Method and Apparatus for Modifying a Cargo Container to Deliver Sand to a Frac Site

a technology for frac sites and cargo containers, applied in the direction of loading/unloading, packaging, well accessories, etc., can solve the problems of insufficient viscosity, permeability or reservoir pressure, and the amount of proppant such as sand used can cost five or six million dollars, and the bulk of the cost of sand is for handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

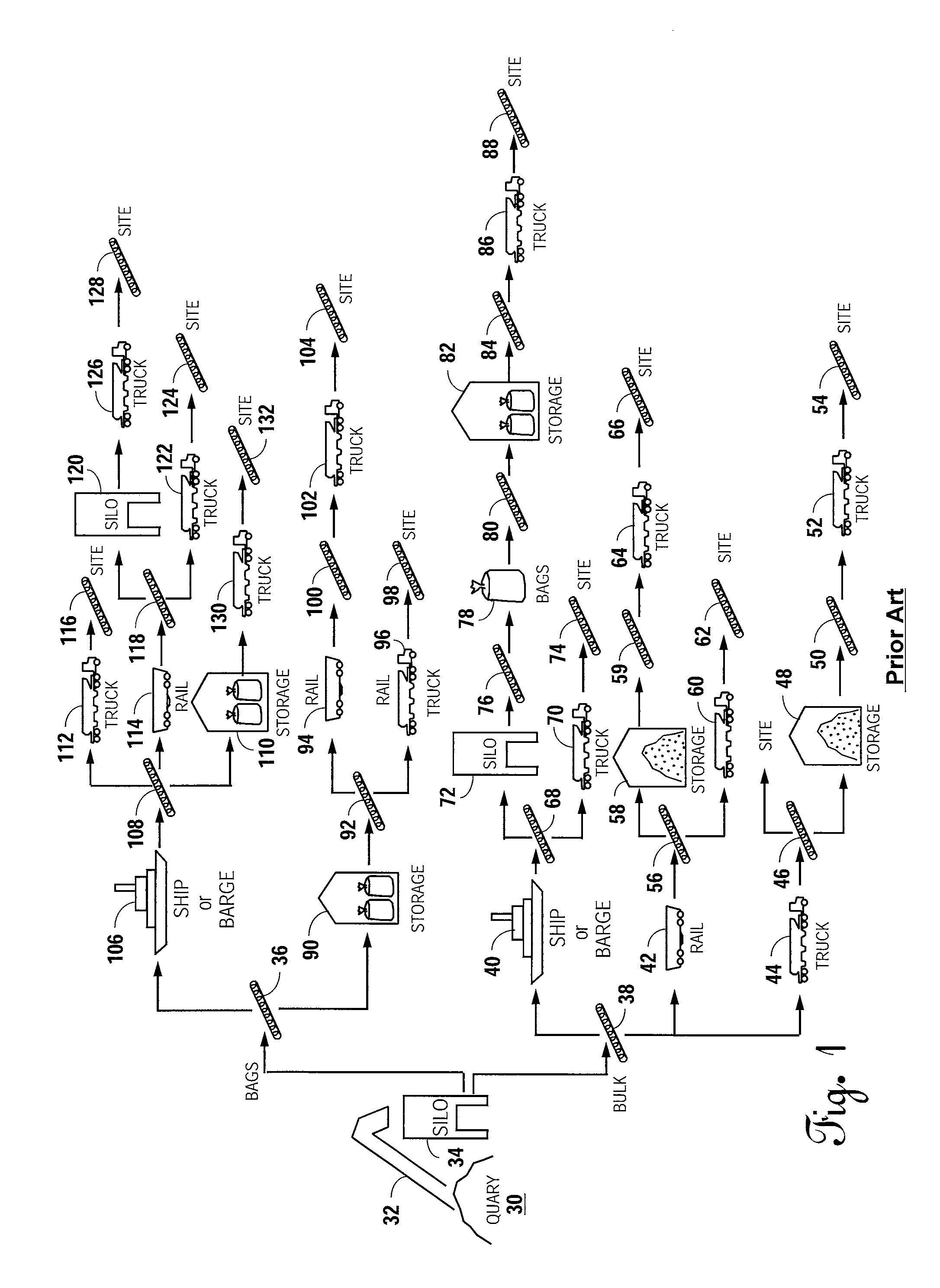

[0042]Referring first to FIG. 1, fracing sand may be produced in a quarry 30, which sand is loaded to an elevator 32 into a sand silo 34. From the sand silo 34, sand may be loaded by conveyer 36 into bags or is left in bulk by conveyer 38 into a ship or barge 40, rail car 42, or truck 44.

[0043]Referring first to the truck 44, the truck 44 may be unloaded by conveyer 46 at the site or at the storage 48. While shown as conveyer 46, any other type of unloading / loading device can be used, such as a pneumatic pump. From storage 48, the sand may be reloaded by conveyer 50 onto truck 52 for unloading by conveyer 54 at the site.

[0044]If the fracing sand comes by rail car 42, rail car 42 may be unloaded by conveyer 56 into storage 58 or truck 60. If loaded into truck 60, then the sand would be unloaded by conveyer 62 at the frac site. If the sand goes through storage 58, it will later have to be loaded by conveyer 59 onto trucks 64 and then unloaded at the frac site by conveyer 66.

[0045]If t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com