Extrusion and heat treatment method for high speed railway locator aluminum material

A heat treatment method and positioner technology, which is applied in the extrusion and heat treatment of aluminum materials for high-speed rail positioners, and in the field of aluminum extrusion and heat treatment, can solve the problems of high aluminum alloy, dragging, intergranular cracks, etc., and achieve high mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

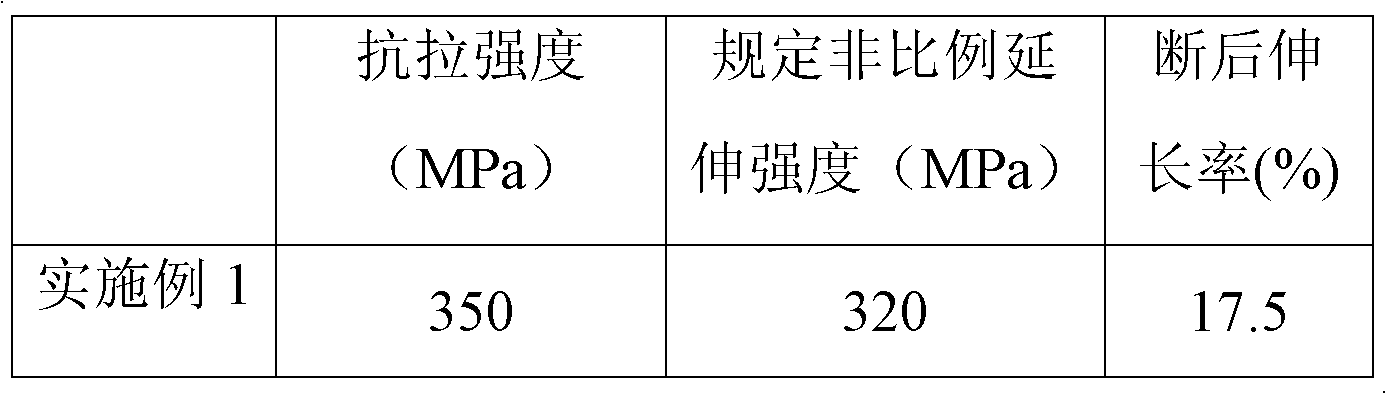

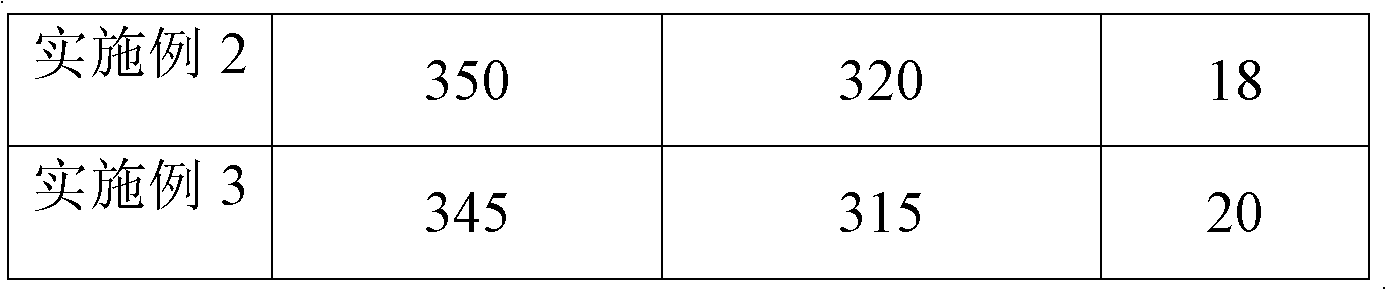

Examples

Embodiment 1

[0029] (1) Aluminum rod preheating: Preheat the aluminum rod with the grade 6082 (Foshan Hongjinyuan Aluminum Products Co., Ltd., the average diameter of the aluminum rod is 150mm, and its component percentage is shown in Table 1) to 450°C, The temperature difference between the two ends of the aluminum rod is controlled within 3°C;

[0030] (2) Mold preheating: Preheat the square tube mold at 460°C for 6 hours;

[0031] (3) Preheating of the ingot barrel: Preheat the ingot barrel of the extruder to 400°C;

[0032] (4) Extrusion: the mold after step (2) preheating is packed into extruder, and mold uses the special die cushion that adapts to mold shape, then puts the aluminum bar after step (1) preheating into step ( 3) In the preheated ingot cylinder, the aluminum rod is extruded from the die through the ingot cylinder, and the aluminum rod undergoes the filling stage, advection stage and turbulent flow stage in the extruder, and finally the profile is obtained at the outlet ...

Embodiment 2

[0037] (1) Aluminum rod preheating: Preheat the aluminum rod with the grade of 6082 (Foshan Hongjinyuan Aluminum Products Co., Ltd., the average diameter of the aluminum rod is 150mm, and the percentage content of its components is shown in Table 1) to 540 ° C, The temperature difference between the two ends of the aluminum rod is controlled within 3°C;

[0038] (2) Mold preheating: Preheat the square tube mold at 510°C for 2 hours;

[0039] (3) Preheating of the ingot barrel: Preheat the ingot barrel of the extruder to 450°C;

[0040] (4) Extrusion: the mold after step (2) preheating is packed into extruder, and mold uses the special die cushion that adapts to mold shape, then puts the aluminum bar after step (1) preheating into step ( 3) In the preheated ingot cylinder, the aluminum rod is extruded from the die through the ingot cylinder, and the aluminum rod undergoes the filling stage, advection stage and turbulent flow stage in the extruder, and finally the profile is obta...

Embodiment 3

[0045] (1) Aluminum rod preheating: Preheat the aluminum rod with the grade 6082 (Foshan Hongjinyuan Aluminum Products Co., Ltd., the average diameter of the aluminum rod is 150mm, and its component percentage is shown in Table 1) to 510°C, The temperature difference between the two ends of the aluminum rod is controlled within 3°C;

[0046] (2) Mold preheating: Preheat the square tube mold at 490°C for 4 hours;

[0047] (3) Preheating of the ingot barrel: Preheat the ingot barrel of the extruder to 440°C;

[0048] (4) Extrusion: the mold after step (2) preheating is packed into extruder, and mold uses the special die cushion that adapts to mold shape, then puts the aluminum bar after step (1) preheating into step ( 3) In the preheated ingot cylinder, the aluminum rod is extruded from the die through the ingot cylinder, and the aluminum rod undergoes the filling stage, advection stage and turbulent flow stage in the extruder, and finally the profile is obtained at the outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com