Magnesium crystal fireproof and flame-retardant plate and preparation method thereof

A fire-retardant, magnesium oxide technology, applied in the field of building materials, can solve the problems of poor effect, low formaldehyde emission, inability to balance fire prevention and waterproof and moisture-proof, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

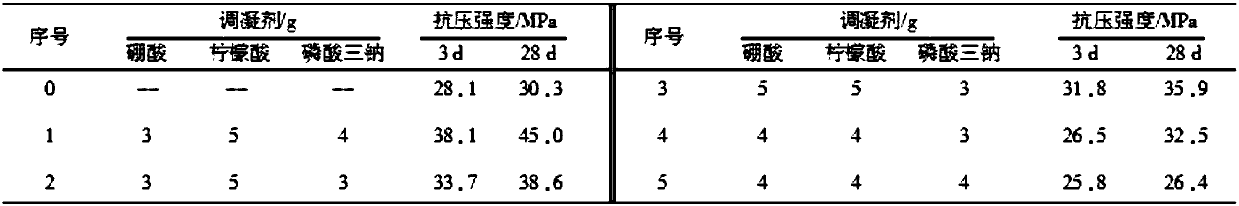

[0016] A magnesium crystal fireproof flame retardant board, calculated by weight, including 18 parts of magnesium oxide, 10 parts of magnesium sulfate, 45 parts of sawdust, 5 parts of aluminum oxide, 2.5 parts of copper sulfate, 9 parts of bentonite, 1 part of organic silicon, stearin Calcium acid 3 parts, boric acid 1 part, citric acid 1.7 parts, trisodium phosphate 1.3 parts, water 11 parts, polyvinyl alcohol 2 parts, polypropylene fiber 1 part, silyl powder 5 parts.

Embodiment 2

[0018] A magnesium crystal fireproof flame retardant board, including 18 parts of magnesium oxide, 10 parts of magnesium sulfate, 40 parts of sawdust, 6 parts of aluminum oxide, 2.5 parts of copper sulfate, 8 parts of bentonite, 2 parts of organic silicon, 4 parts of calcium stearate, 4.5 parts of modifier, 12 parts of water, 3 parts of polyvinyl alcohol, 2 parts of polypropylene fiber, and 5 parts of silane-based powder.

[0019] The invention also discloses a preparation method of a magnesium crystal fire-proof and flame-retardant board, which includes the following steps: (1) stirring and mixing magnesium sulfate and water to make a solution, which is metered and put into a mixer for use;

[0020] (2) Magnesium oxide, polyvinyl alcohol, polypropylene fiber, silane-based powder, and sawdust are weighed and measured successively, put into the batching bin, transported to the mixer and stirred with the solution for 10 minutes;

[0021] (3) After adding bentonite, aluminum oxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com