Railway goods train hook safety hook-chain mechanism

A railway freight car and safety hook technology, which is applied in railway car body parts, railway couplings, transportation and packaging, etc., can solve the problems of social security disorder, damage, loss of parts, etc., and achieves convenient use, simple repair and maintenance. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

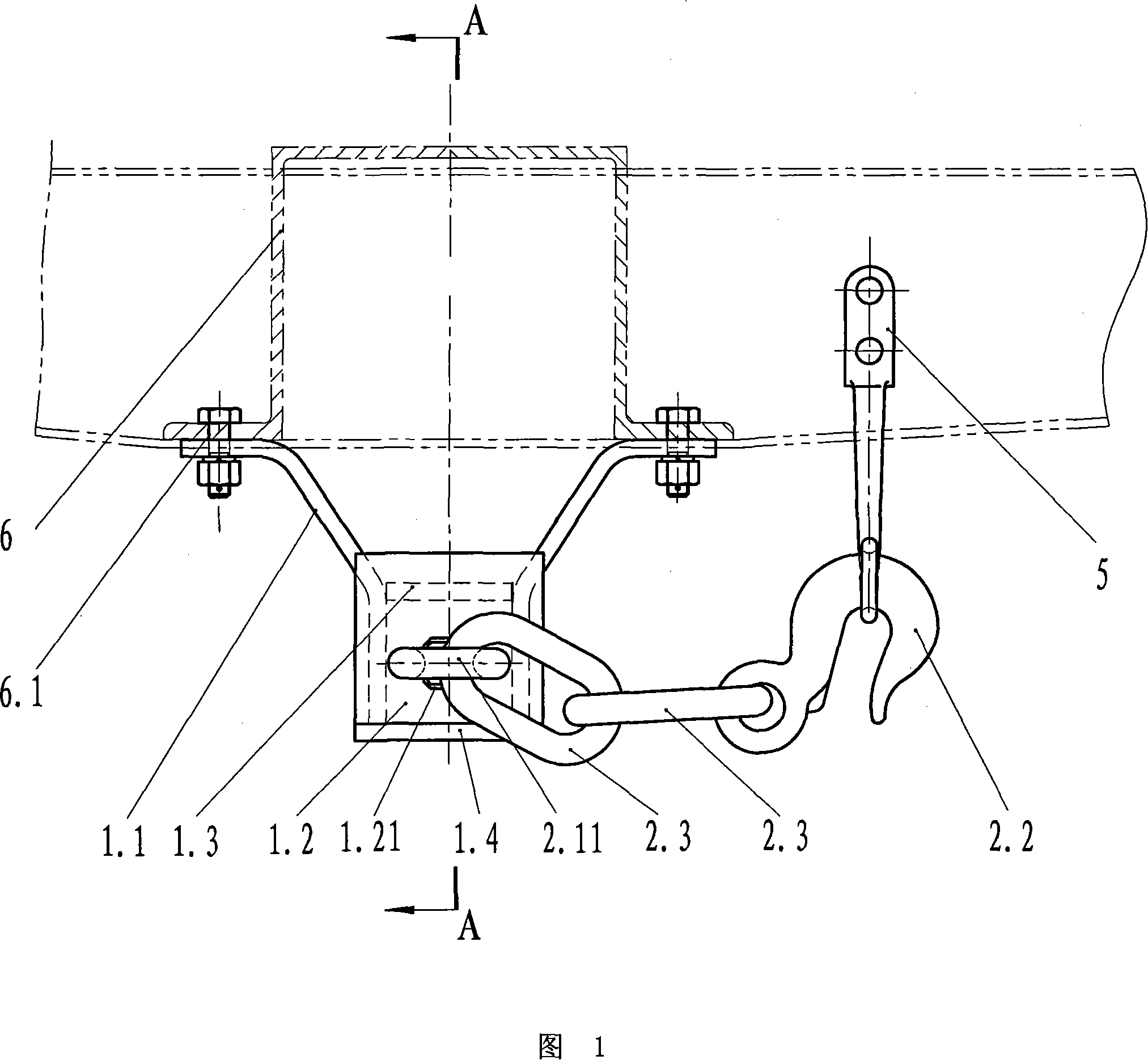

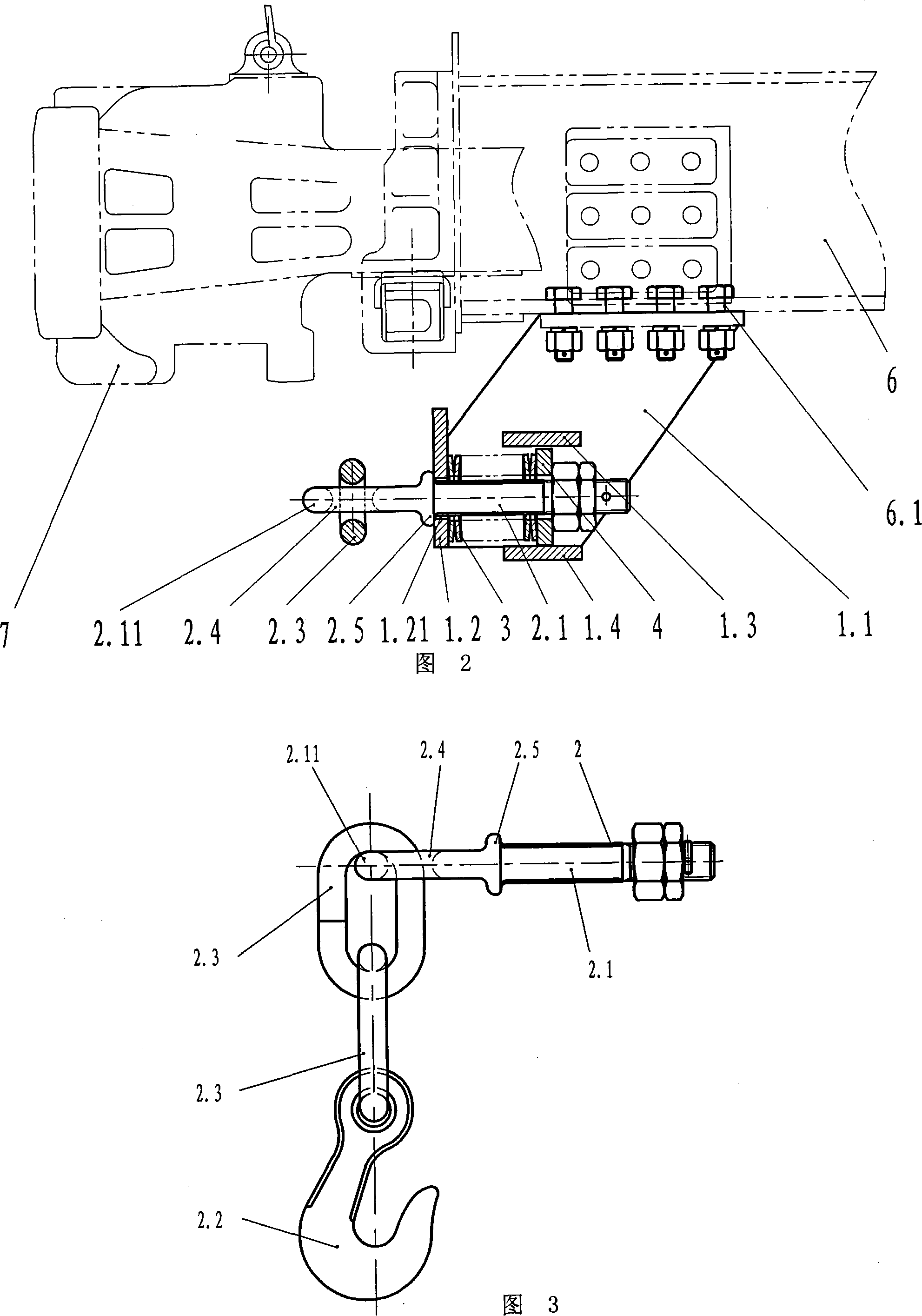

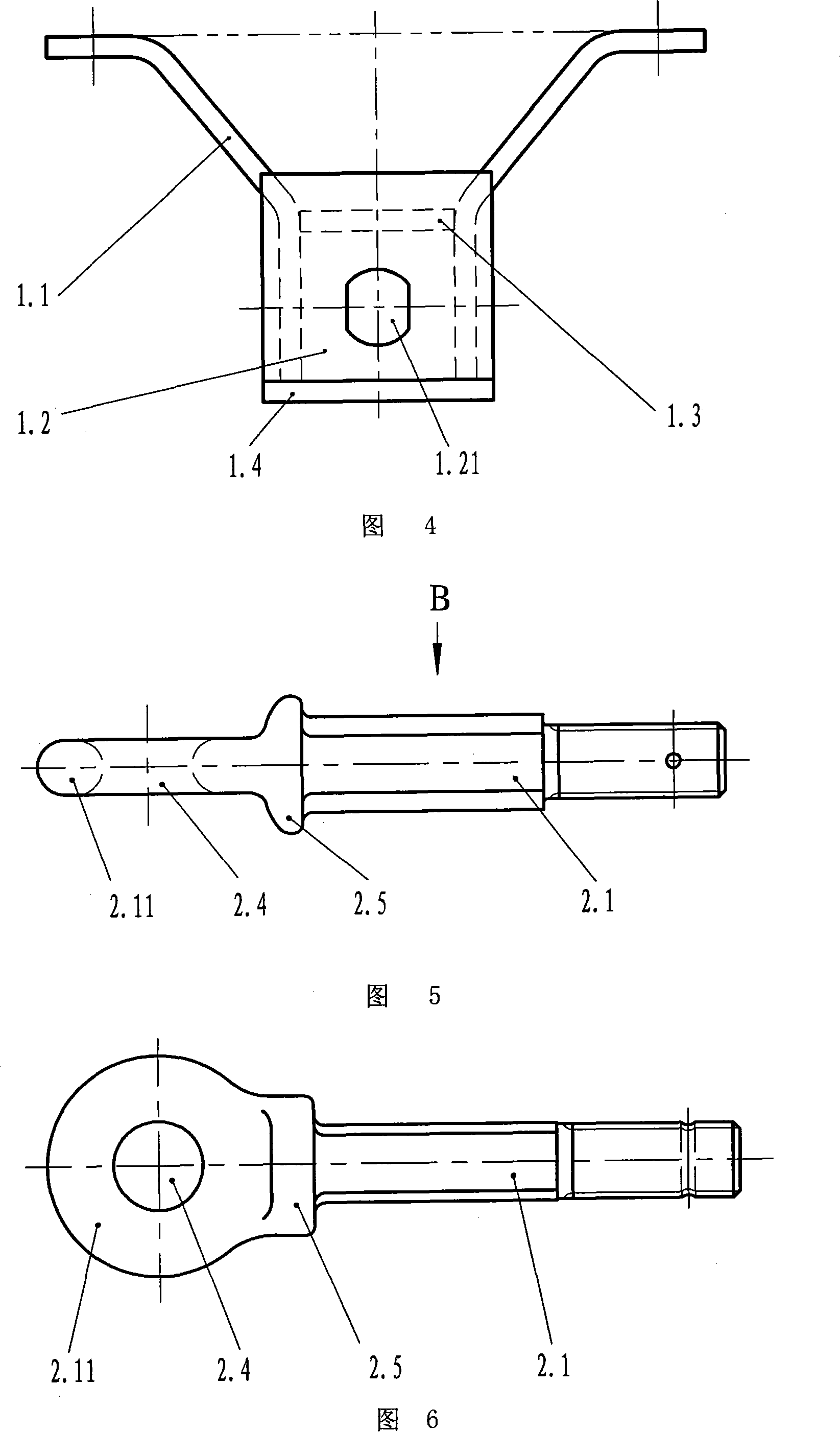

[0014] Referring to Fig. 1-Fig. 6, the present invention connects the seat plate 1.1 with bolts or rivets through the installation hole 6.1 below the end of the railway freight car draw beam 6. An upper baffle 1.3 and a lower baffle 1.4 parallel to each other are assembled and welded on the seat plate 1.1, a front baffle 1.2 perpendicular to the upper and lower baffles is welded in front of the upper and lower baffles, the upper baffle 1.3, the lower Baffle plate 1.4 and front baffle plate 1.2 constitute safety chain seat 1. A support hole 1.21 is opened on the front baffle plate 1.2, and a buffer rod body 2.1 is passed through the support hole 1.21 to be located in the safety chain seat 1, and the buffer rod body 2.1 in the safety chain seat 1 is set with a buffer spring 3, a movable stop Block 4 and nut, locking back nut, cotter pin, movable block 4 are vertically positioned between upper baffle plate 1.3 and lower baffle plate 1.4. The supporting hole 1.21 is a rectangular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com