Preparation method of ibuprofen spherical crystal

A technology of spherical crystals and spheres is applied in the field of preparation of spherical ibuprofen crystals to achieve the effects of reducing industrialization costs, preventing agglomeration and having good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Prepare 150 mL of 0.01 g / mL ibuprofen-water mixed solution at 75°C, stir until liquid-liquid phase separation occurs and ibuprofen droplets are evenly distributed in the water;

[0029] (2) Cool the solution to 1° C. at a cooling rate of 50° C. / 10 min, maintain a stirring rate of 600 rpm until crystallization, and add 0.02% surfactant sodium stearate (based on the quality of the ibuprofen-water mixed solution). Stir continuously for 0.5h to make the crystals coalesce into compact spheres;

[0030] (3) After vacuum filtration, washing with water, and drying at normal pressure at 30° C. for 12 hours, spherical ibuprofen crystals were obtained.

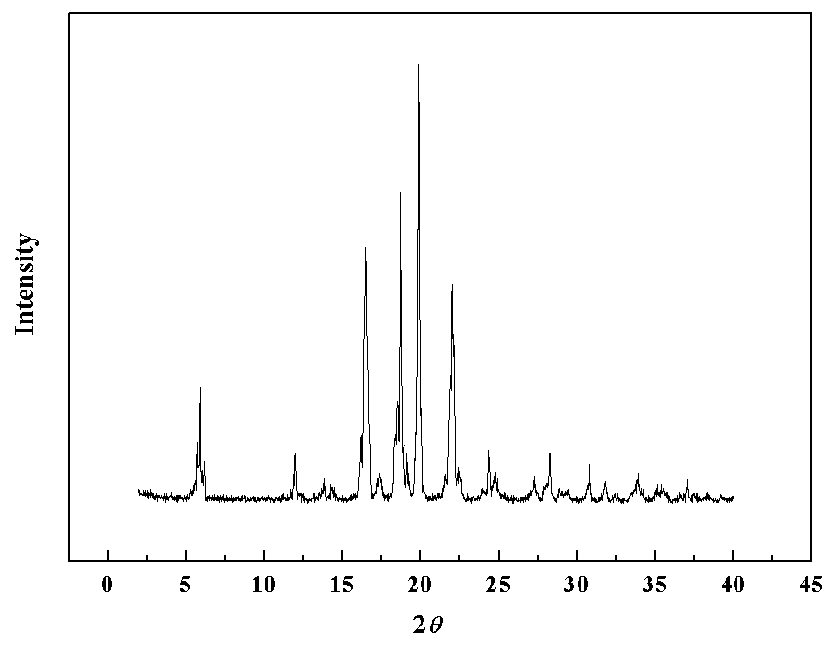

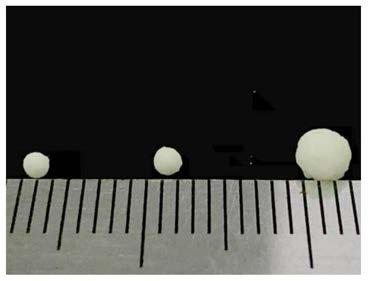

[0031] The XRD pattern of the product is shown in figure 1 , it can be seen that the product is a stable crystal; the average particle size of spherical particles is 500 microns, the angle of repose is 29°, and the tap density is 0.47g / cm 3 .

Embodiment 2

[0033] (1) At 80°C, prepare 150 mL of a 0.10 g / mL ibuprofen-water mixed solution, stir until liquid-liquid phase separation occurs and the ibuprofen droplets are evenly distributed in the water;

[0034] (2) Cool the solution to 5°C at a cooling rate of 45°C / 10min, maintain a stirring rate of 450rpm until crystallization, and add 0.15% surfactant sodium hexametaphosphate (based on the quality of the ibuprofen-water mixed solution). Continue to stir for 2 hours to make the crystals coalesce into compact spheres;

[0035] (3) After vacuum filtration, washing with water, and drying at 40° C. under normal pressure for 24 hours, spherical ibuprofen crystals were obtained.

[0036] The XRD pattern of the product is shown in figure 1 , it can be seen that the product is a stable crystal; the average particle size of spherical particles is 700 microns, the angle of repose is 29°, and the tap density is 0.55g / cm 3 .

Embodiment 3

[0038] (1) At 85°C, prepare 150 mL of a 0.15 g / mL ibuprofen-water mixed solution, stir until the liquid-liquid phase separation occurs and the ibuprofen droplets are evenly distributed in the water;

[0039] (2) The solution is cooled to 20°C at a cooling rate of 40°C / 10min, and the stirring rate is maintained at 300rpm to crystallize, and 0.40% of the surfactant sodium dodecylbenzenesulfonate (based on ibuprofen-water mixed solution) is added. quality). Continue stirring for 3 hours to make the crystals coalesce into compact spheres;

[0040] (3) After vacuum filtration, washing with water, and drying at normal pressure at 50° C. for 36 hours, spherical ibuprofen crystals were obtained.

[0041] The XRD pattern of the product is shown in figure 1 , it can be seen that the product is a stable crystal; the average particle size of spherical particles is 800 microns, the angle of repose is 30°, and the tap density is 0.50g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Angle of repose | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com