Lubricating coating with low friction and long service life

A long-life, low-friction technology, used in lubricating compositions, coatings, additives, etc., can solve problems such as cylinder surface strain, scrapping of automobile engines, and leakage of lubricating oil, and achieve improved wear resistance and long wear life. , the effect of good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

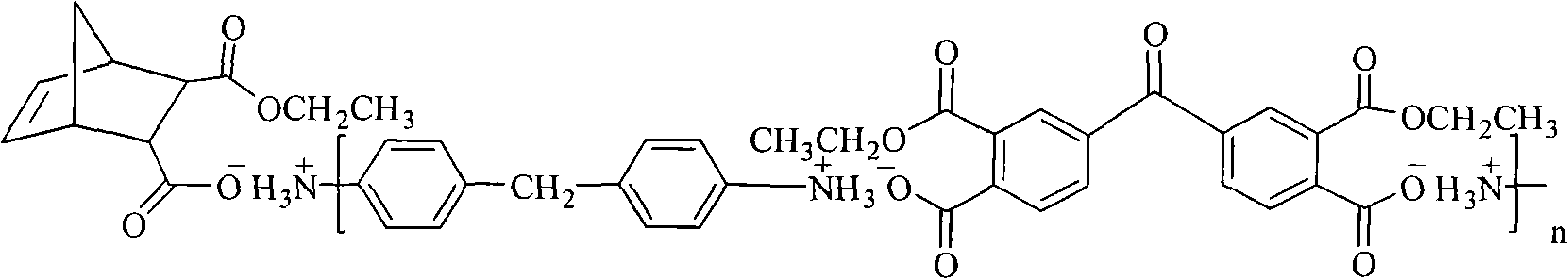

Method used

Image

Examples

Embodiment 1

[0019] Weigh 300 grams of mixed organic solvents, 100 grams of polyimide resin, 0.95 grams of nano-lanthanum trifluoride, 27.1 grams of molybdenum disulfide, 9.1 grams of graphite, and ball-milled for 48 hours. ): N,N-dimethylformamide 35%, toluene 65%].

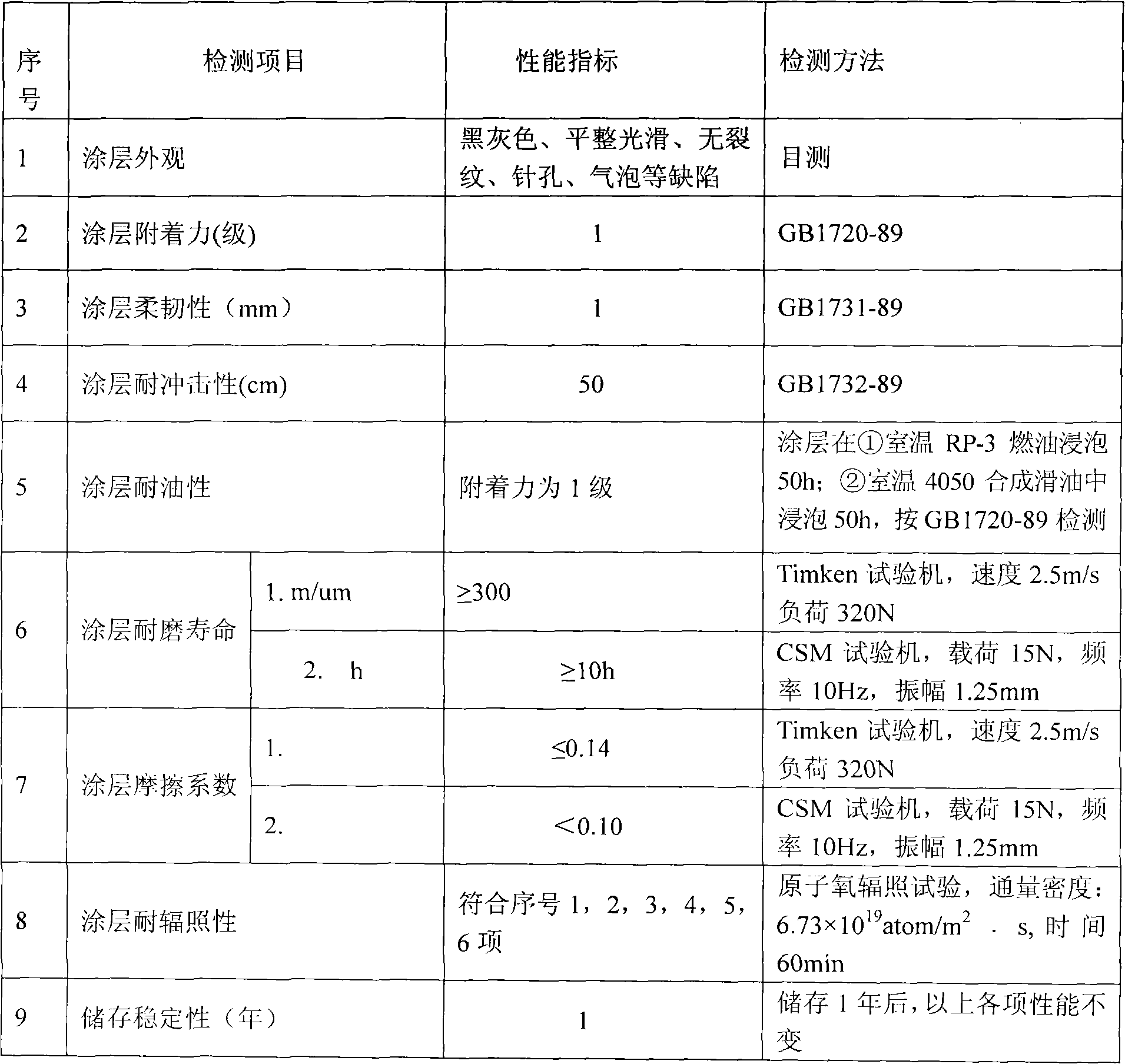

[0020] The main properties are shown in Table 1.

[0021] Table 1 Main technical indicators of invention products

[0022]

Embodiment 2

[0023] Example 2: (unit: grams)

[0024] Polyimide resin 100 Molybdenum disulfide 22.5

[0025] Graphite 11.3 nm Lanthanum trifluoride 0.95

[0026] Mixed organic solvent 300g [wherein: N,N-dimethylformamide 40%, toluene 60%, (volume percentage)]

Embodiment 3

[0027] Example 3: (unit: grams)

[0028] Polyimide resin 100 Molybdenum disulfide 30.33

[0029] Graphite 7.6 nm Lanthanum trifluoride 0.95

[0030] Mixed organic solvent 300g [wherein: N,N-dimethylformamide 40%, toluene 60%, (volume percentage)]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com