Production method of high-strength marine aluminum alloy cylinder profiles

A production method and aluminum alloy technology, which are applied in the production field of high-strength marine aluminum alloy cylinder profiles, can solve the problems of decreased corrosion resistance, low mechanical properties, poor strengthening effect, etc., so as to improve production efficiency and achieve localization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

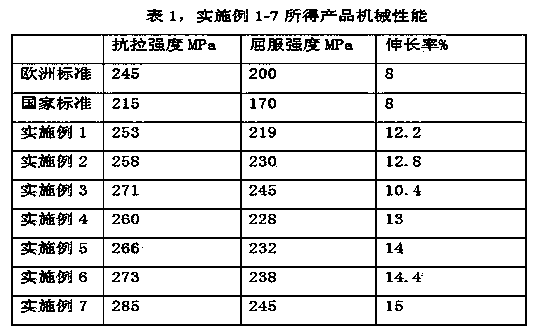

Examples

Embodiment 2

[0014] The cast aluminum alloy is a six-series aluminum alloy round ingot with a specification of Φ380mm×4000mm. When smelting the No. 6 aluminum alloy round ingot, it is required to calculate the ingredients, liquid slag removal, and degassing. It is required to filter during casting. Slag removal, slag removal once after refining in the smelting furnace, once after refining in the holding furnace; once degassing after refining in the smelting furnace, once degassing after refining in the holding furnace, and degassing by a degasser after refining in the holding furnace. . 2. Cut the No. 6 aluminum alloy round ingot wagon with a specification of Φ380mm×4000mm, cut the head, cut the tail, take the low magnification, chemical composition, and cut the wool material if the low magnification and chemical composition are qualified. The wool material specification is Φ368mm×1450mm; the wool material is homogeneous, Heating temperature: 560°C, heat preservation for more than 10 hours...

Embodiment 3

[0016] The difference from specific examples 1 and 2 is that the No. 6 aluminum alloy round ingot used in step 1 has a refining degree that meets the requirements of the primary oxide film, no metal compound segregation, and the ratio of Mg and Si alloys is not according to Mg:Si= 1.73: 1 conventional ratio, but Si is surplus, Fe and Cu are added as the main elements, in order to improve the strength of the alloy, Mn is added as the main element, in order to eliminate the adverse effects of excess Fe, Si is 0.54%, Fe is 0.172% , Cu is 0.088%, Mn is 0.085%, Mg is 0.53%, Zn is 0.045%, Ti is 0.043%, Cr is 0.04%, single impurity ≤ 0.05%, total impurity ≤ 0.15%, the rest is Al; other steps and Parameters are the same as in Example 1.

Embodiment 4

[0018] The difference between this example and Example 1 is that the wool is homogeneous, the heating temperature is 555°C, and the temperature is kept for more than 10 hours. The cooling method is: air cooling to 200°C, then adding water cooling to room temperature, low-magnification inspection of oxide film, inspection of compound segregation , meeting the requirements of the primary oxide film, other steps and parameters are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com