Export S355J2 titanium-added steel plate and production method thereof

A technology of S355J2 and production method, applied in the field of S355J2 titanium-added steel plate, can solve the problems of narrow B element range design, large impact performance fluctuation, poor low temperature toughness, etc., to improve safety performance, short production process, and production cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

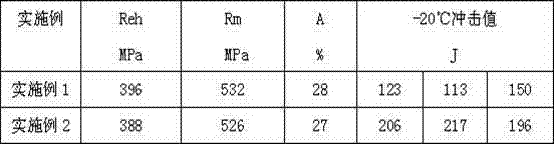

Examples

Embodiment 1

[0026] The steel grade is S355J2, the thickness of the continuous casting slab is 280mm, and the thickness of the rolled product is 40mm.

[0027] The chemical composition wt% content is: C: 0.14%, Si: 0.30%, Mn: 1.1%, Ti: 0.055%, P: 0.01%, S: 0.003%, and the rest is iron and unavoidable trace impurities.

[0028] The production process is: continuous casting slab - heating - dephosphorization - controlled rolling - controlled cooling - hot straightening - stacking slow cooling - cutting - inspection - finished product.

[0029] A low-temperature heating system is adopted to reduce the heating temperature to avoid coarsening of grains caused by high-temperature burning of steel, and to keep the austenite grains before rolling fine. Two-stage controlled rolling is adopted to form as many ferrite transformation nuclei as possible and effectively refine ferrite grains. Through the repeated deformation of the recrystallization zone in the first stage, the austenite grains are ref...

Embodiment 2

[0034] The steel grade is S355J2, the thickness of the continuous casting slab is 240mm, and the thickness of the rolled product is 20mm.

[0035] The chemical composition wt% content is: C: 0.16%, Si: 0.25%, Mn: 1.4%, Ti: 0.059%, P: 0.016%, S: 0.002%, and the rest is iron and unavoidable trace impurities.

[0036] The production process is: continuous casting slab - heating - dephosphorization - controlled rolling - controlled cooling - hot straightening - stacking slow cooling - cutting - inspection - finished product.

[0037] A low-temperature heating system is adopted to reduce the heating temperature to avoid coarsening of grains caused by high-temperature burning of steel, and to keep the austenite grains before rolling fine. Two-stage controlled rolling is adopted to form as many ferrite transformation nuclei as possible and effectively refine ferrite grains. Through the repeated deformation of the recrystallization zone in the first stage, the austenite grains are re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com