Coarse-cereal solid beverage and preparation method thereof

A technology of solid beverages and whole grains, applied in the direction of food science, etc., can solve the problems of over-bodied, complicated preparation process, high cost, etc., and achieve the effect of less nutrient loss, simple preparation process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

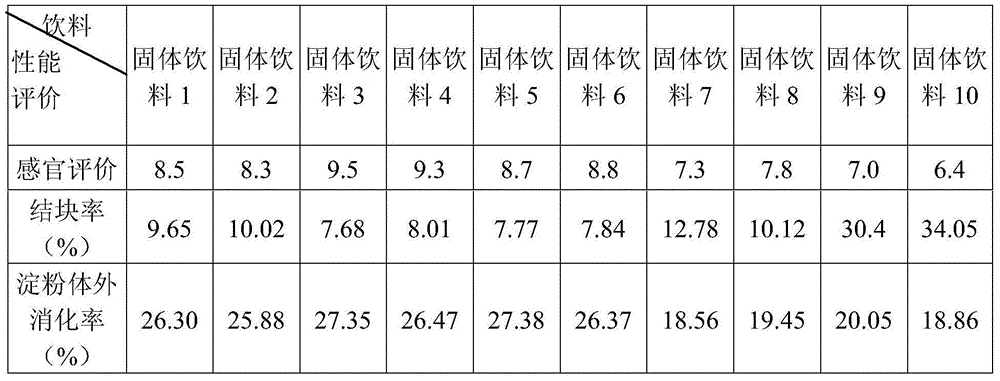

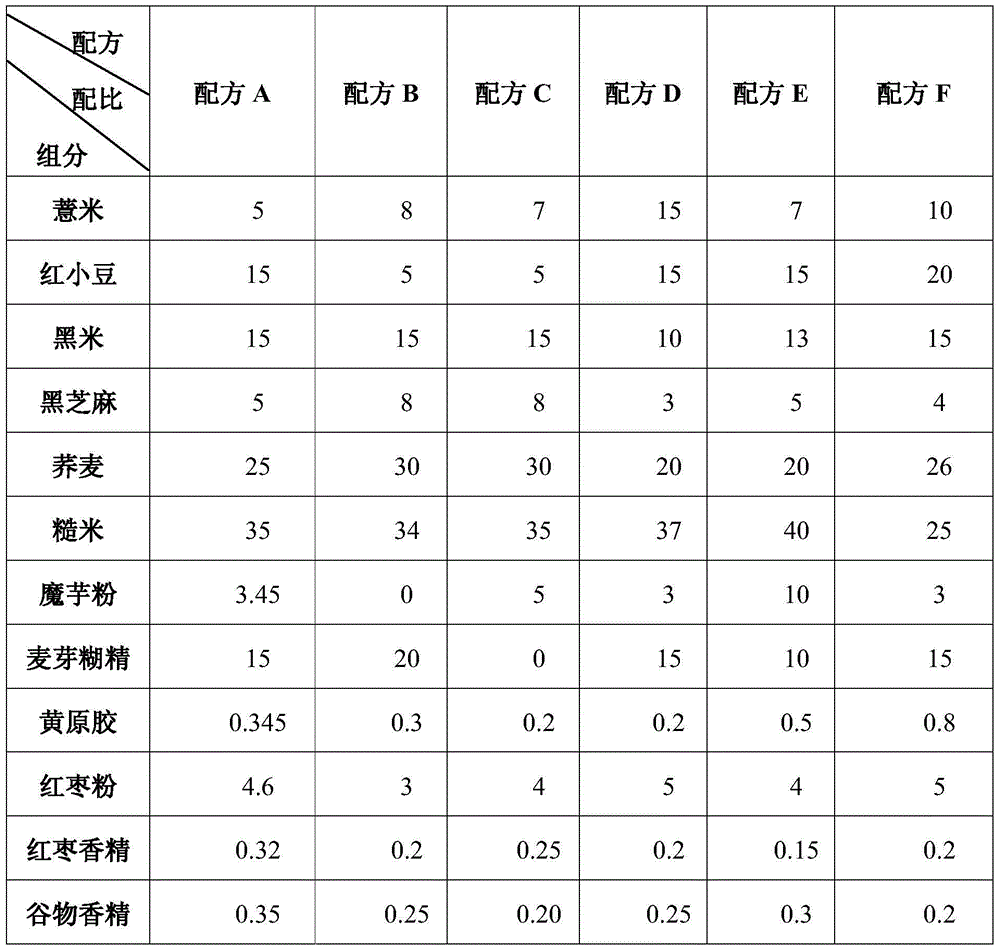

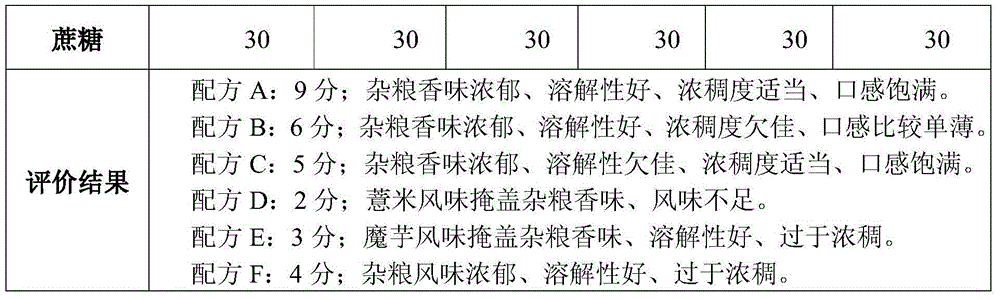

Examples

preparation example Construction

[0043] In the preparation method of whole grain solid beverage of the present invention, adopt following condition to carry out extrusion expansion:

[0044] Adjust the operating parameters of the extrusion machine as follows: the temperature in the first zone of the barrel is 70-90°C, preferably 75-85°C; the temperature in the second zone of the barrel is 110-130°C, preferably 118-122°C; the temperature in the third zone of the barrel is 110- 130°C, preferably 118-122°C; the temperature in the fourth zone of the barrel is 155-175°C, preferably 160-170°C; the feeding rate is 15-25H Z , the screw speed is 140-160r / min, preferably 150r / min, and the miscellaneous grain powder is extruded and puffed, cut and granulated at the outlet, and dried until the moisture content is ≤5%.

[0045] In addition, the boiling granulation of this invention is performed by the following method.

[0046] Put the miscellaneous grains powder into the conical container of the fluidized bed, and pass ...

Embodiment 1

[0048] The whole grain solid beverage 1 of the present invention is prepared according to the following steps.

[0049] 1) Select barley, black rice, buckwheat, black sesame, brown rice and red bean with full grains and good quality to roast according to the following conditions:

[0050] (1) Roast barley at 130°C for 10 minutes;

[0051] (2) Roast black rice at 140°C for 12 minutes;

[0052] (3) Roast buckwheat at 131°C for 10 minutes;

[0053] (4) Roast brown rice at 138°C for 10 minutes;

[0054] (5) Roast black sesame at 130°C for 10 minutes;

[0055] (6) Roast red beans at 131°C for 15 minutes.

[0056] 2) Pulverize the above-mentioned miscellaneous grain powder that has been roasted, pass through a 50-mesh grading sieve in a pulverizing equipment, and take the under-sieve. Take 5 parts of job's tears flour, 15 parts of black rice flour, 30 parts of buckwheat flour, 37 parts of brown rice flour, 3 parts of black sesame powder, and 10 parts of red bean flour, mix them...

Embodiment 2

[0058] Embodiment 2: Prepare whole grain solid beverage 2 of the present invention according to the following method.

[0059] 1) Select barley, black rice, buckwheat, black sesame, brown rice and red bean with full grains and good quality to roast according to the following conditions:

[0060] (1) Roast barley at 140°C for 8 minutes;

[0061] (2) Roast black rice at 130°C for 12 minutes;

[0062] (3) Roast buckwheat at 138°C for 10 minutes;

[0063] (4) Roast brown rice at 130°C for 10 minutes;

[0064] (5) Roast black sesame at 136°C for 10 minutes;

[0065] (6) Roast red beans at 140°C for 15 minutes.

[0066] 2) Crush the above miscellaneous grain powder, pass through a 50-mesh sieve, take 6 parts of job's tears flour, 13 parts of black rice flour, 20 parts of buckwheat flour, 36 parts of brown rice flour, 4 parts of black sesame powder, and 15 parts of red bean flour, mix well, Adjust the water content to 15%, and carry out extrusion and puffing under the following ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com