Gas propelled munitions Anti-fouling system

a technology of anti-fouling system and gas-propelled munitions, which is applied in the field of firearms, can solve the problems of reducing muzzle velocity, misfeeding of rounds, and affecting the effect of art, so as to improve the appreciation of the contribution to the art

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

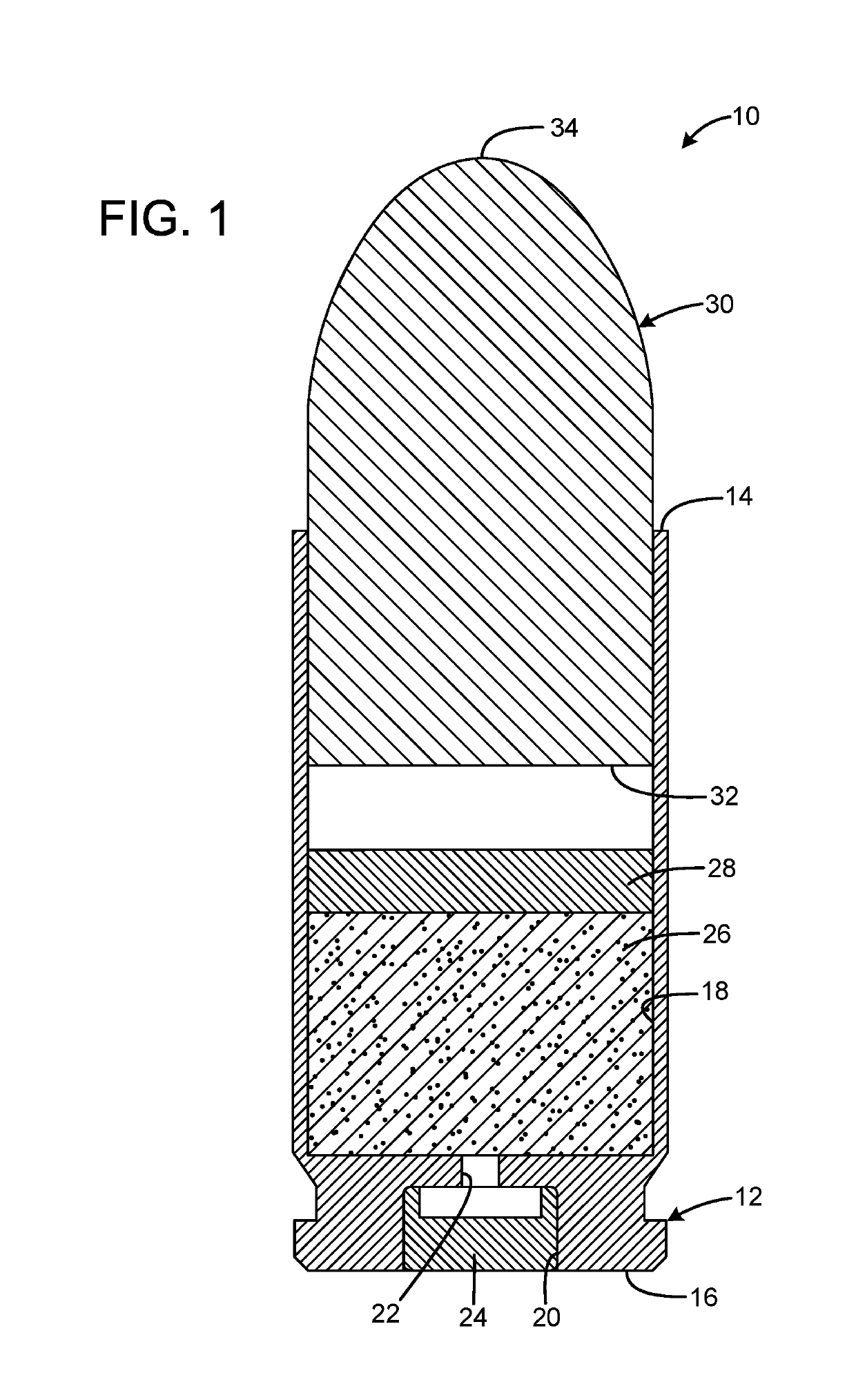

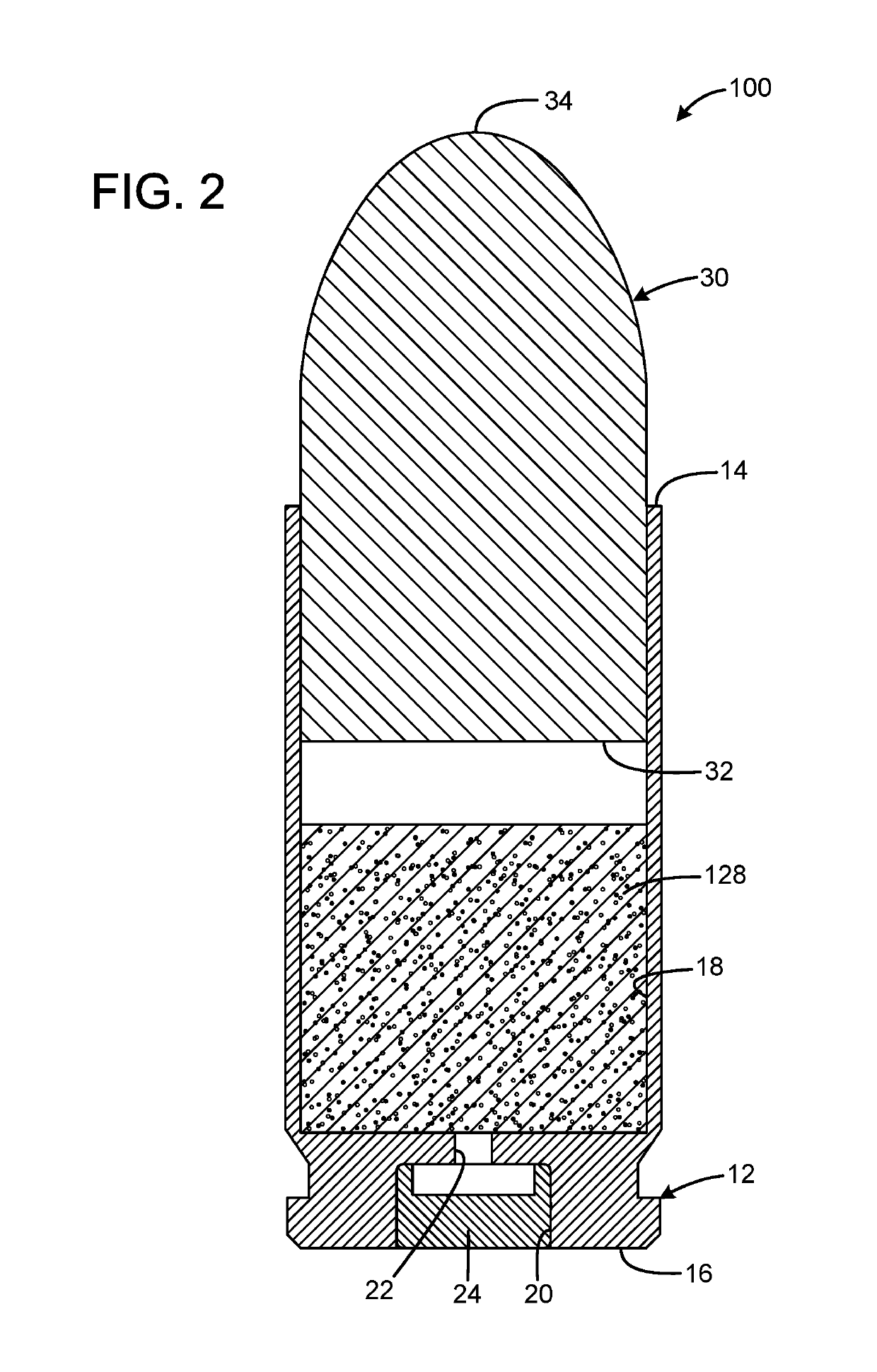

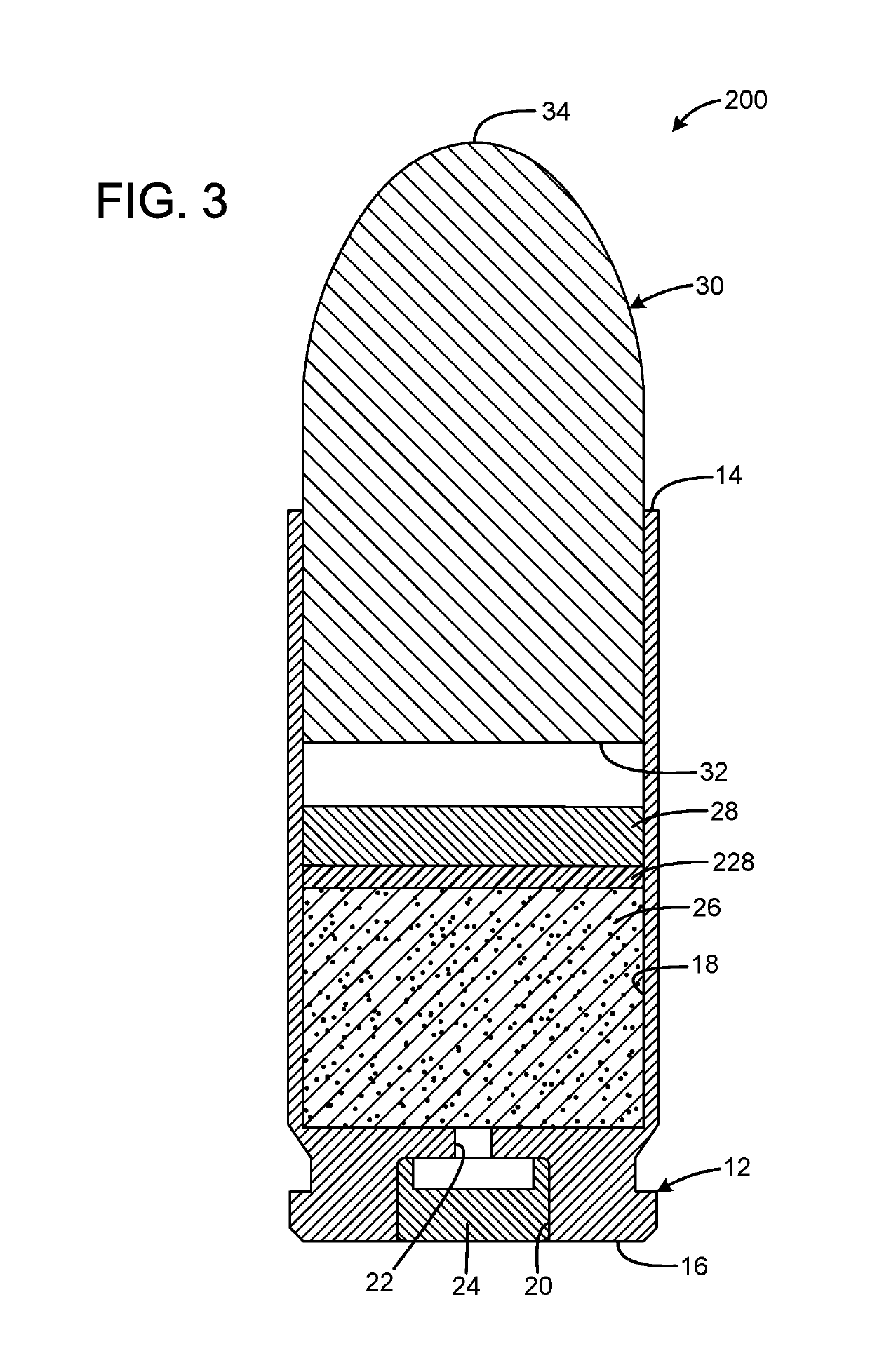

[0028]An embodiment of the gas propelled munitions anti-fouling system of the present invention is shown and generally designated by the reference numeral 10.

[0029]FIG. 1 illustrates the improved gas propelled munitions anti-fouling system 10 of the present invention. More particularly, the gas propelled munitions anti-fouling system is shown in the form of a cartridge having a cylindrical case 12 with an open forward mouth end 14, a partially enclosed rear end 16, and an interior 18. The rear end defines a primer pocket 20 that has a forward-facing passageway 22 to communicate with the interior. The primer pocket receives a primer 24. A quantity of propellant 26 is received within the interior of the case immediately forward of the forward-facing passageway. A quantity of anti-fouling composition 28 is received within the interior of the case immediately forward of the propellant as a distinct, abutting layer. A projectile / bullet 30 has a rear portion 32 inserted into the mouth of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

| dry anti-fouling | aaaaa | aaaaa |

| acid | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com