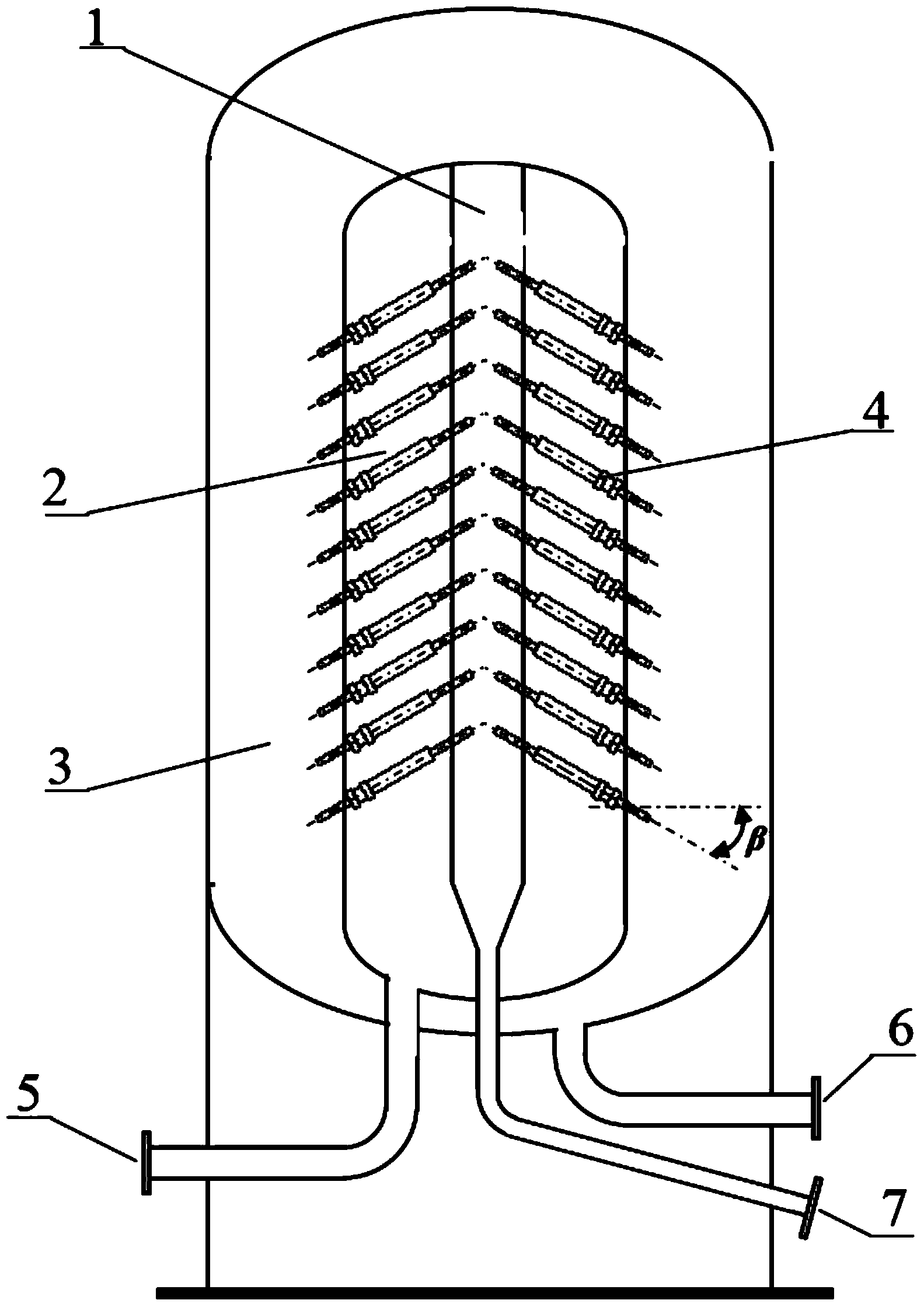

Inverted inclined installation method and device for long-period continuous stable operation of liquid-solid micro cyclone separator

A technology with stable operation and installation method, which is applied in the direction of centrifugal separation water/sewage treatment, etc., and can solve problems such as the blockage of the bottom outlet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

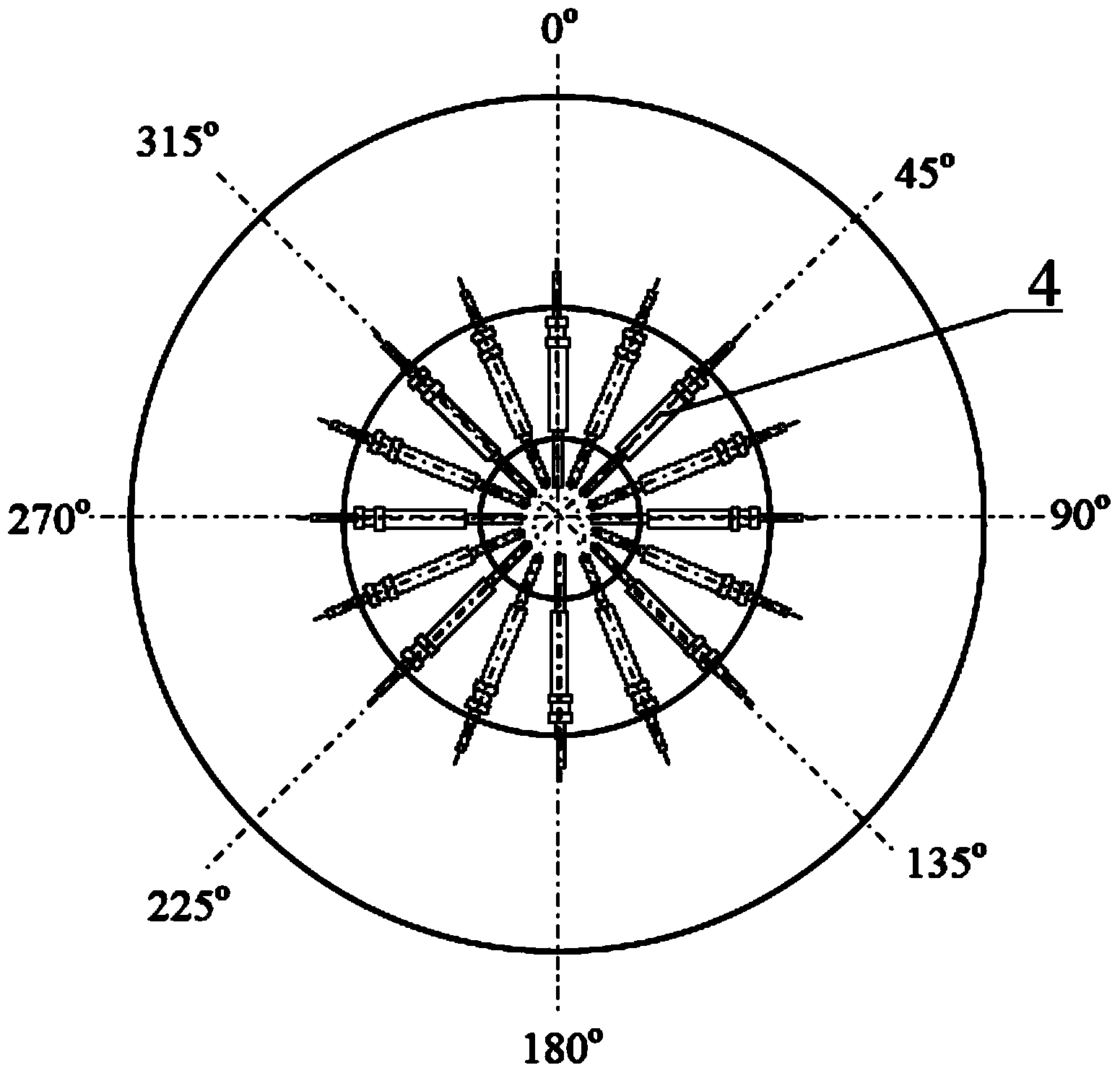

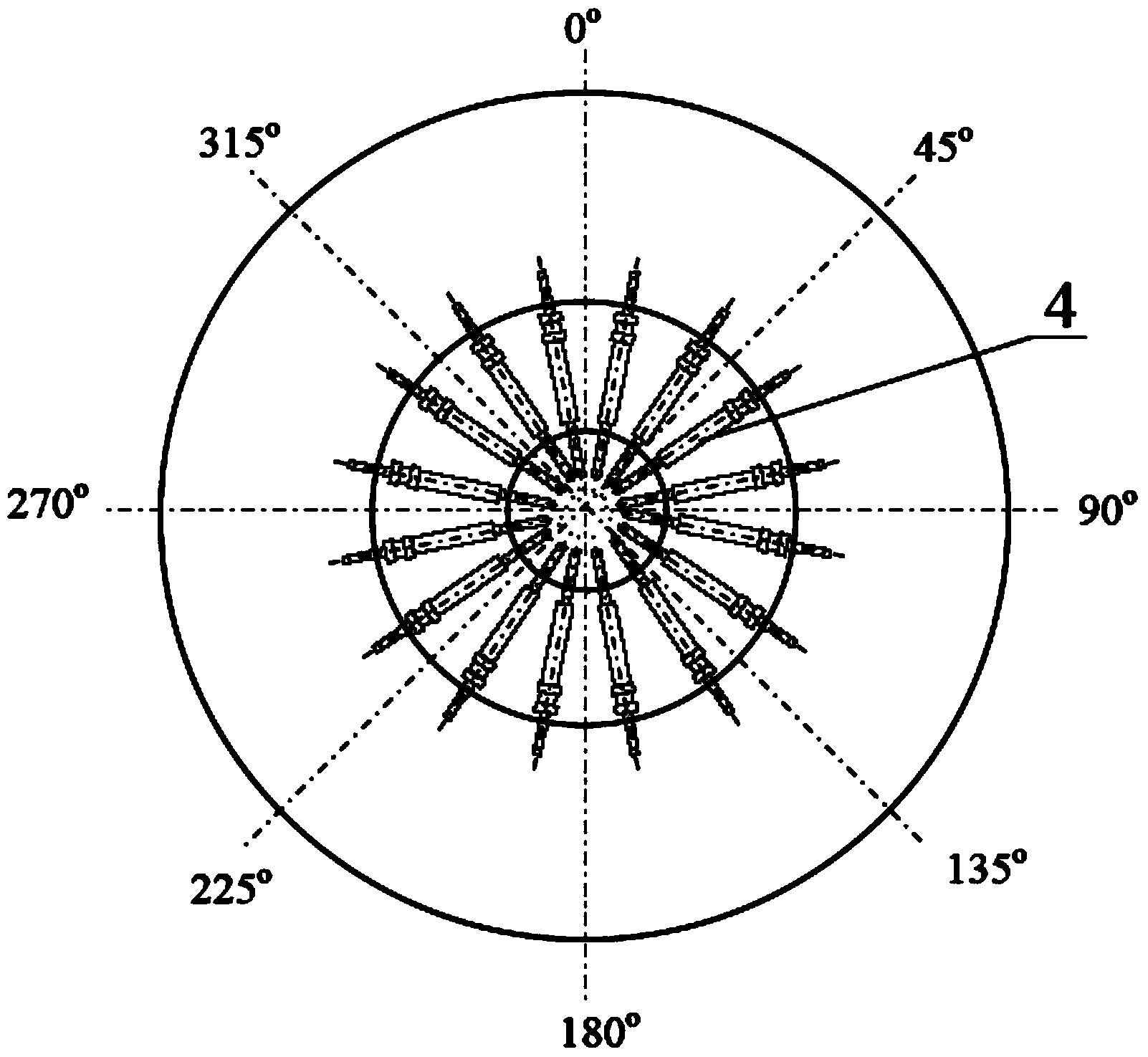

Method used

Image

Examples

Embodiment 1

[0085] The quenching water system of Baotou MTO plant of China Shenhua Group adopts the device of the present invention, wherein the catalyst particle diameter of the catalyst particle micro-cyclone separator is 1-20 μm, the content is 100-1000 mg / L, and the bulk density is 1200 kg / m3 3 , the particle accumulation angle of repose is 40°; a nominal 25mm micro-swirl core tube is used, with b and h 3 Replace h in the above formula (1) and formula (2) respectively o填充 and h u填充 (In the two installation ways, the particle deposition height reaches b and h respectively 3 indicates that the micro-swirl core tube has been blocked), get

[0086] V hy C i ρ p · N = 1 4 π ( D 2 - ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com