Hanging plate socket

A hanger type and socket technology, which is applied in the direction of contact parts, electrical components, coupling devices, etc., can solve the problems that the safety needs to be further improved, and achieve the effect of improving stability and safety, wide application range and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

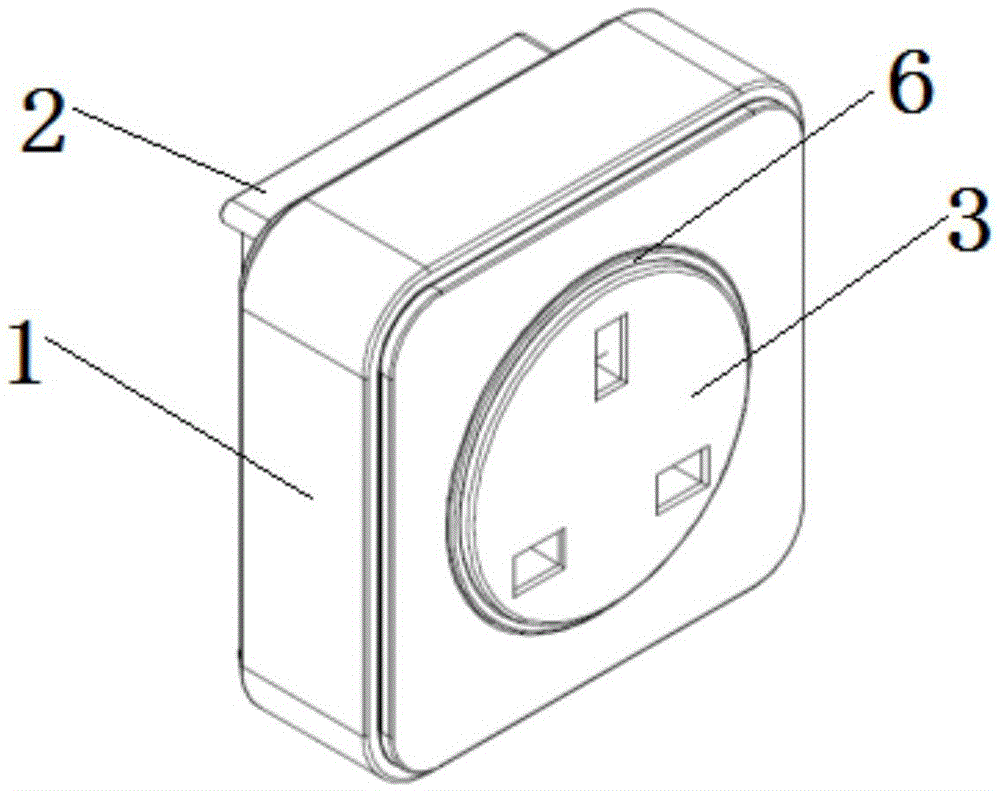

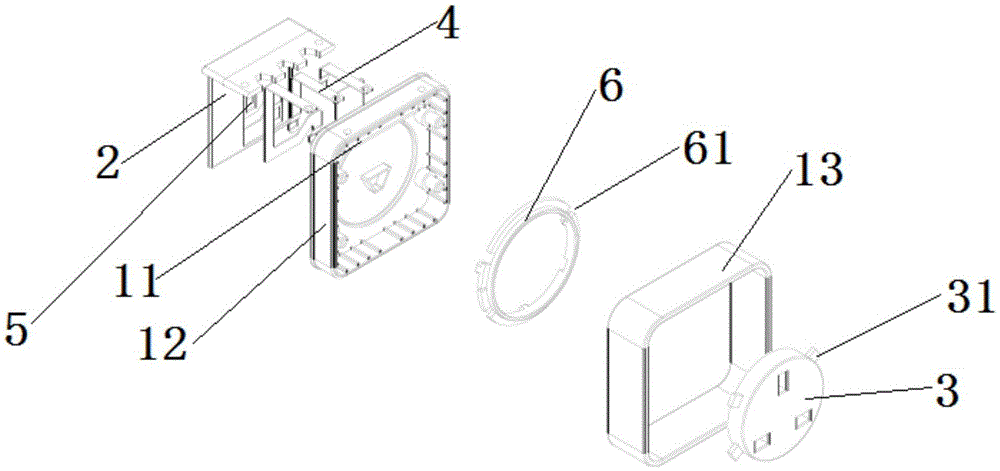

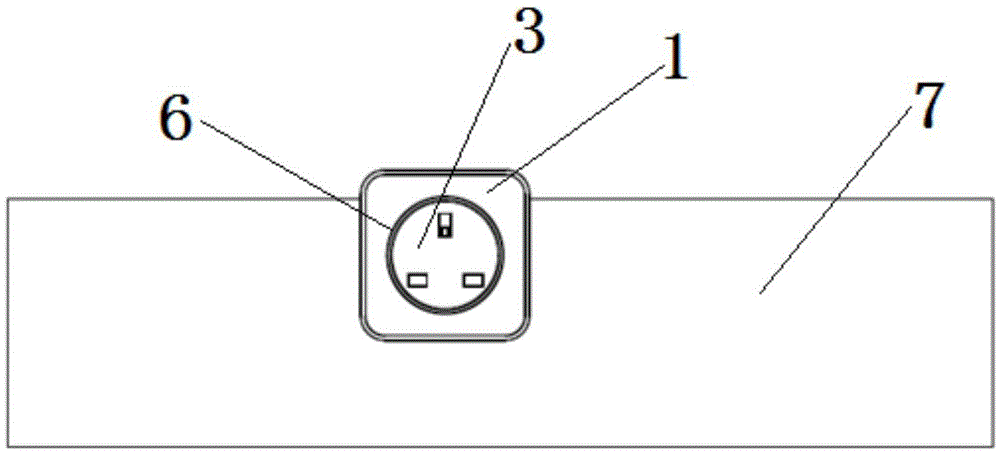

[0047] like figure 1 , figure 2 As shown, a hanger type socket includes a housing 1 and a hanger 2, the housing 1 is composed of a rear shell 12 and a front shell 13, and the front side of the front shell 13 is provided with a socket core 3 for connecting with a plug. The hanging piece 2 is hung on the rear side of the rear shell 12, and a connecting conductive piece 4 is arranged inside the housing 1. One end of the connecting conductive piece 4 is connected to the socket core 3, and the other end is connected to the hanging piece 2. An indicator light 6 is provided, and the indicator light 6 is connected with the connecting conductive sheet 4 .

[0048] In this embodiment, the form of the coupon is as follows:

[0049] There is a hanging groove 11 on the shell 1, and the hanging piece 2 includes a vertical plate and a horizontal plate connected to each other. The horizontal plate goes deep into the inside of the shell 1 from the hanging groove 11 and is fixed. The piece ...

Embodiment 2

[0058] like Image 6 As shown, the difference from Embodiment 1 is that in this embodiment, the socket core 3 adopts a national standard socket to adapt to the national standard plug form, and the rest of the structure and usage are the same as in Embodiment 1.

[0059] For Embodiment 1 and Embodiment 2, the socket core 3 can be replaced by a power-taking unit, and the power-taking unit includes a router, a sensor, an alarm, a detector, a camera, a charger or a converter, and the present invention becomes a corresponding The hanging piece power-taking unit instead of the socket.

Embodiment 3

[0061] The difference from Embodiment 1 is that in this embodiment, the implementation form of the coupon is different.

[0062] like Figure 7-11 As shown, the back of the housing 1 is provided with a connecting groove 8, and an internal contact 81 is arranged in the connecting groove 8, and the internal contact 81 is connected and conducted with the connecting conductive piece 4. The surface of the hanging piece 2 is provided with an elastic conductor contact 5, and the hanging piece 2 Connector 21 is arranged on the upper end, and external contact 22 is arranged on the connector 21, and the external contact 22 is connected with the elastic conductor contact 5. After the connector 21 is inserted into the connecting groove 5, the hanging piece 2 is hung on the back of the housing 1, Moreover, there is a gap between the hanging piece 2 and the back of the housing 1 for plugging the hanging piece 2 to take power, and at this time, the outer contact 22 and the inner contact 81 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com