Preparation method of graphene oxide modified polycarboxylic acid type water-reducer

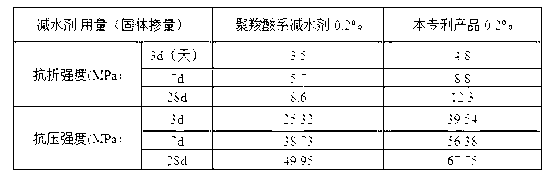

A technology of graphene modification and polycarboxylate system, which is applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of inability to significantly improve the mechanical properties of concrete, low water-reducing rate of the dosage, and achieve flexural resistance Enhanced compressive strength, reasonable preparation process, and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

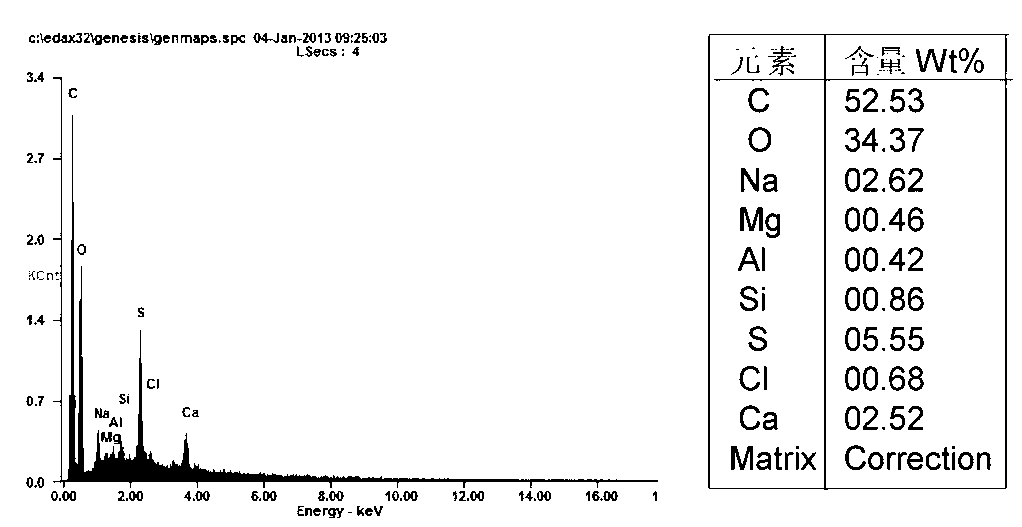

Image

Examples

Embodiment 1

[0028] Step 1: Pre-oxidation of graphite:

[0029] Under stirring conditions, 20 parts by mass of concentrated sulfuric acid with a mass fraction of 98%, 2.5 parts by mass of potassium persulfate and 2.5 parts by mass of phosphorus pentoxide were successively added into the reactor, the temperature was raised to 80°C, and the mixture was added in batches under stirring. 2 parts by mass of natural graphite raw materials, stirred until uniform, kept at 80°C for 6 hours, filtered and washed with water until the solution was neutral, dried for later use;

[0030] Step 2: preparation of graphene oxide:

[0031] Under ice bath conditions, add 1.5 parts by mass of graphite powder, 1 part by mass of sodium nitrate, 60 parts by mass, and concentrated sulfuric acid with a mass fraction of 98% into the reactor and mix evenly, and add 6 parts by mass within 1 hour under stirring. Potassium permanganate, stirred and reacted for 1 hour at a temperature not exceeding 5°C, raised the tempera...

Embodiment 2

[0036] Step 1: Pre-oxidation of graphite:

[0037] Under stirring conditions, 25 parts by mass of concentrated sulfuric acid with a mass fraction of 98%, 3 parts by mass of potassium persulfate and 3 parts by mass of phosphorus pentoxide were successively added into the reactor, the temperature was raised to 80°C, and the 4 parts by mass of natural graphite raw materials, stirred until uniform, kept at 80°C for 6 hours, filtered and washed with water until the solution was neutral, dried for later use;

[0038] Step 2: preparation of graphene oxide:

[0039] Under ice bath conditions, 1.5 parts by mass of graphite powder, 1 part by mass of sodium nitrate, 60 parts by mass of concentrated sulfuric acid with a mass fraction of 98% were sequentially added to the reactor and mixed evenly, and 8 parts by mass were added within 1 hour under stirring. Potassium permanganate, stirred and reacted for 1 hour at a temperature not exceeding 5°C, raised the temperature to 40°C and stirred...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com