Ring forge piece material of wind power rotary supporting ring and ring forge piece manufacturing technology thereof

A technology of slewing bearing and manufacturing process, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems of low plasticity and hardenability, simple and rough heat treatment process, low quality stability, etc., to achieve stable and reliable quality, plasticity and so on. and the effect of large hardenability

Inactive Publication Date: 2010-08-25

ZHANGJIAGANG HAILU ANNULAR FORGINGS

View PDF4 Cites 27 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The disadvantages of traditional wind power slewing bearing ring forgings are: due to the large range of material composition and physical and chemical indicators allowed, the heat treatment process is simple and rough, resulting in low toughness, plasticity and hardenability of the product, and low quality stability , it is still difficult to meet specific requirements such as strong wind force and +40~-40℃ ambient temperature, safe and stable load bearing, etc.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Circularity | aaaaa | aaaaa |

Login to View More

Abstract

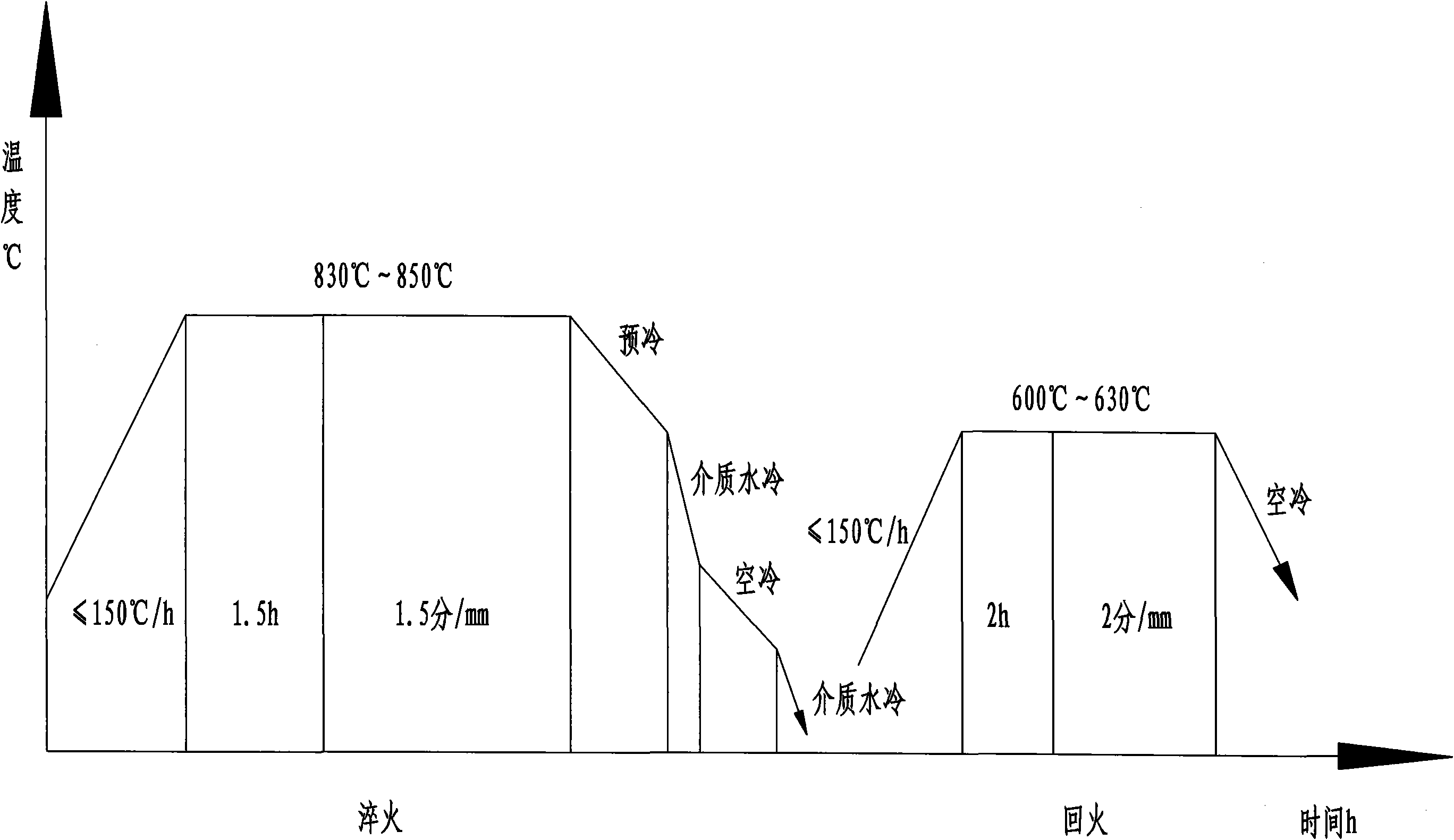

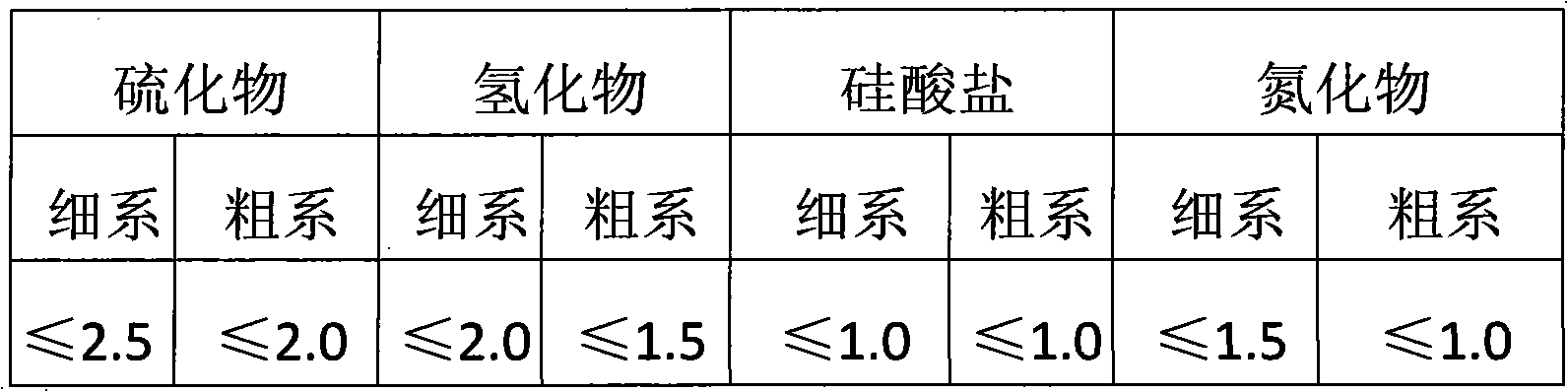

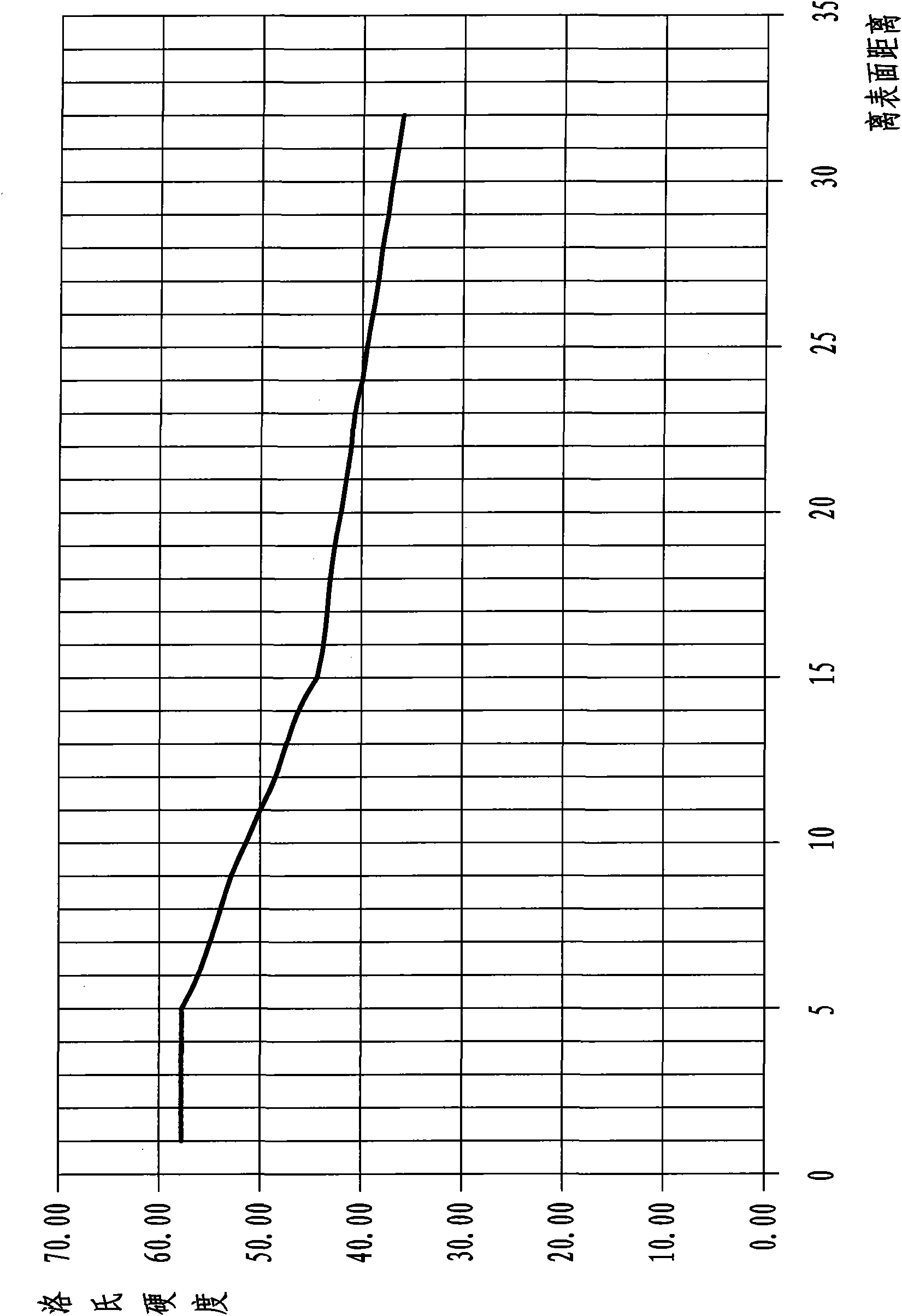

The invention discloses a ring forge piece material of a wind power rotary supporting ring, comprising the following chemical elements in weight percentage: 0.41-0.45 percent of C, 0.17-0.37 percent of Si, 0.80-1.00 percent of Mn, at most 0.020 percent of P, at most 0.020 percent of S, 1.05-1.20 percent of Cr, at most 0.30 percent of Ni, 0.20-0.25 percent of Mo, at most 0.20 percent of Cu, 0.02-0.04 percent of Al, at most 20ppm of O, at most 2.0ppm of H and Fe as the rest. A wind power rotary supporting ring forge piece manufactured by the material comprises the following technical steps: blanking, forging to manufacture a blank, rolling a ring, hot treating and accurately turning, wherein the hot treating step comprises the steps of hot treatment normalization and hot treatment hardening and tempering. The ring forge piece material is suitable for the ring forge piece of the wind power rotary supporting ring.

Description

technical field The invention relates to a wind power slewing support ring forging, in particular to a material for a wind power slewing support ring forging and a manufacturing process for the ring forging. Background technique As a clean and renewable energy, wind power is a new emerging industry. The slewing support ring on the pitch of the wind turbine used for wind power equipment and the yaw tower is the load-bearing and transmission part of the wind power equipment, which needs to be used under strong wind force and +40~-40℃ ambient temperature to meet the specific use of bearing load and so on. requirements; and it is required that under relatively severe weather conditions, quality problems cannot occur within 20 years. The currently used wind power slewing support rings are generally made of billet steel made of 42CrMo4V material in the European standard BS EN10083-1:2006 as the raw material for initial processing, and are made after forging, ring rolling and heat...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/44C21D9/00C21D1/28C21D1/18

Inventor 吴君三王雷刚戴玉同胡振奇张毅峰

Owner ZHANGJIAGANG HAILU ANNULAR FORGINGS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com