Bin level testing method

A technology of material level detection and detection device, which is applied in the direction of measuring device, liquid/fluid solid measurement, liquid level indicator for physical variable measurement, etc., can solve the problem that the sensor cannot be selected, the signal accuracy and stability are difficult to guarantee, and the price of the sensor Advanced problems, to achieve the effect of wide application, high reliability, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

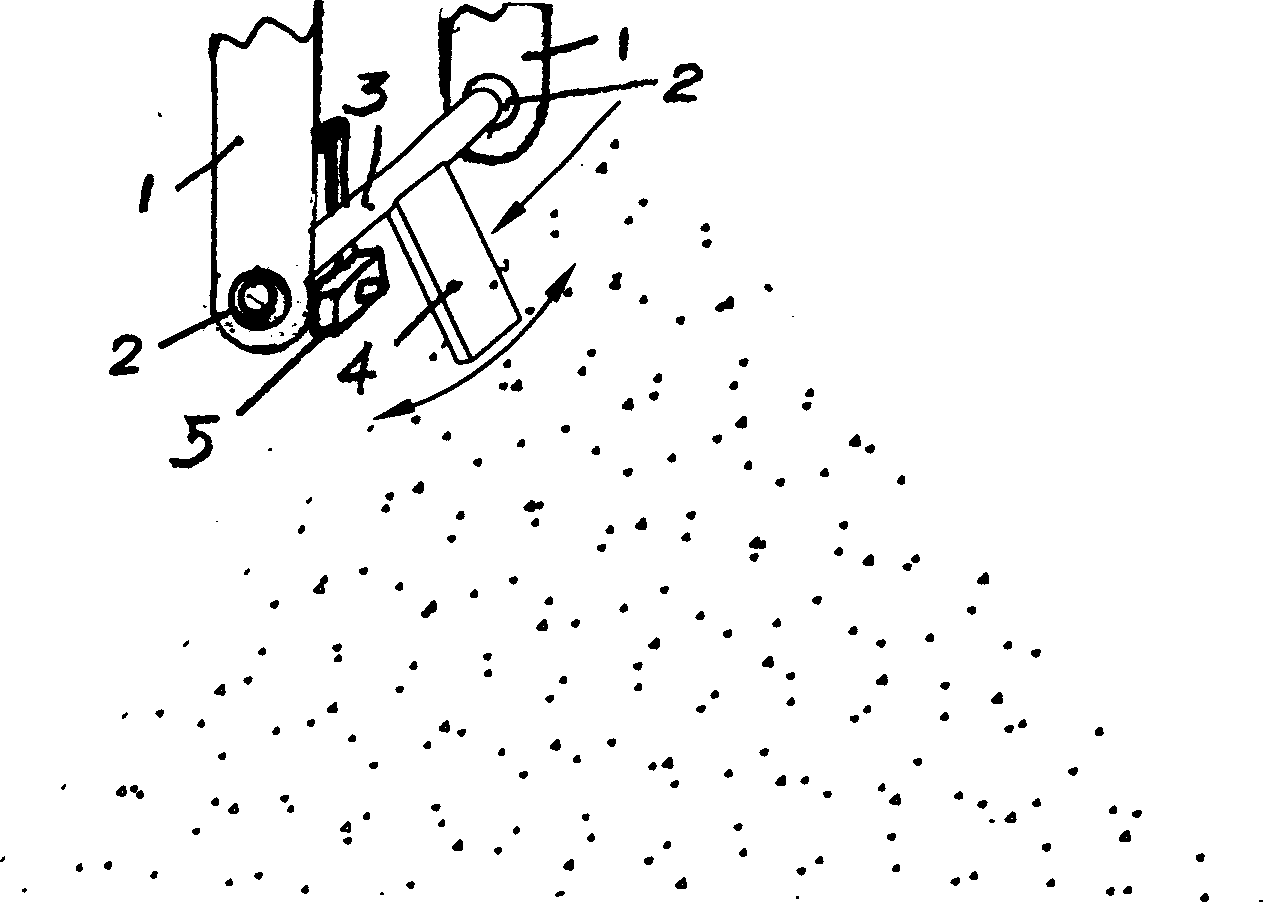

[0020] Brief description of structure and working principle

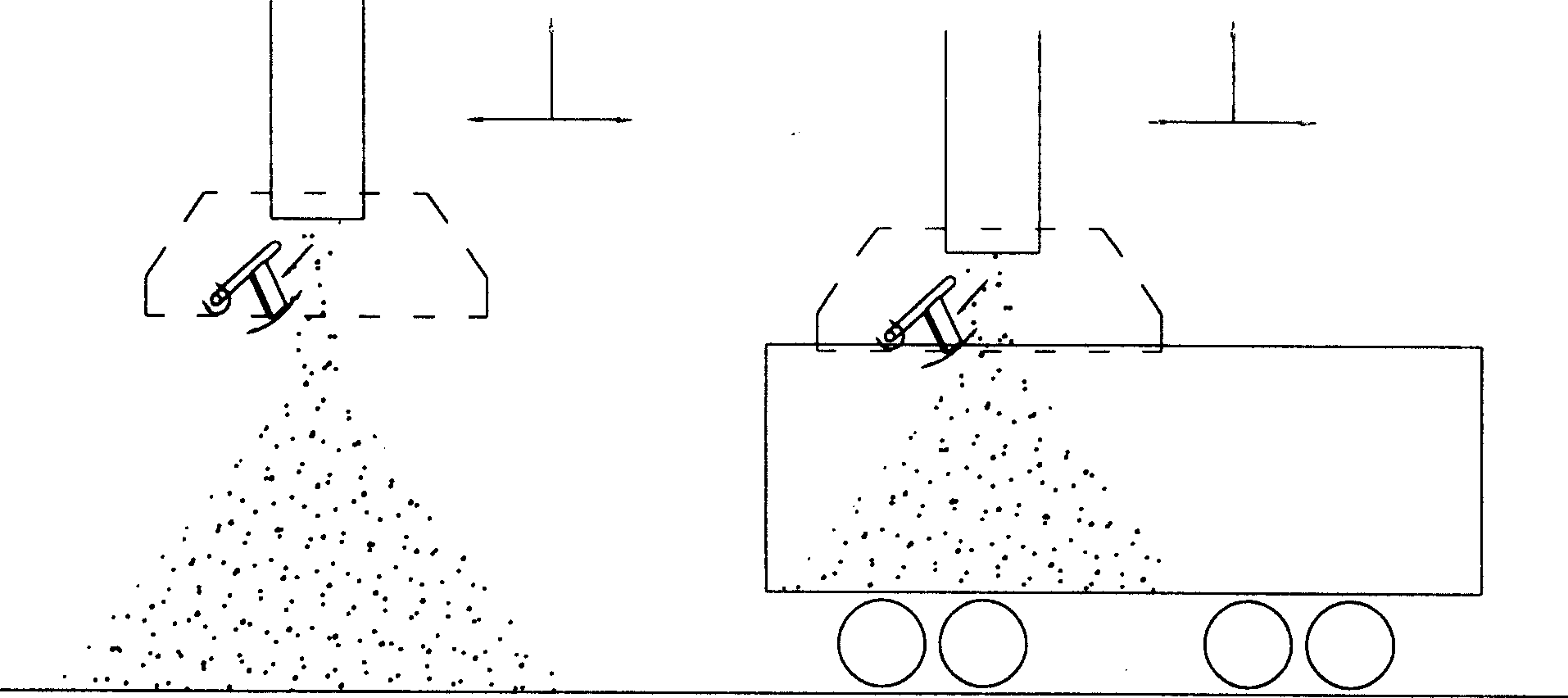

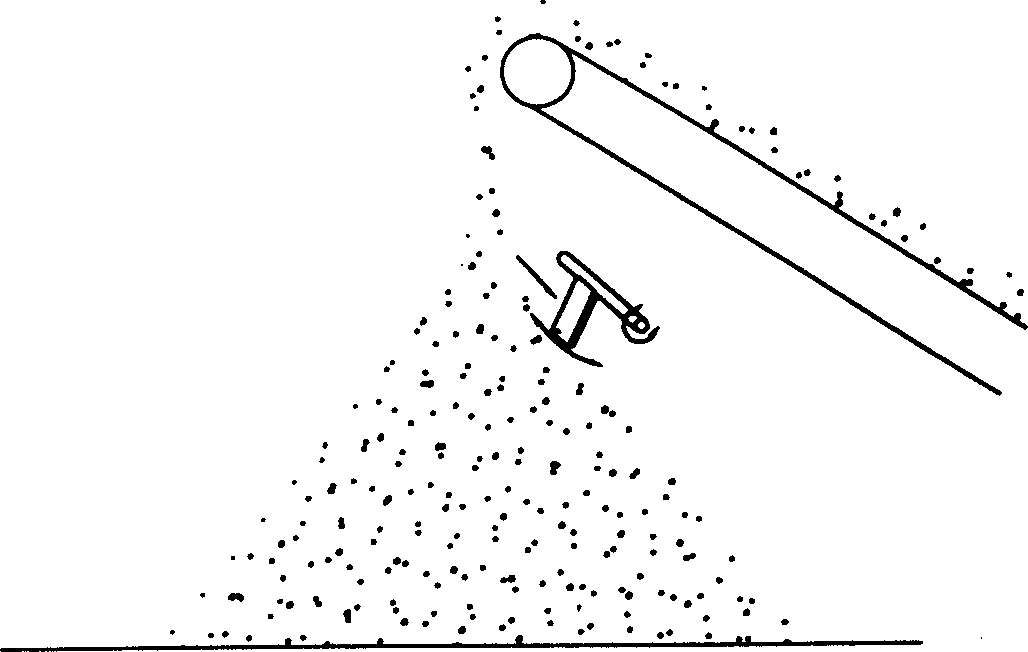

[0021] figure 1 In the material level detection method shown, a freely rotating or swinging object is installed at the position where the material level signal needs to be obtained. The material will flow downward along the angle of repose, and the material that has contacted the device object will push the device object to generate displacement when it flows downward, and the displacement is the signal that the material reaches the position. The displacement signal can be converted into an electrical switch signal through a proximity switch or a travel switch.

[0022] The object that can rotate freely and swing is that a bearing 2 is arranged on a fixed frame 1, and the bearing is equipped with a shaft 3, and a swing plate 4 is installed on the shaft; a displacement signal detection device 5 is installed near the swing plate on the fixed frame. The displacement signal detection device may be a travel switch. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com