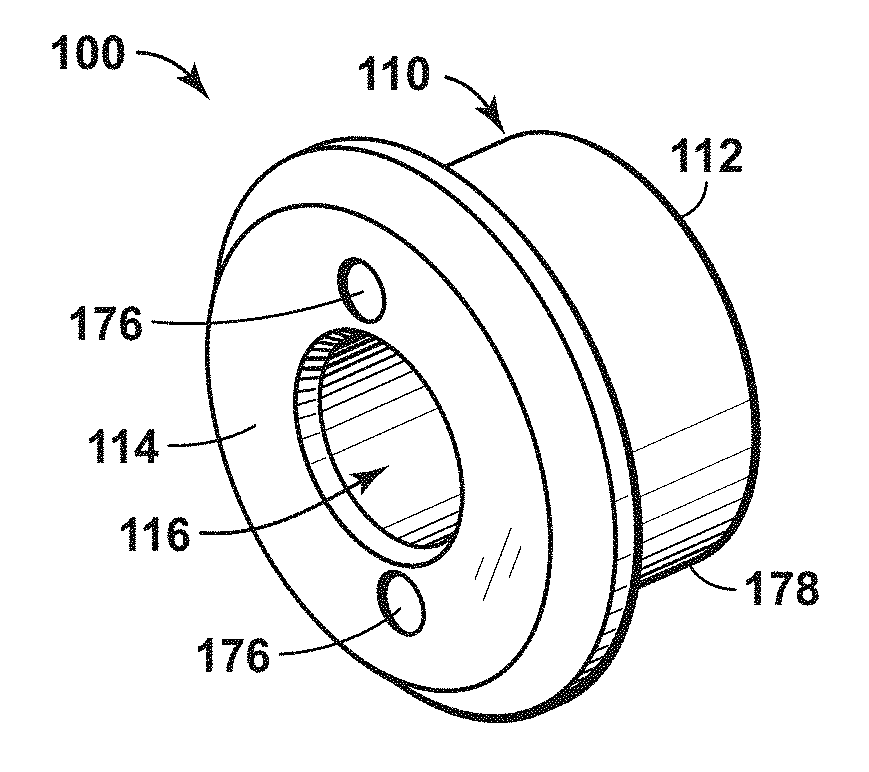

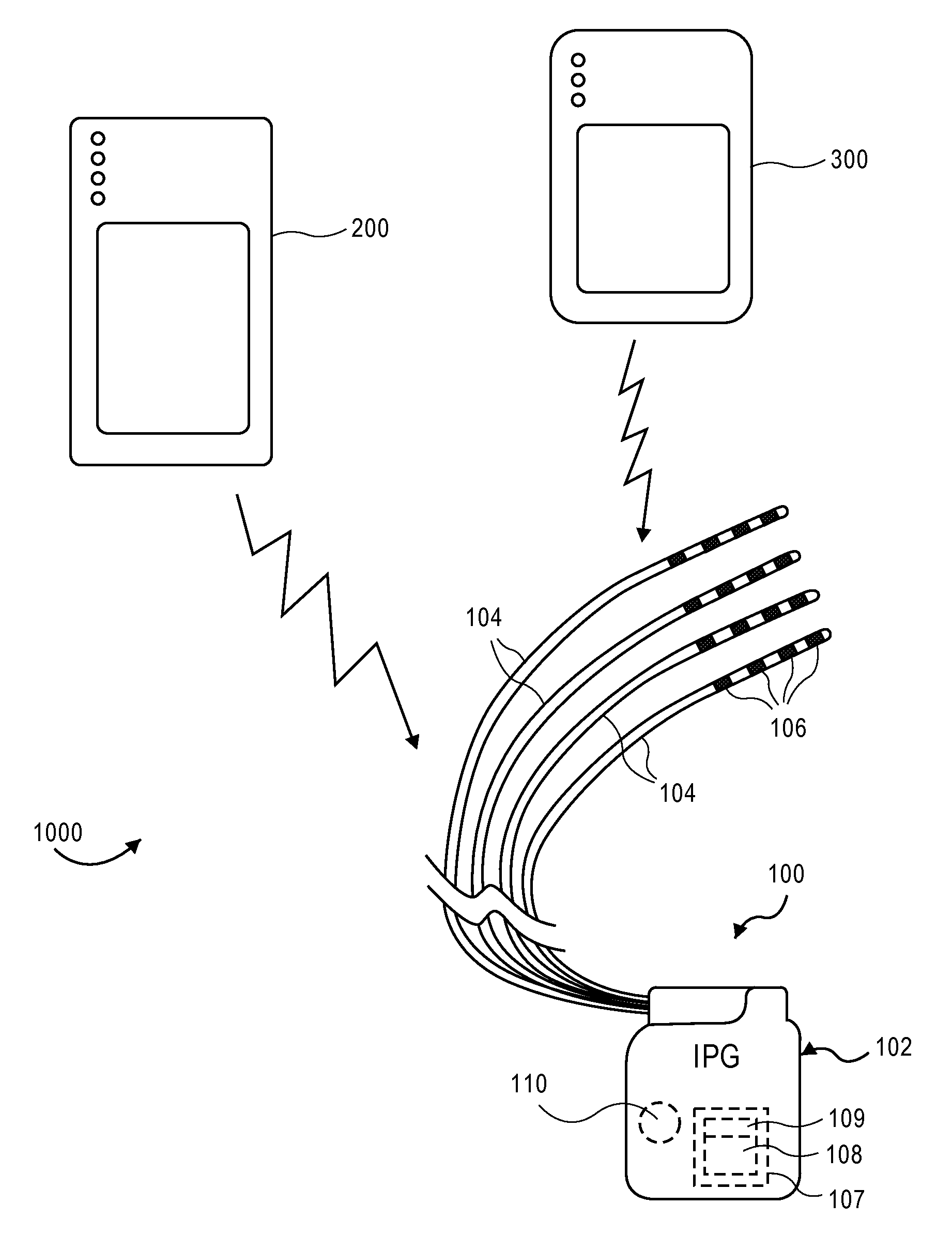

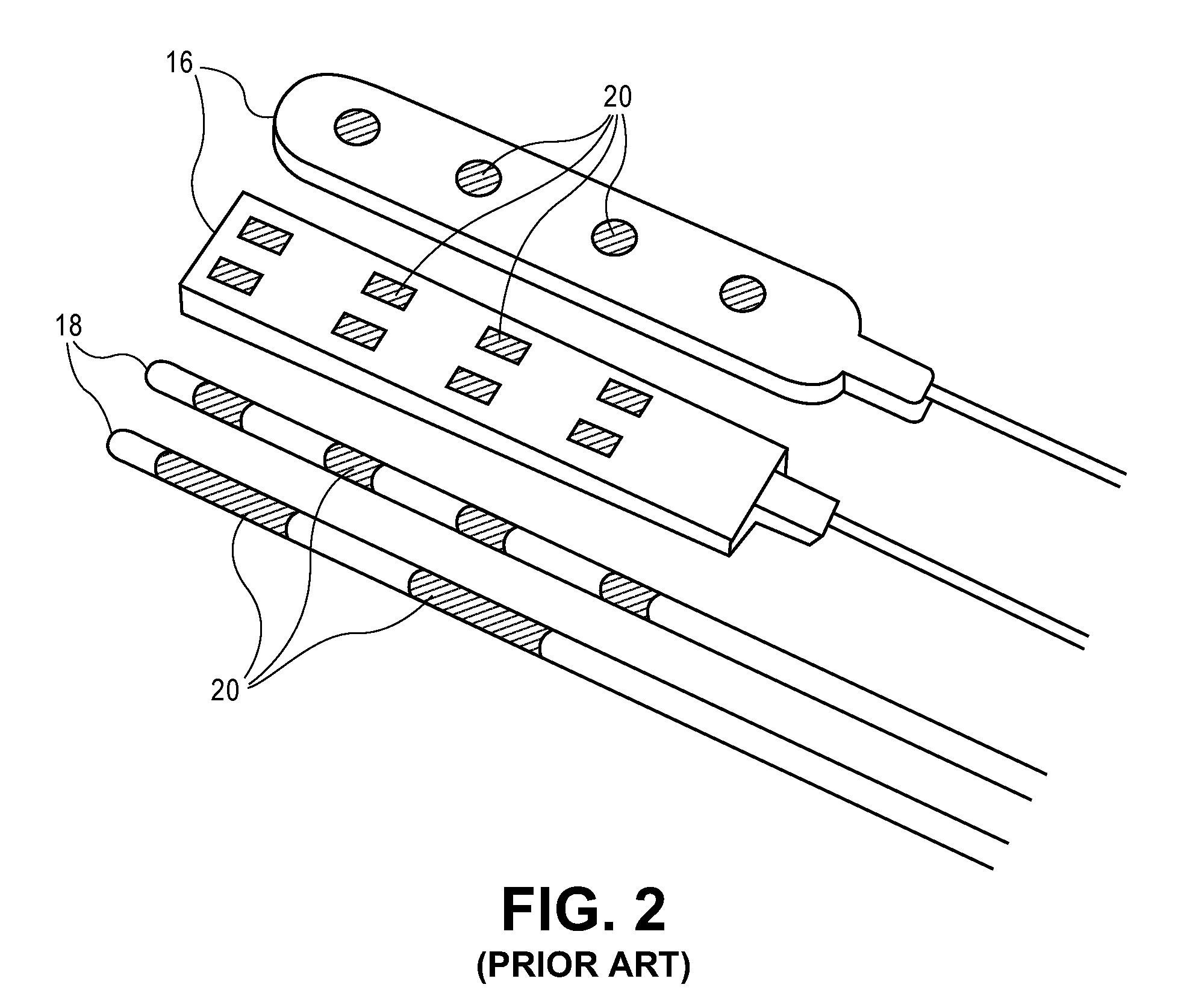

Apparatus, system and method for selective stimulation

InactiveUS20100241195A1Spinal electrodesImplantable neurostimulatorsSelective stimulationBiomedical engineering

An implantable neurostimulator system is disclosed, the neurostimulator system comprising a hollow cylindrical electronics enclosure having a top, a bottom, and a side; a coil extending from a first part of the electronics enclosure; and at least one electrode operatively connected to the electronics enclosure.

Owner:IMTHERA MEDICAL

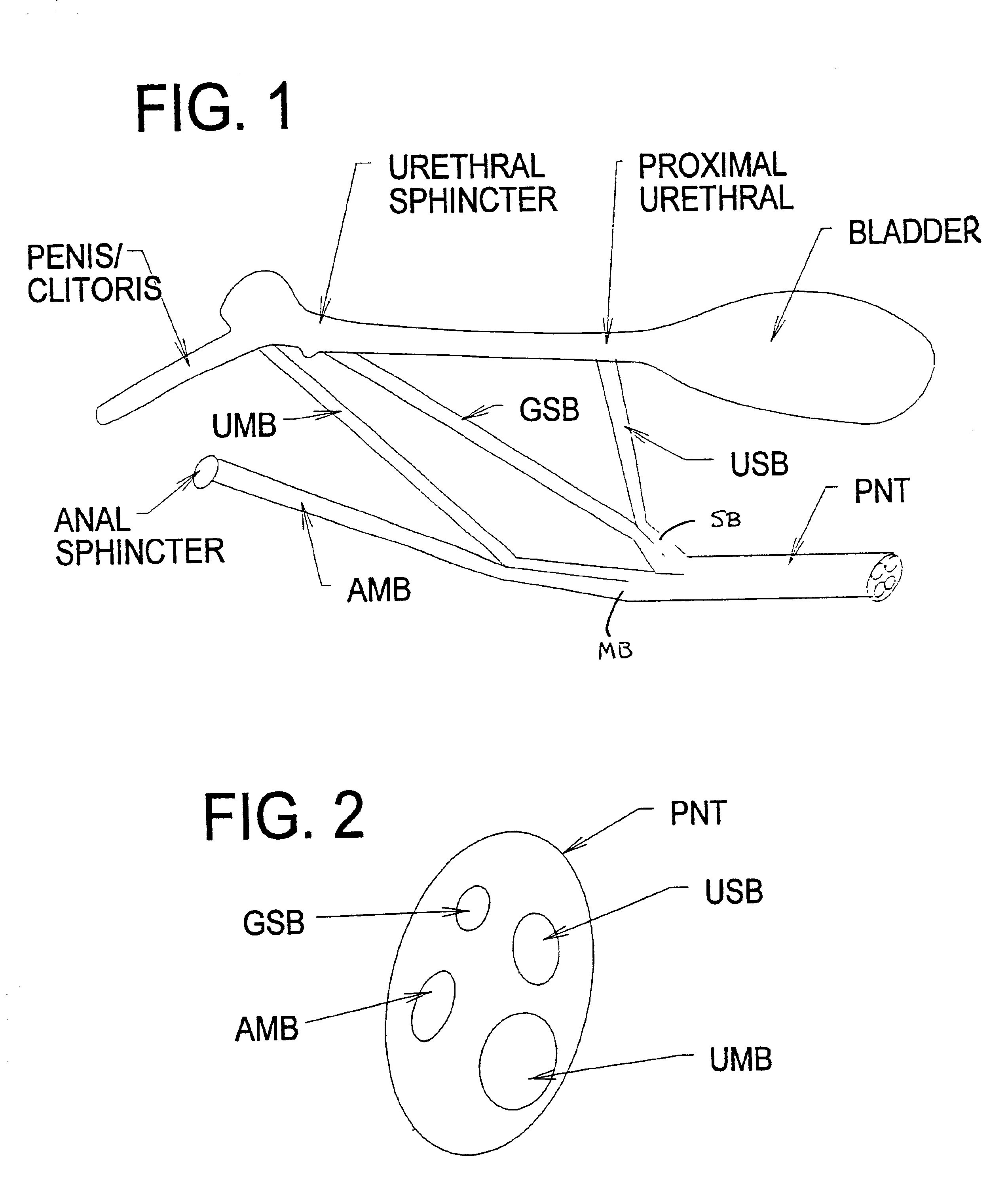

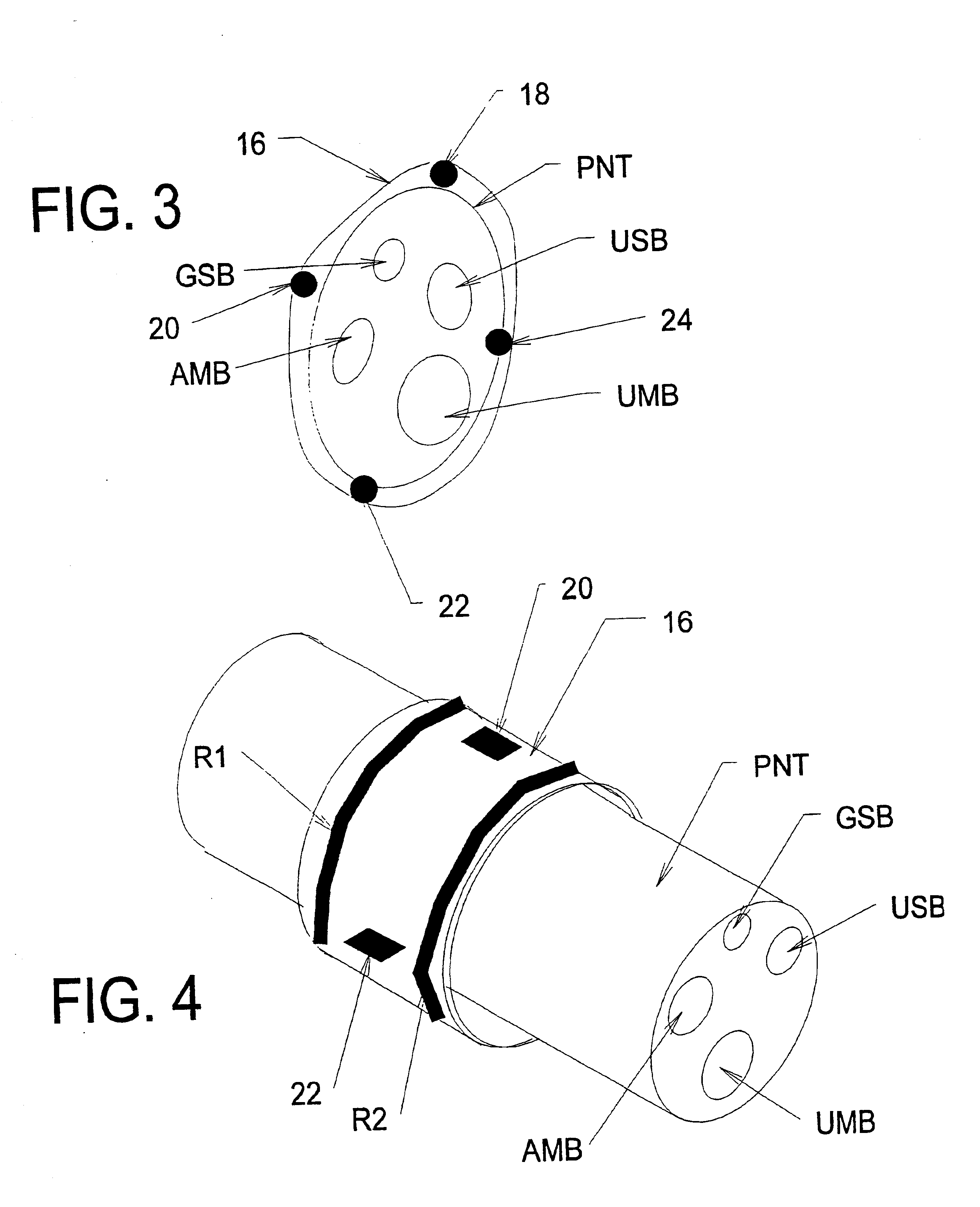

Systems and methods for selectively stimulating components in, on, or near the pudendal nerve or its branches to achieve selective physiologic responses

ActiveUS6907293B2Easy to defecatePromote contractionSpinal electrodesExternal electrodesMedicineMultielectrode array

Systems and methods selectively stimulate components of the pudendal nerve away from the sacral root to evoke desired physiologic responses in persons who lack the ability to otherwise produce these responses—e.g., maintain continence and / or produce micturition, and / or provide male / female sexuality responses, and / or provide bowel responses. The systems and methods use a multiple electrode array, or individual electrodes, placed on, in, or near the pudendal nerve. The electrode array, or individual electrodes, in association with a pulse generator, provide selective stimulation of individual fascicles within the pudendal nerve, to achieve different physiologic responses.

Owner:CASE WESTERN RESERVE UNIV

Methods for stimulating a nerve root ganglion

Some embodiments of the present invention provide stimulation systems and components for selective stimulation and / or neuromodulation of one or more nerve root ganglia through implantation of an electrode on, in or around a nerve root ganglia. Some other embodiments of the present invention provide methods for selective neurostimulation of one or more dorsal root ganglia as well as techniques for applying neurostimulation to the spinal cord. Still other embodiments of the present invention provide stimulation systems and components for selective stimulation and / or neuromodulation of one or more nerve root ganglia through implantation of an electrode on, in or around a nerve root ganglia in combination with a pharmacological agent.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV +2

Neurostimulation system

Some embodiments of the present invention provide neurostimulation systems and components for selective stimulation and / or neuromodulation of one or more dorsal root ganglia through implantation of an electrode on, in or around a dorsal root ganglia. Some other embodiments of the present invention provide neurostimulation systems adapted for selective neurostimulation of one or more nerve root ganglia as well as techniques for applying neurostimulation to the spinal cord. Still other embodiments of the present invention provide stimulation systems and components for selective stimulation and / or neuromodulation of one or more dorsal root ganglia through implantation of an electrode on, in or around a dorsal root ganglia in combination with a pharmacological agent.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

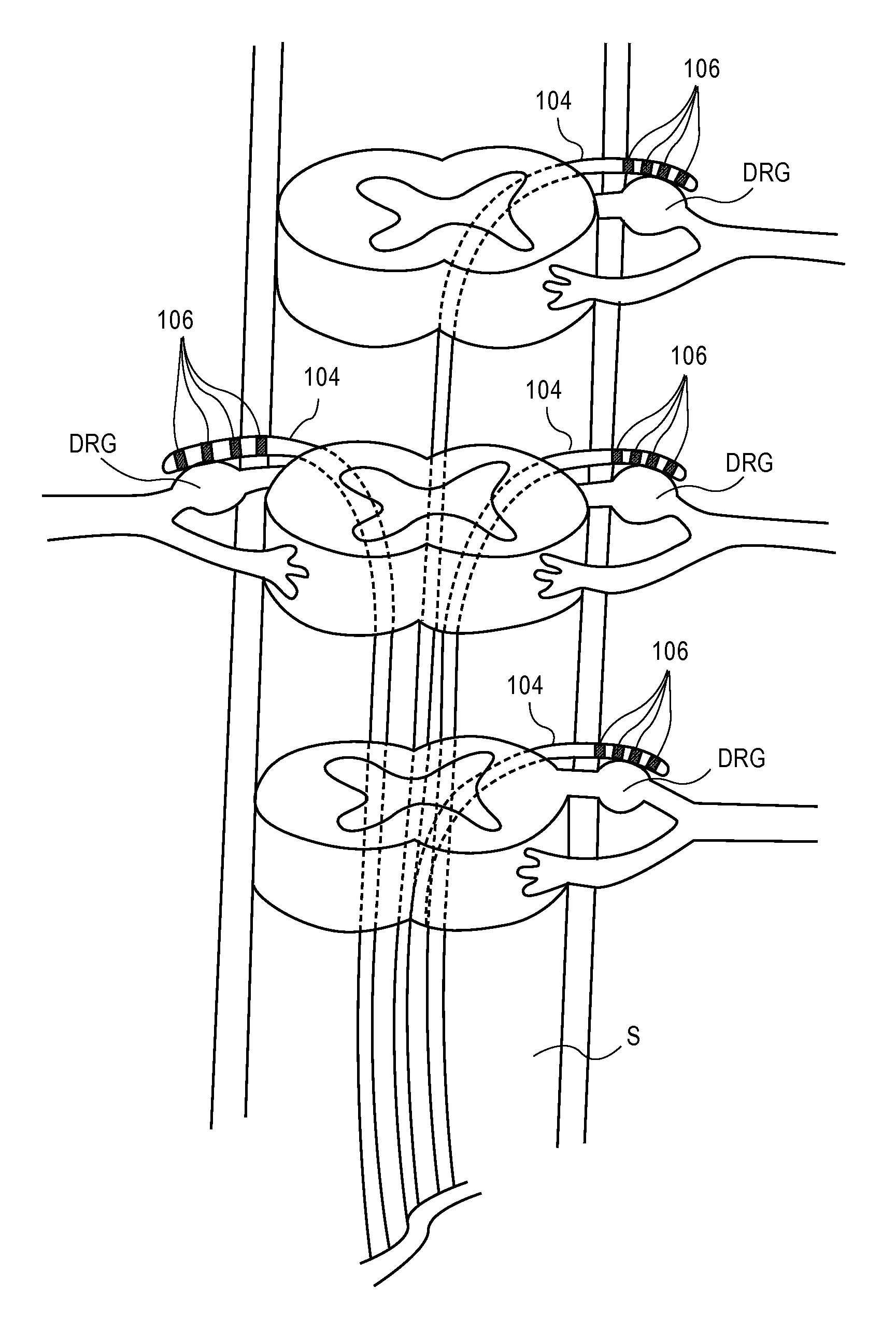

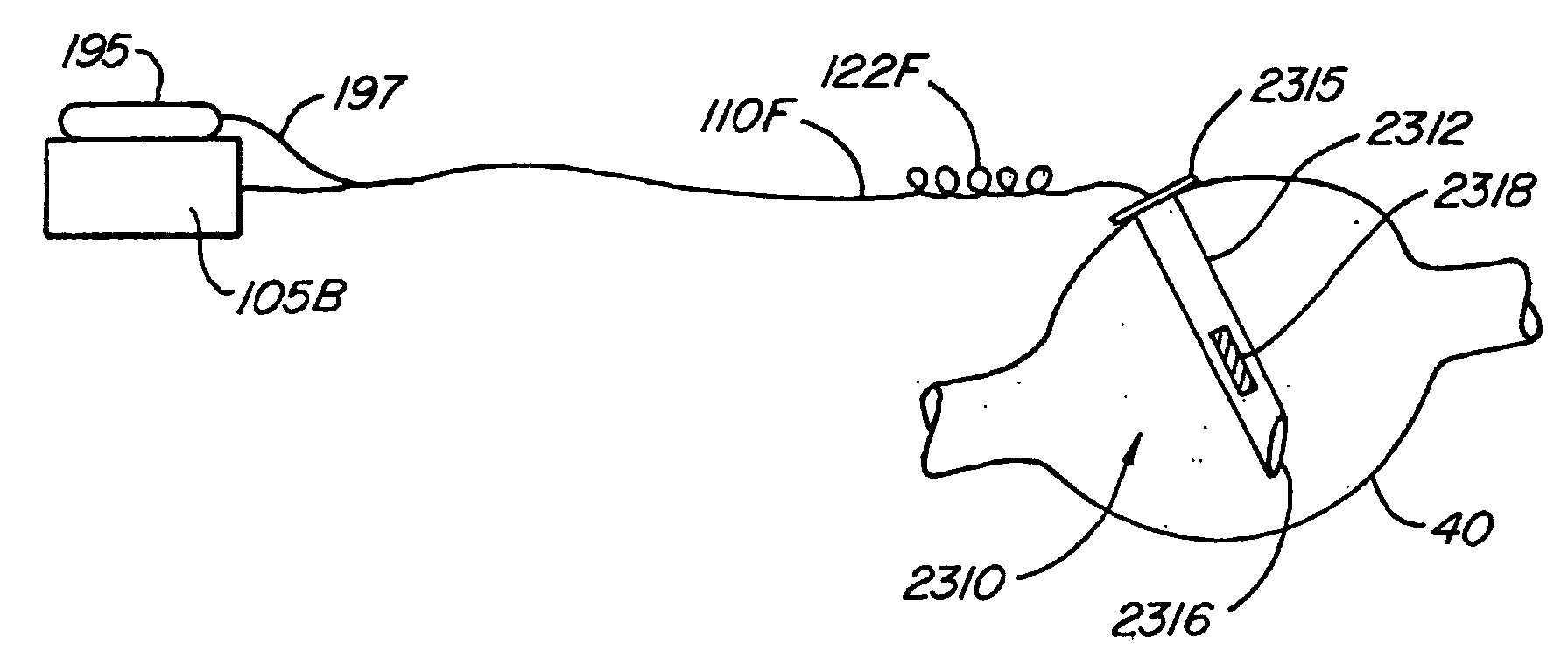

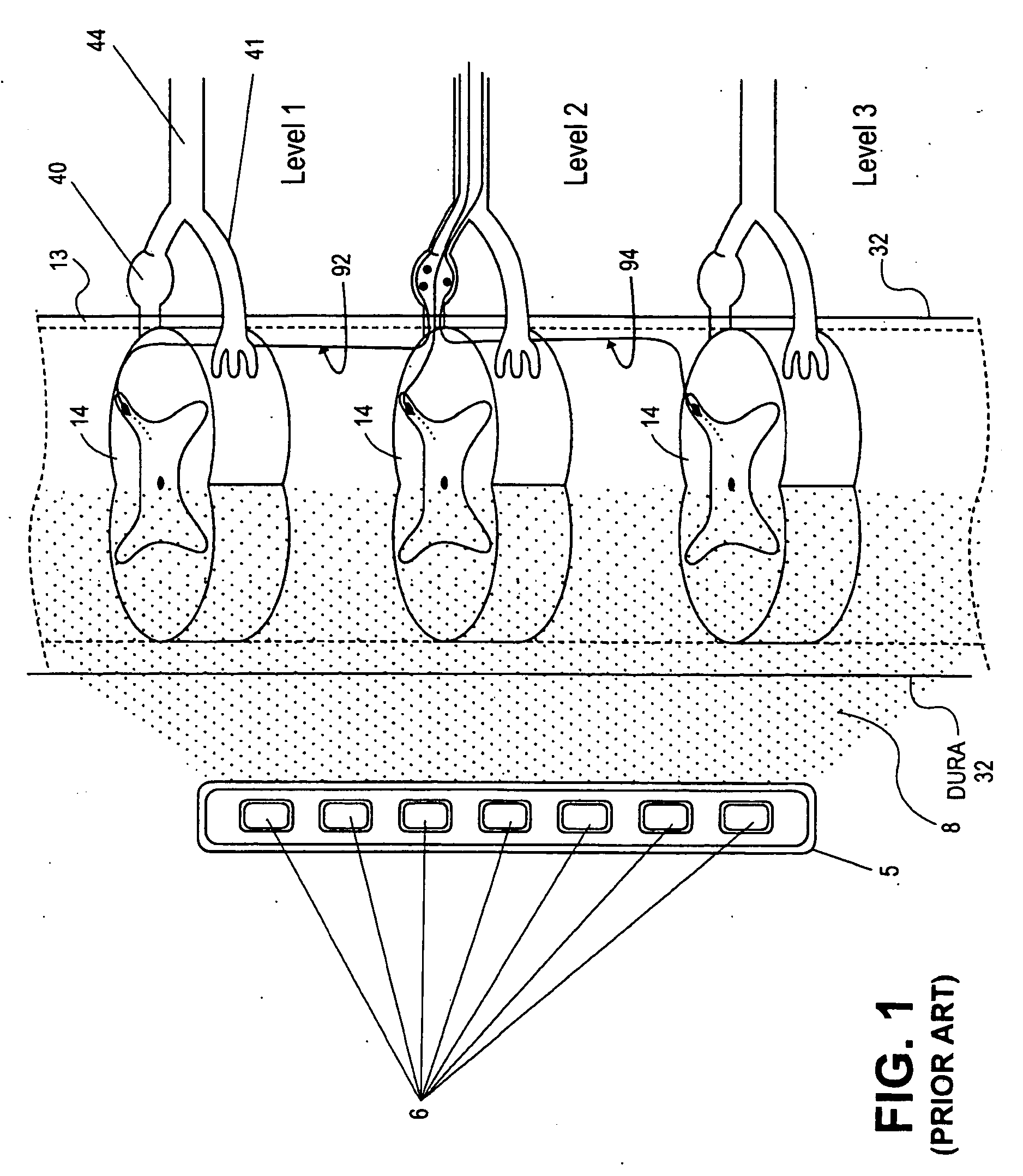

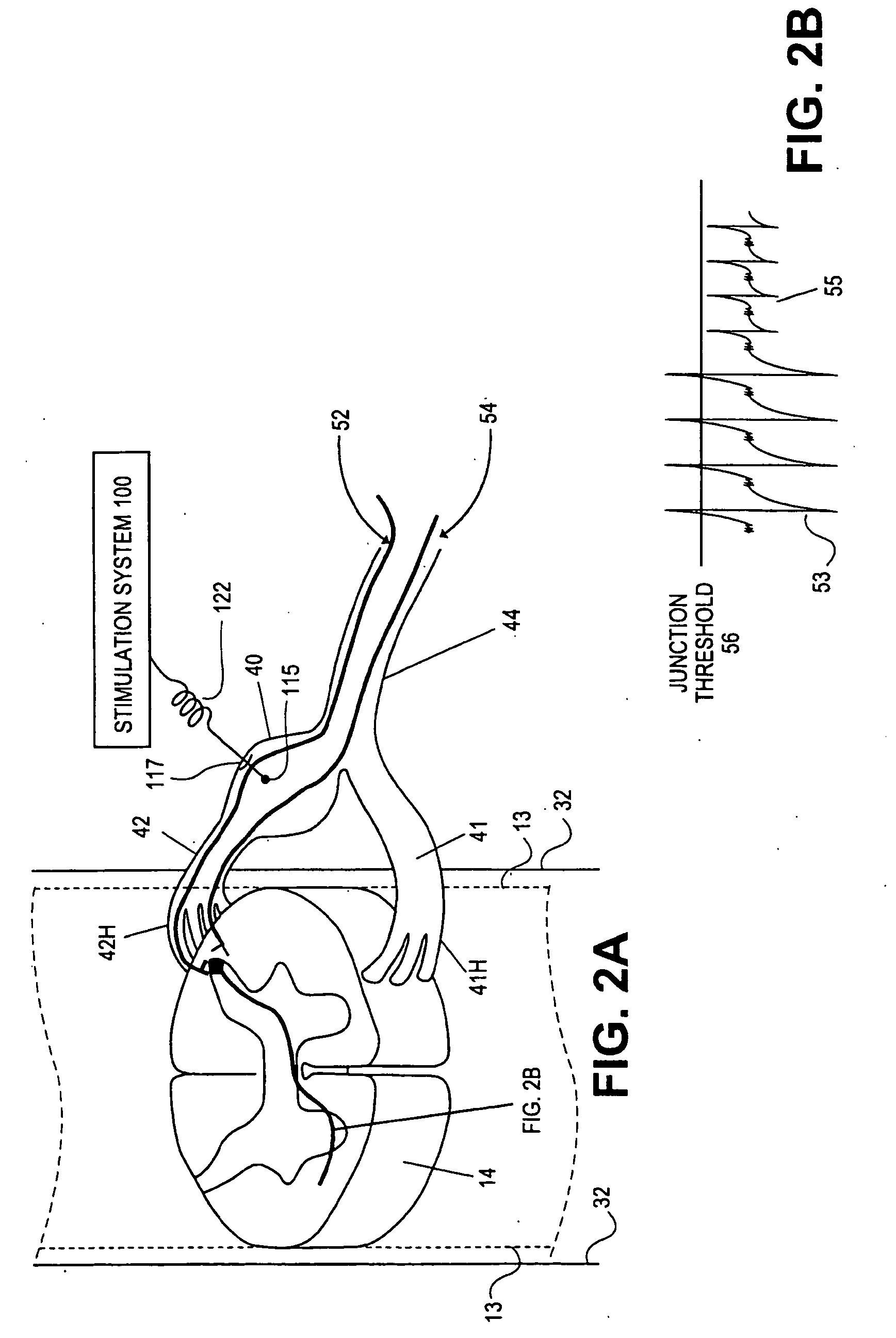

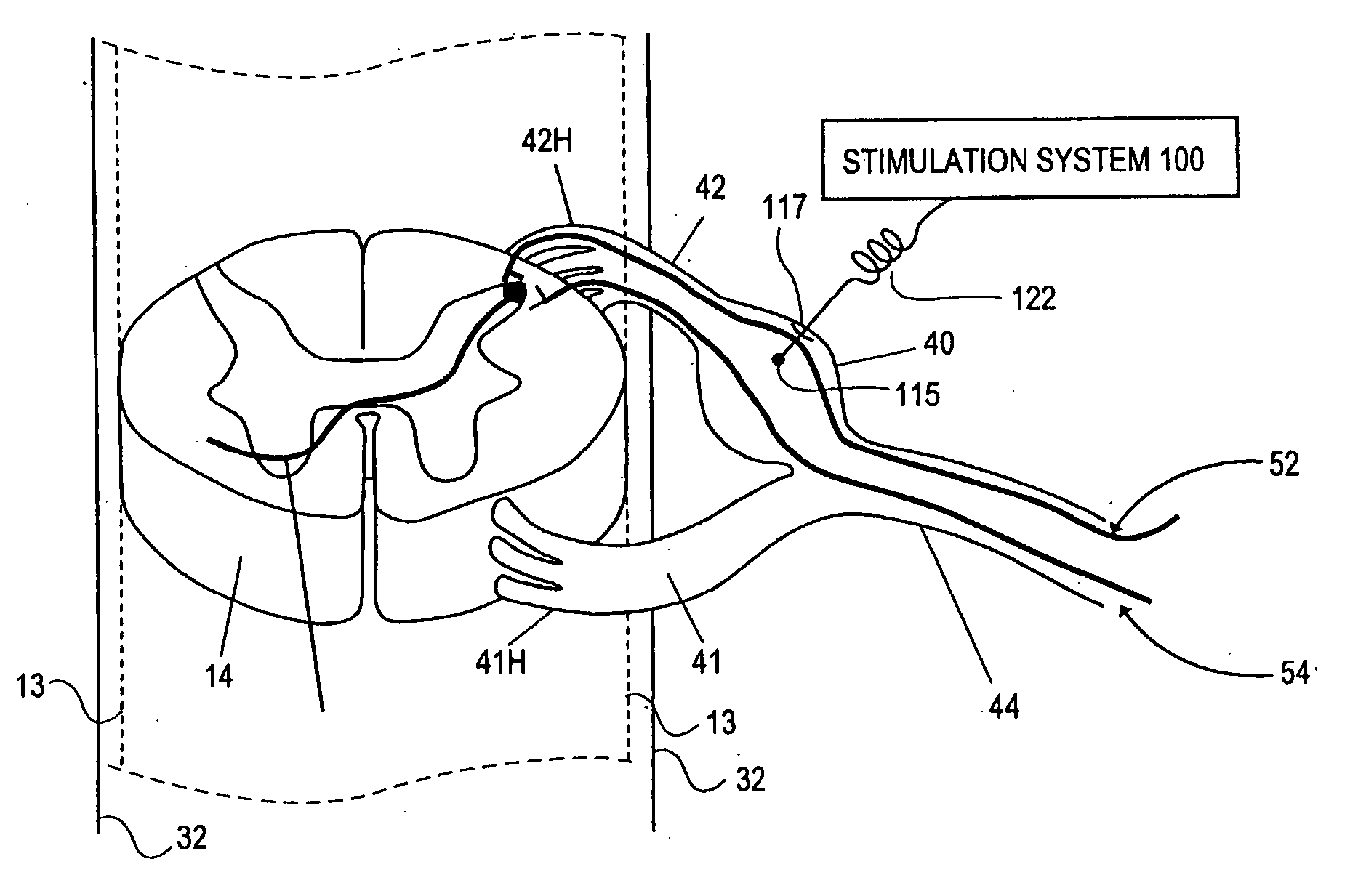

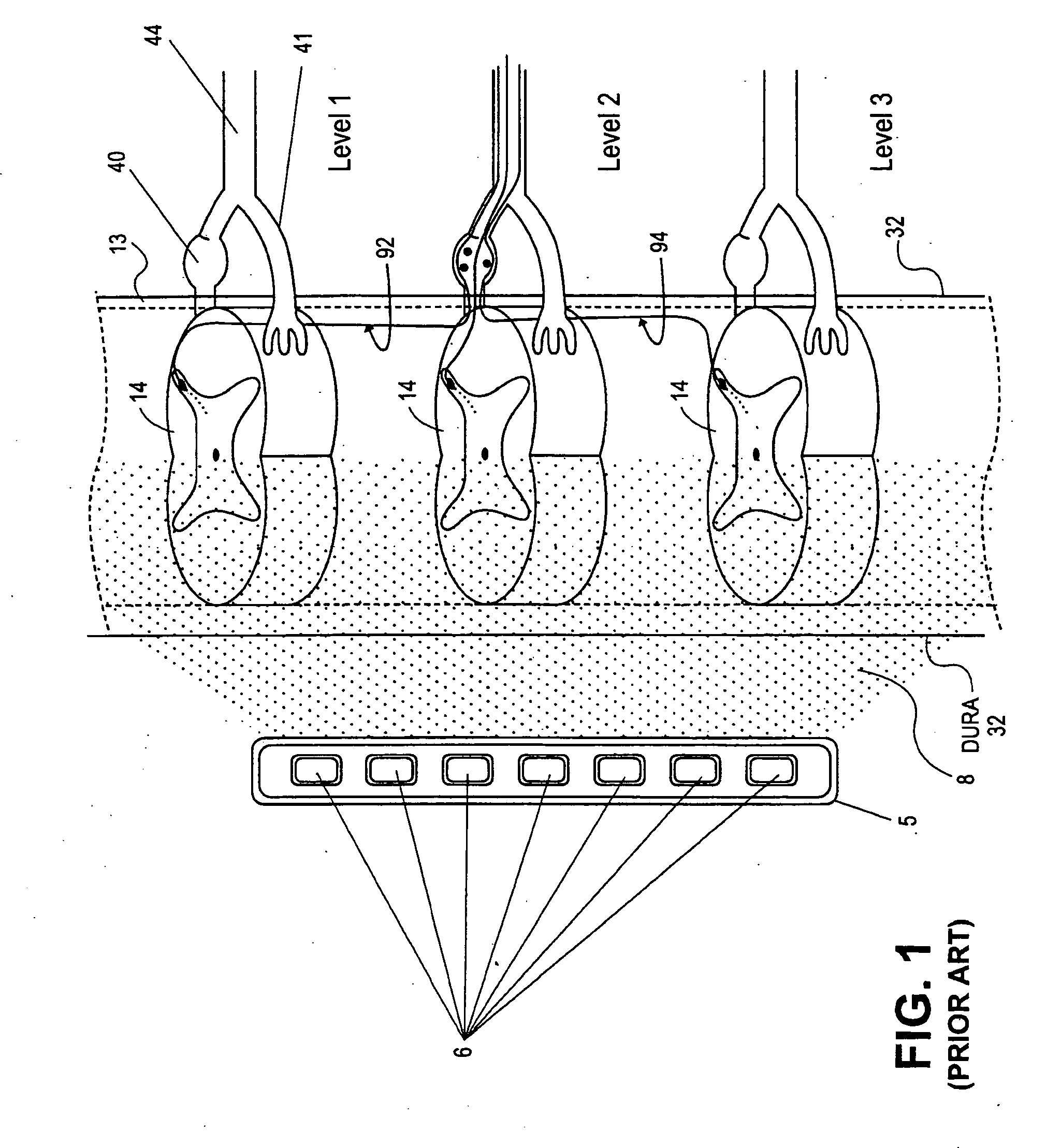

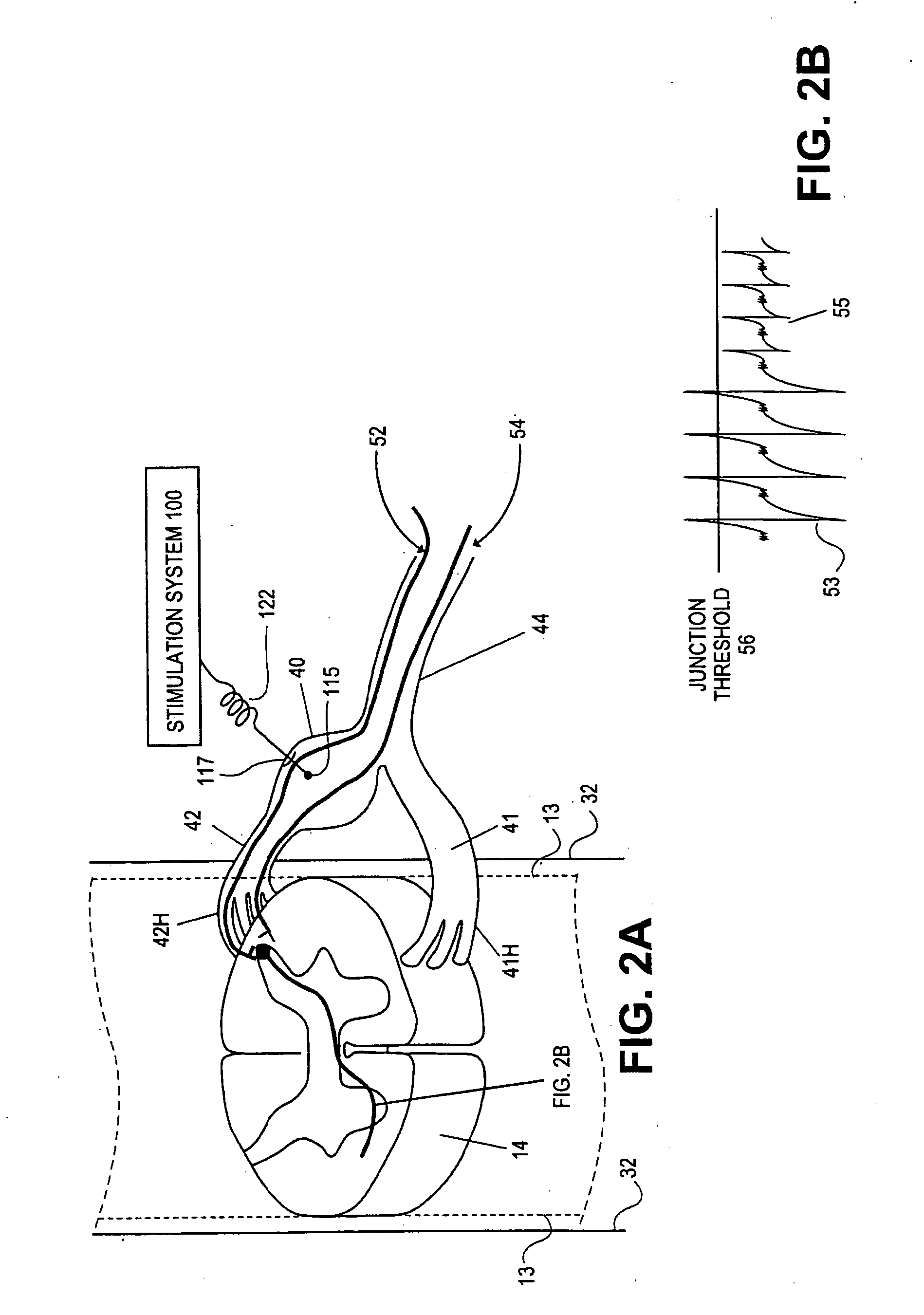

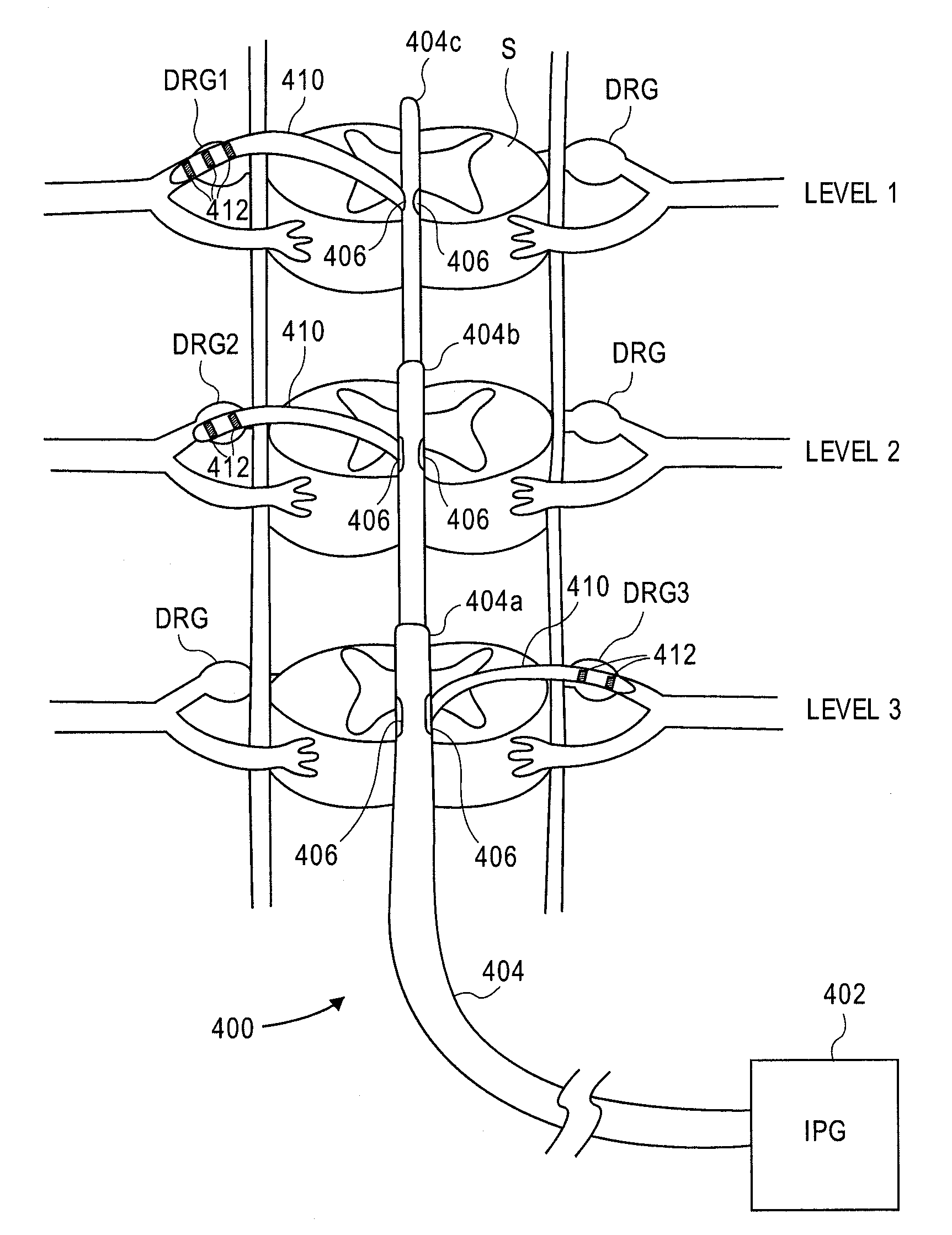

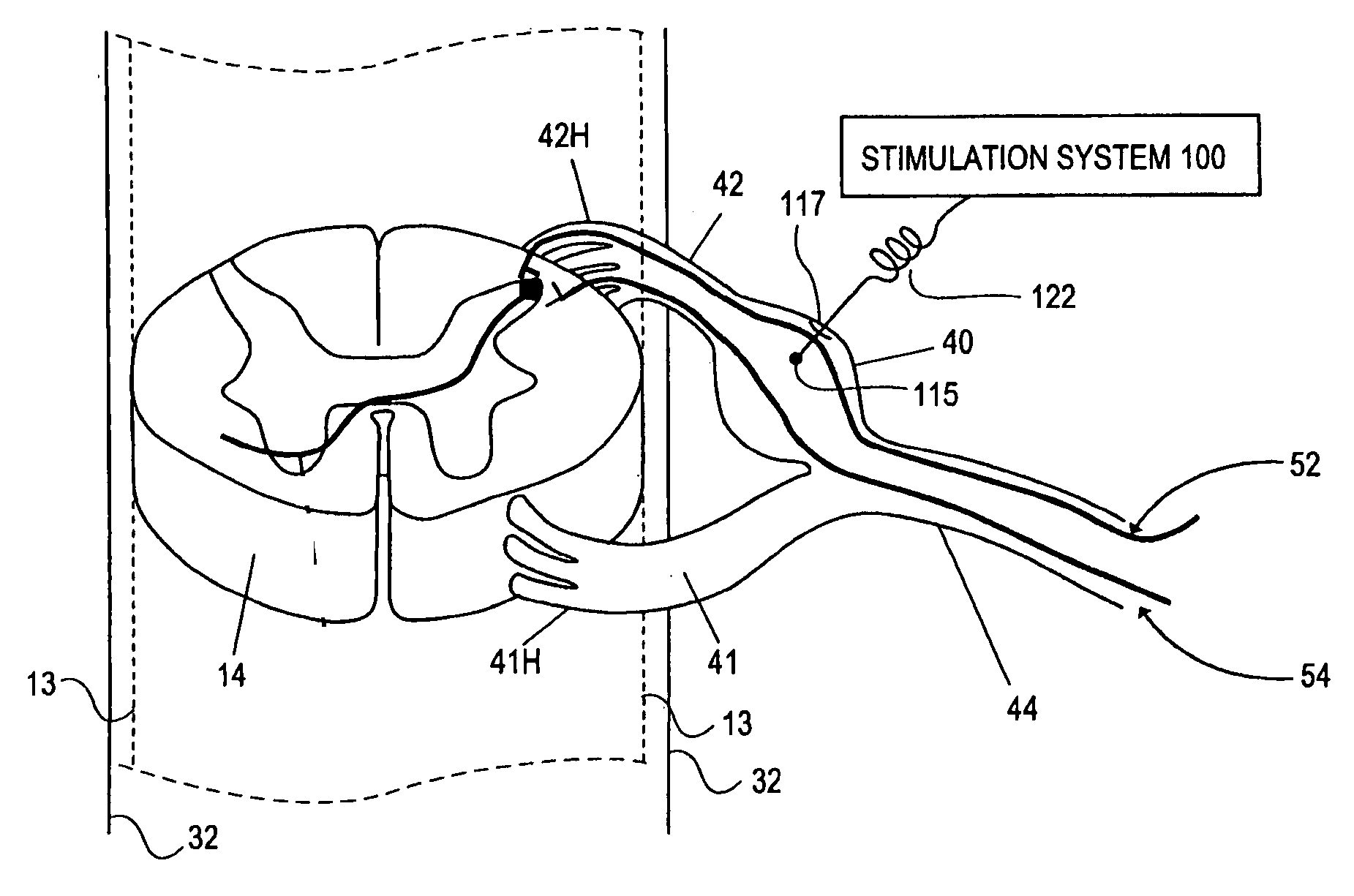

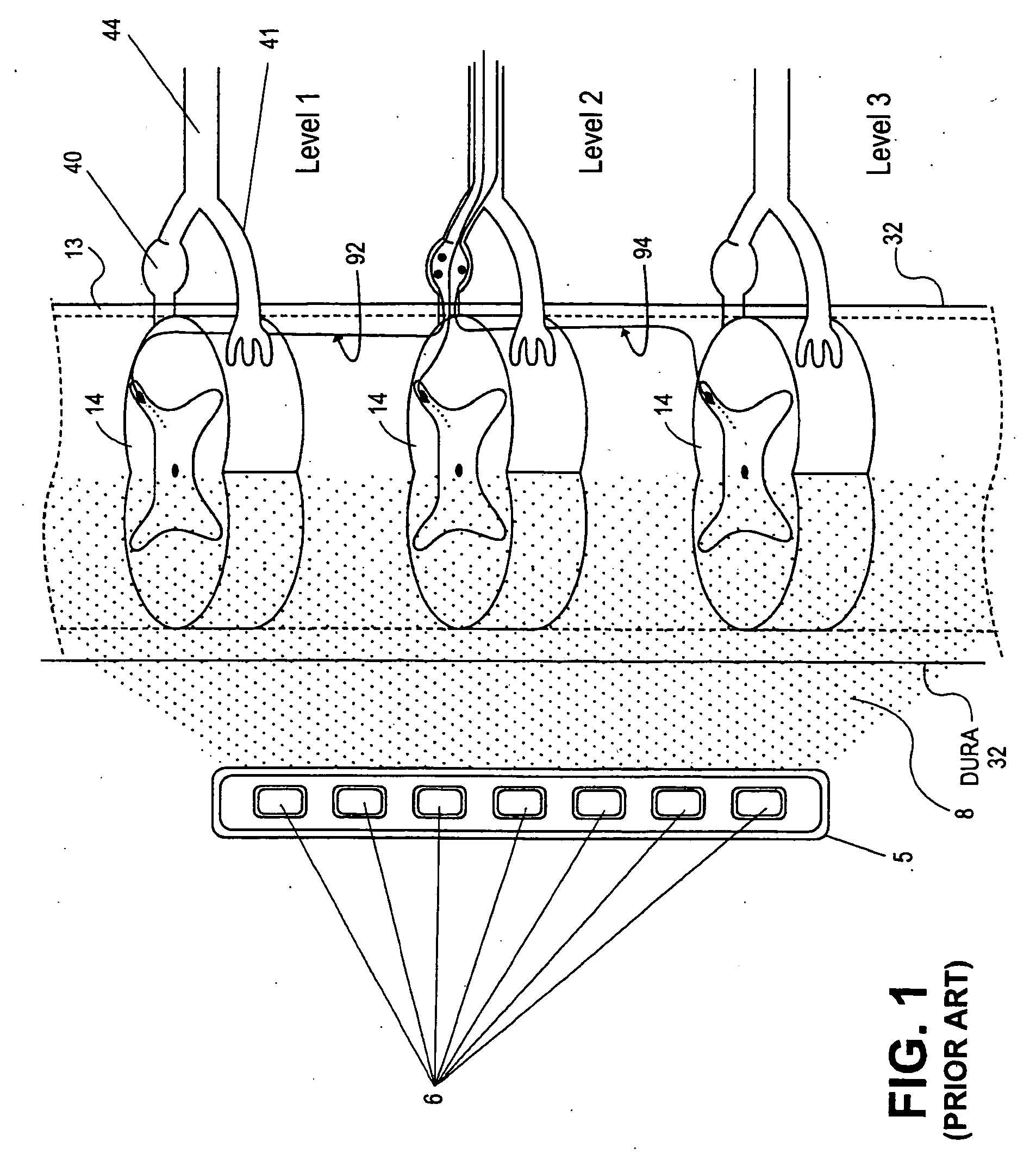

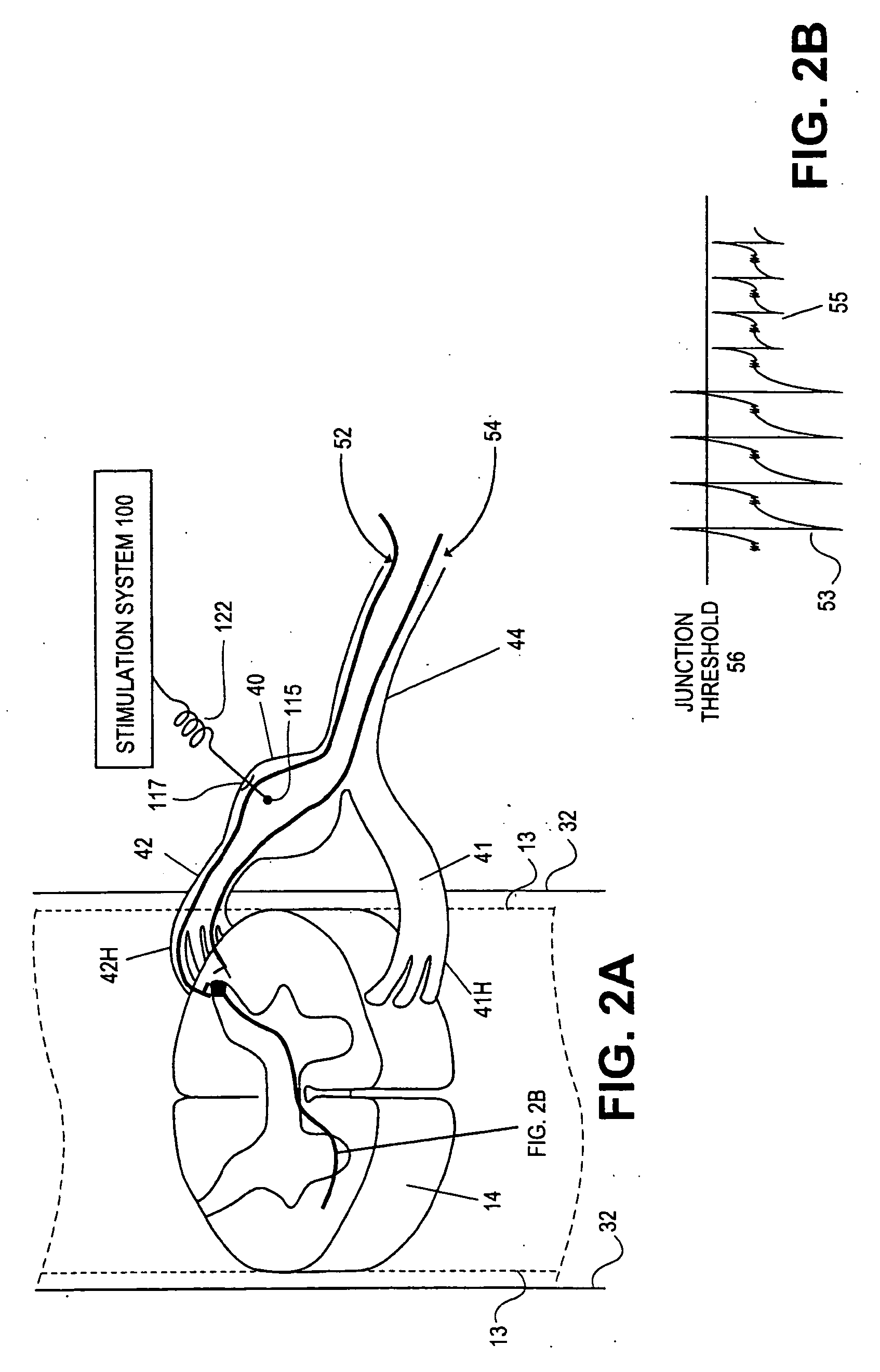

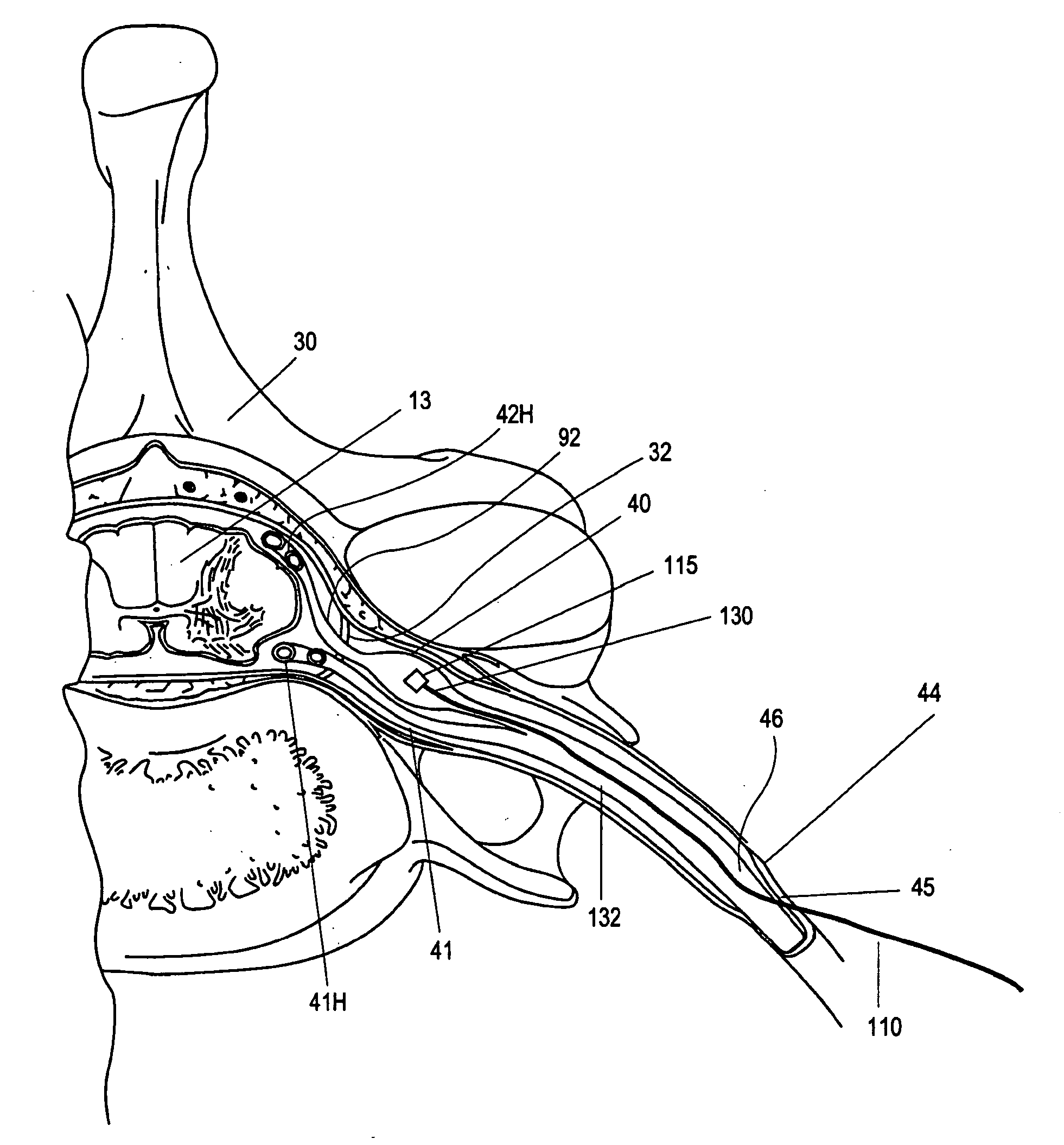

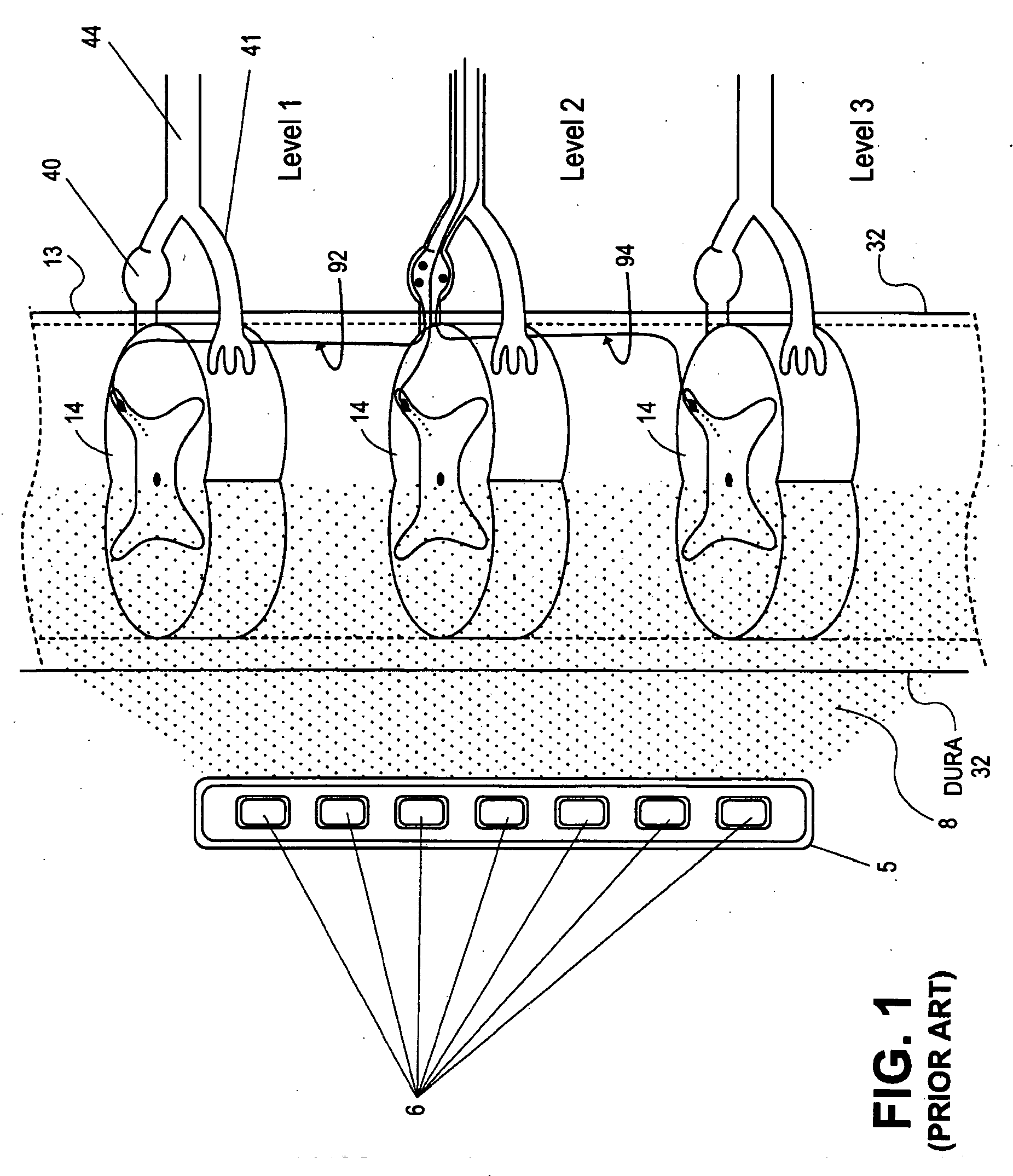

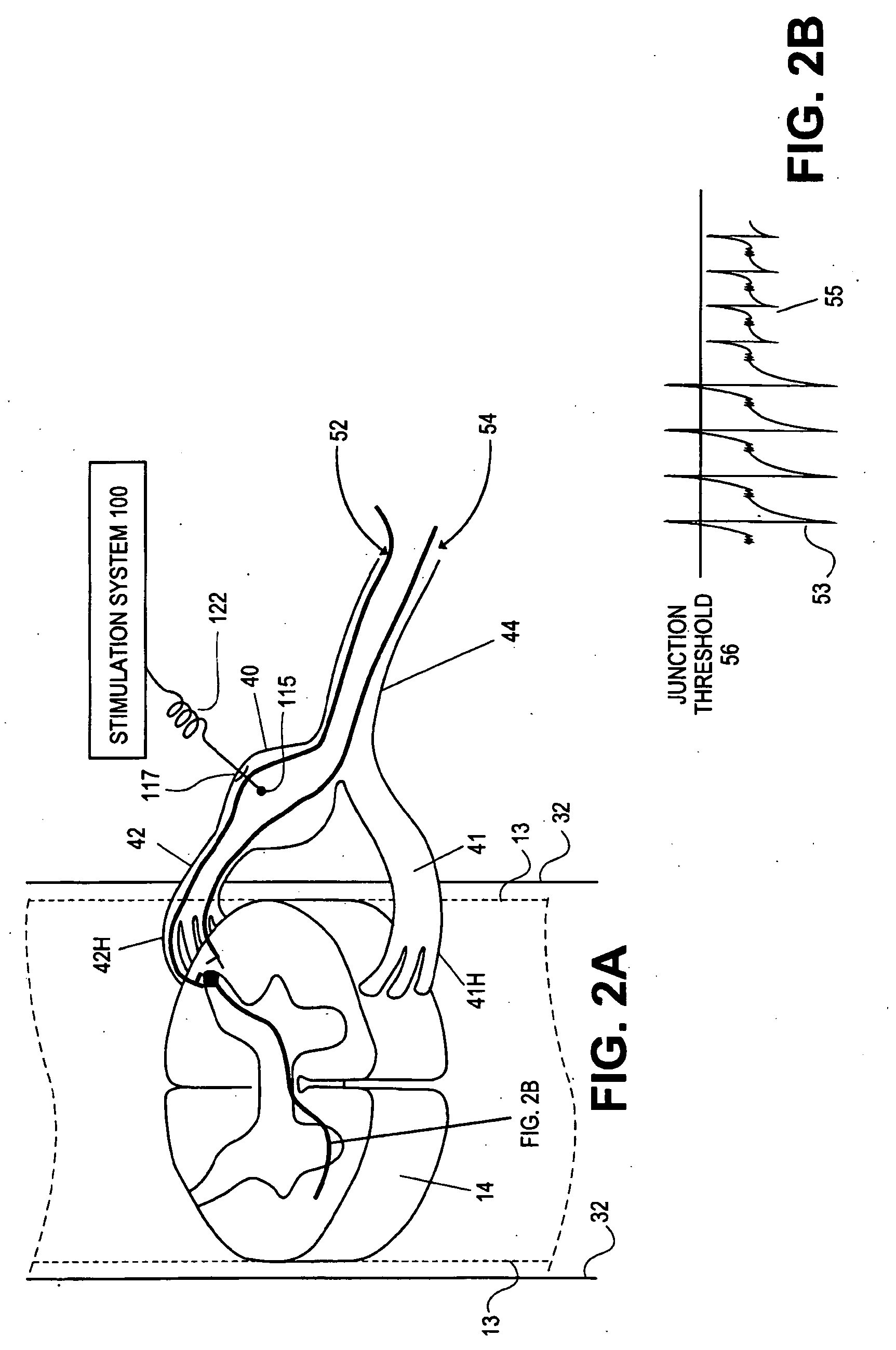

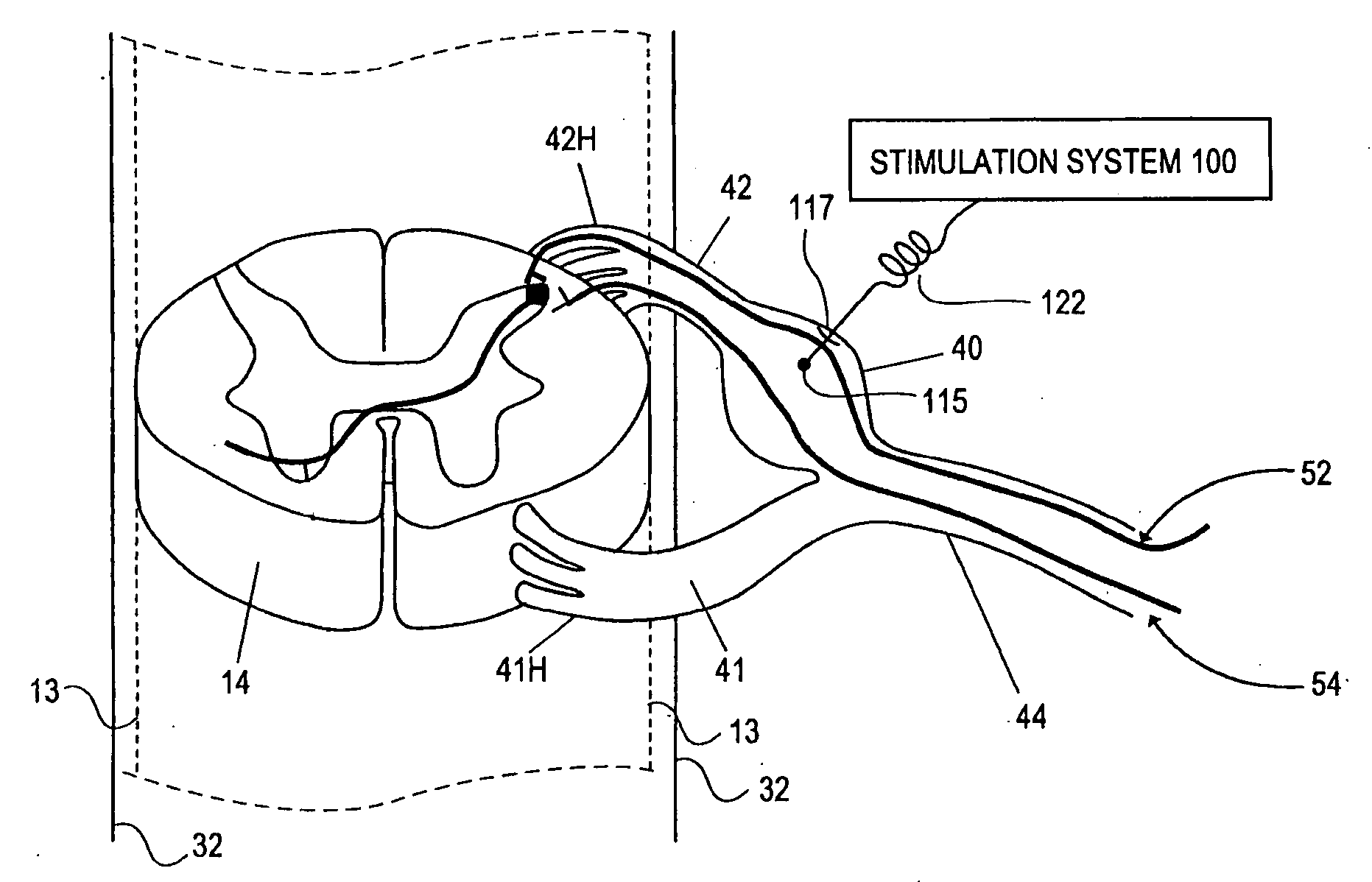

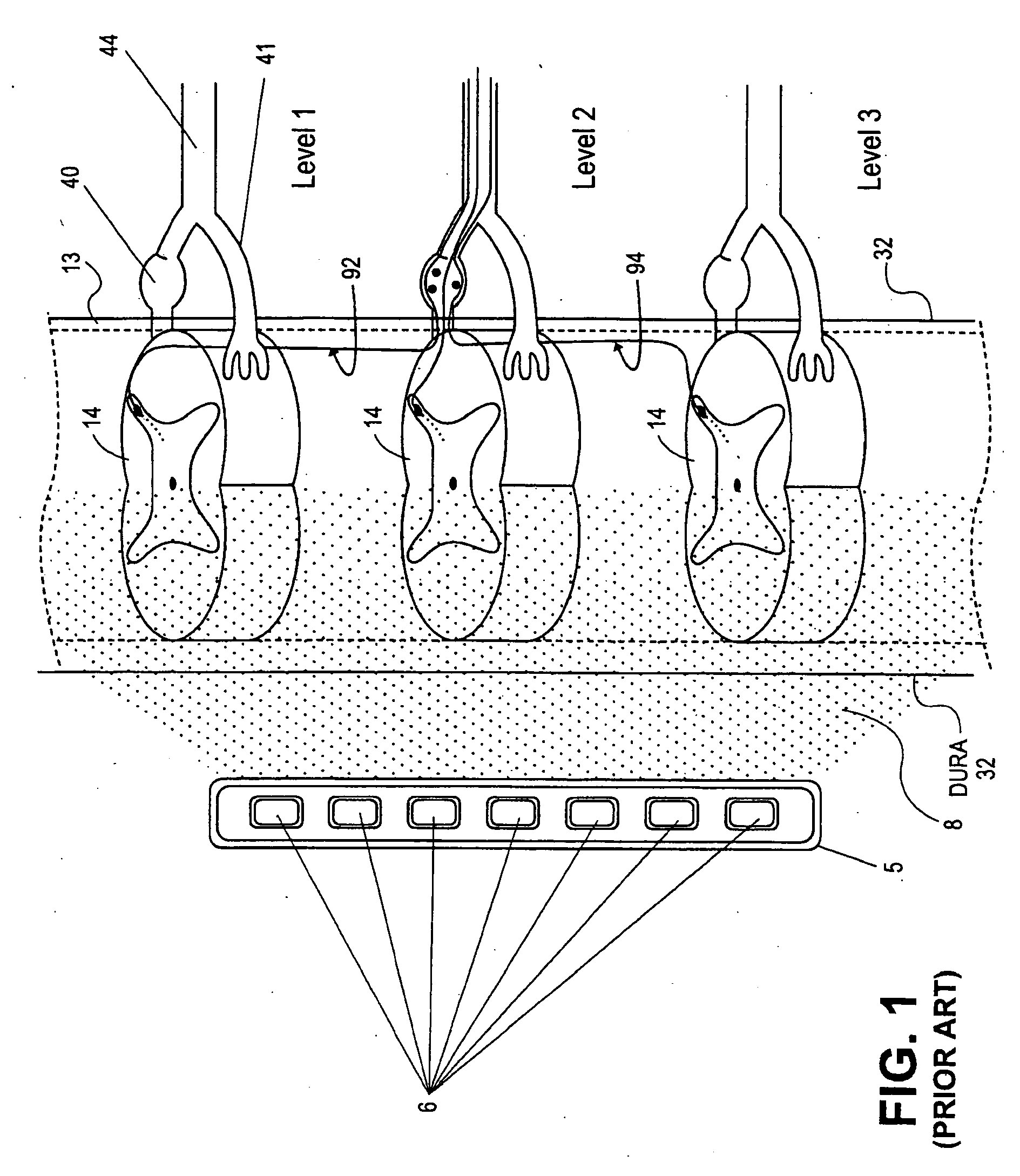

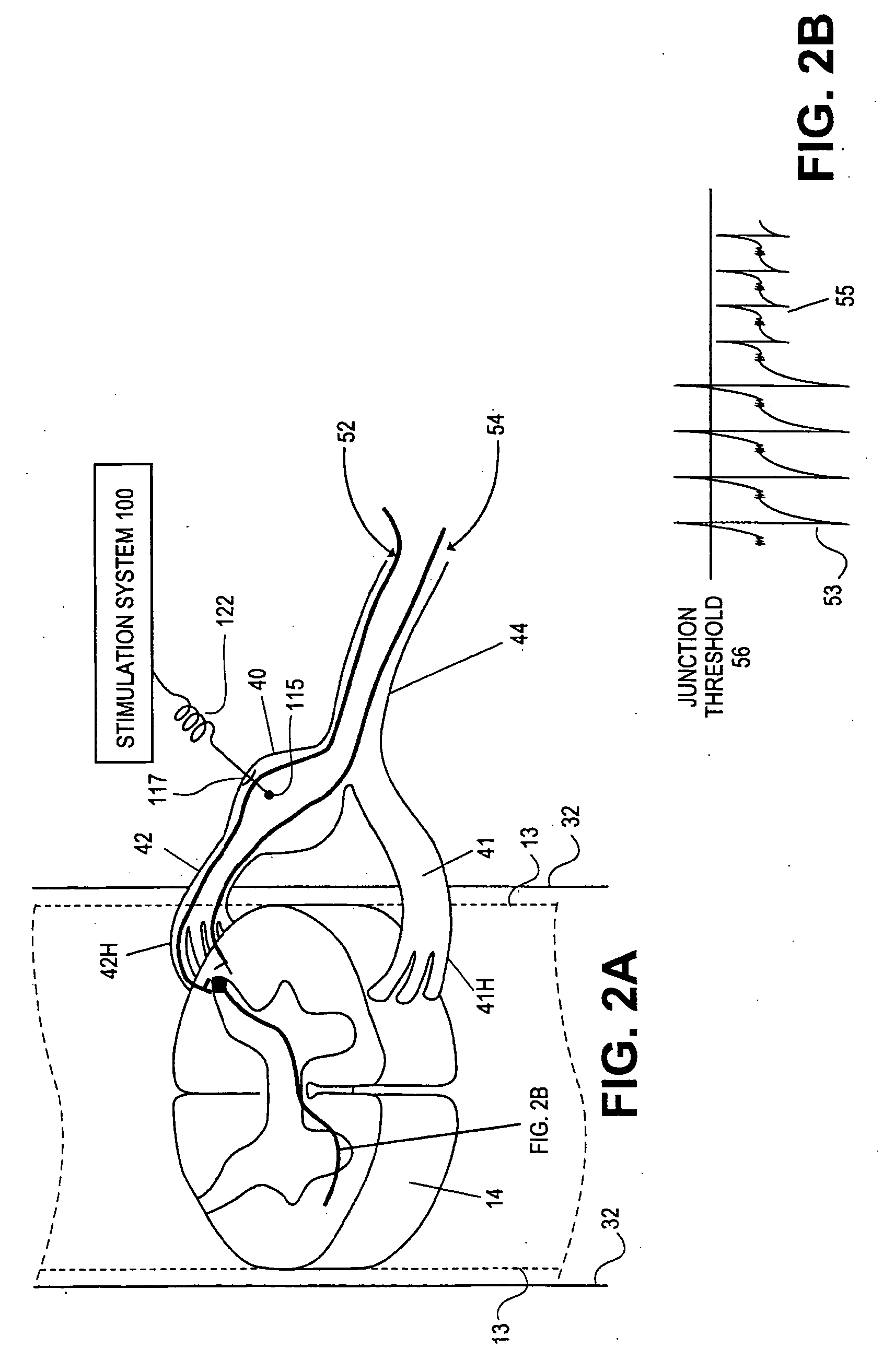

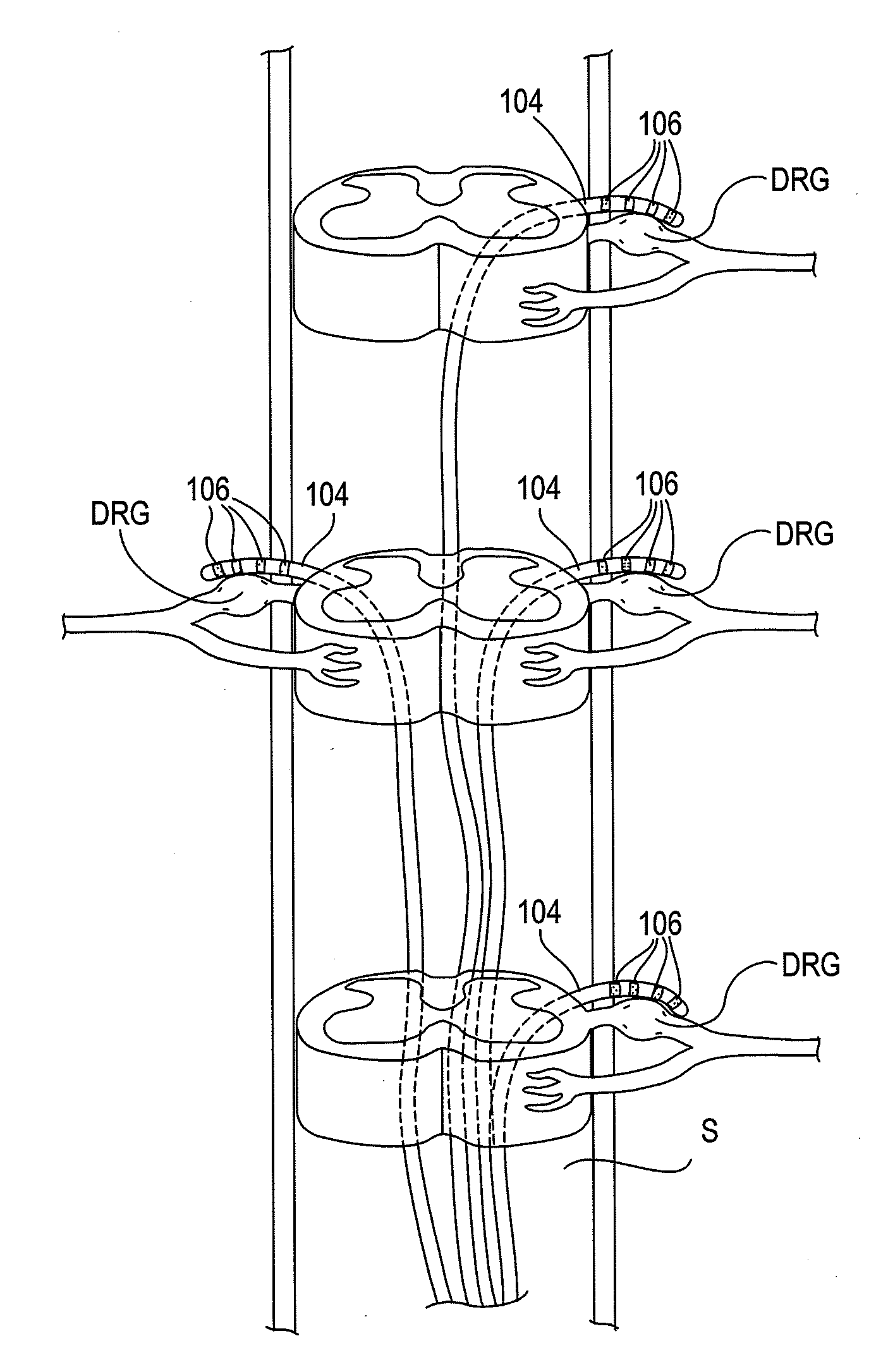

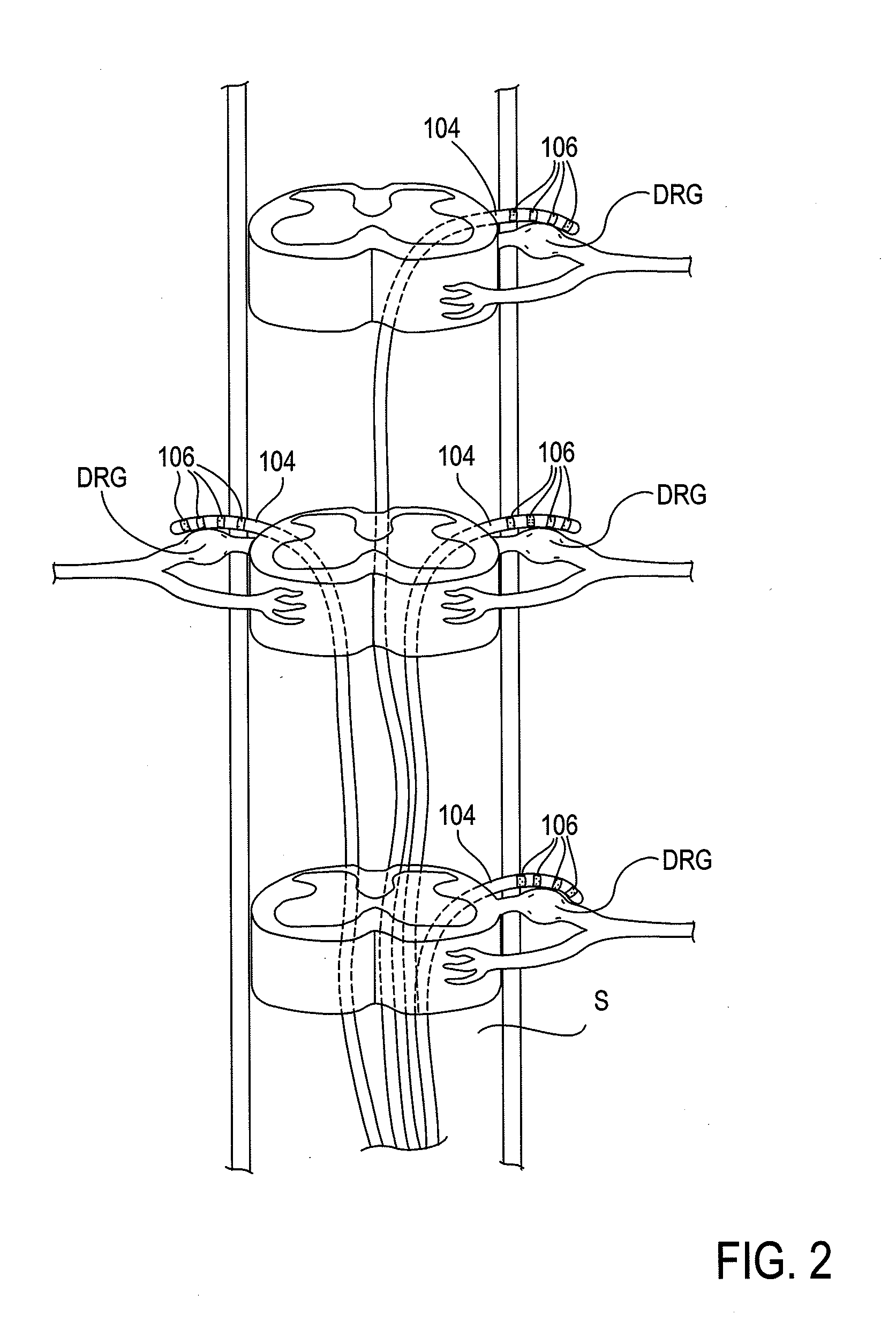

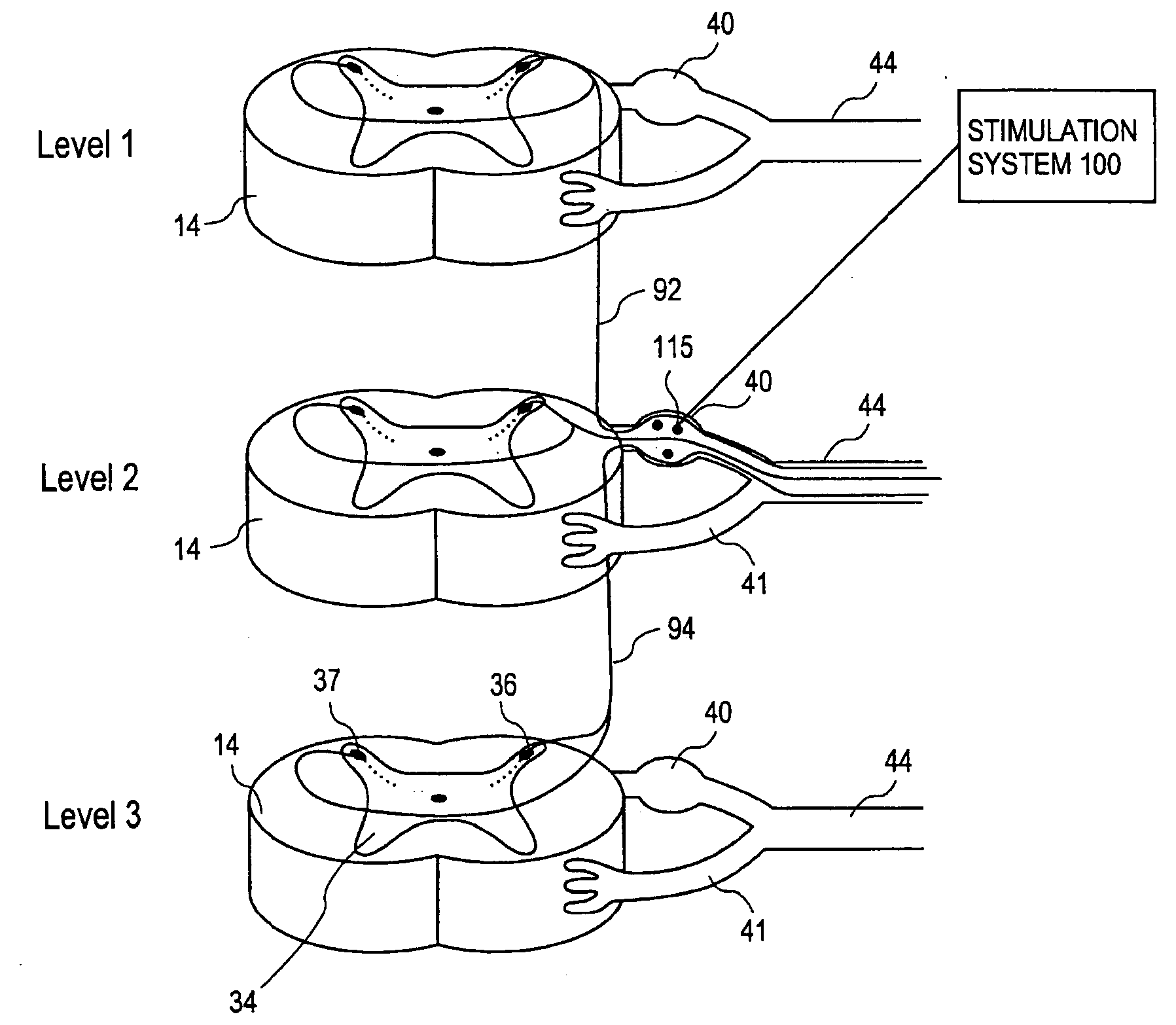

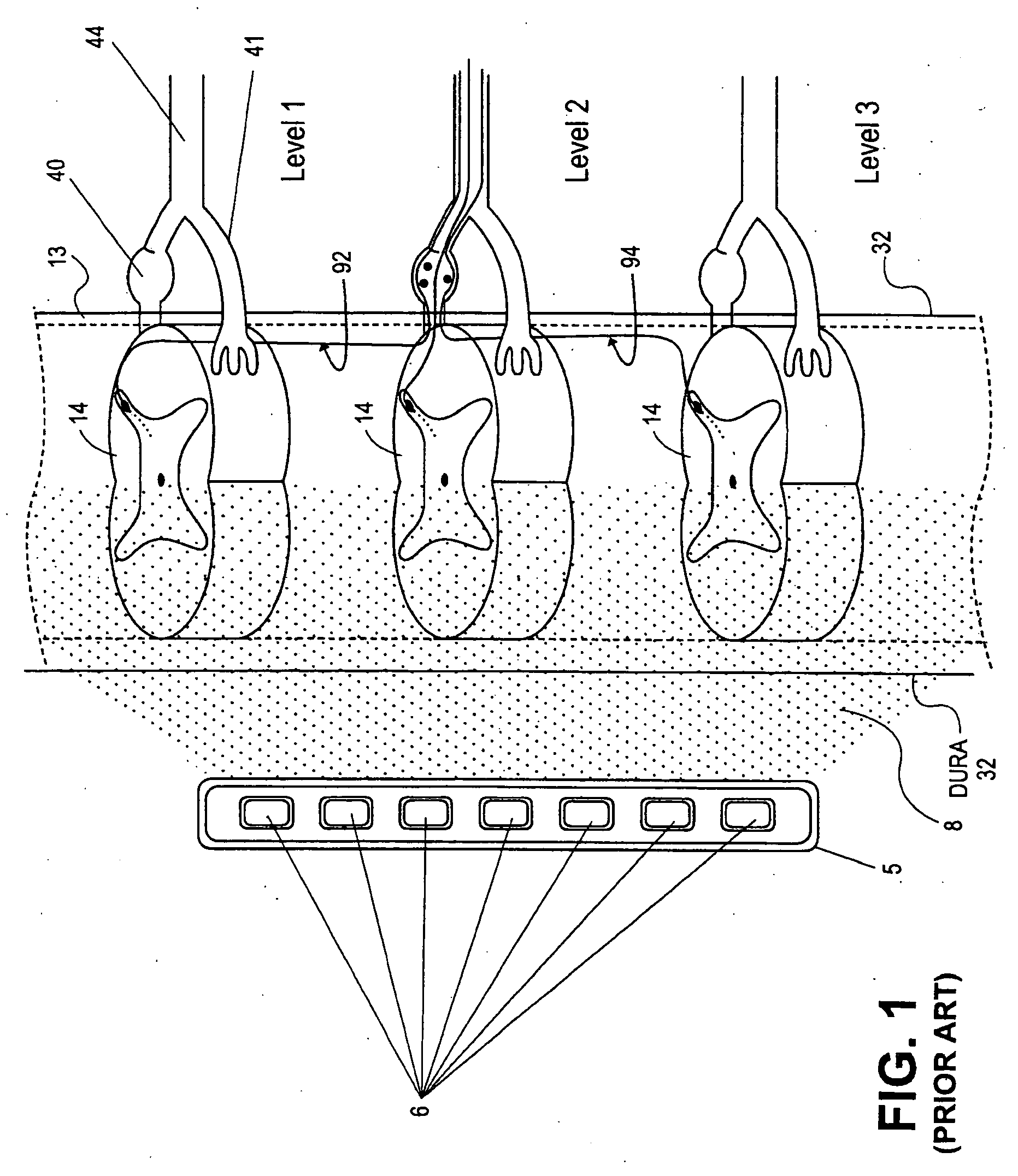

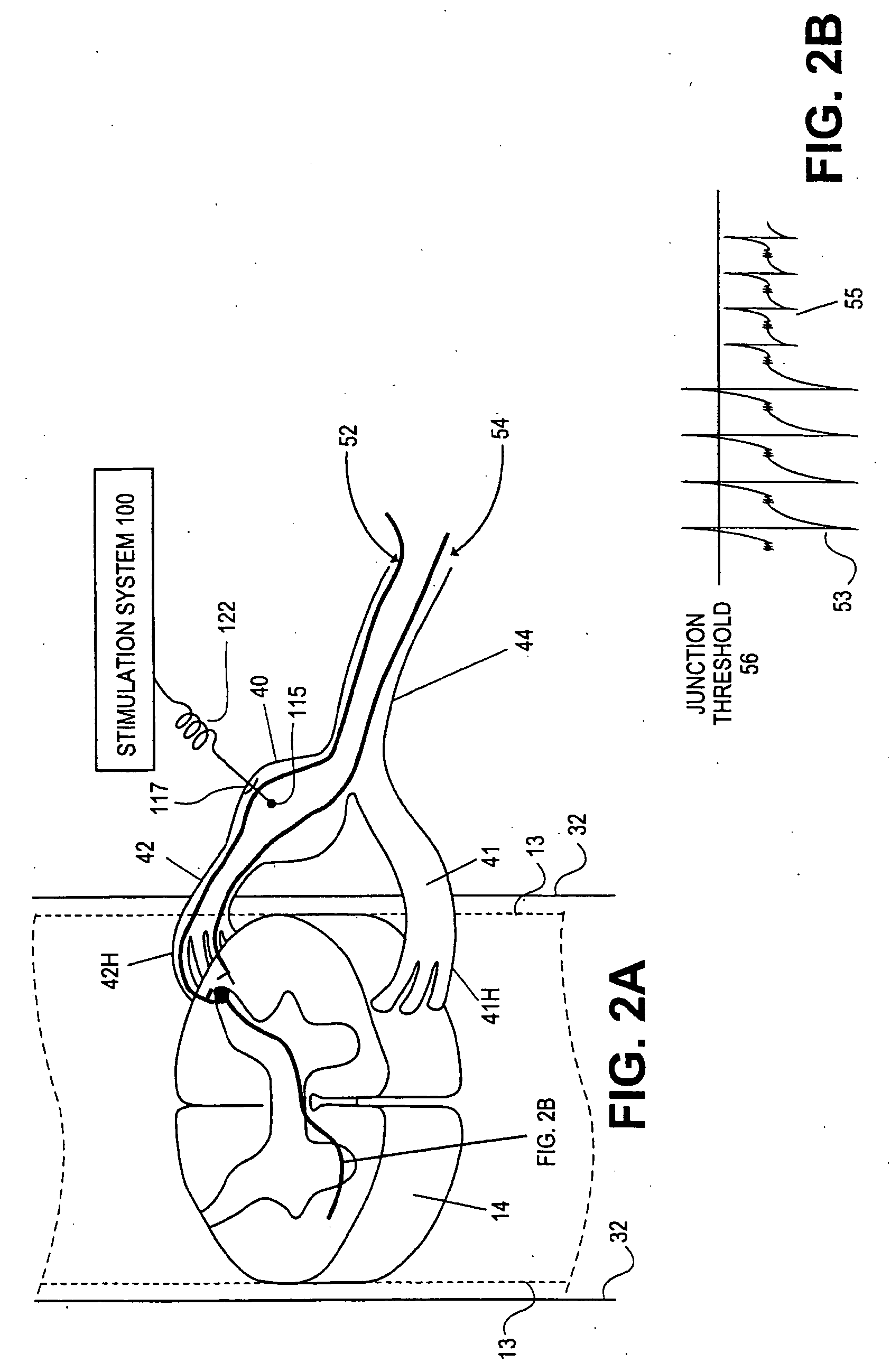

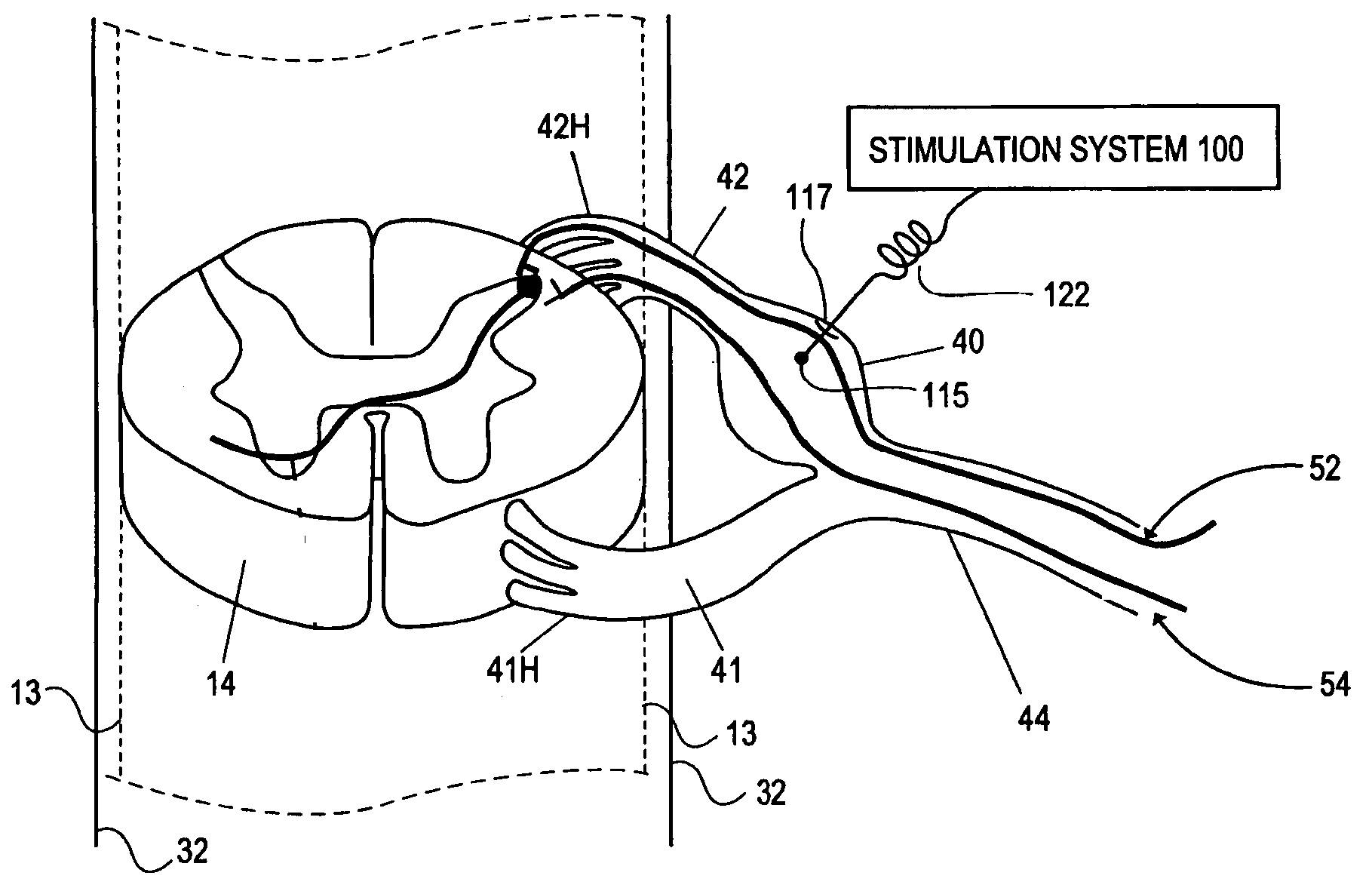

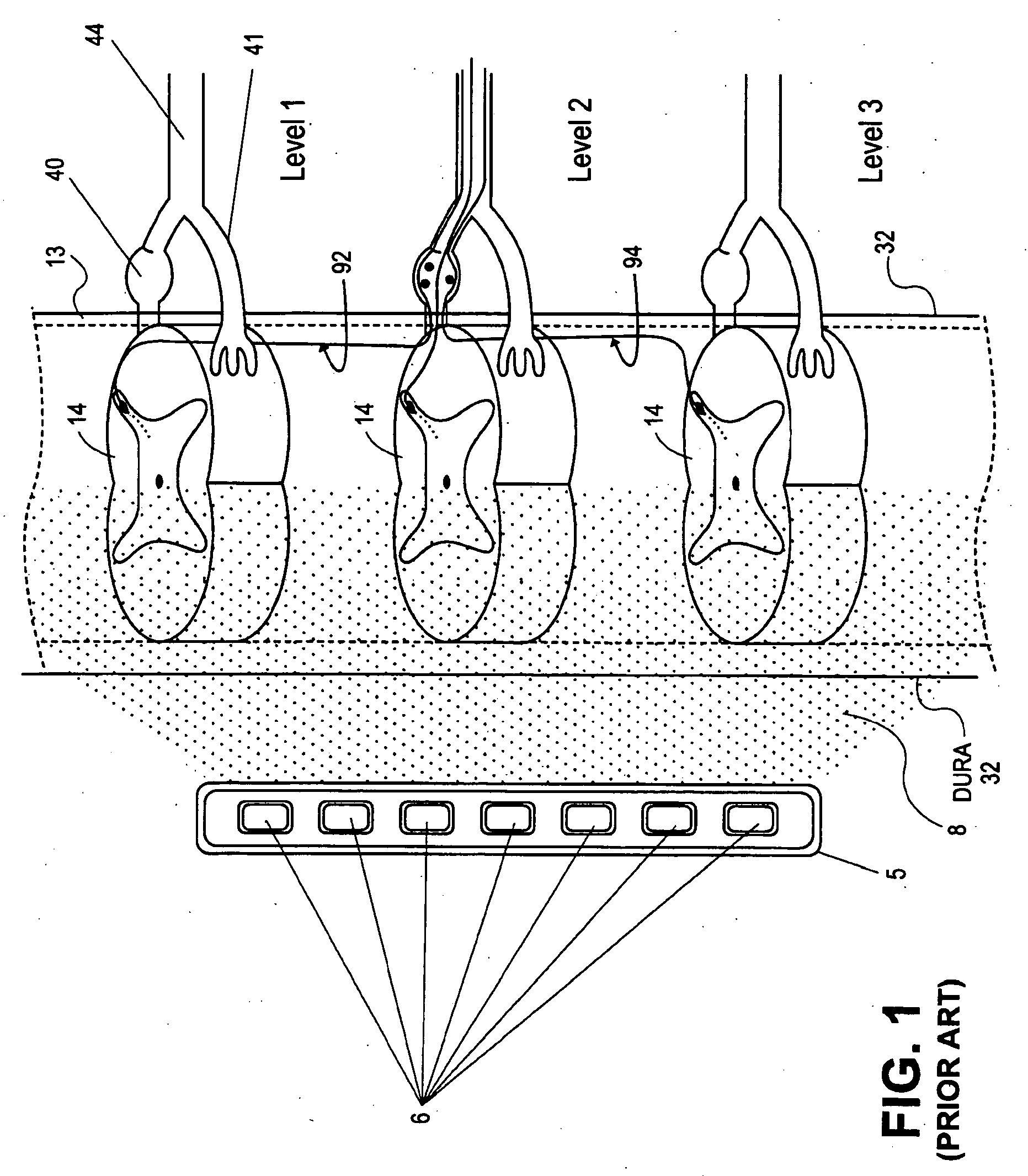

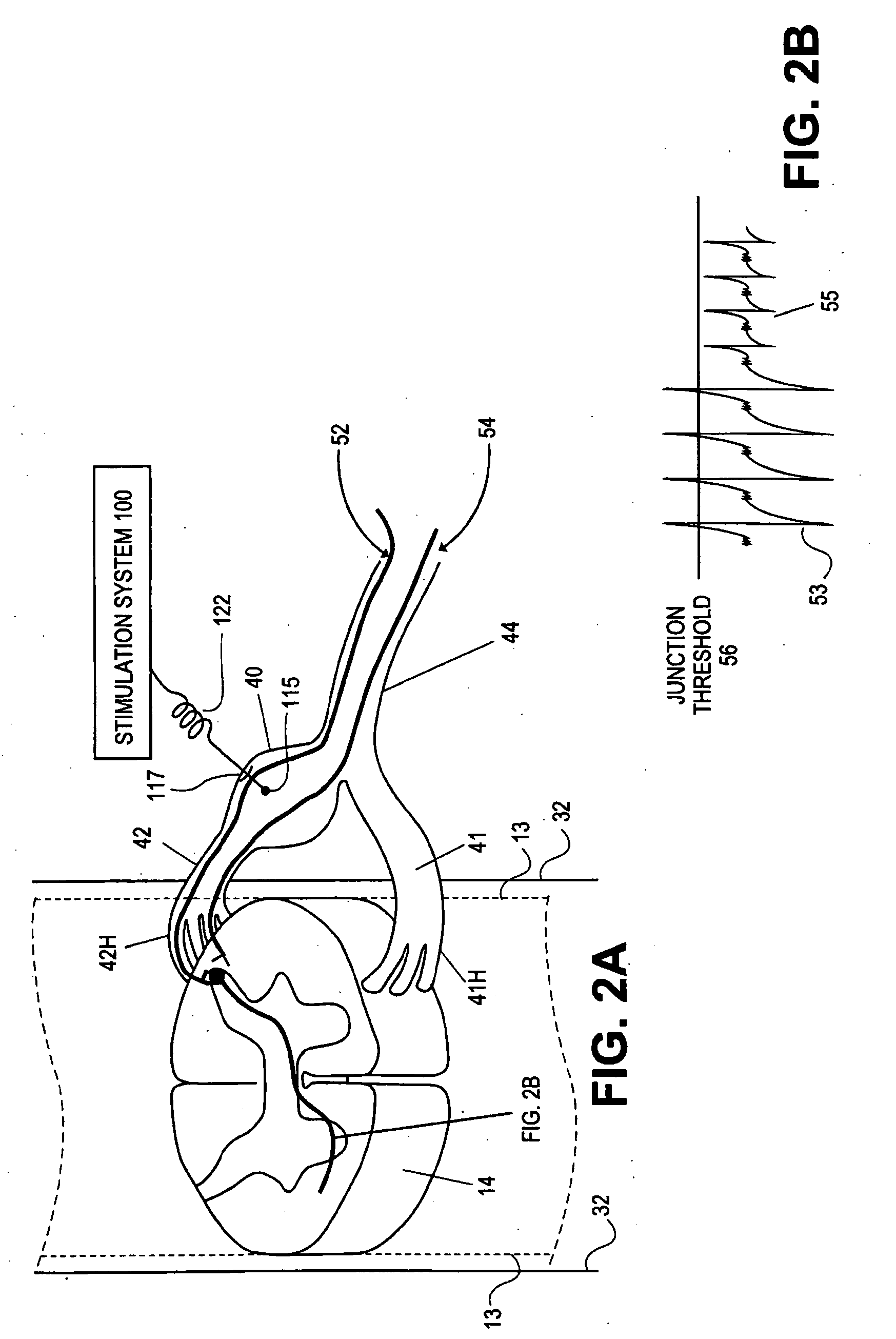

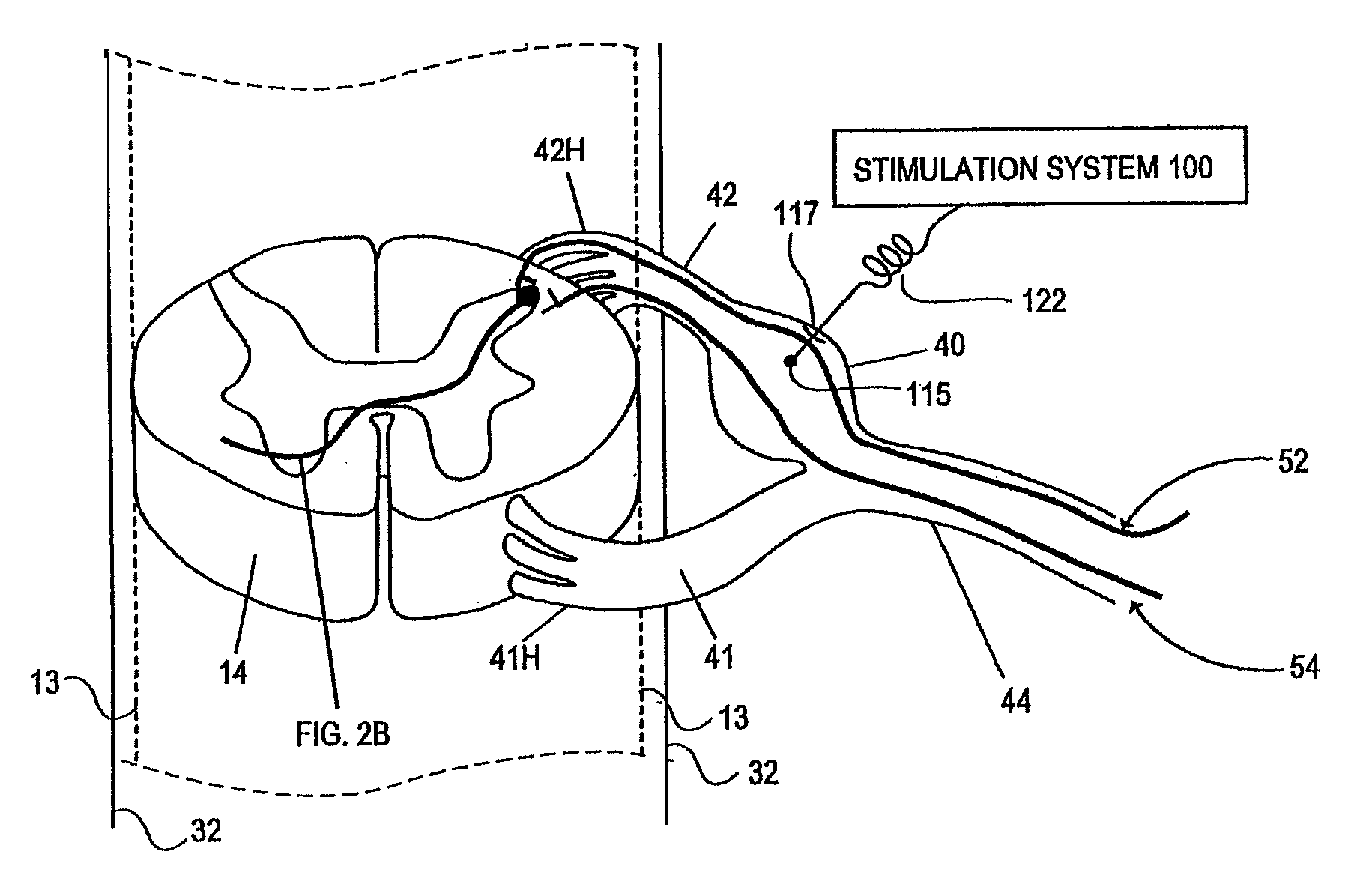

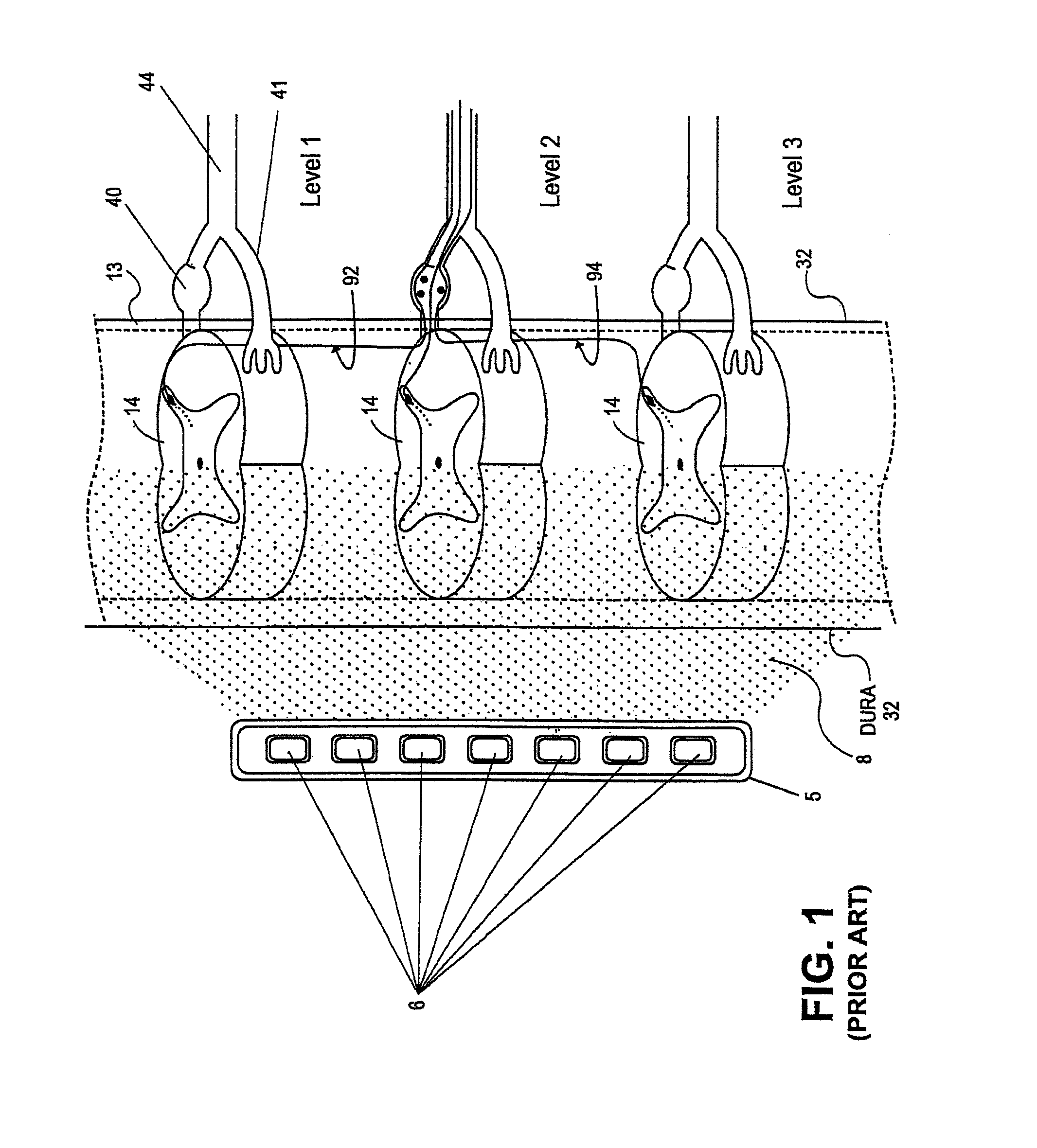

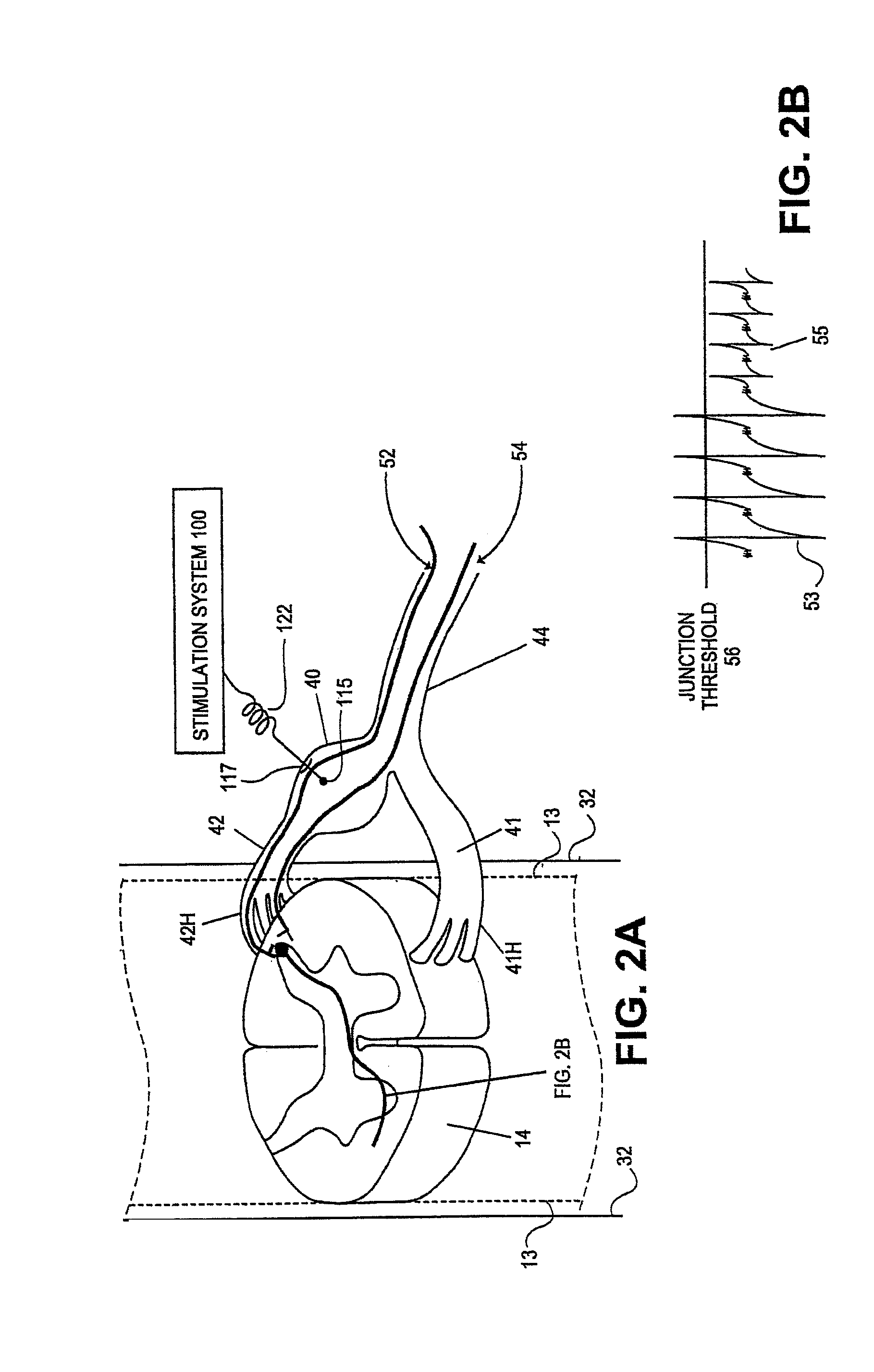

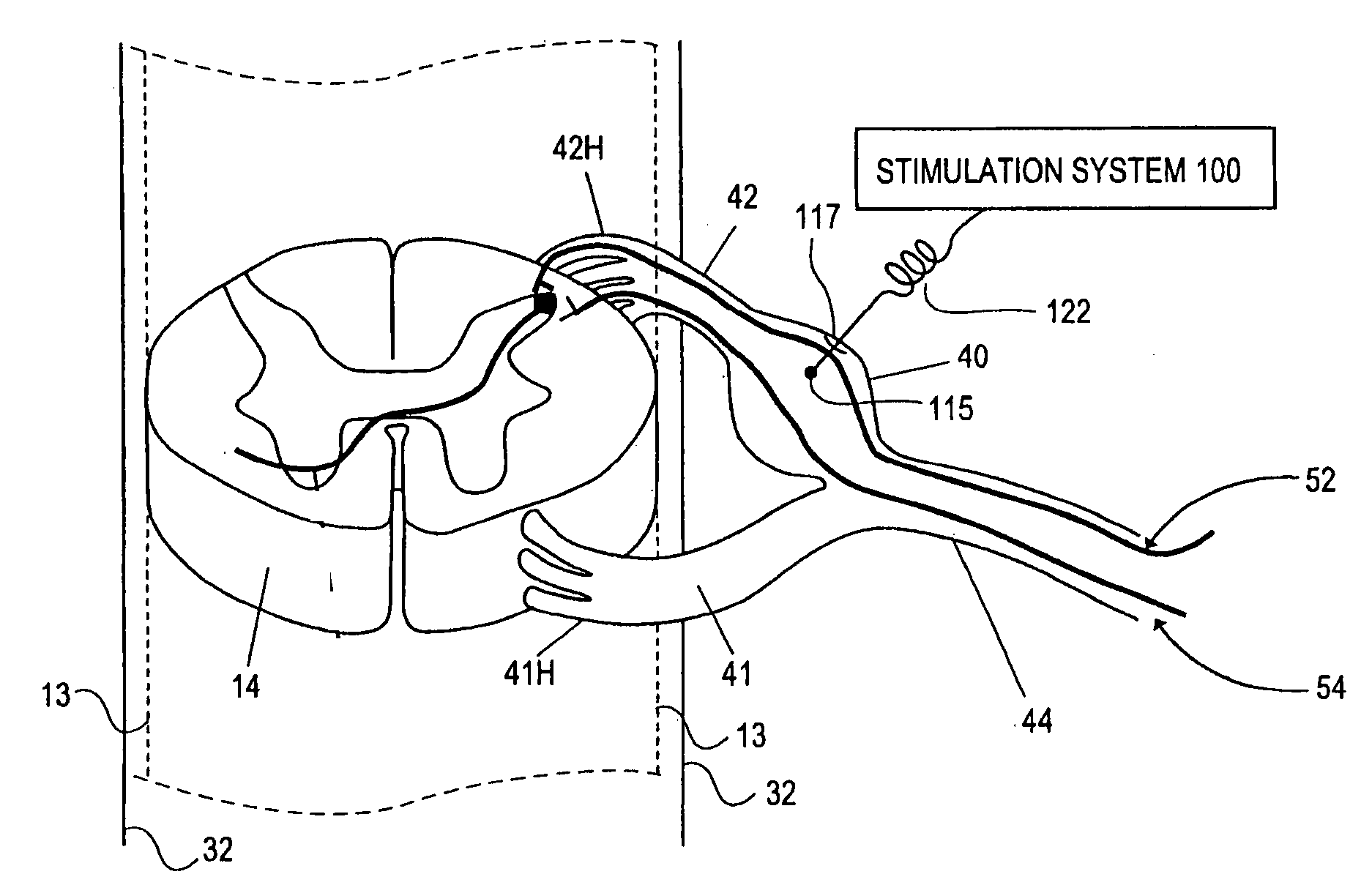

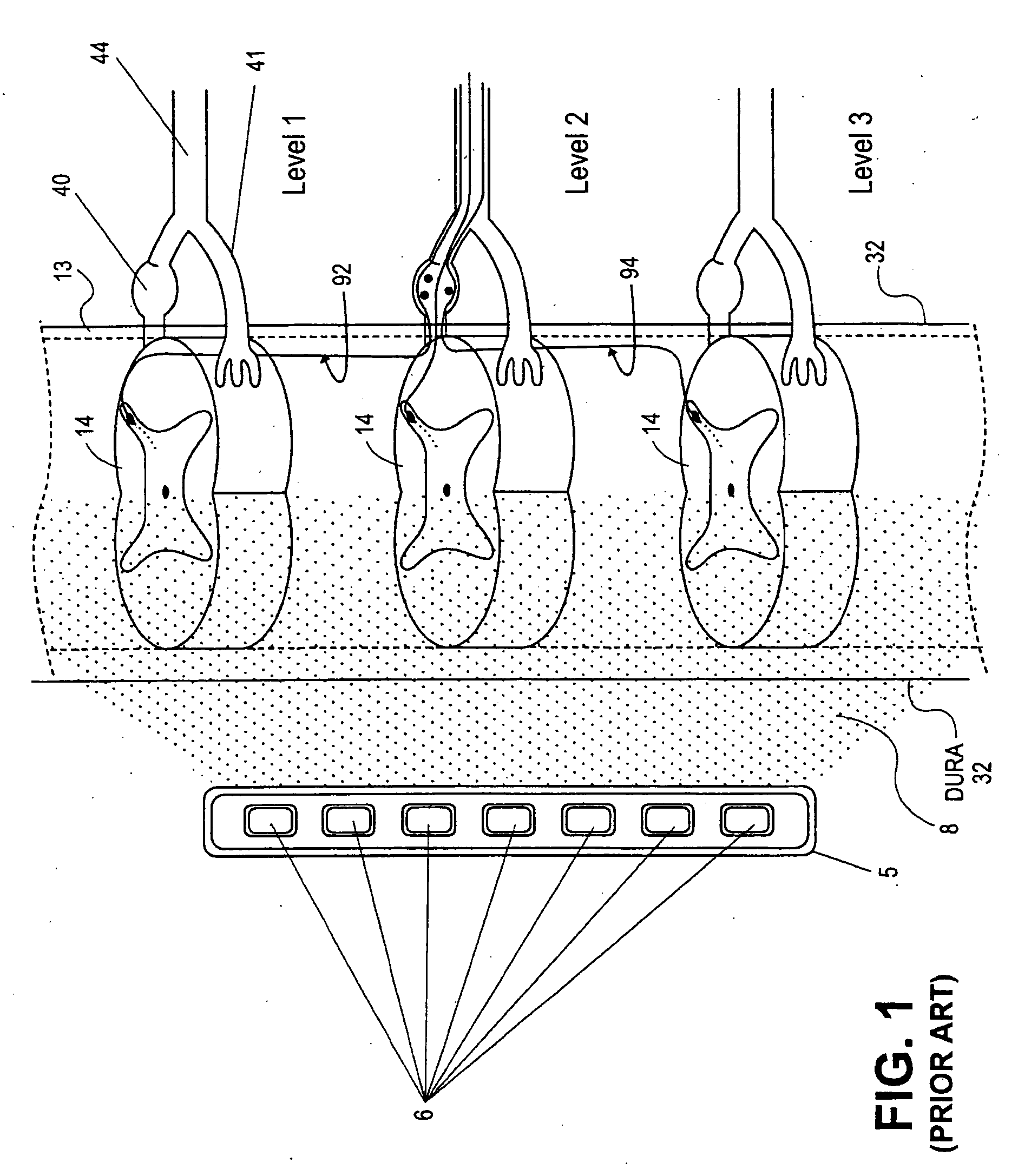

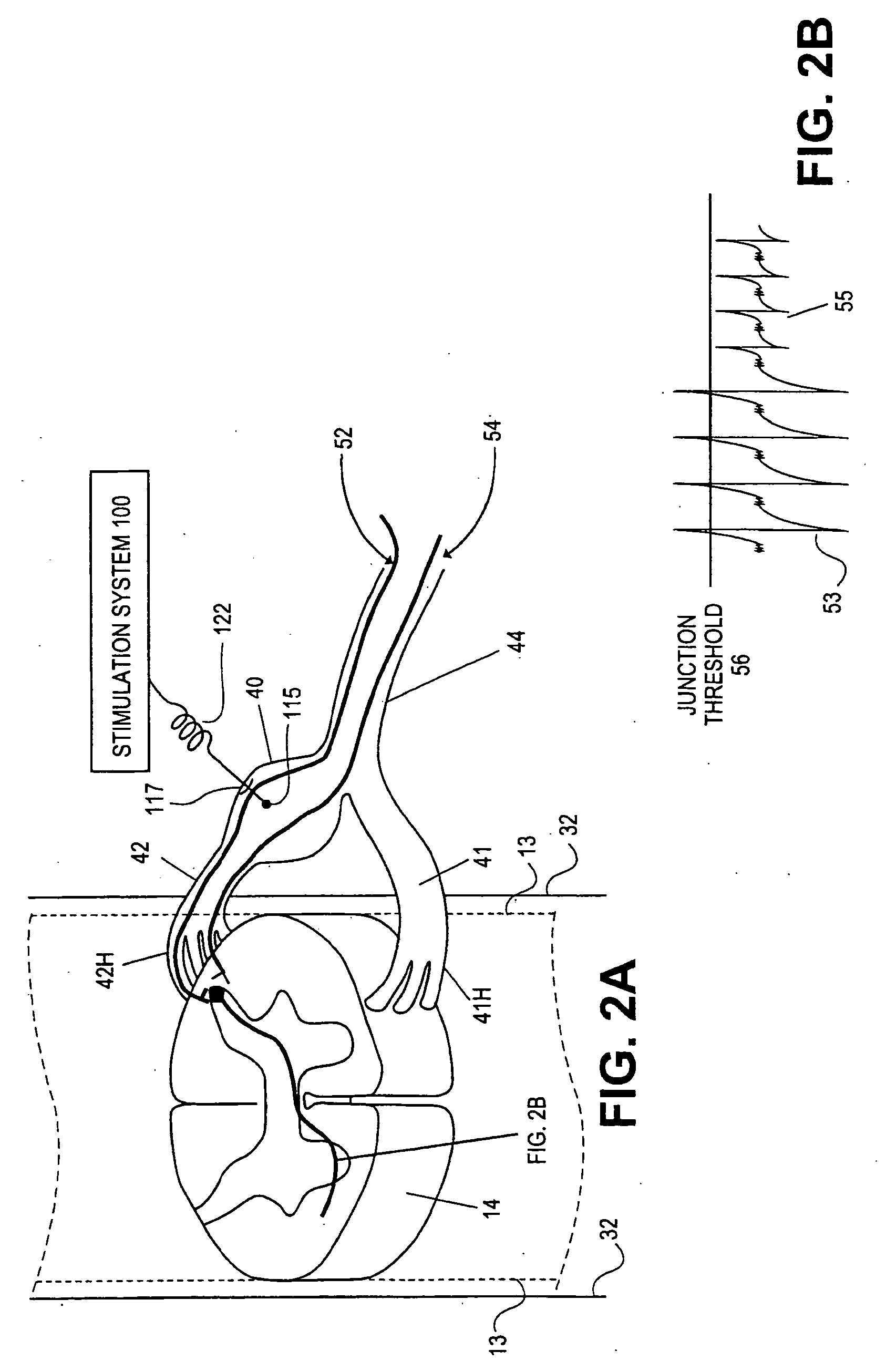

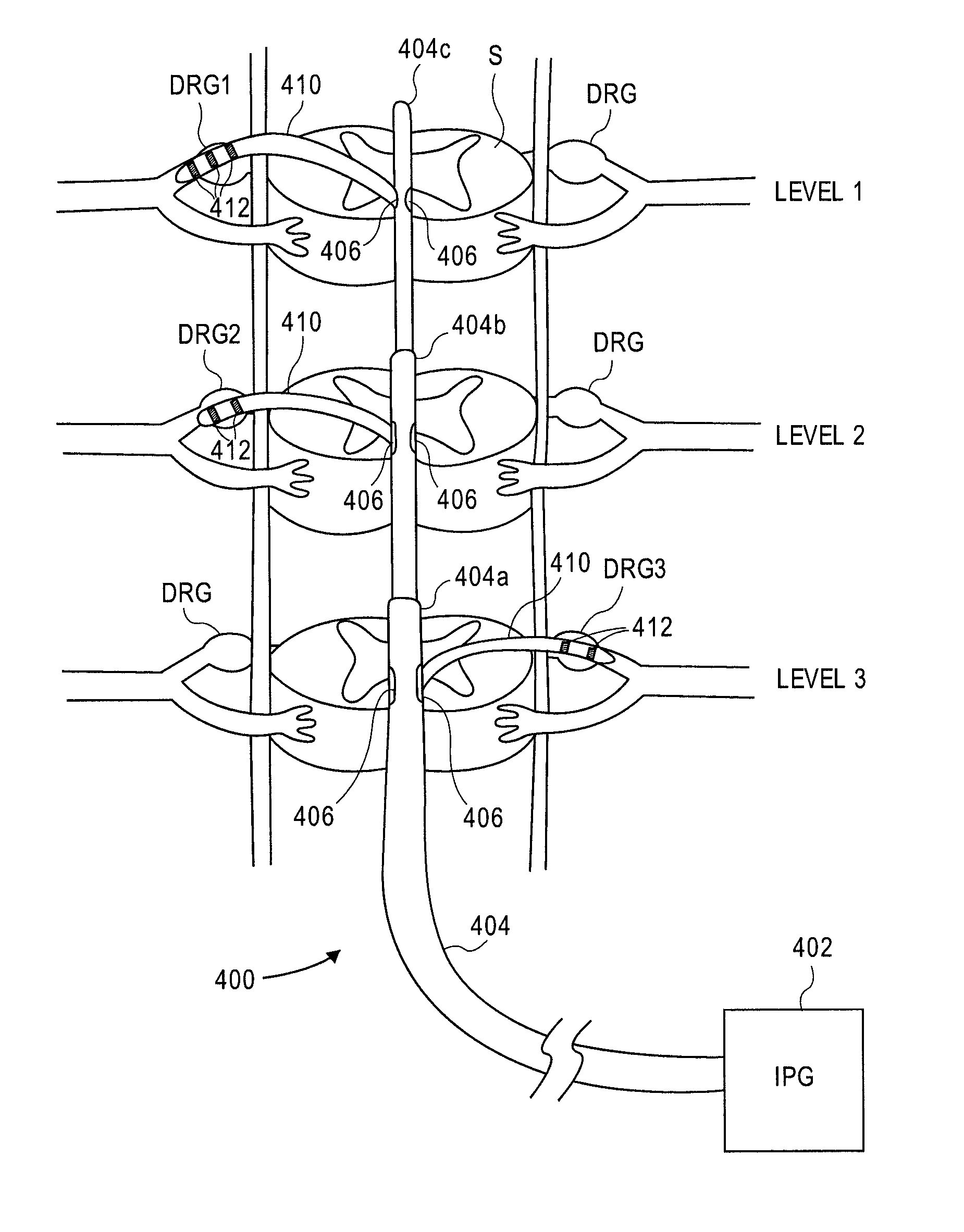

Delivery devices, systems and methods for stimulating nerve tissue on multiple spinal levels

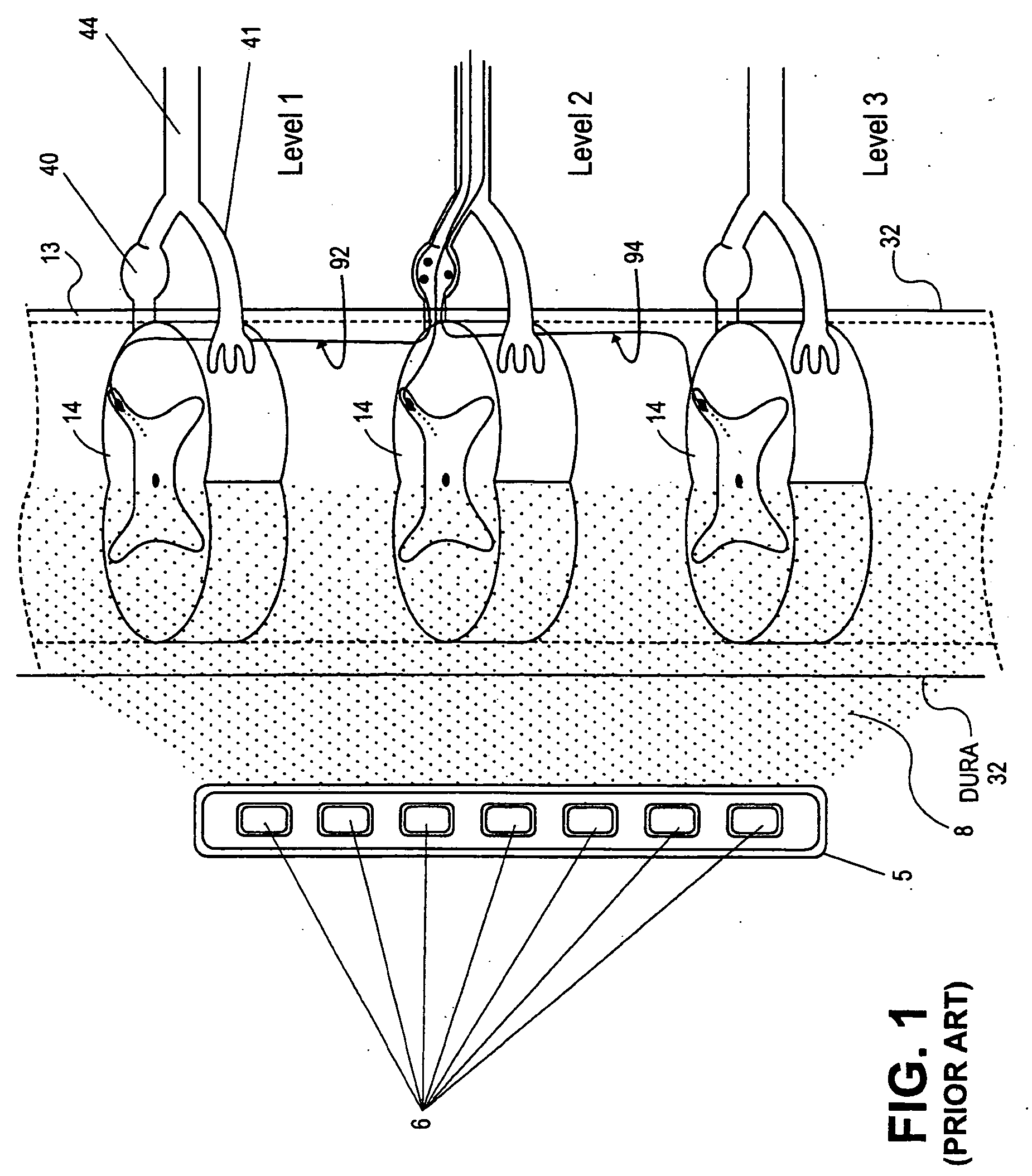

ActiveUS20080140169A1Effectively treat pain symptomReduce deleterious side effectSpinal electrodesImplantable neurostimulatorsSpinal columnSpinal anatomy

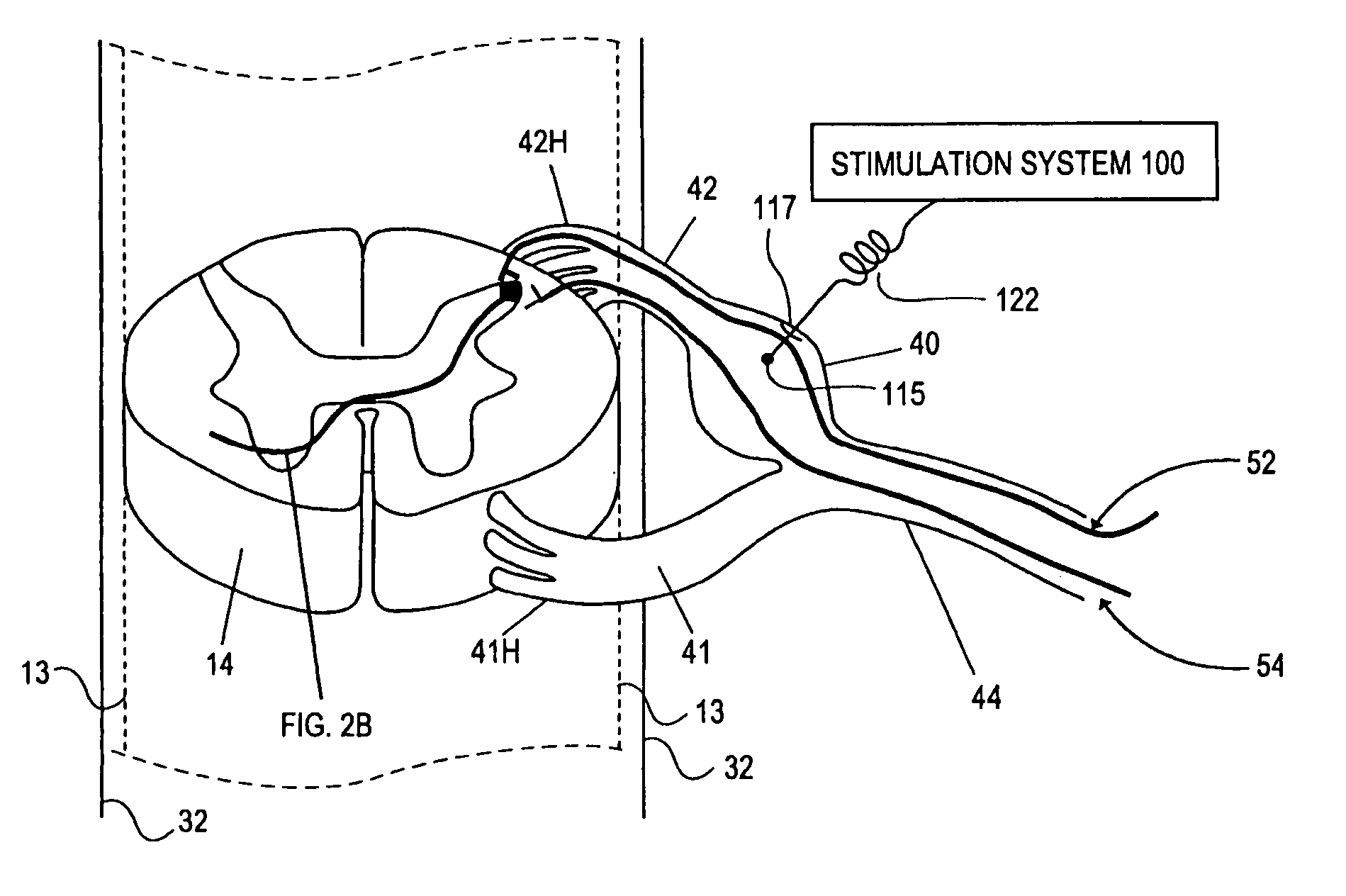

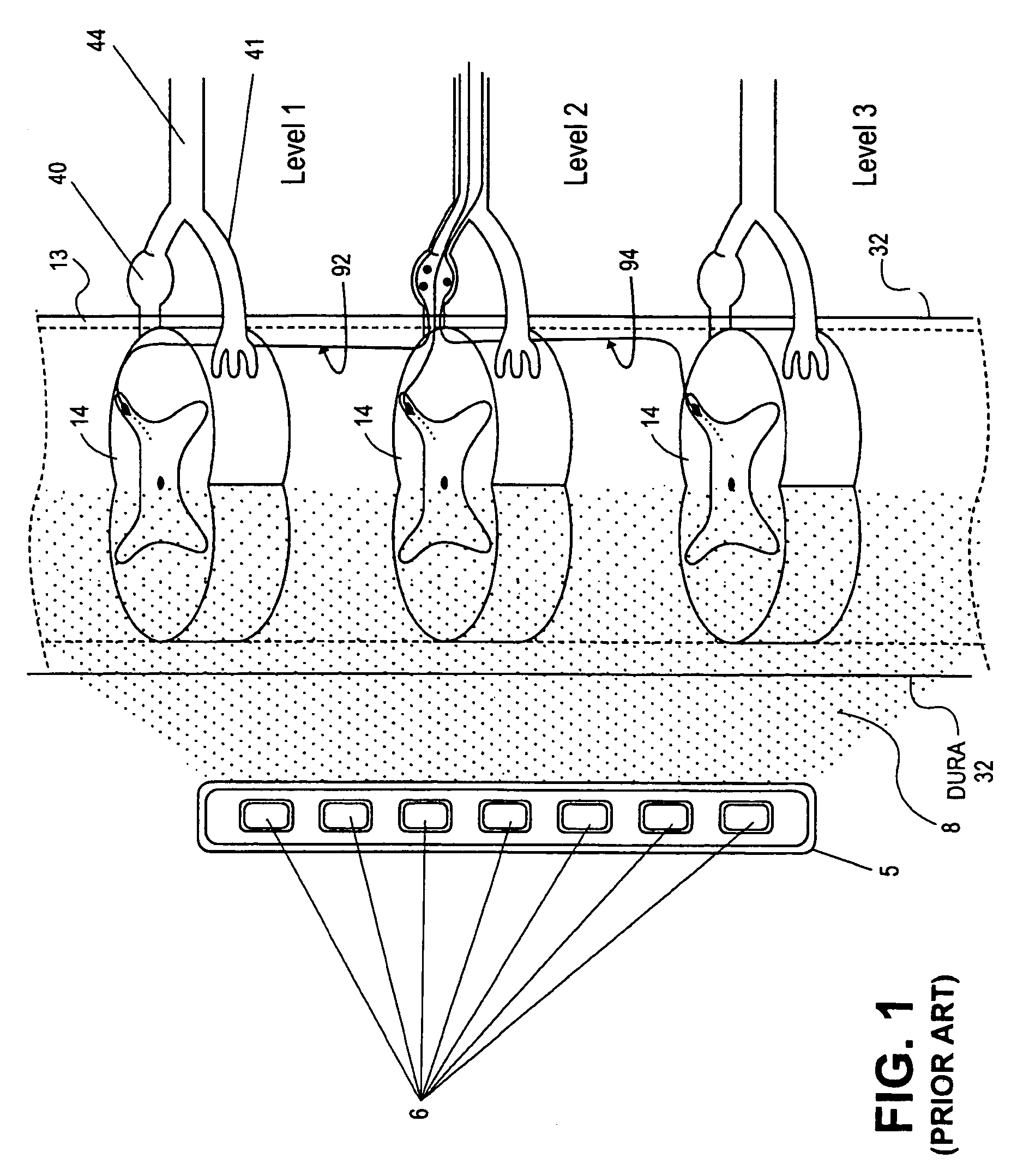

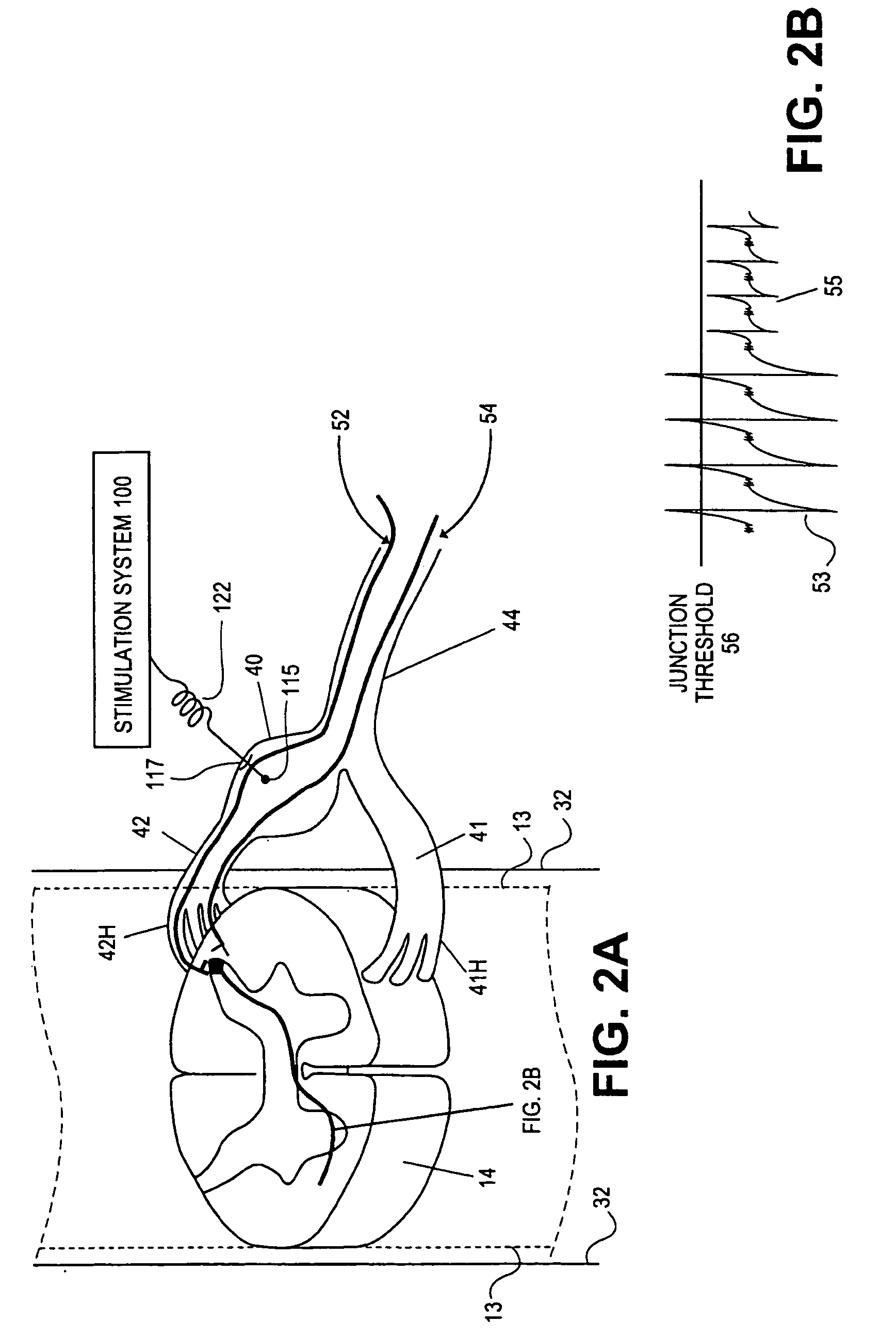

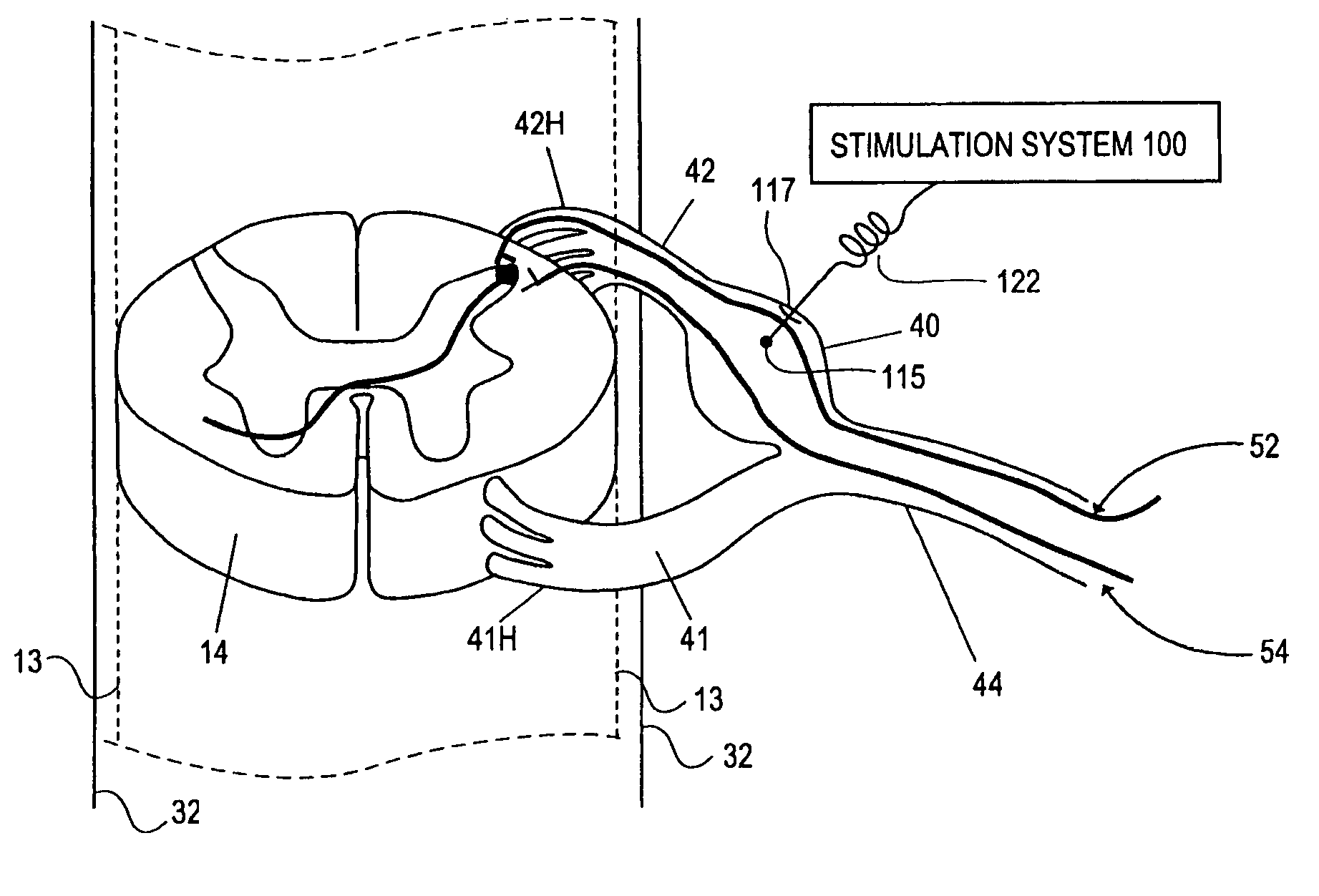

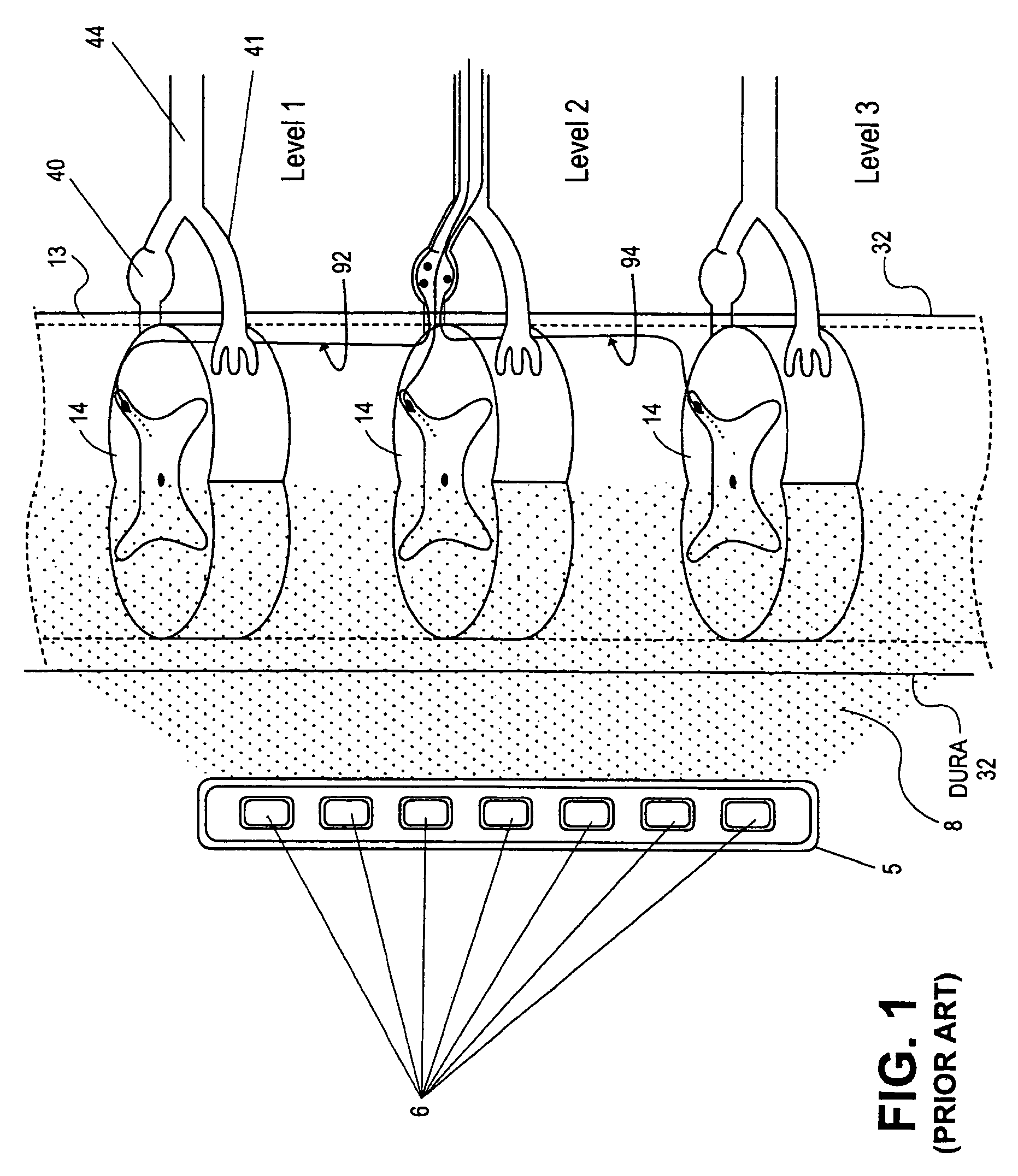

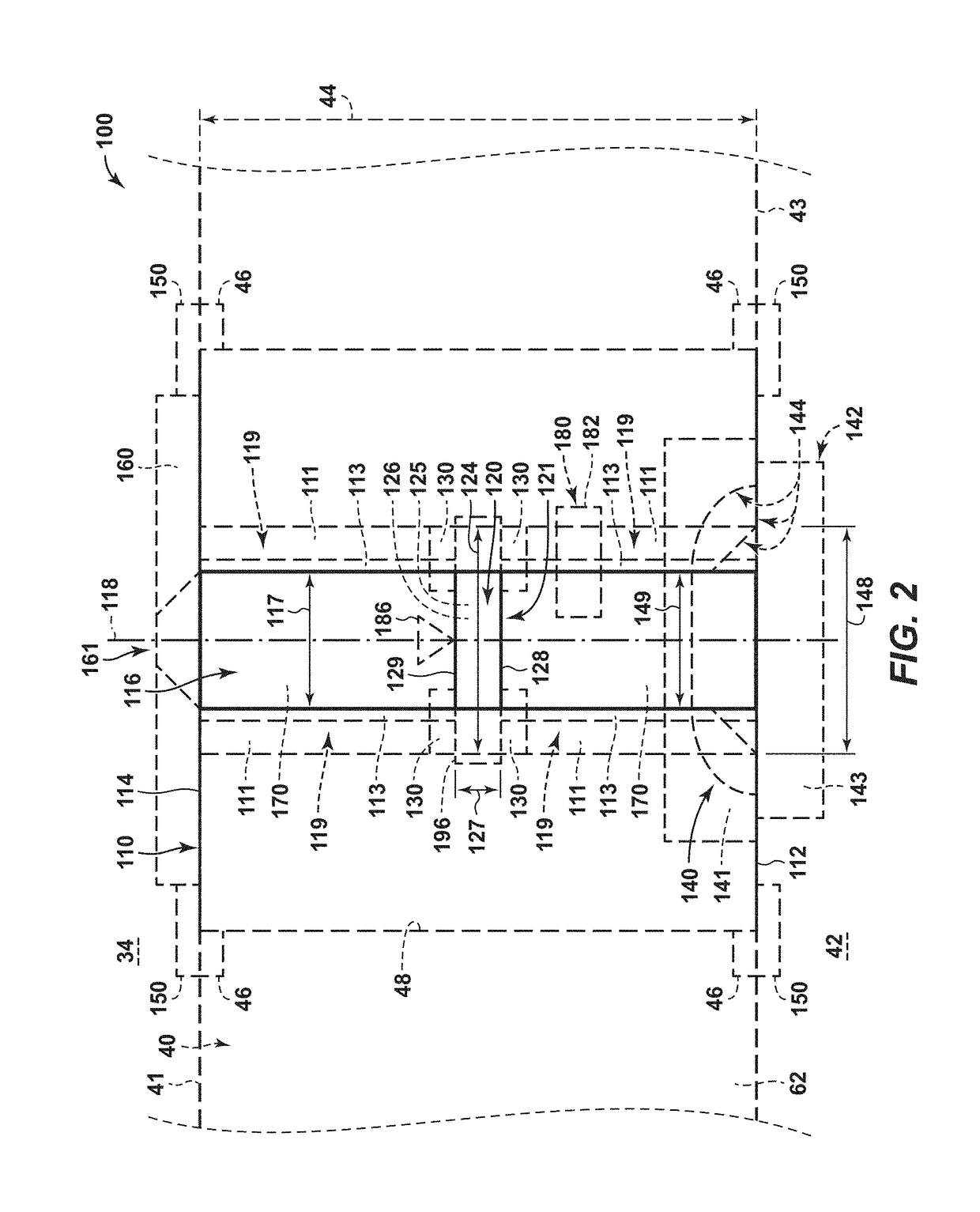

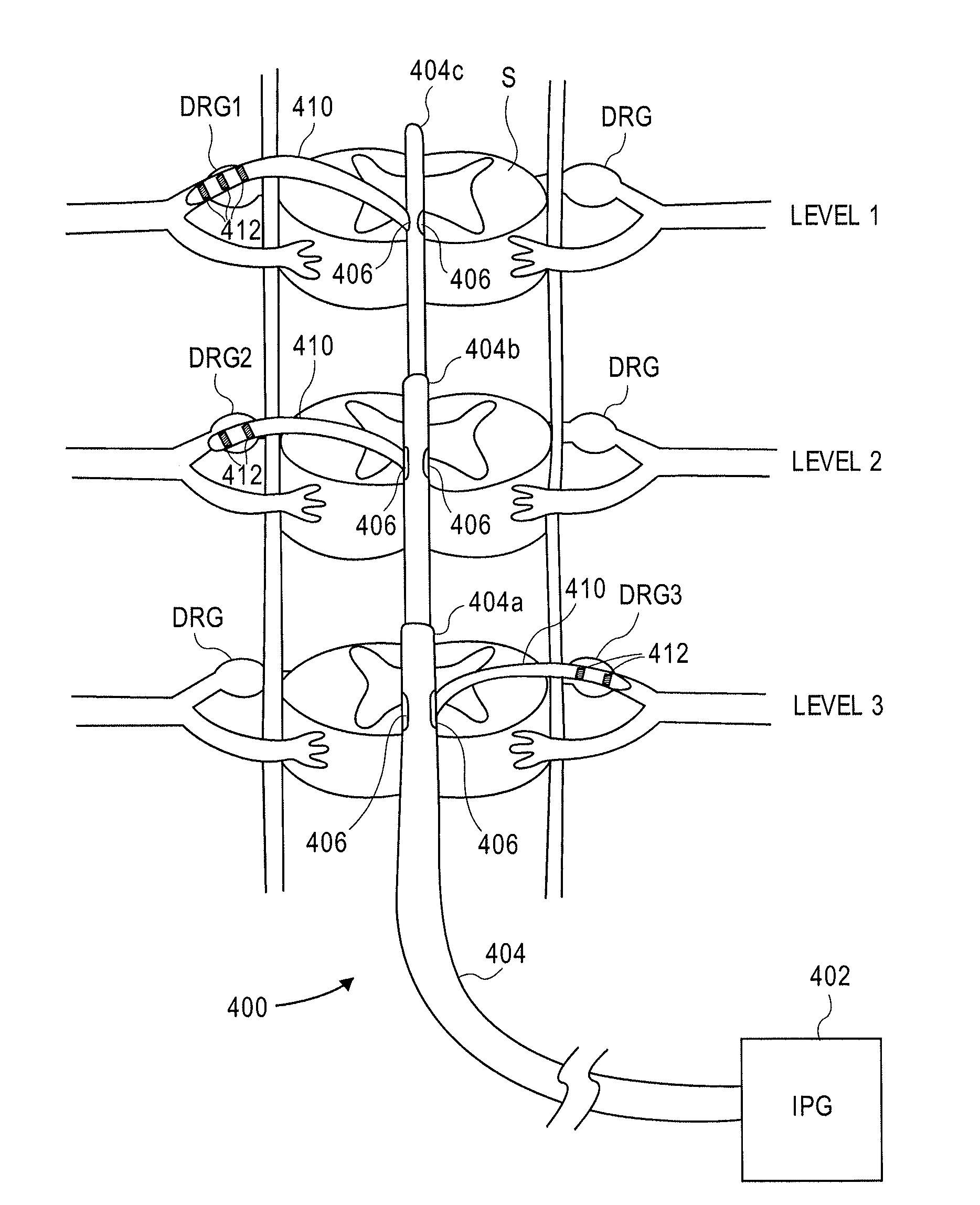

Devices, systems and methods are provided for simultaneously stimulating the spinal anatomy at various locations, such as spinal levels, along the spinal cord. By stimulating multiple levels of the spinal column with the use of a single device, a single access path is created to an implantable pulse generator (IPG) rather than individual access paths for each lead at each spinal level to an IPG. By reducing the number of pathways, the procedure complexity, time and recovery are reduced. In addition, some embodiments provide additional specificity within each targeted level, such as selective stimulation of specific tissue, such as the dorsal root ganglion.

Owner:ST JUDE MEDICAL LUXEMBOURG HLDG SMI S A R L SJM LUX SMI

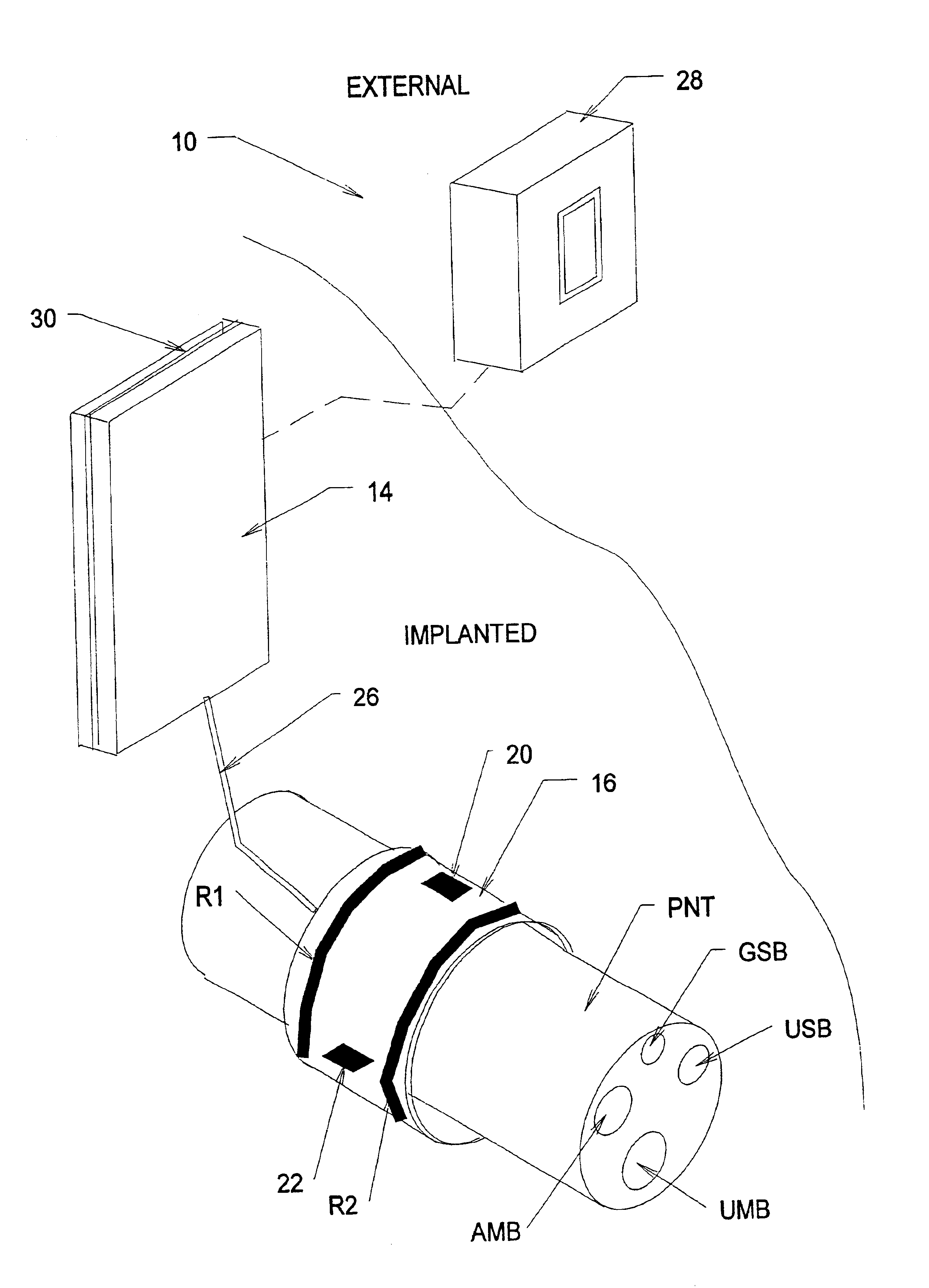

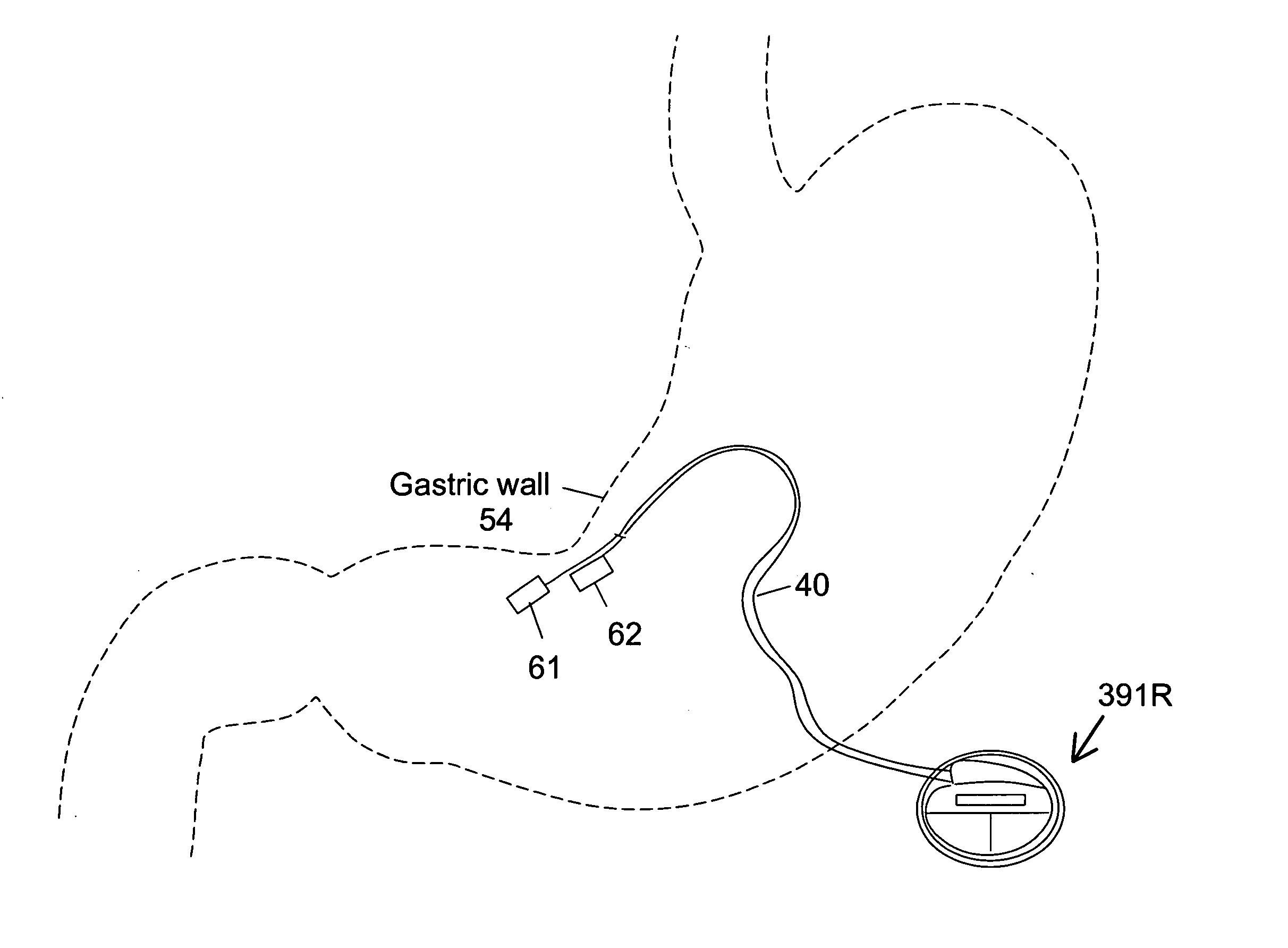

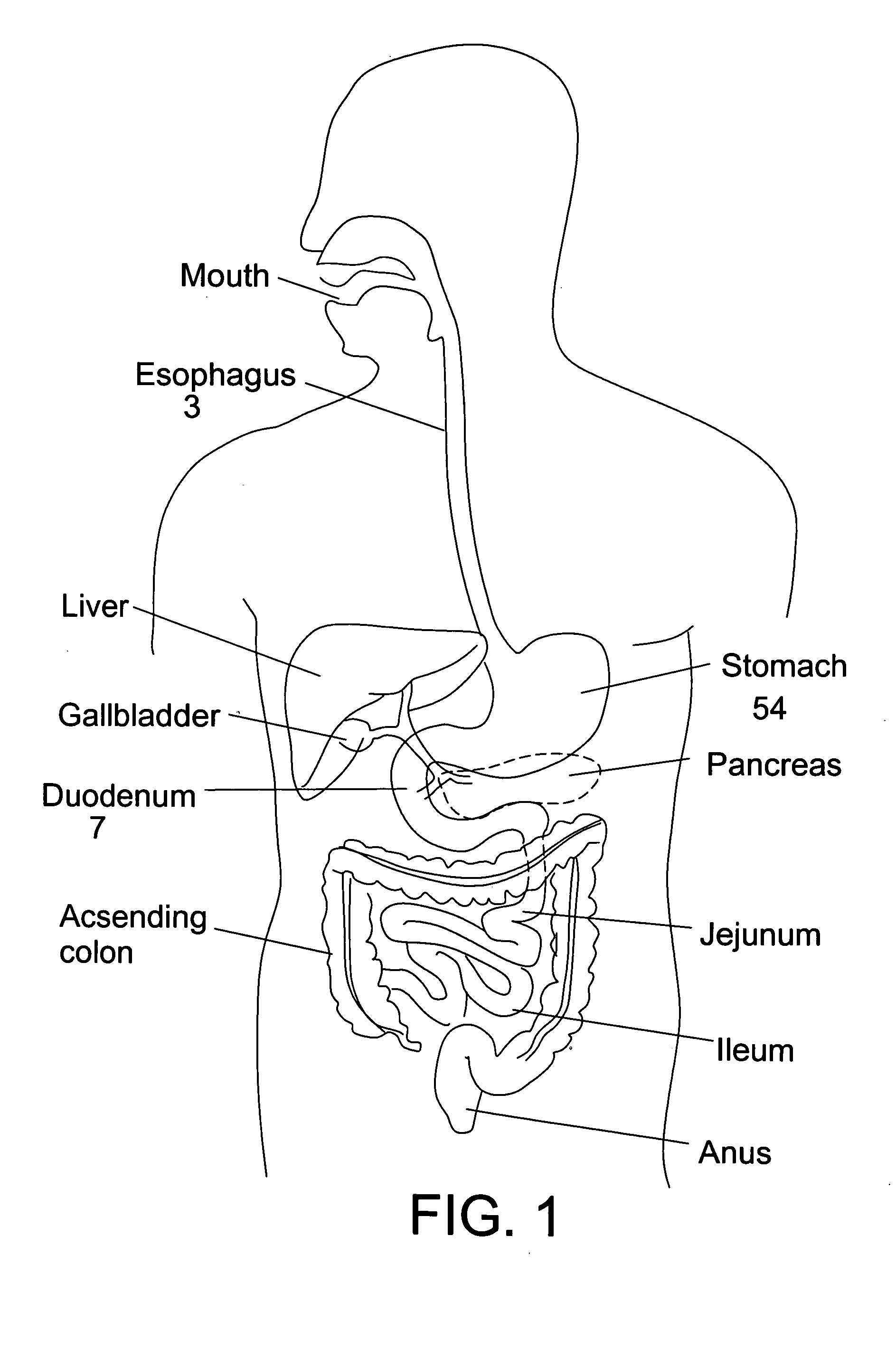

Method and system for providing electrical pulses to gastric wall of a patient with rechargeable implantable pulse generator for treating or controlling obesity and eating disorders

Method and system for providing electrical pulses to the gastric wall of a patient to provide therapy for obesity / eating disorders comprises implantable and external components. The implantable components are a lead and rechargeable implantable pulse generator, comprising rechargeable lithium-ion or lithium-ion polymer battery. The external components are a programmer and an external recharger. In one embodiment, the implanted pulse generator may also comprise stimulus-receiver means, and a pulse generator means with rechargeable battery. The rechargeable implanted pulse generator of this embodiment is also adapted to work in conjunction with an external stimulator. In another embodiment, the implanted pulse generator is adapted to be rechargeable, utilizing inductive coupling with an external recharger. Existing gastric stimulators may also be adapted to be used with rechargeable power sources as disclosed herein. The implanted system may also use a lead with two or more electrodes, for selective stimulation and / or blocking. In another embodiment, the external stimulator and / or programmer may comprise an optional telemetry unit. The addition of the telemetry unit to the external stimulator and / or programmer provides the ability to remotely interrogate and change stimulation programs over a wide area network, as well as other networking capabilities.

Owner:BOVEJA BIRINDER R +1

Pulse generator for high impedance electrodes

Some embodiments of the present invention provide a pulse generator for high impedance electrodes as well as stimulation systems and components for selective stimulation and / or neuromodulation of targeted neural tissue. Targeted neural tissue may include one or more dorsal root ganglia with an electrode implanted on, in or around a dorsal root ganglia. Some other embodiments of the present invention provide methods for selective neurostimulation of one or more dorsal root ganglia as well as techniques for applying neurostimulation to the spinal cord. Still other embodiments of the present invention provide stimulation systems and components for selective stimulation and / or neuromodulation of one or more dorsal root ganglia through implantation of an electrode on, in or around a dorsal root ganglia in combination with a pharmacological agent.

Owner:KIM DANIEL H +2

Stimulation components

Some embodiments of the present invention provide stimulation systems and components for selective stimulation and / or neuromodulation of one or more dorsal root ganglia through implantation of an electrode on, in or around a dorsal root ganglia. Some other embodiments of the present invention provide methods for selective neurostimulation of one or more dorsal root ganglia as well as techniques for applying neurostimulation to the spinal cord. Still other embodiments of the present invention provide stimulation systems and components for selective stimulation and / or neuromodulation of one or more dorsal root ganglia through implantation of an electrode on, in or around a dorsal root ganglia in combination with a pharmacological agent.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Methods for stimulating a dorsal root ganglion

Some embodiments of the present invention provide stimulation systems and components for selective stimulation and / or neuromodulation of one or more dorsal root ganglia through implantation of an electrode on, in or around a dorsal root ganglia. Some other embodiments of the present invention provide methods for selective neurostimulation of one or more dorsal root ganglia as well as techniques for applying neurostimulation to the spinal cord. Still other embodiments of the present invention provide stimulation systems and components for selective stimulation and / or neuromodulation of one or more dorsal root ganglia through implantation of an electrode on, in or around a dorsal root ganglia in combination with a pharmacological agent.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV +2

Apparatus, System, and Method for Selective Stimulation

ActiveUS20130165996A1Spinal electrodesImplantable neurostimulatorsSelective stimulationBiomedical engineering

An implantable neurostimulator system is disclosed, the neurostimulator system comprising a hollow cylindrical electronics enclosure having a top, a bottom, and a side; a coil extending from a first part of the electronics enclosure; and at least one electrode operatively connected to the electronics enclosure.

Owner:IMTHERA MEDICAL

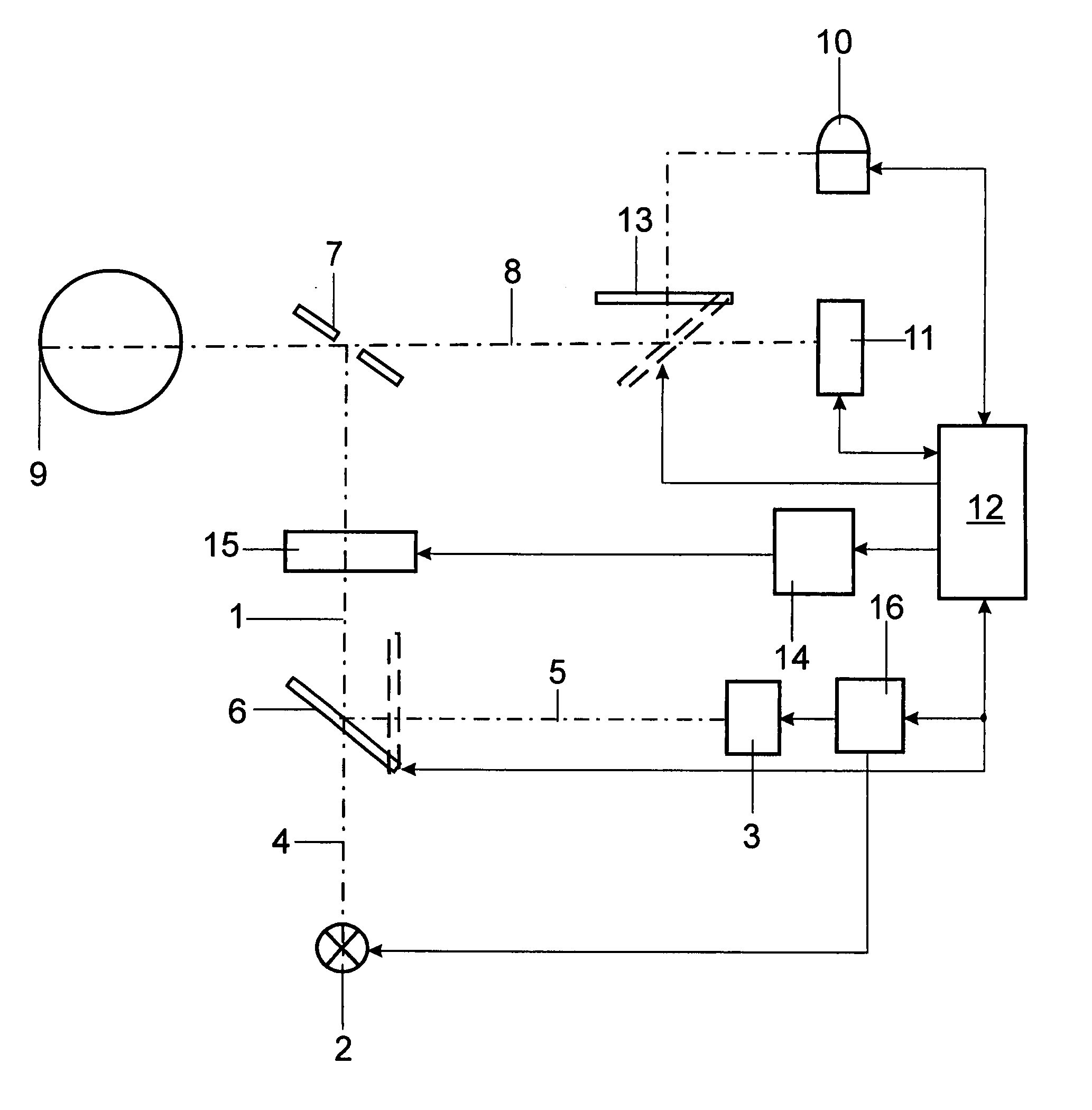

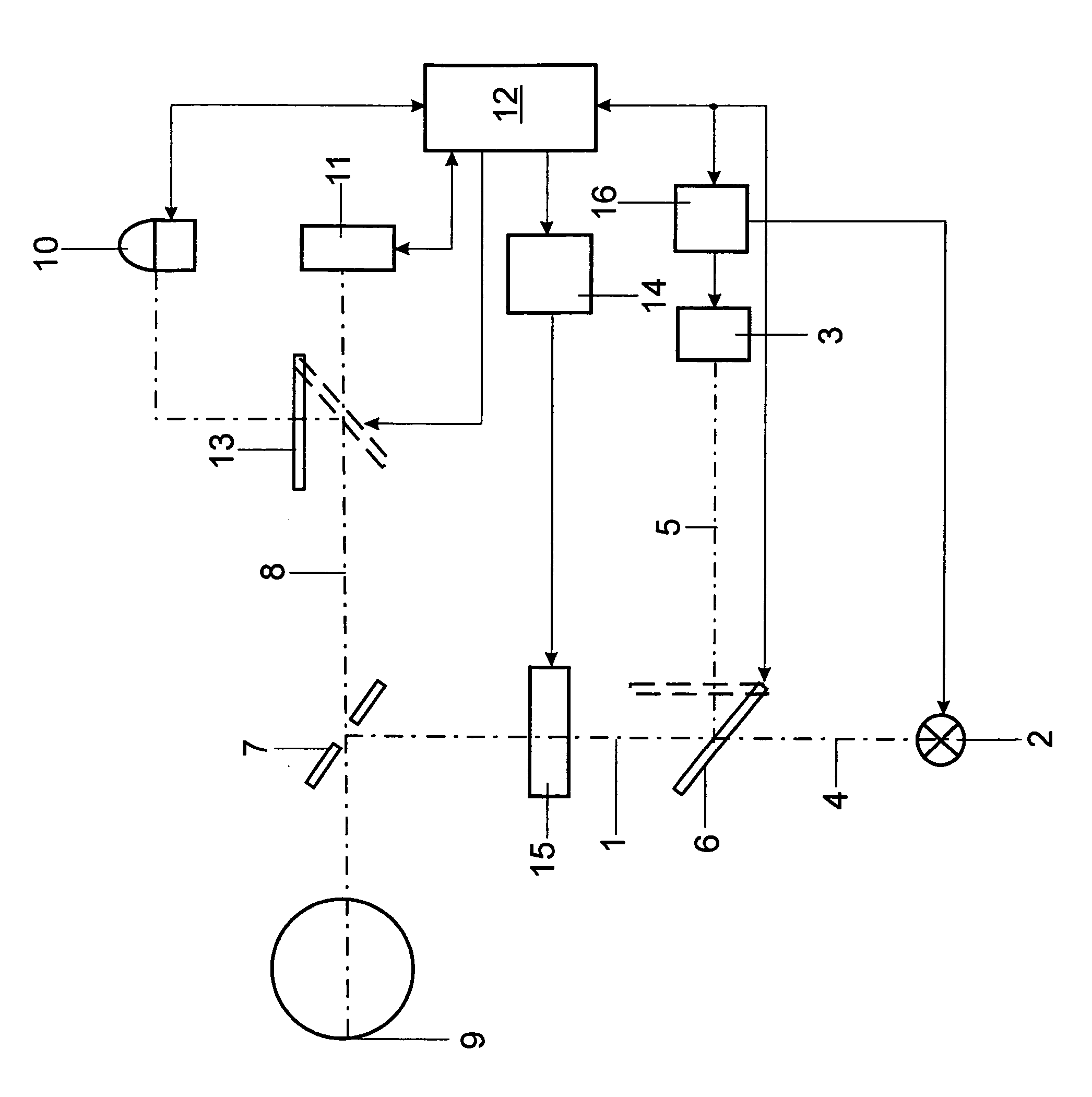

Universal ophthalmic examination device and ophthalmic examination method

A universal ophthalmic examination device and an ophthalmic examination method have the object of combining in an inexpensive apparatus in a simple manner the device-related requirements for image generation, measurement and functional imaging for carrying out visual stimulation and highly time-resolved and highly spatially resolved image documentation using continuous illumination and flash mode and the requirements for measurements in the infrared spectral region and visible spectral region with a time regime that can be freely selected to a great extent. The light of at least one light source is modified in a program-oriented manner with respect to its intensity curve and / or time curve with a temporally defined relationship to the adjustments of the at least one light source, of the image recording and of the evaluation for purposes of adaptive matching to an examination task in the illumination beam path by an individual, shared light manipulator and is used as modified light for illumination and for selective stimulation.

Owner:IMEDOS INTELLIGENTE OPTISCHE SYST DER MEDIZIN & MESSTECHNIK GMBH

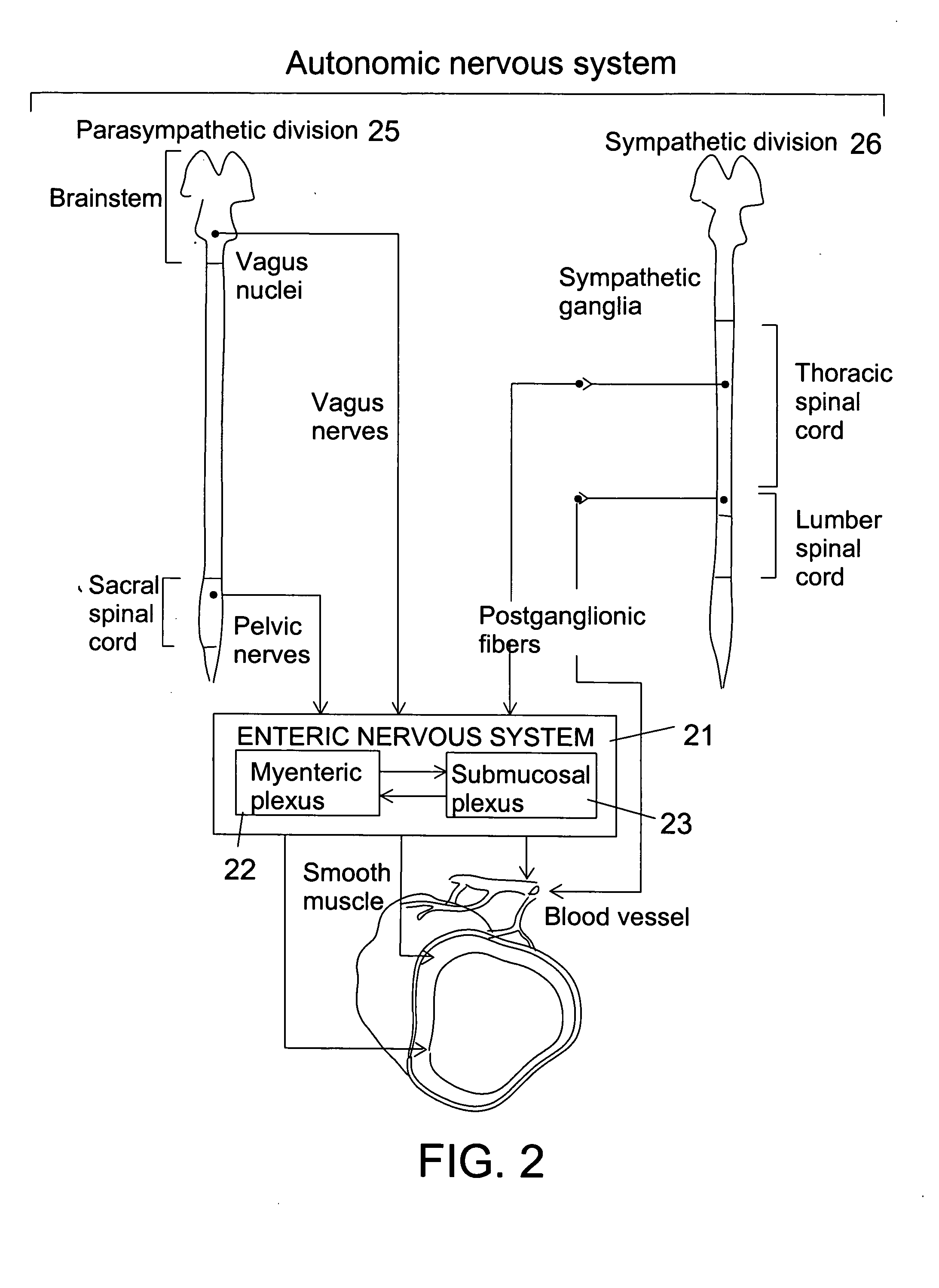

Selective stimulation to modulate the sympathetic nervous system

InactiveUS20120277839A1Minimizing and excluding undesired neuromodulationReduces and eliminates undesired side effectSpinal electrodesExternal electrodesAnatomical structuresMedicine

Systems, methods and devices are provided for the targeted treatment of a variety of medical conditions by directly neuromodulating a target anatomy associated with the condition while minimizing or excluding undesired neuromodulation of other anatomies. Typically, the target anatomy includes one or more dorsal root ganglia, dorsal roots, dorsal root entry zones, or portions thereof. Such target stimulation areas are utilized due in part to their effect on the sympathetic nervous system.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV +1

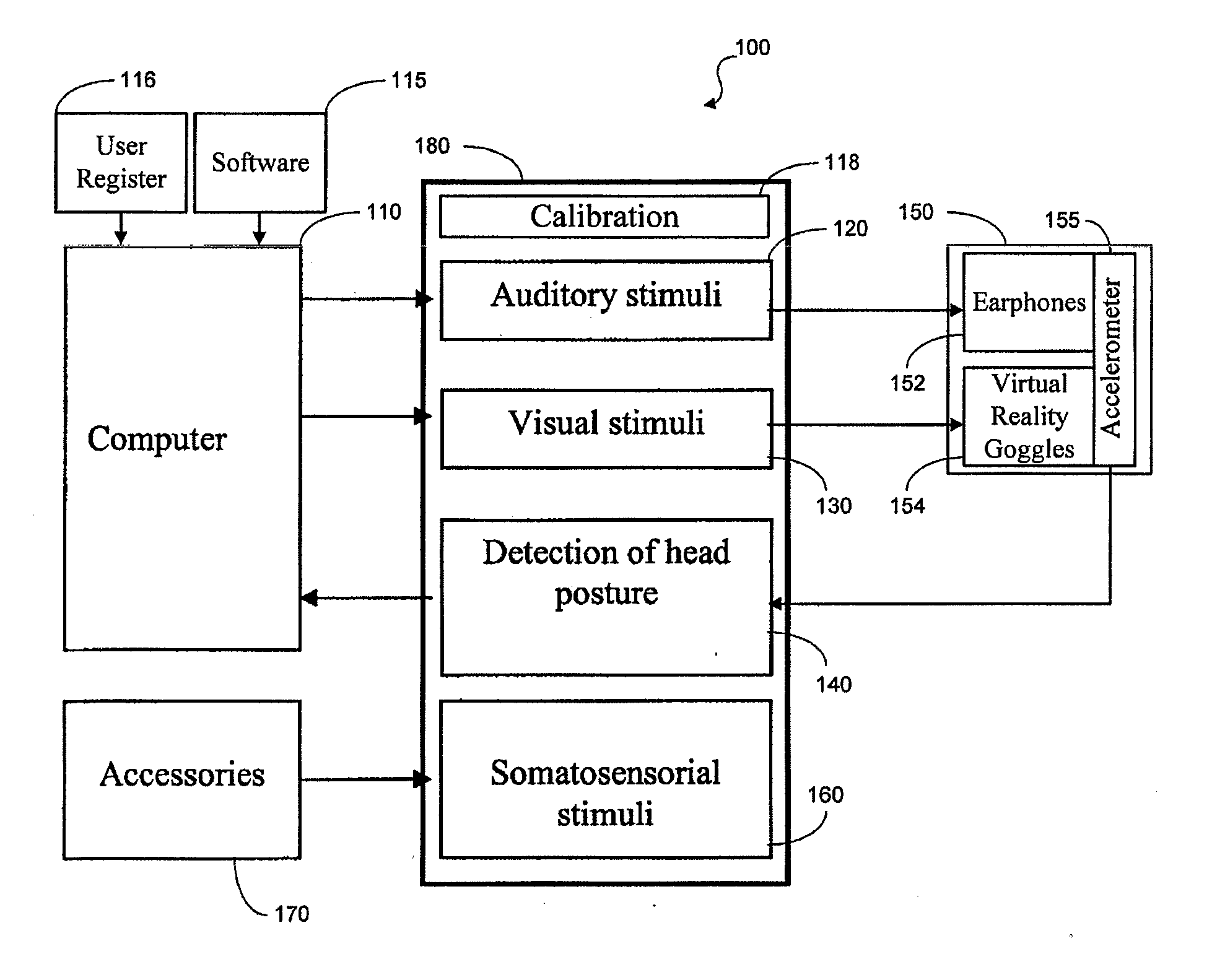

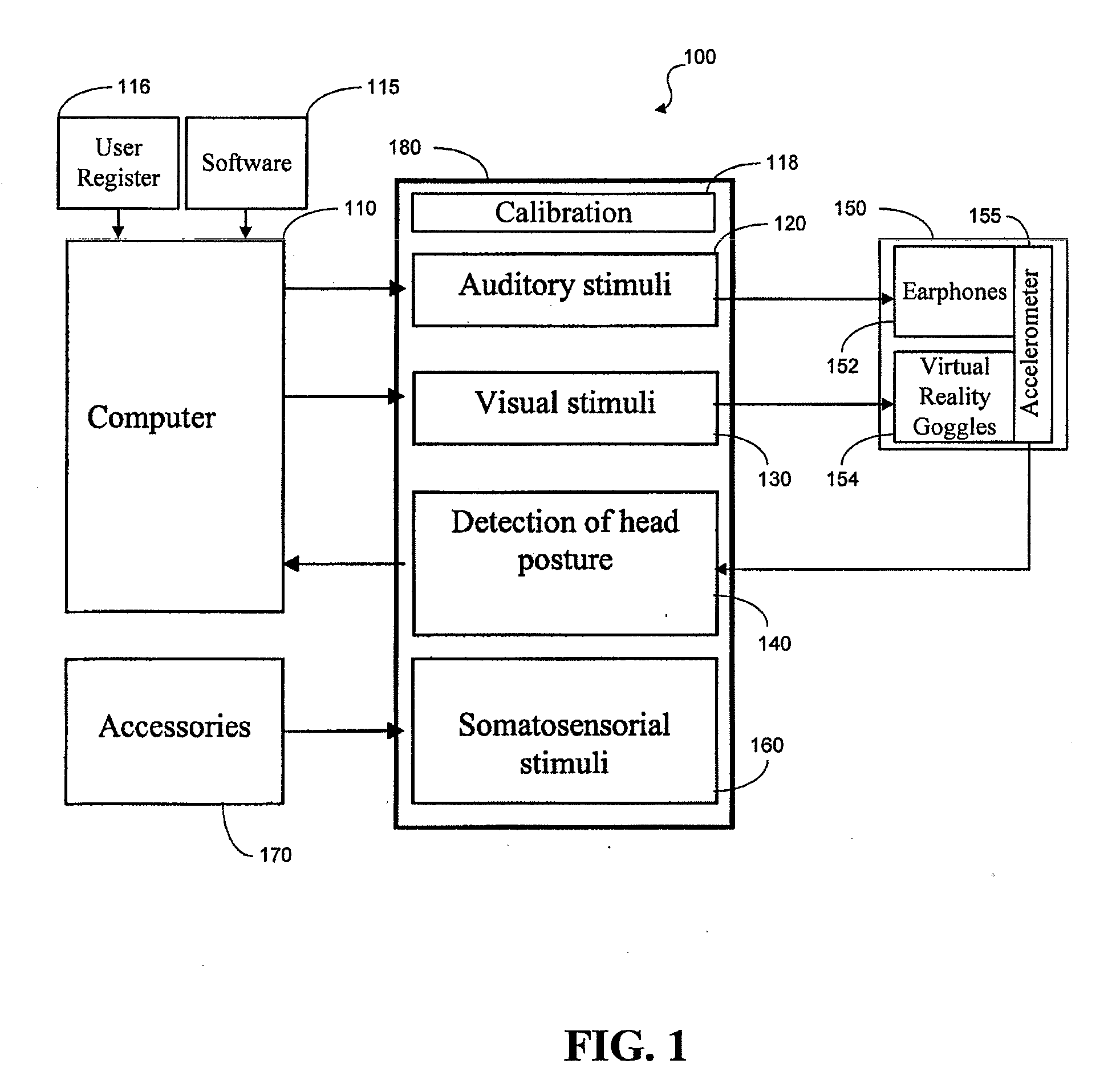

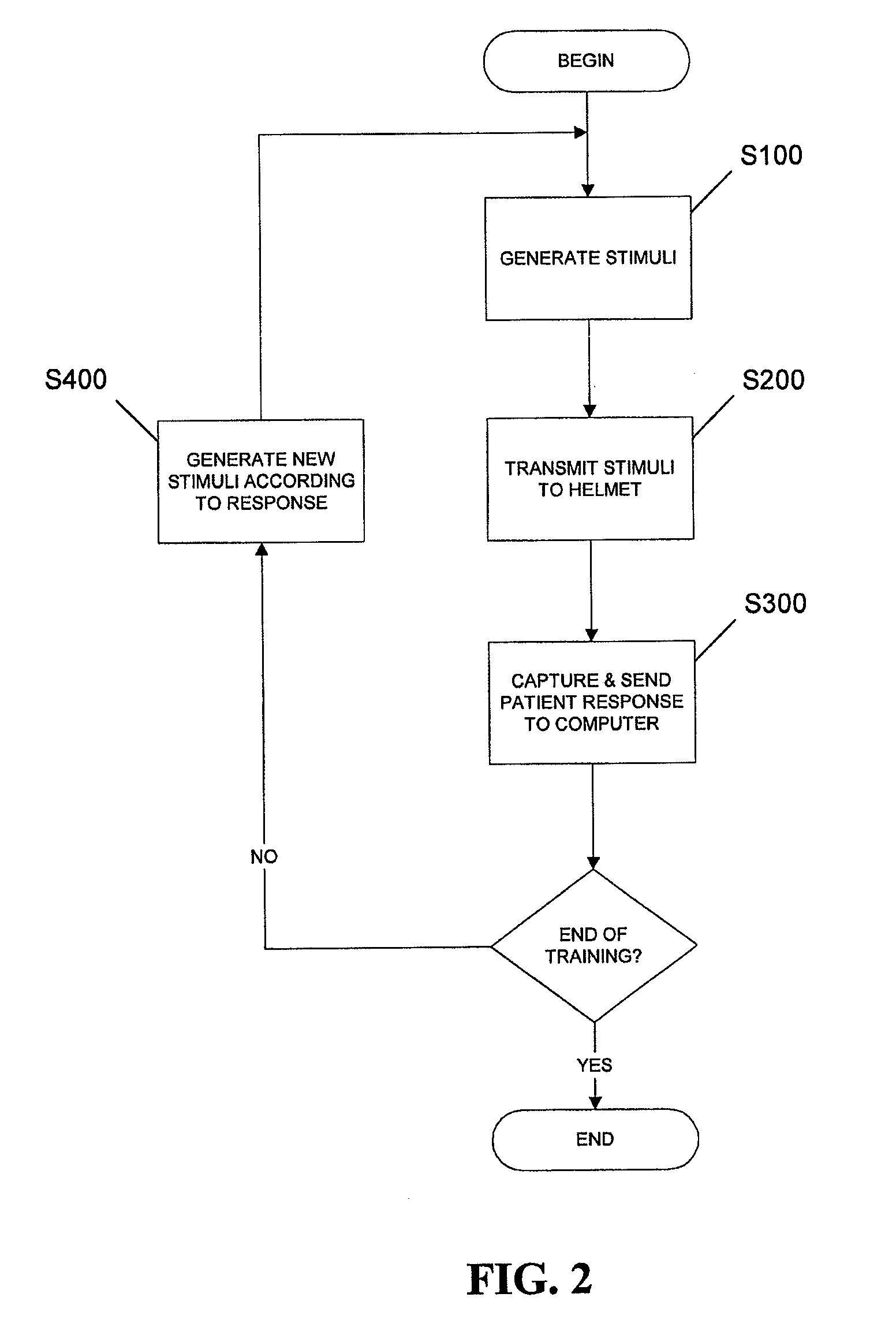

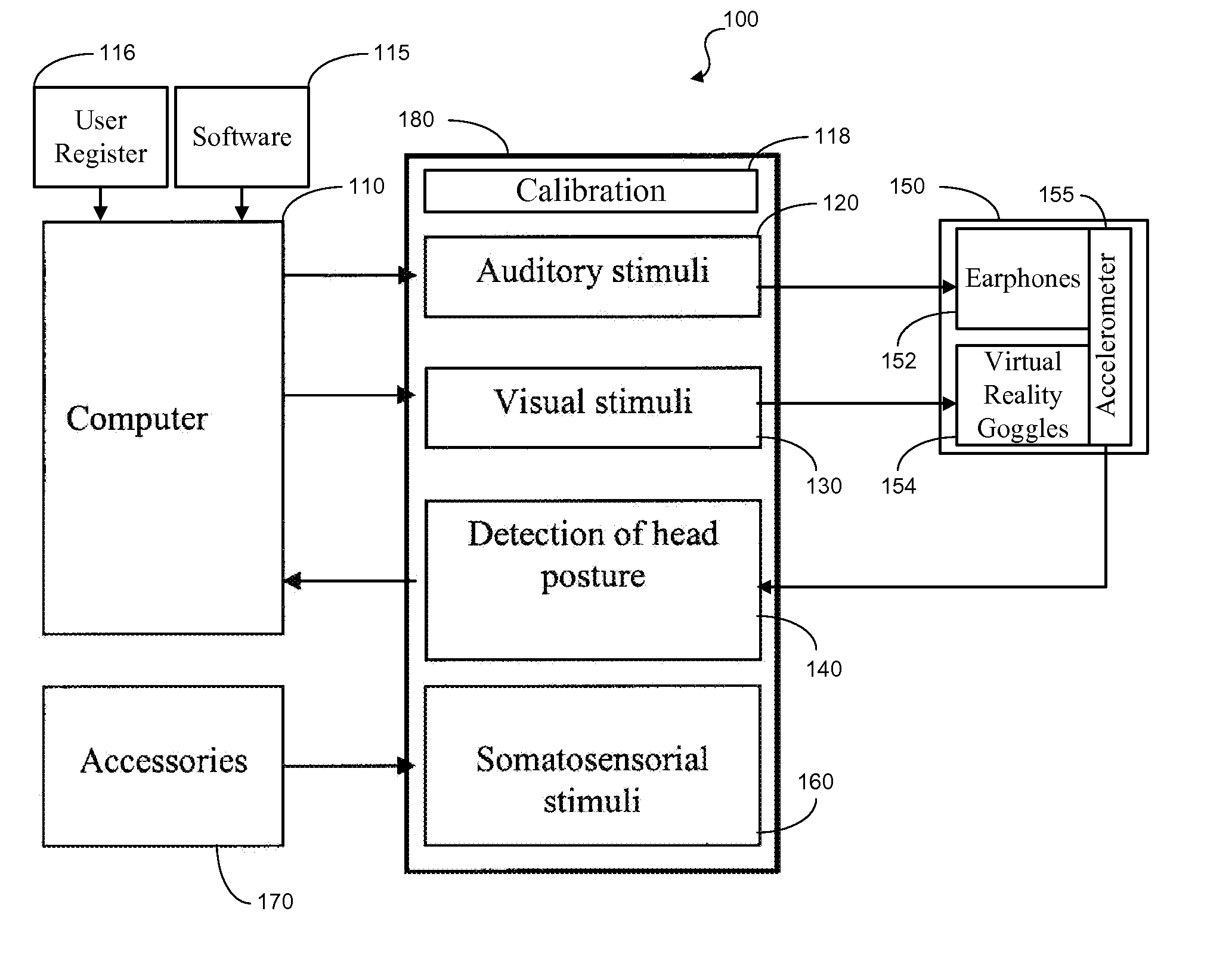

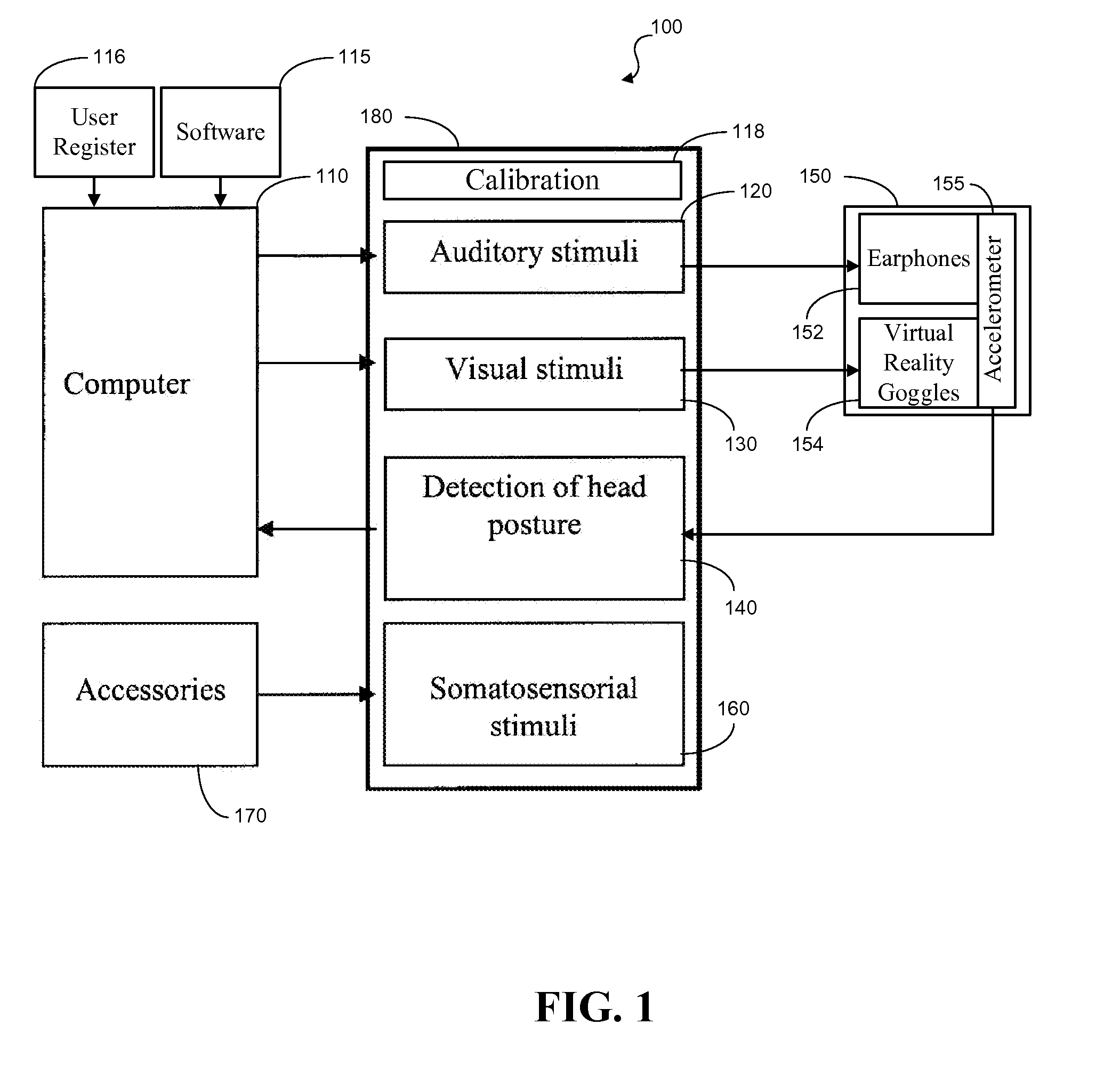

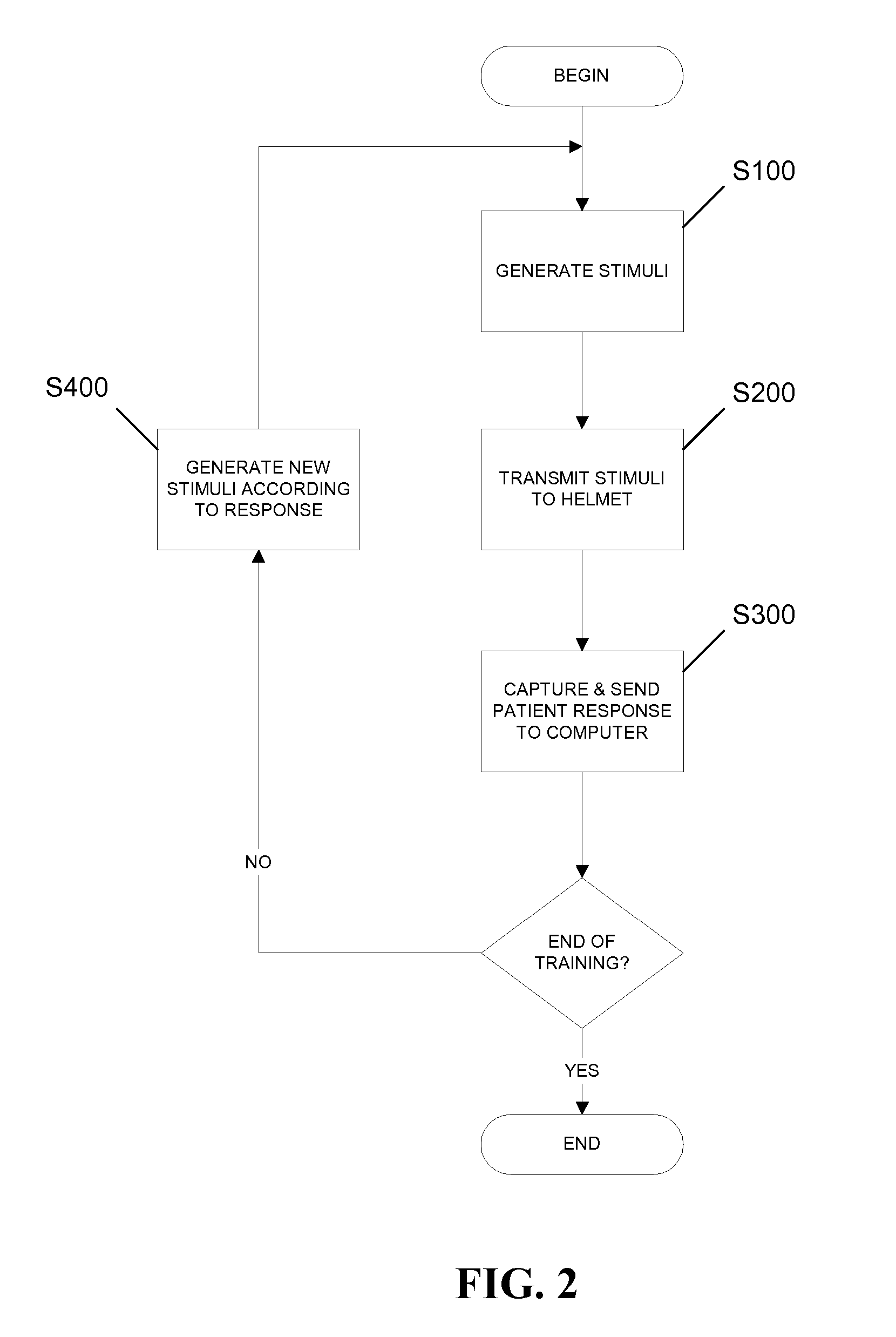

Vestibular rehabilitation unit

InactiveUS20090240172A1Increase capacityAccurately determinePerson identificationSensorsHead movementsReflex

An apparatus and method for enabling selective stimulation of oculomotor reflexes involved in retinal image stability. The apparatus enables real-time modification of auditory and visual stimuli according to the patient's head movements, and allows the generation of stimuli that integrate vestibular and visual reflexes. The use of accessories allow the modification of somatosensory stimuli to increase the selective capacity of the apparatus. The method involves generation of visual and auditory stimuli, measurement of patient response and modification of stimuli based on patient response. The apparatus and method may include a vestibular rehabilitation unit (VRU) and a remote training unit (RTU). Instructions may be transmitted from the VRU to the RTU, and information of detected responses may be transmitted from the RTU to the VRU.

Owner:TRENO CORP

Methods and systems for modulating neural tissue

Some embodiments of the present invention provide methods and systems for modulating neural tissue including systems and components for selective stimulation and / or neuromodulation of targeted neural tissue. Targeted neural tissue may include one or more ganglia including those of the spinal nerves in the dorsal root and the sympathetic chain. Methods also include implantation of an electrode on, in or around a dorsal root ganglia. Some other embodiments of the present invention provide methods for selective neurostimulation of one or more dorsal root ganglia as well as techniques for applying neurostimulation to the spinal cord. Still other embodiments of the present invention provide stimulation systems and components for selective stimulation and / or neuromodulation of one or more dorsal root ganglia through implantation of an electrode on, in or around a dorsal root ganglia in combination with a pharmacological agent.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV +2

Stimulation systems

Some embodiments of the present invention provide stimulation systems and components for selective stimulation and / or neuromodulation of one or more dorsal root ganglia through implantation of an electrode on, in or around a dorsal root ganglia. Some other embodiments of the present invention provide methods for selective neurostimulation of one or more dorsal root ganglia as well as techniques for applying neurostimulation to the spinal cord. Still other embodiments of the present invention provide stimulation systems and components for selective stimulation and / or neuromodulation of one or more dorsal root ganglia through implantation of an electrode on, in or around a dorsal root ganglia in combination with a pharmacological agent.

Owner:KIM DANIEL H +2

Vestibular rehabilitation unit

InactiveUS20060206175A1Increase capacityAccurately determineCosmonautic condition simulationsChiropractic devicesHead movementsReflex

An apparatus and method for enabling selective stimulation of oculomotor reflexes involved in retinal image stability. The apparatus enables real-time modification of auditory and visual stimuli according to the patient's head movements, and allows the generation of stimuli that integrate vestibular and visual reflexes. The use of accessories allow the modification of somatosensory stimuli to increase the selective capacity of the apparatus. The method involves generation of visual and auditory stimuli, measurement of patient response and modification of stimuli based on patient response.

Owner:TRENO CORP

Methods for stimulating the spinal cord and nervous system

Some embodiments of the present invention provide stimulation systems, components and methods for stimulation of the spinal cord and the nervous system. Additional embodiments provide for selective stimulation and / or neuromodulation of one or more dorsal root ganglia through implantation of an electrode on, in or around a dorsal root ganglia. Some other embodiments of the present invention provide methods for selective neurostimulation of one or more dorsal root ganglia as well as techniques for applying neurostimulation to the spinal cord and nervous system. Still other embodiments of the present invention provide stimulation systems and components for selective stimulation and / or neuromodulation of one or more dorsal root ganglia through implantation of an electrode on, in or around a dorsal root ganglia in combination with a pharmacological agent.

Owner:KIM DANIEL H +2

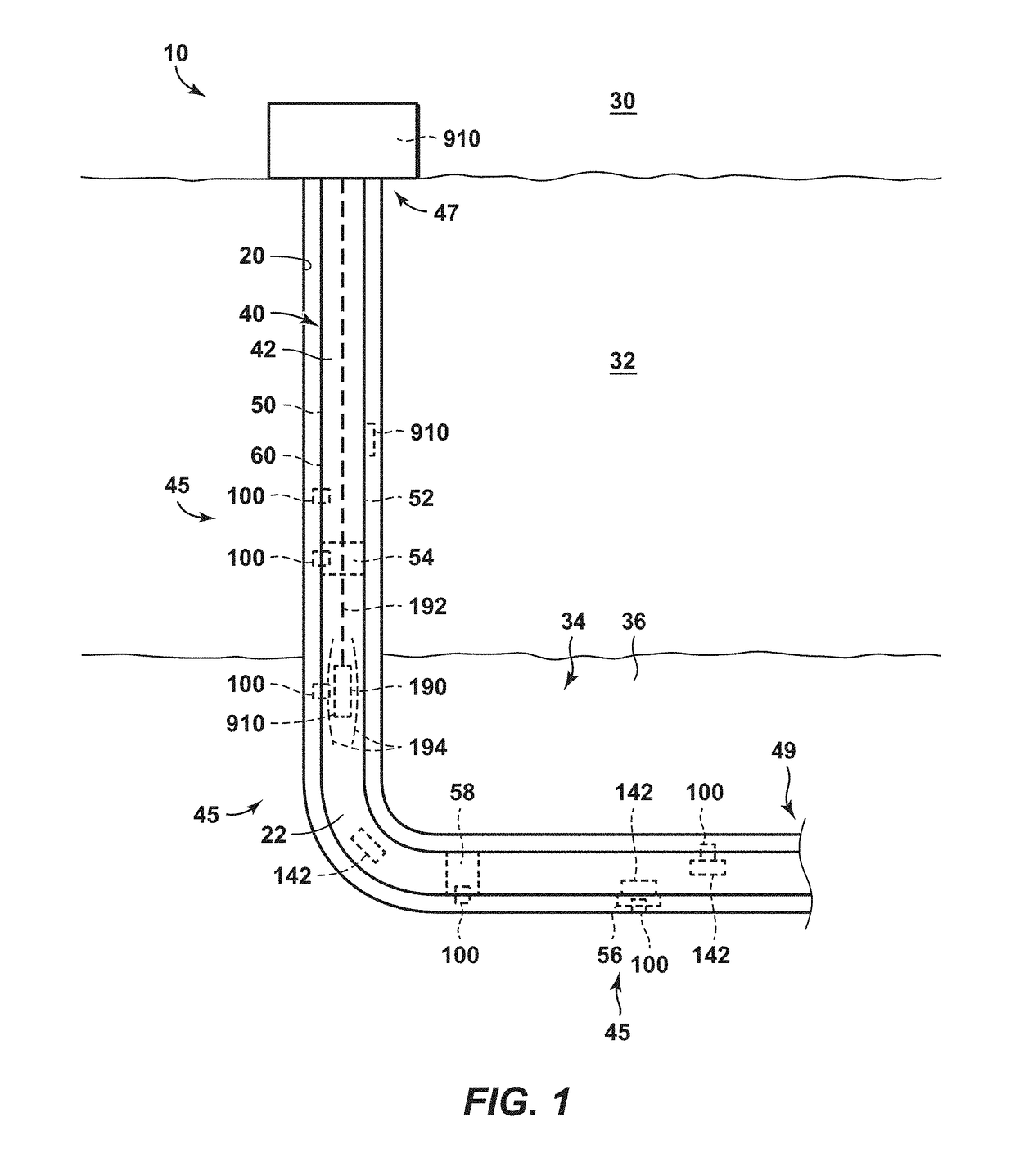

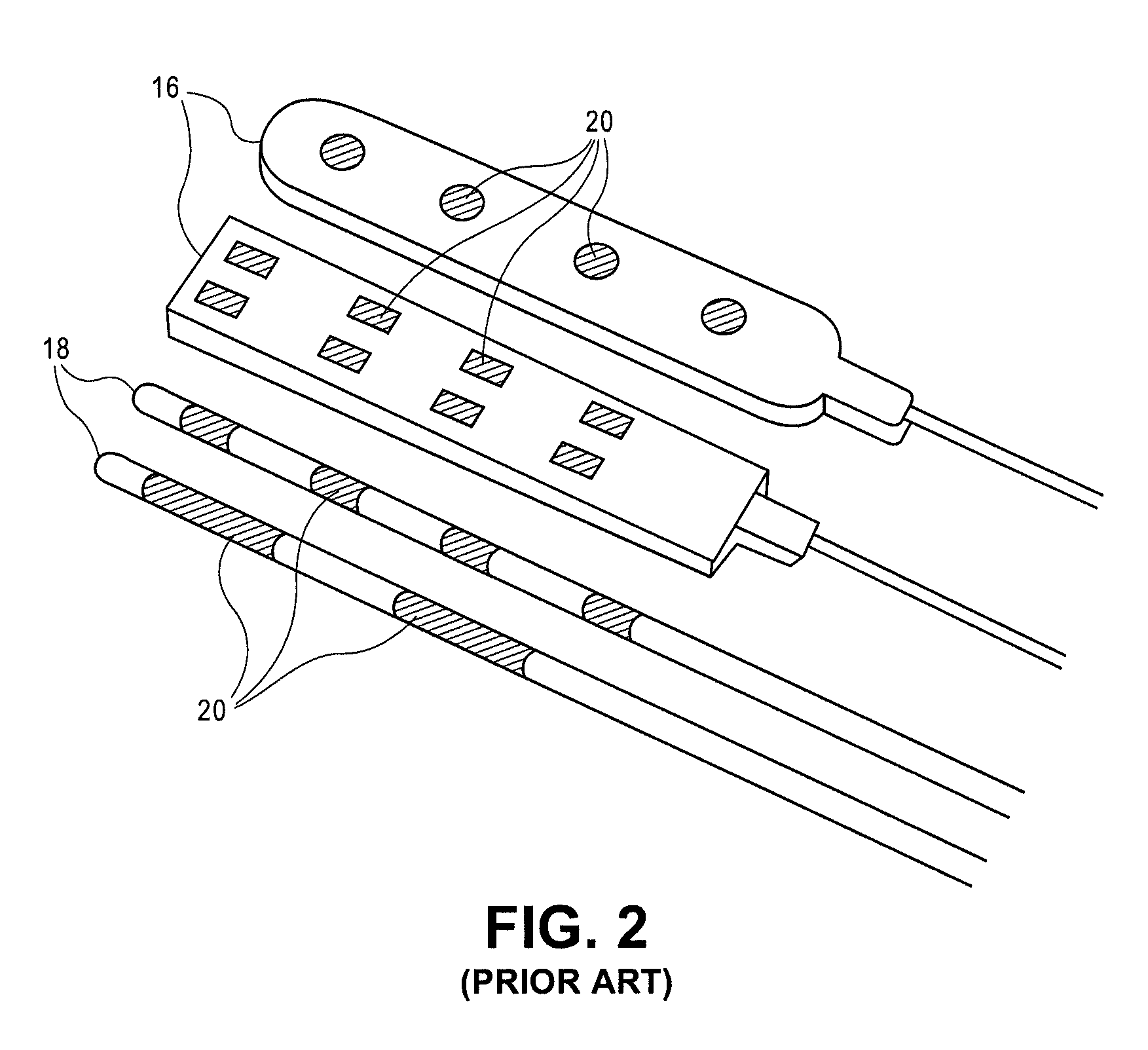

Wellbore Tubulars Including Selective Stimulation Ports Sealed with Sealing Devices and Methods of Operating the Same

Wellbore tubulars including selective stimulation ports (SSPs) sealed with sealing devices and methods of operating the same are disclosed herein. The wellbore tubulars include a tubular body that defines a tubular conduit and a plurality of selective stimulation ports. Each selective stimulation port includes an SSP conduit and a sealing device seat. The wellbore tubulars further include a plurality of sealing devices. Each sealing device includes a primary sealing portion that is seated on a corresponding sealing device seat and forms a primary seal with the corresponding sealing device seat. Each sealing device also includes a secondary sealing portion that extends from the primary sealing portion and forms a secondary seal between the primary sealing portion and the corresponding sealing device seat. The methods include methods of stimulating a subterranean formation utilizing the wellbore tubulars.

Owner:TOLMAN RANDY C

Delivery devices, systems and methods for stimulating nerve tissue on multiple spinal levels

ActiveUS20150165193A1Effectively pain symptomDeleterious side effectSpinal electrodesImplantable neurostimulatorsSpinal columnRadiology

Devices, systems and methods are provided for simultaneously stimulating the spinal anatomy at various locations, such as spinal levels, along the spinal cord. By stimulating multiple levels of the spinal column with the use of a single device, a single access path is created to an implantable pulse generator (IPG) rather than individual access paths for each lead at each spinal level to an IPG. By reducing the number of pathways, the procedure complexity, time and recovery are reduced. In addition, some embodiments provide additional specificity within each targeted level, such as selective stimulation of specific tissue, such as the dorsal root ganglion.

Owner:TC1 LLC

Neurostimulation methods and systems

ActiveUS9205261B2Reduce exerciseMaintained distributionSpinal electrodesDiagnostic recording/measuringMedicineSelective stimulation

Some embodiments of the present invention provide stimulation systems and components for selective stimulation and / or neuromodulation of one or more dorsal root ganglia through implantation of an electrode on, in or around a dorsal root ganglia. Some other embodiments of the present invention provide methods for selective neurostimulation of one or more dorsal root ganglia as well as techniques for applying neurostimulation to the spinal cord. Still other embodiments of the present invention provide stimulation systems and components for selective stimulation and / or neuromodulation of one or more dorsal root ganglia through implantation of an electrode on, in or around a dorsal root ganglia in combination with a pharmacological agent.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV +1

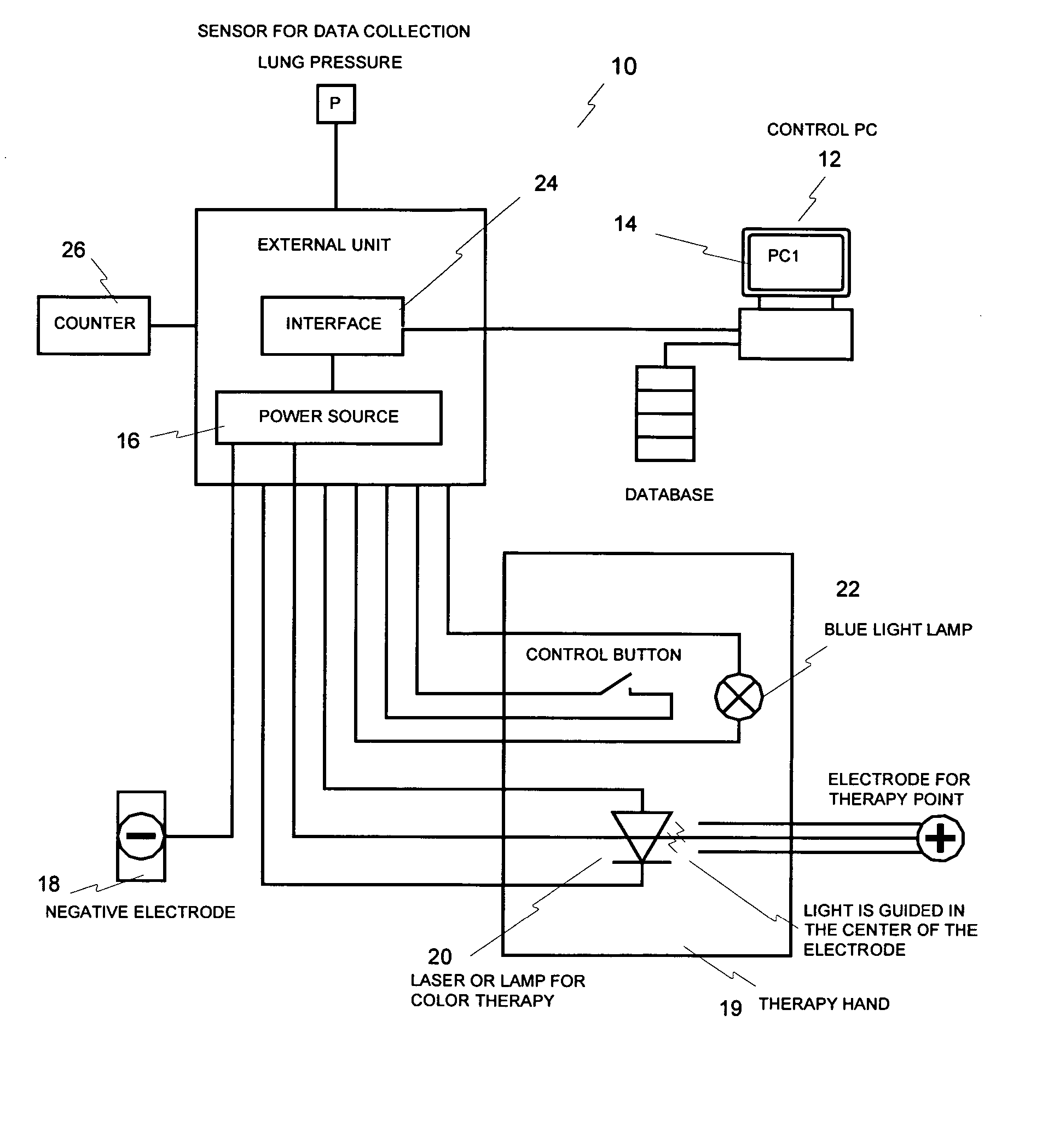

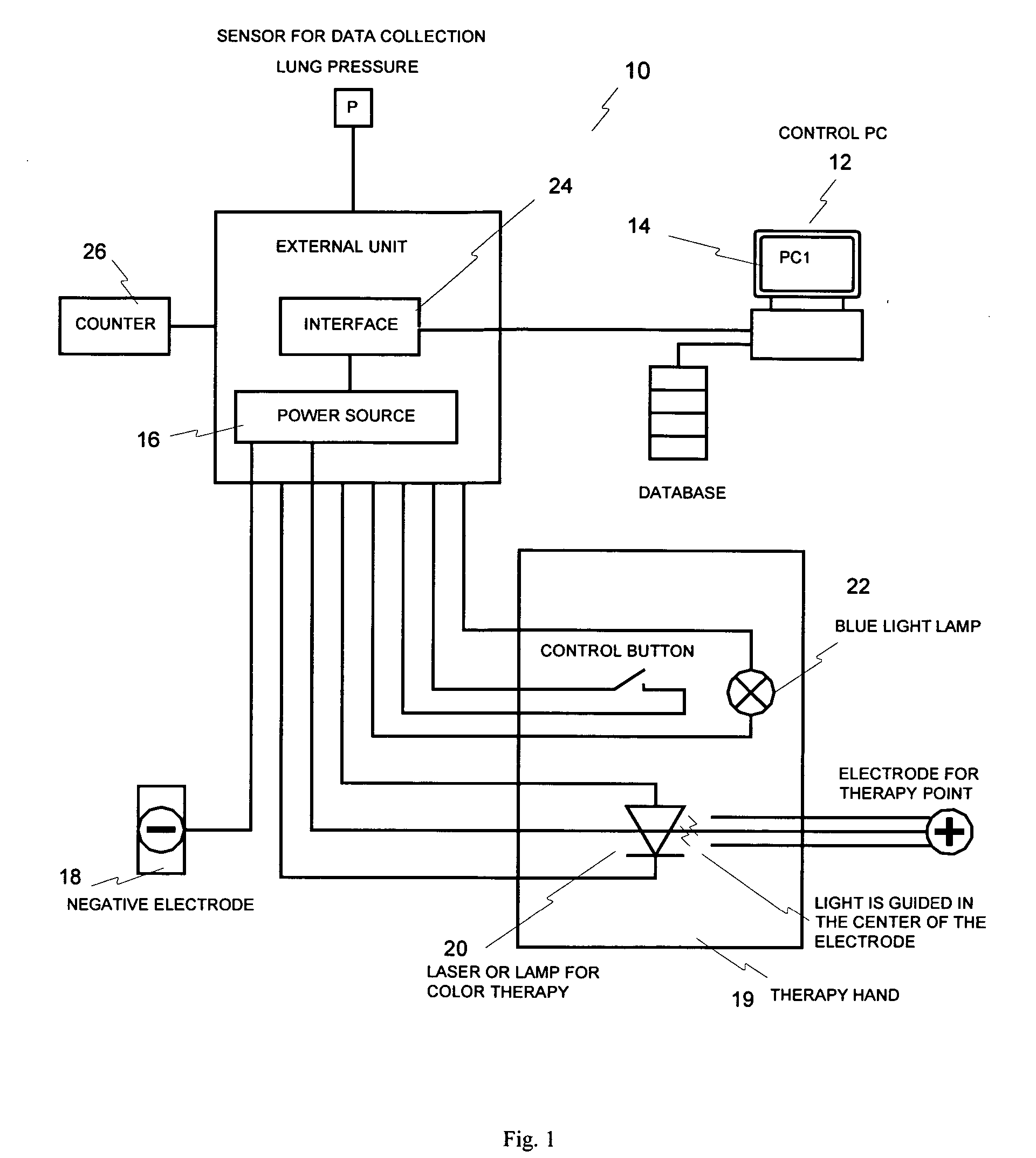

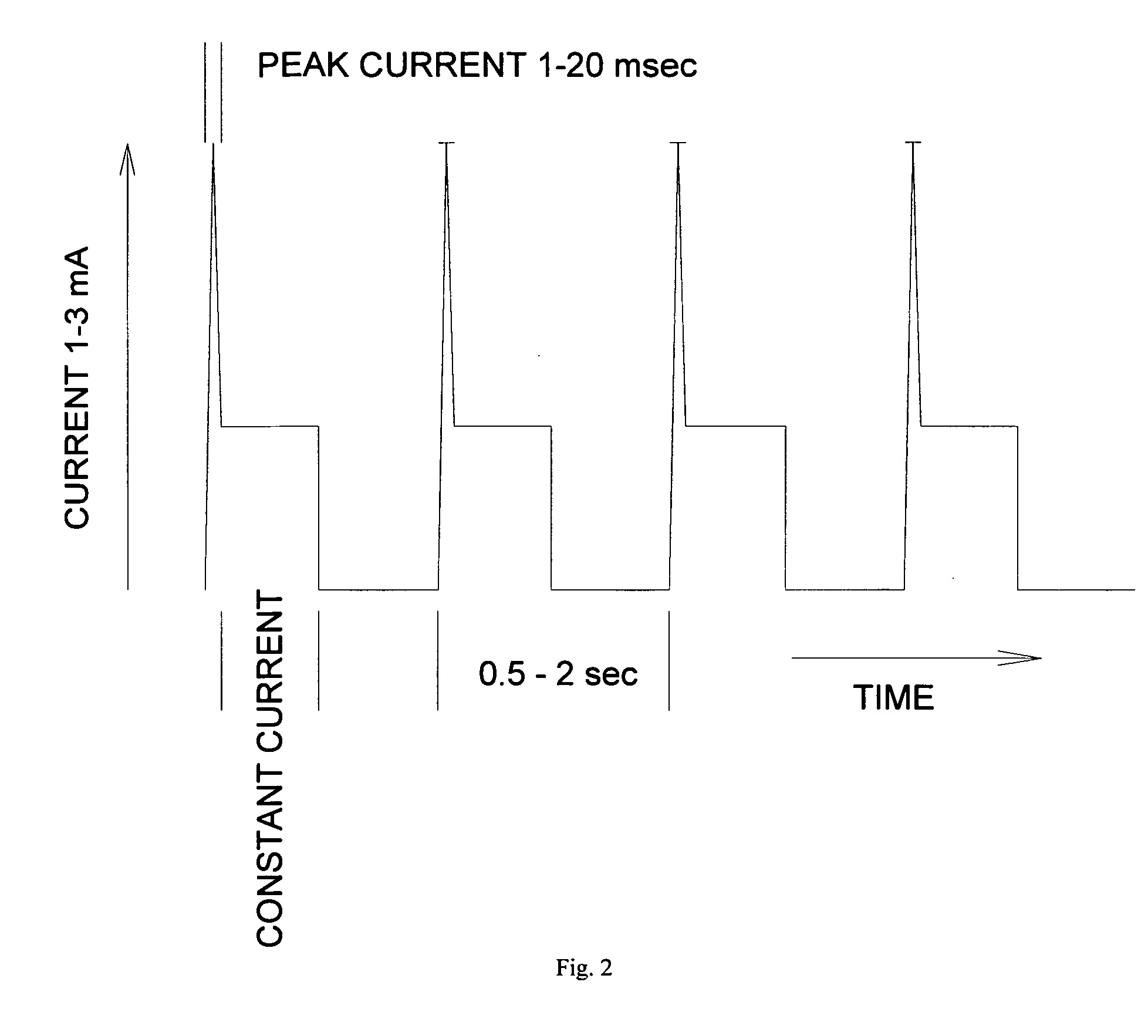

System for the stimulation of acupuncture points

An invention is disclosed for a stimulation therapy utilizing stimulation of acupuncture points by employing a combination of an electrical current and a laser beam in which pulsed stimulation is generally preferred. The invention also comprises an illumination of radiated light for inhibiting the stimulation of nearby acupuncture points, thus enable selective stimulation. The invention can further comprise a stimulation point indicator, showing a sequence of selected body acupuncture points according to the intended treatment effect, which are stimulationable, distinguishable from other points.

Owner:NS WELLTEC

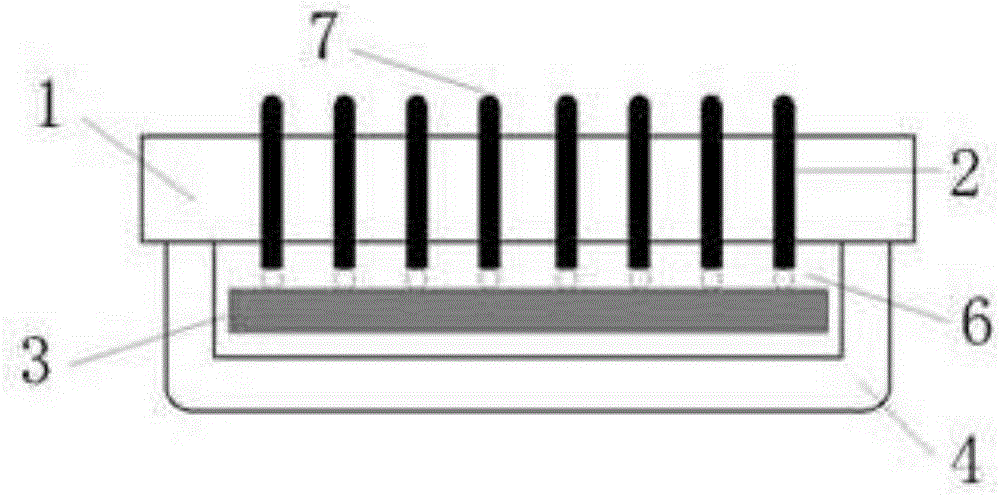

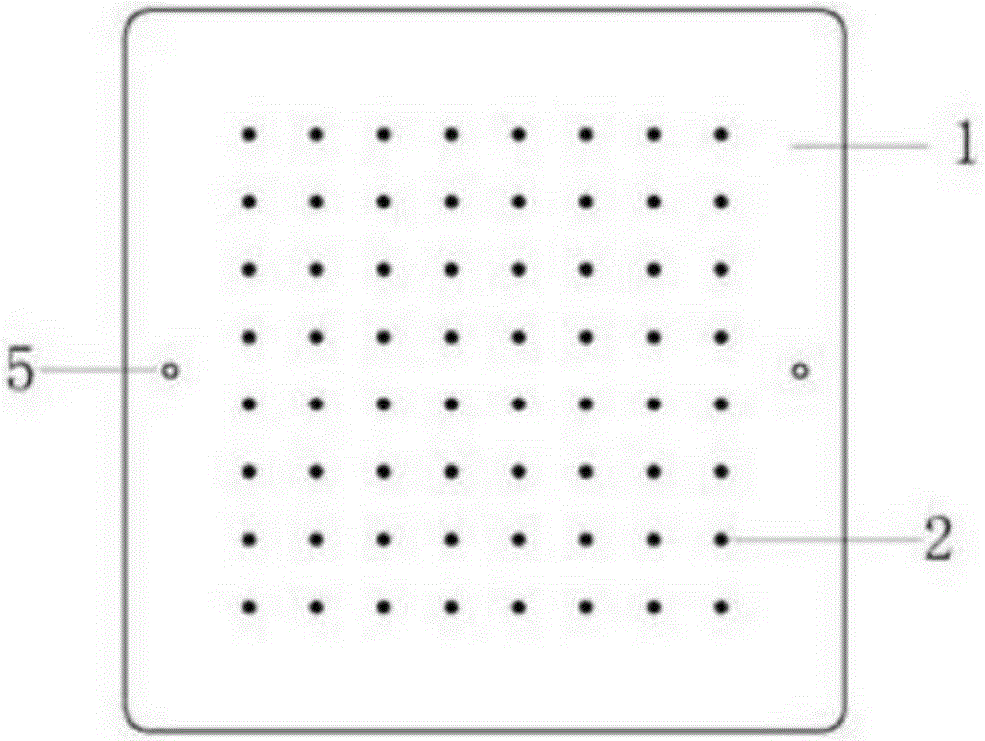

Nerve stimulator and manufacturing method thereof

The invention relates to the technical field of bio-medical engineering, and particularly relates to a nerve stimulator. The nerve stimulator comprises a substrate provided with a plurality of through holes, a plurality of microelectrodes arranged on the substrate through being filled in the through holes, a stimulus chip and a shell. One side of each microelectrode, leaks out of the substrate, serves as the stimulus part of the microelectrode, while the other side of the microelectrode serves as the connection part of the microelectrode. The connection parts of the microelectrodes are directly inverted and welded onto the stimulus chip. The shell is hermetically connected with the substrate. The manufacturing method of the nerve stimulator is composed of the laser drilling step, the through hole plating step and other machining steps, and the packaging manner thereof is realized through the laser welding step. According to the technical scheme of the invention, the microelectrodes are connected with the stimulus chip through the flip-chip bonding process, so that the tissue damage caused during the implantation process of the nerve stimulator can be greatly reduced. The manufacturing method is simple in process, and short in period. Based on the method, a high-density and orderly-arranged three-dimensional microelectrode array can be implemented. Meanwhile, the high-density selective stimulating and recording function can be realized. Therefore, the nerve stimulator and the manufacturing method thereof have a good application prospect.

Owner:WENZHOU INST OF BIOMATERIALS & ENG

Methods of neurostimulating targeted neural tissue

Some embodiments of the present invention provide methods of neurostimulating targeted neural tissues. Also described are stimulation systems and components for selective stimulation and / or neuromodulation of one or more dorsal root ganglia through implantation of an electrode on, in or around a dorsal root ganglia. Some other embodiments of the present invention provide methods for selective neurostimulation of one or more dorsal root ganglia as well as techniques for applying neurostimulation to the spinal cord. Still other embodiments of the present invention provide stimulation systems and components for selective stimulation and / or neuromodulation of one or more dorsal root ganglia through implantation of an electrode on, in or around a dorsal root ganglia in combination with a pharmacological agent.

Owner:KIM DANIEL H +2

Selective stimulation systems and signal parameters for medical conditions

ActiveUS9056197B2Lower energy levelFine granularitySpinal electrodesExternal electrodesSide effectNervous system

Owner:TC1 LLC

Delivery devices, systems and methods for stimulating nerve tissue on multiple spinal levels

ActiveUS8983624B2Effectively pain symptomDeleterious side effectSpinal electrodesImplantable neurostimulatorsSpinal columnRadiology

Devices, systems and methods are provided for simultaneously stimulating the spinal anatomy at various locations, such as spinal levels, along the spinal cord. By stimulating multiple levels of the spinal column with the use of a single device, a single access path is created to an implantable pulse generator (IPG) rather than individual access paths for each lead at each spinal level to an IPG. By reducing the number of pathways, the procedure complexity, time and recovery are reduced. In addition, some embodiments provide additional specificity within each targeted level, such as selective stimulation of specific tissue, such as the dorsal root ganglion.

Owner:TC1 LLC

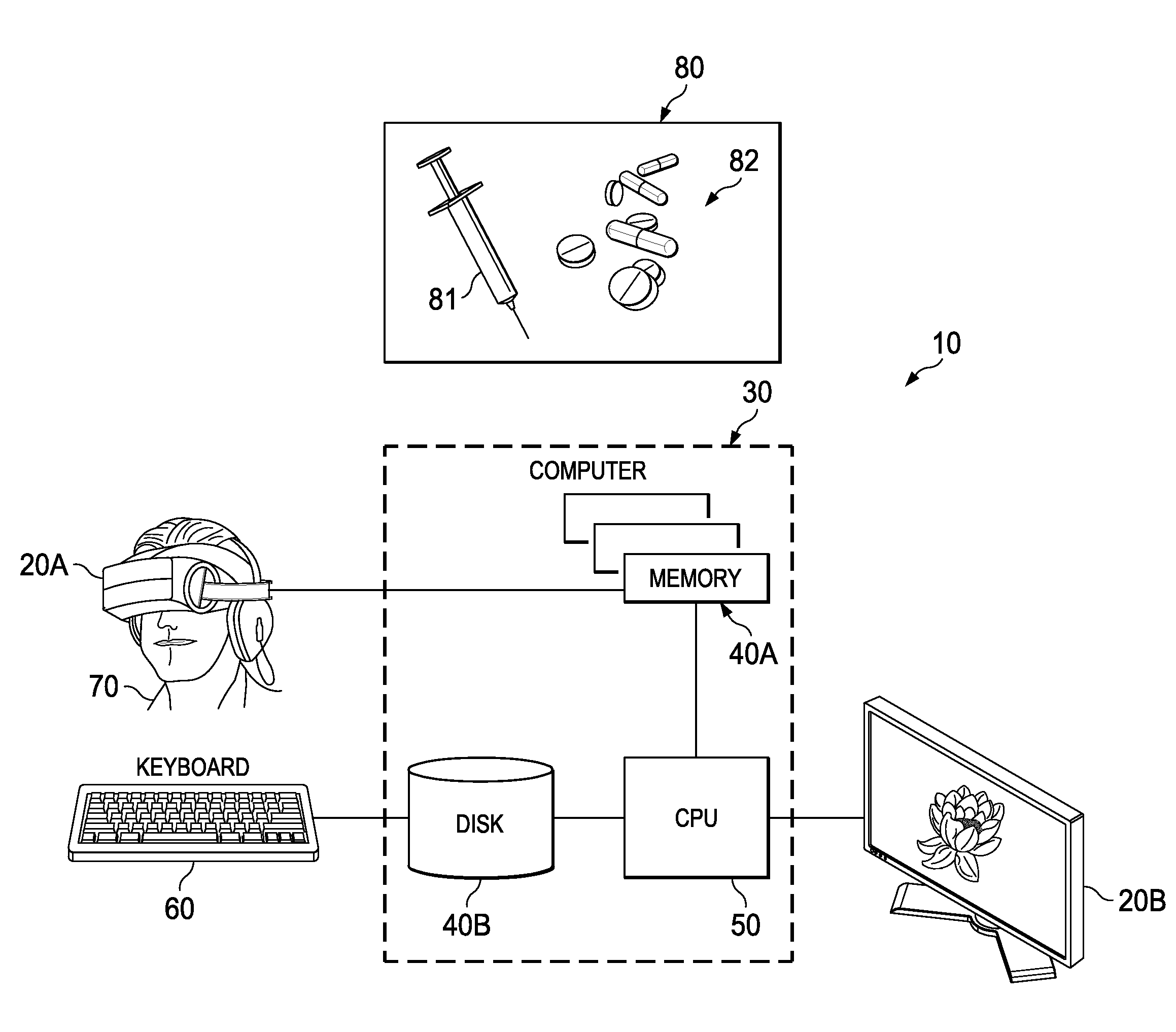

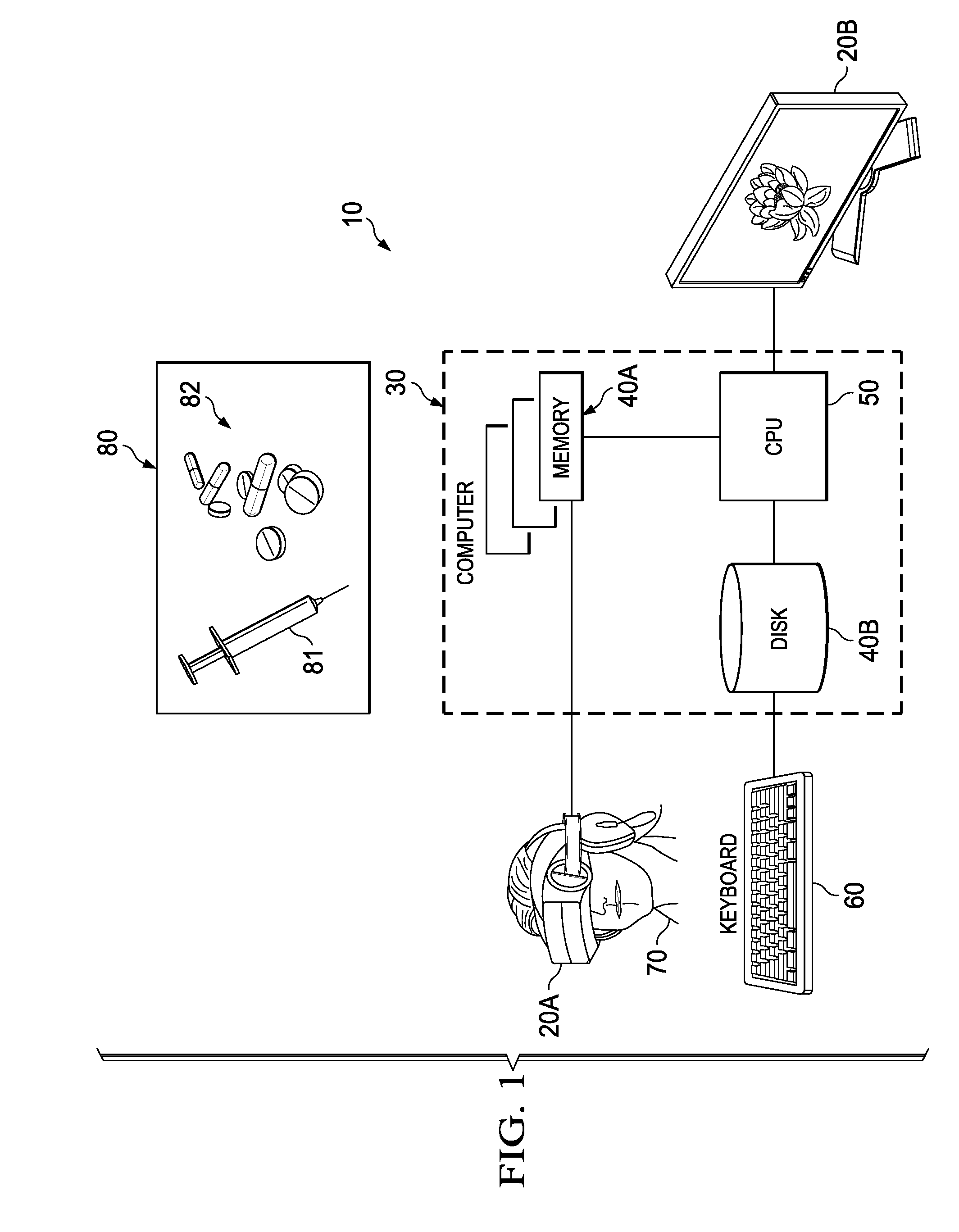

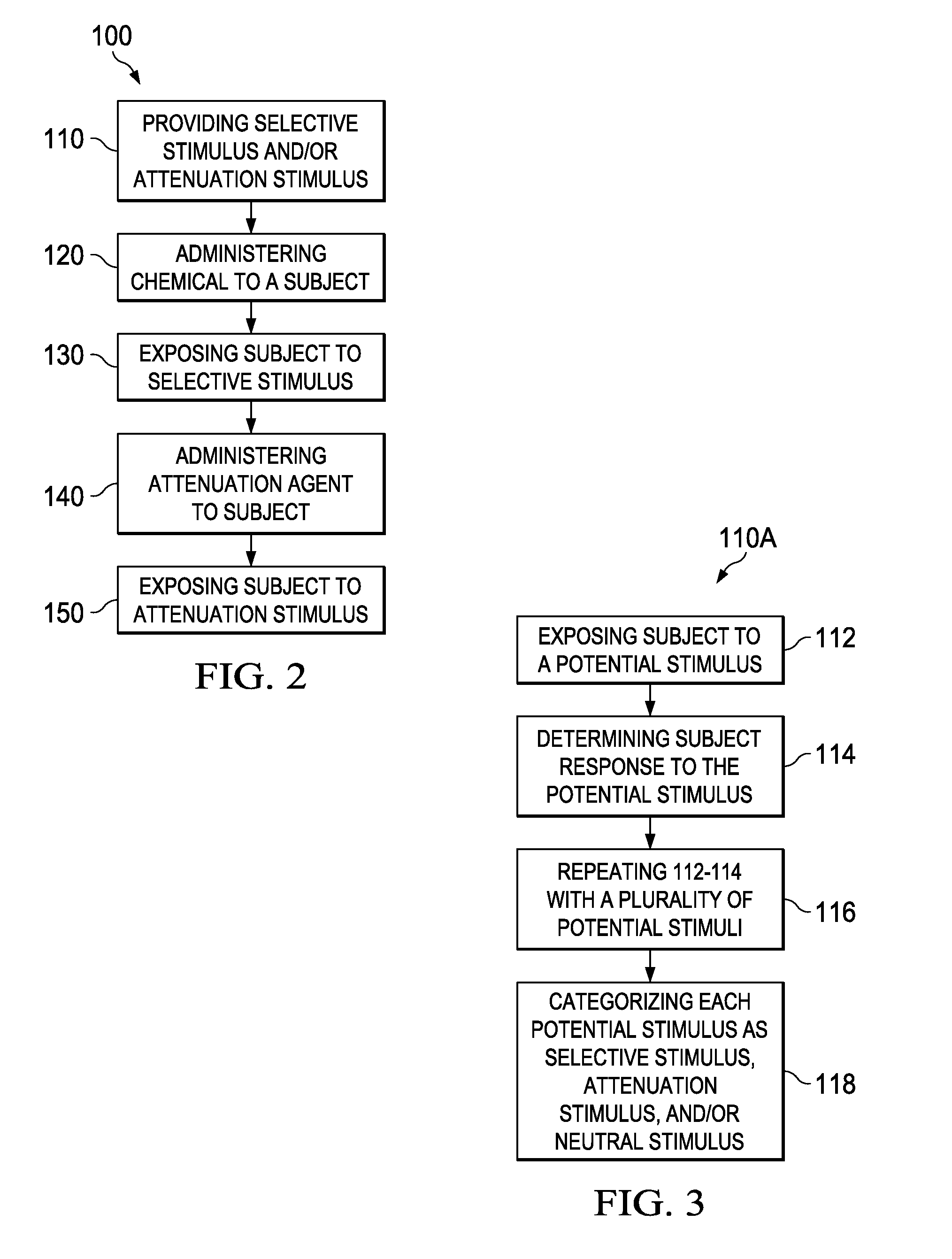

Digital drug delivery

ActiveUS20110092805A1Promote blood flowMinimize effect of treatmentInfusion syringesMedical devicesDisplay deviceComputer science

For delivery of a chemical to a target region of a subject's brain, an apparatus comprising a storage medium on which is stored digital representations of subject-specific selective visual stimuli that, when viewed, selectively stimulate blood flow to the target area of the brain; and an electronic display device coupled thereto and configured for converting the stored digital representations to images viewable by the subject; wherein the one or more selective visual stimuli were determined by exposing the subject to a plurality of potential stimuli; measuring the blood flow response to multiple regions of the brain, including the target area and one or more non-target areas; comparing the blood flow responses to the potential stimuli, and selecting as selective stimuli potential stimuli that result in relatively more blood flow to the target area and relatively less blood flow one or more non-target areas.

Owner:TEXAS INSTR INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com