High-hardness high-toughness ZW552 steel for heading machine cutter ring

A high-toughness, roadheader technology, applied in the field of steel alloys, can solve the problems of strength and toughness not meeting hard rock formations, cost and efficiency waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

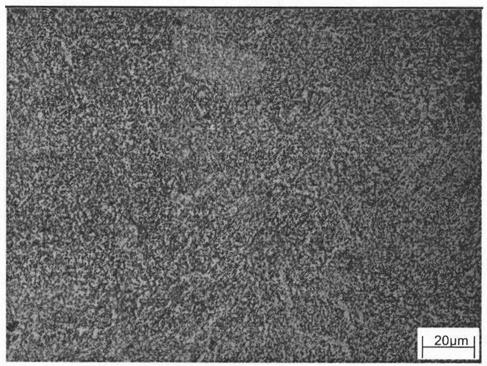

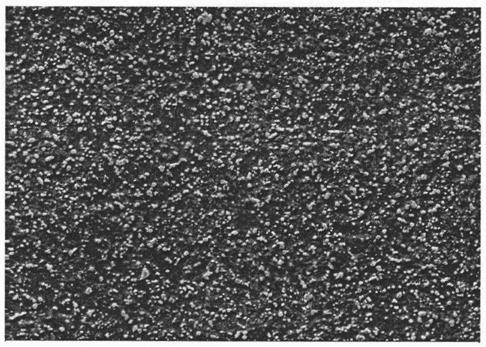

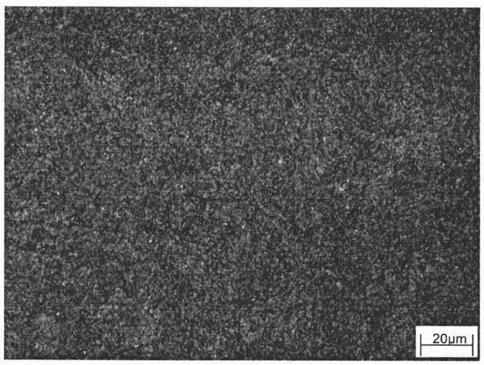

Image

Examples

Embodiment 1

[0035] A high-hardness, high-toughness ZW552 steel for roadheader cutter rings, the chemical composition and percentage of the steel are:

[0036] C 0.48%,

[0037] Si 0.26%,

[0038] Mn 0.38%,

[0039] Cr 5.12%,

[0040] Mo 2.31%,

[0041] V 0.58%,

[0042] Nb 0.011%,

[0043] P 0.010%,

[0044] S 0.0009%,

[0045] Ni 0.010%,

[0046] Cu 0.005%,

[0047] Ti 0.004%,

[0048] The balance is Fe and unavoidable impurities;

Embodiment 2

[0050] A high-hardness, high-toughness ZW552 steel for roadheader cutter rings, the chemical composition and percentage of the steel are:

[0051] C 0.50%,

[0052] Si 0.23%,

[0053] Mn 0.39%,

[0054] Cr 5.10%,

[0055] Mo 2.26%,

[0056] V 0.57%,

[0057] Nb 0.009%,

[0058] P 0.010%,

[0059] S 0.0007%,

[0060] Ni 0.010%,

[0061] Cu 0.005%,

[0062] Ti 0.003%,

[0063] The balance is Fe and unavoidable impurities

Embodiment 3

[0065] A high-hardness, high-toughness ZW552 steel for roadheader cutter rings, the chemical composition and percentage of the steel are:

[0066] C 0.51%,

[0067] Si 0.20%,

[0068] Mn 0.37%,

[0069] Cr 5.13%,

[0070] Mo 2.32%,

[0071] V 0.60%,

[0072] Nb 0.008%,

[0073] P 0.011%,

[0074] S 0.0010%,

[0075] Ni 0.010%,

[0076] Cu 0.005%,

[0077] Ti 0.003%,

[0078] The balance is Fe and unavoidable impurities;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com