Method for manufacturing crushing pellet sinter

A manufacturing method and a technology for sintering ore, which are applied in the field of blast furnace ironmaking, can solve problems such as difficult implementation, poor green ball strength, and difficult control, and achieve the effects of simplified operation, increased stacking angle, and favorable low-temperature reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

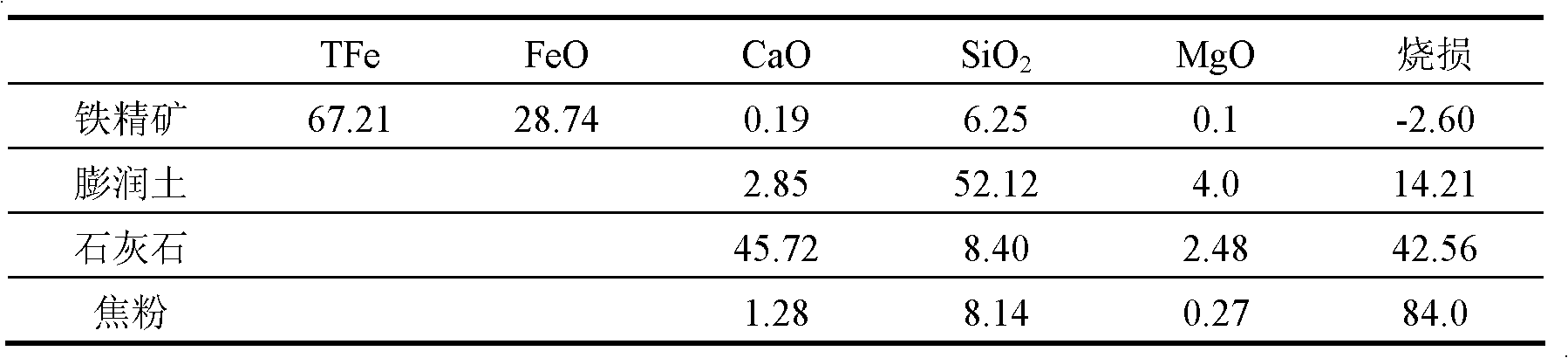

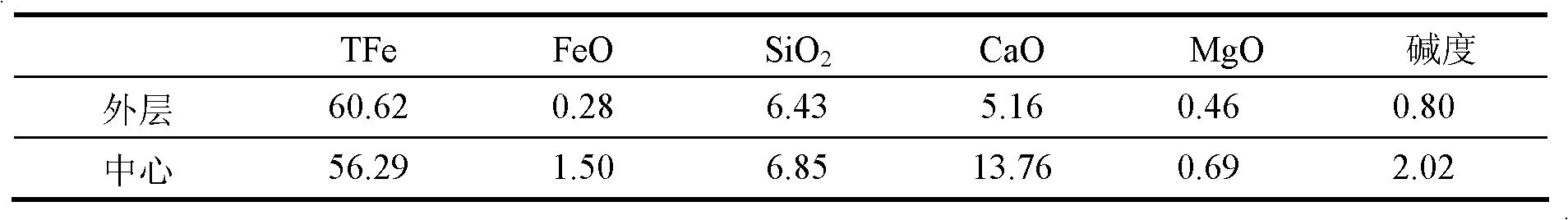

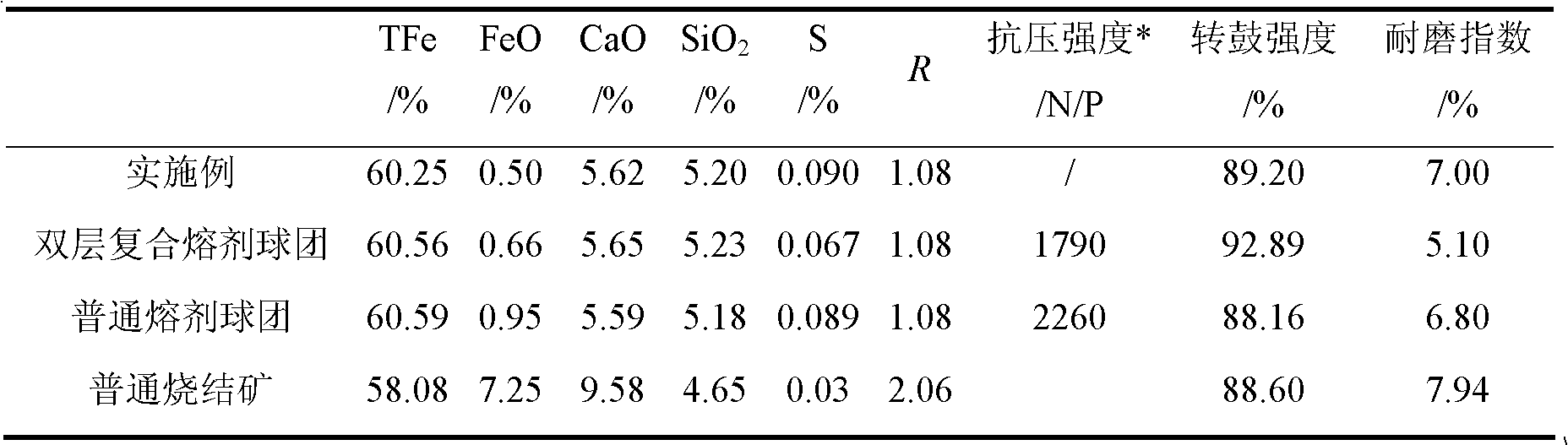

[0018] Below by embodiment the present invention will be further described.

[0019] In the embodiment of the present invention, double-layer green pellets are prepared in two steps on a disc pelletizer. The diameter of the pelletizing machine is 1000mm, the rotating speed is 32 rpm, and the inclination angle is 47°. The ball-making process is divided into three stages: cue ball formation, cue ball growth, and raw ball compaction. First, add the mixed high-alkalinity materials into the rotating pelletizer with a small shovel, add water to make cue balls, and then continuously add water and feed materials. The amount of each batch is 10kg, so that the cue balls grow to a diameter of 25-30mm. Use a 25mm sieve to sieve out the raw balls of the particle size, clean the pelletizing disk, and then pour it into the pelletizing disk for secondary pelletizing of the low-alkalinity flux material rolled out. After the green balls are rolled tightly for 2 minutes When the diameter reach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com