A railway freight open wagon

A railway freight and car body technology, applied in railway car body parts, freight cars, transport passenger cars, etc., can solve the problems of unsuitable loading of light-weight cargo and small volume, and achieve increased reliability, high connection strength, and transportation functions. Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

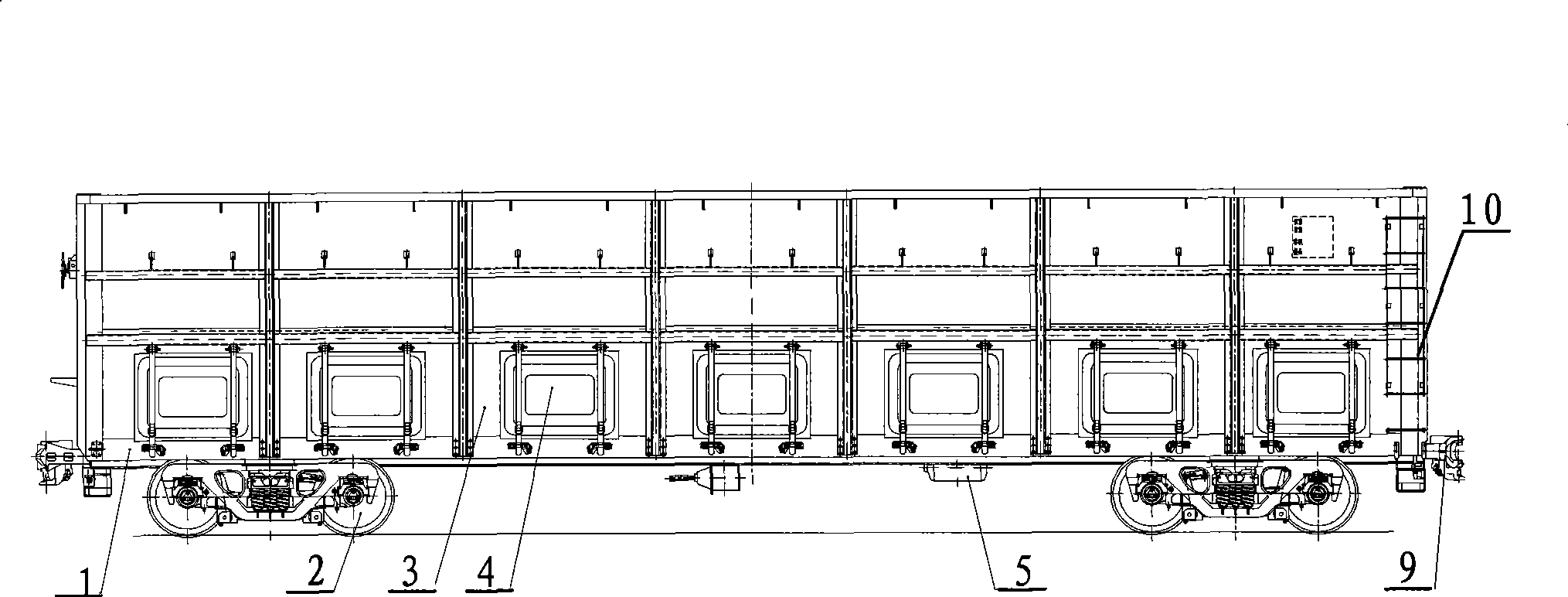

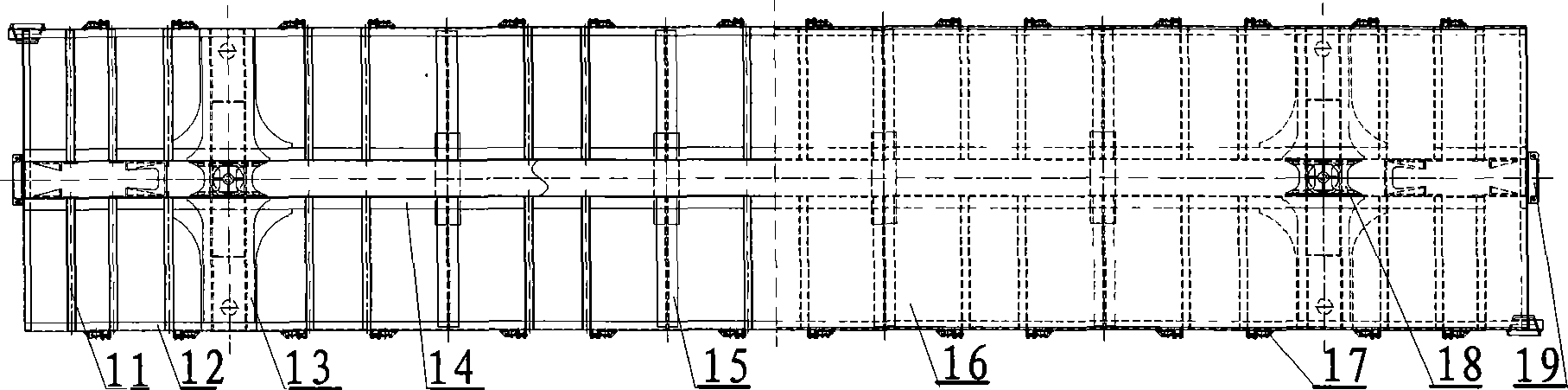

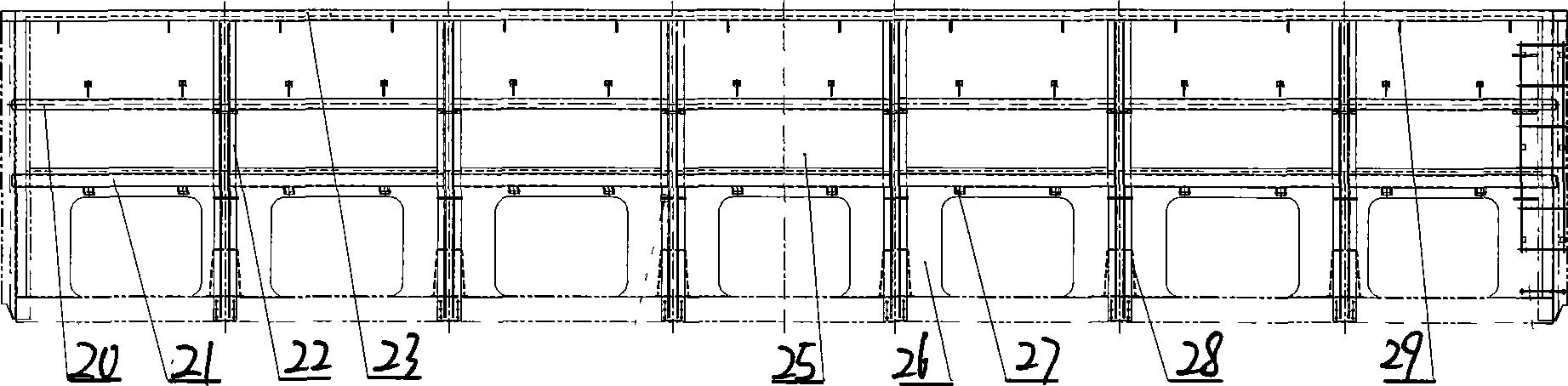

[0017] see figure 1 — Image 6 , the present invention includes car body, bogie 2, coupler buffer device 9 and wind hand braking device 5. The car body is an all-steel welded structure, and the main section steel and plates are made of high-strength weather-resistant steel, including the underframe 1, side walls 3 and end walls 10. , the small beam 11 and the end beam 19, the middle beam 14 is located in the middle of the underframe along the longitudinal direction of the underframe, the side beams 12 are parallel to the middle beam and are located on both sides of the underframe, and the end beams 19 are located at both ends of the underframe, The small crossbeam 11 and the large crossbeam 15 are installed in parallel between the side beams 12 along the transverse direction of the underframe, the corbel 13 is close to the end beam 19 and parallel to the end beam, and a cast steel integral upper is installed at the intersection of the middle beam and the corbel. Heart plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com