Patents

Literature

43results about How to "Eliminate operational safety hazards" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

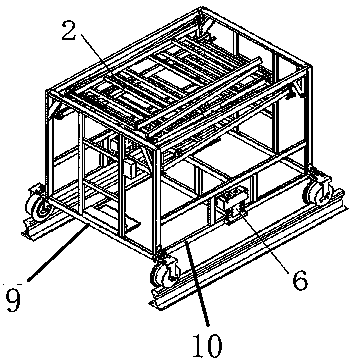

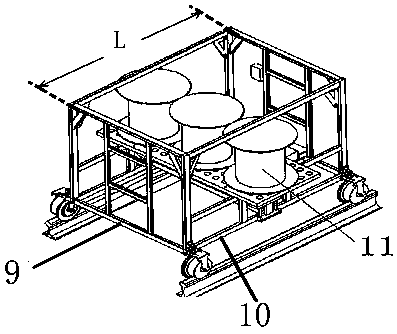

Storehouse intelligent storage system and material transferring method

InactiveCN105549596AFacilitate intelligent managementEasy to monitorPosition/course control in two dimensionsVehiclesMarine engineeringArtificial materials

The invention discloses a storehouse intelligent storage system and a material transferring method. The storehouse intelligent storage system comprises a safety storehouse, an unmanned carrier and a controller. The safety storehouse is used for storing dangerous materials which are stored in the safety storehouse in classification by a plurality of pallets; a guiding rail is paved inside the safety storehouse and the guiding rail is extended to the outside of the safety storehouse; the unmanned vehicle is provided with a communication module, a storage battery for supplying working power to the unmanned carrier and a climbing mechanism; and the controller is arranged outside of the storehouse and can perform wireless communication with the communication module on the unmanned carrier. The invention replaces the traditional artificial material conveying and reduces the labor intensity. The dangerous materials are flowed automatically, which effectively eliminates the safety hazard and improves the working efficiency. The invention benefits the intelligentized management and monitoring of the material flow information and is applicable to the unmanned management of the storehouse storing the dangerous materials like the industrial explosive in the commercial explosive industry.

Owner:CHANGSHA CTR ROBOTICS

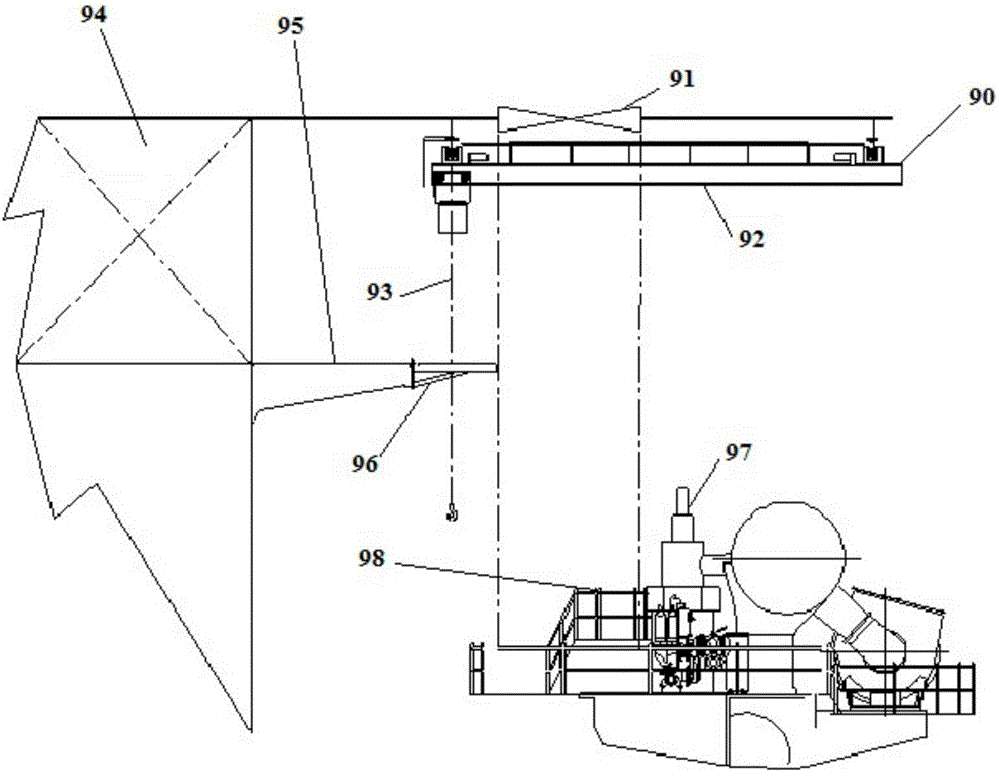

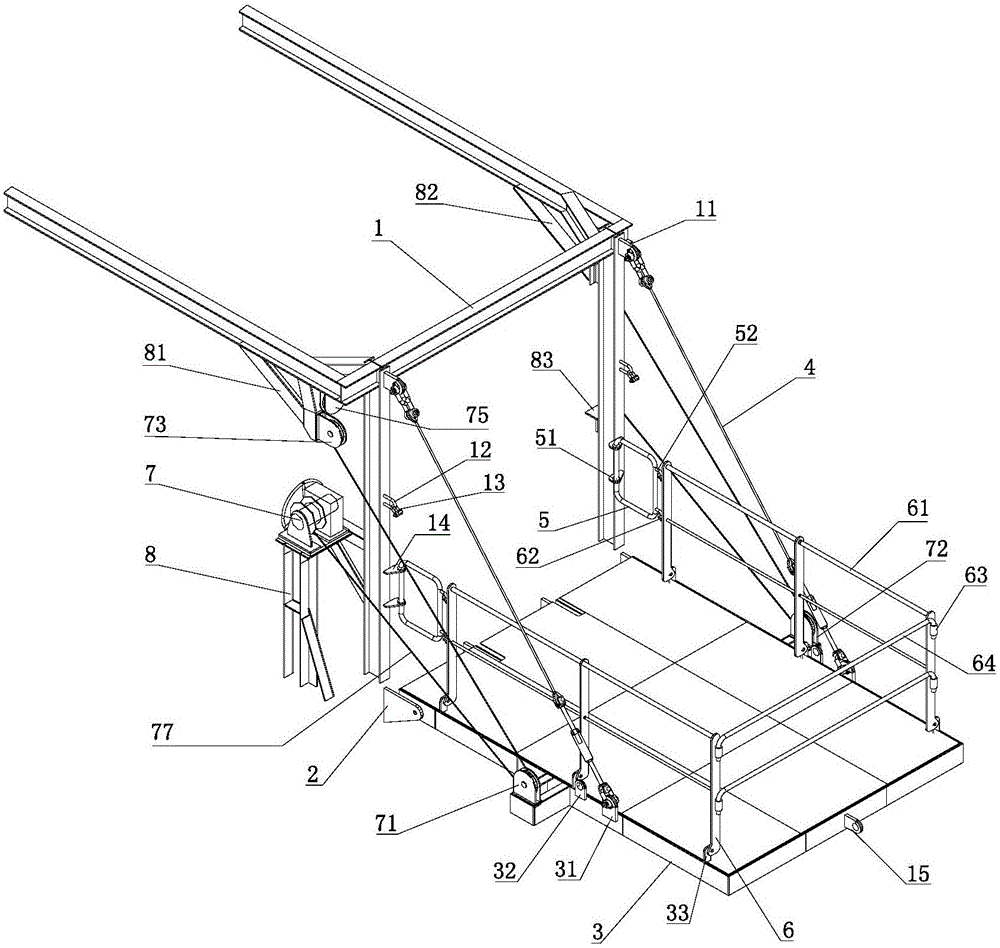

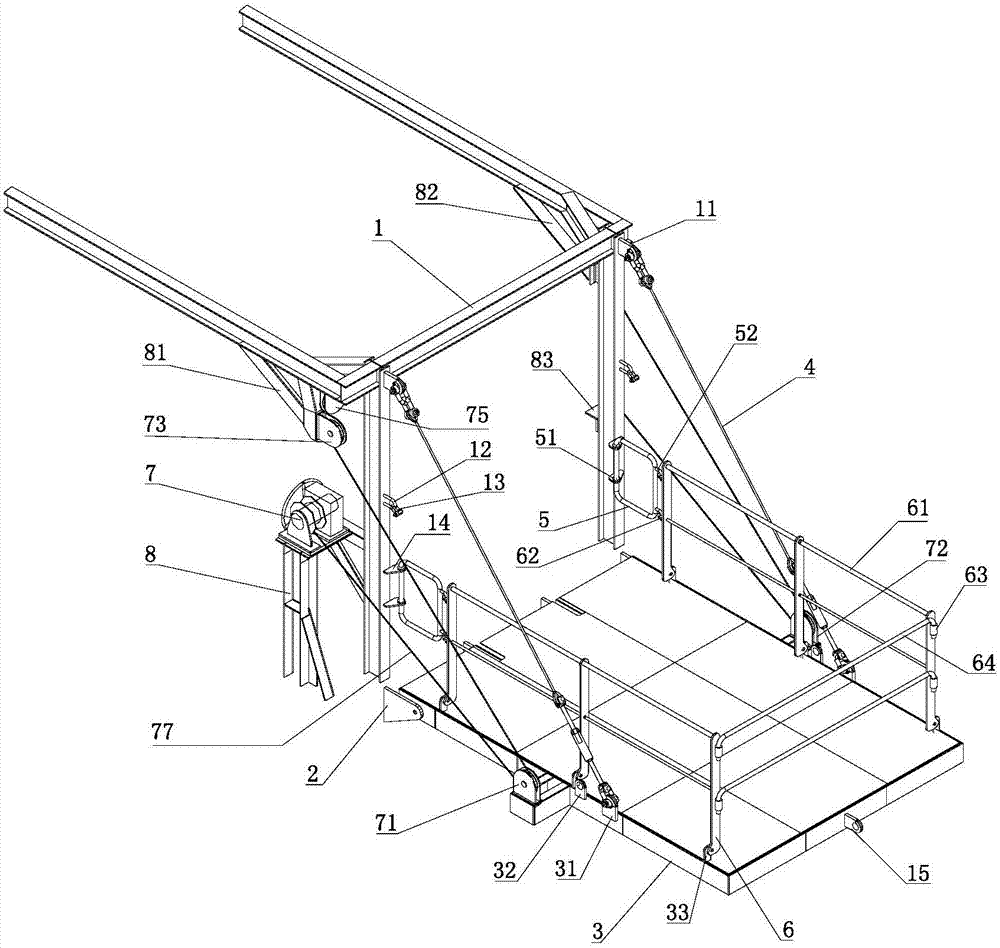

Retractable type movable hoisting platform and ship comprising same

ActiveCN105752271ATurnaround steps savedImprove lifting efficiencyCargo handling apparatusVessel partsMarine engineeringPortal frame

The invention discloses a retractable type movable hoisting platform and a ship comprising the same.The retractable type movable hoisting platform comprises a portal frame, a platform and a retractable system.The platform is arranged at one end of the portal frame, and multiple platform lug plates are hinged to the end, close to the portal frame, of the platform.The retractable system is installed between the portal frame and the platform and used for enabling the platform to rotate relative to the vertical portal frame, so that the platform is switched between a horizontal state and a vertical state.The ship comprises a cabin wall and a storeroom deck.The storeroom deck extends outwards from the cabin wall.The ship comprises the retractable type movable hoisting platform.By adopting the retractable movable hoisting platform, great convenience is brought for achieving safe goods hoisting.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD +1

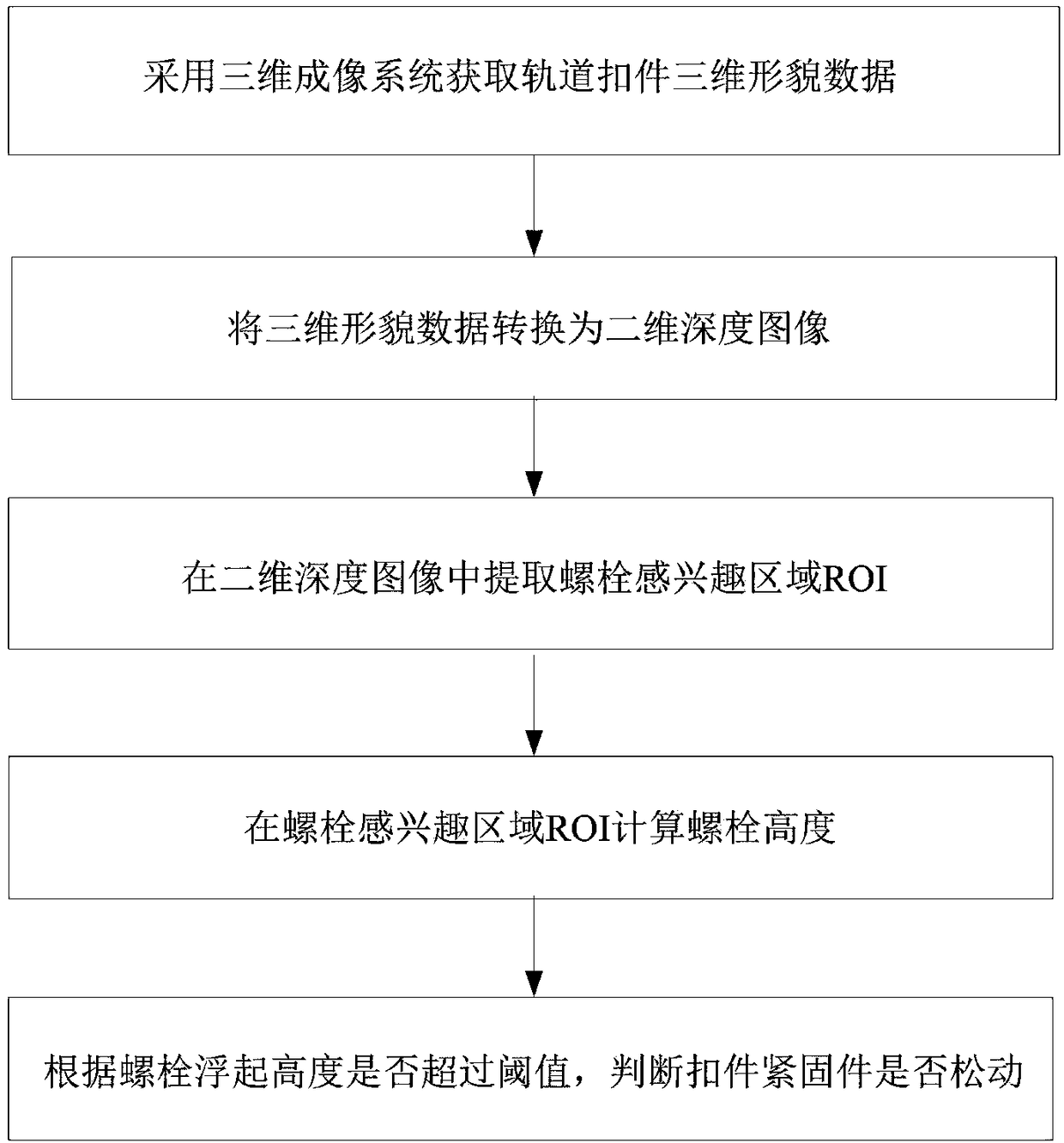

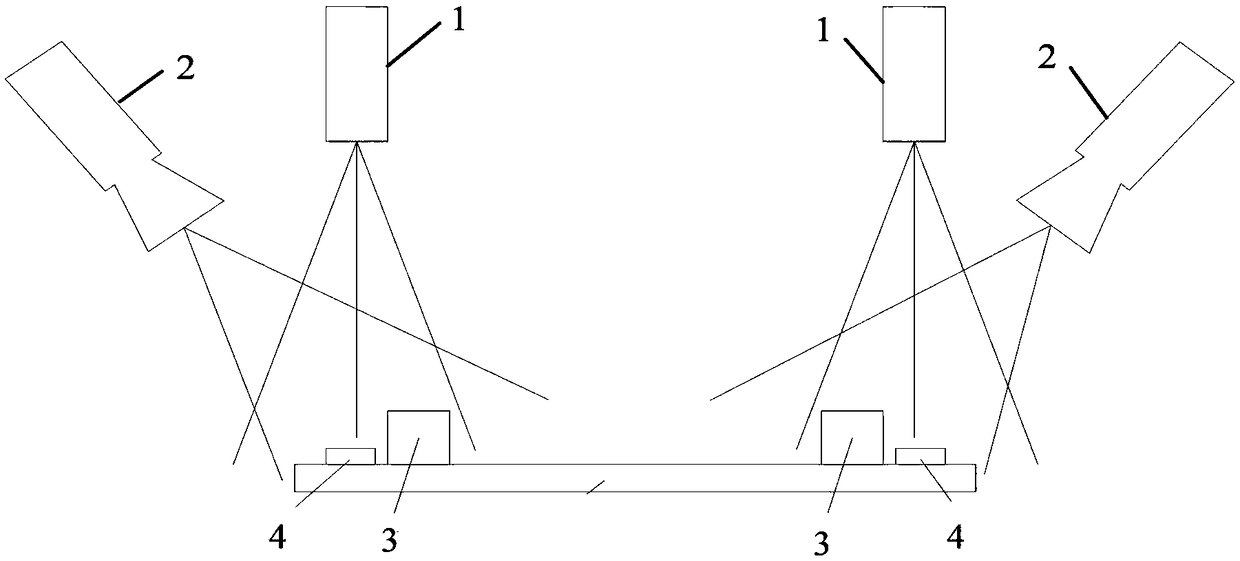

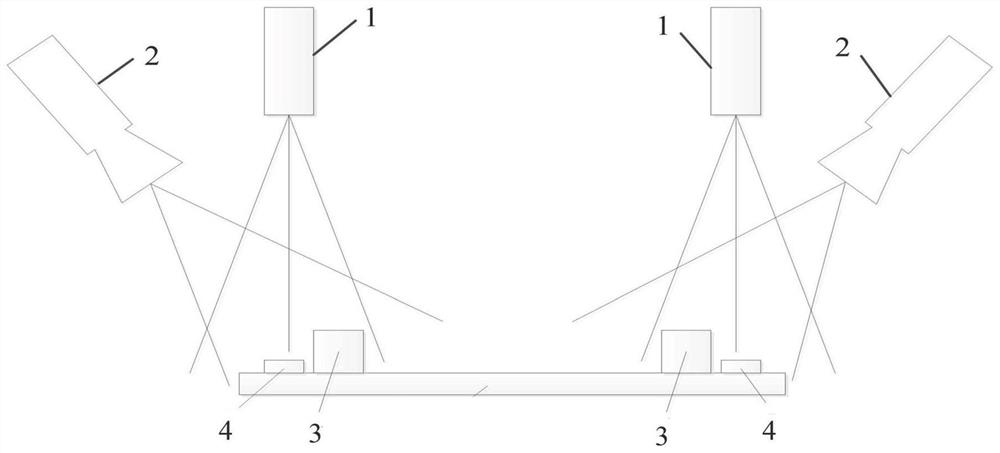

Method for detecting floating of track fastener bolts based on height comparison

ActiveCN109029283ARealize automatic detection of floatingEliminate operational safety hazardsUsing optical meansThree dimensional shapeEngineering

The invention discloses a method for detecting floating of track fastener bolts based on height comparison, which belongs to the field of railway infrastructure detection. The method mainly comprisesthe following steps of: obtaining three-dimensional shape data of the track fastener and converting the date into a two-dimensional depth image; determining an area of interest of the bolts in the two-dimensional depth image; and calculating bolt height in the area of interest of the bolts, and comparing the bolt height with reference height value when the bolts are not floating, for detecting whether the bolts are floating. The method for detecting floating of the track fastener bolts disclosed by the invention has the advantages that an existing railway fastener structure is not changed, themethod is simple and reliable, use range is wide, use mode is flexible, and the like, the loose defect of the fastener can be effectively detected in advance, and running safety of the track is guaranteed.

Owner:成都精工华耀科技有限公司

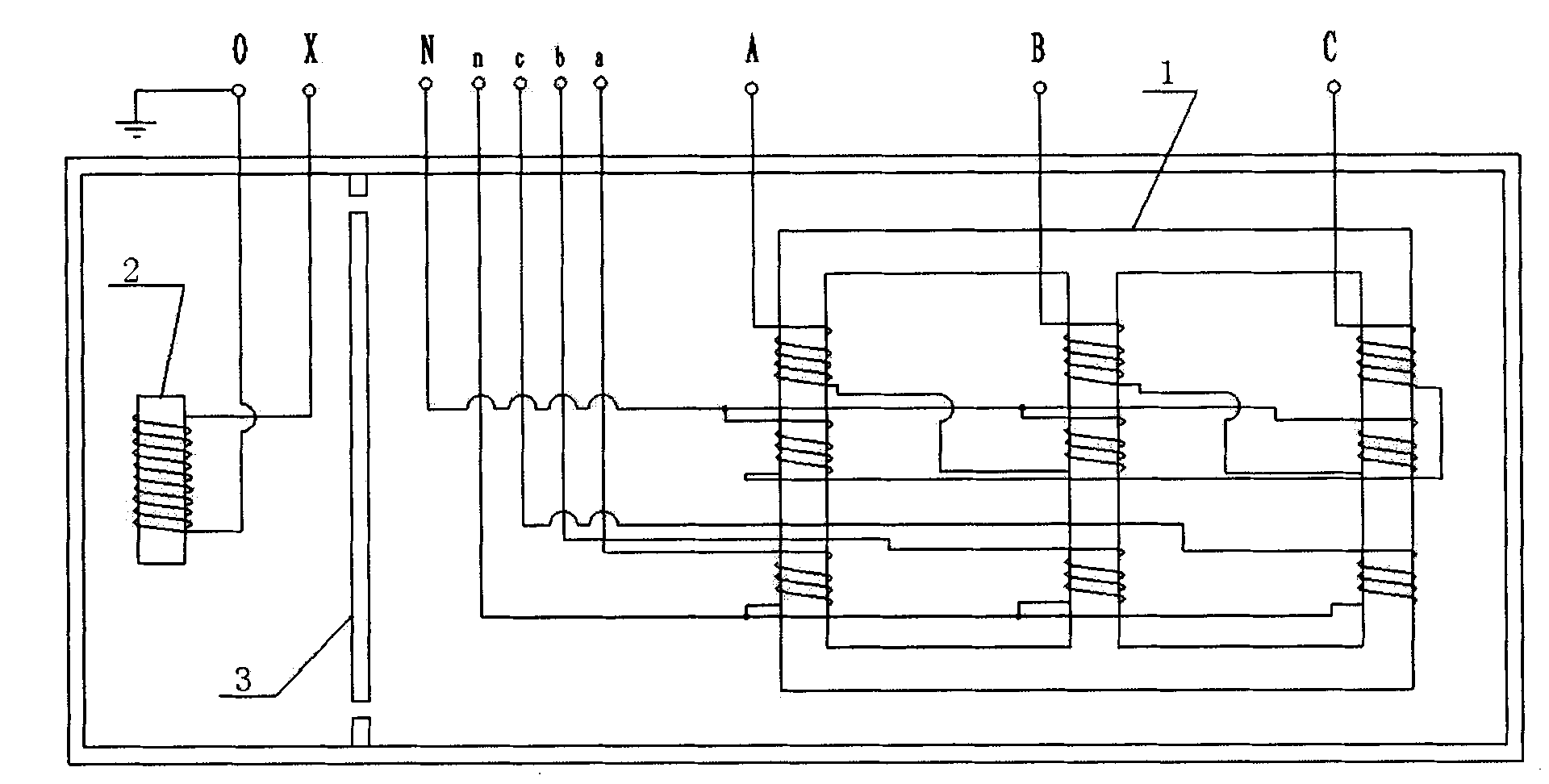

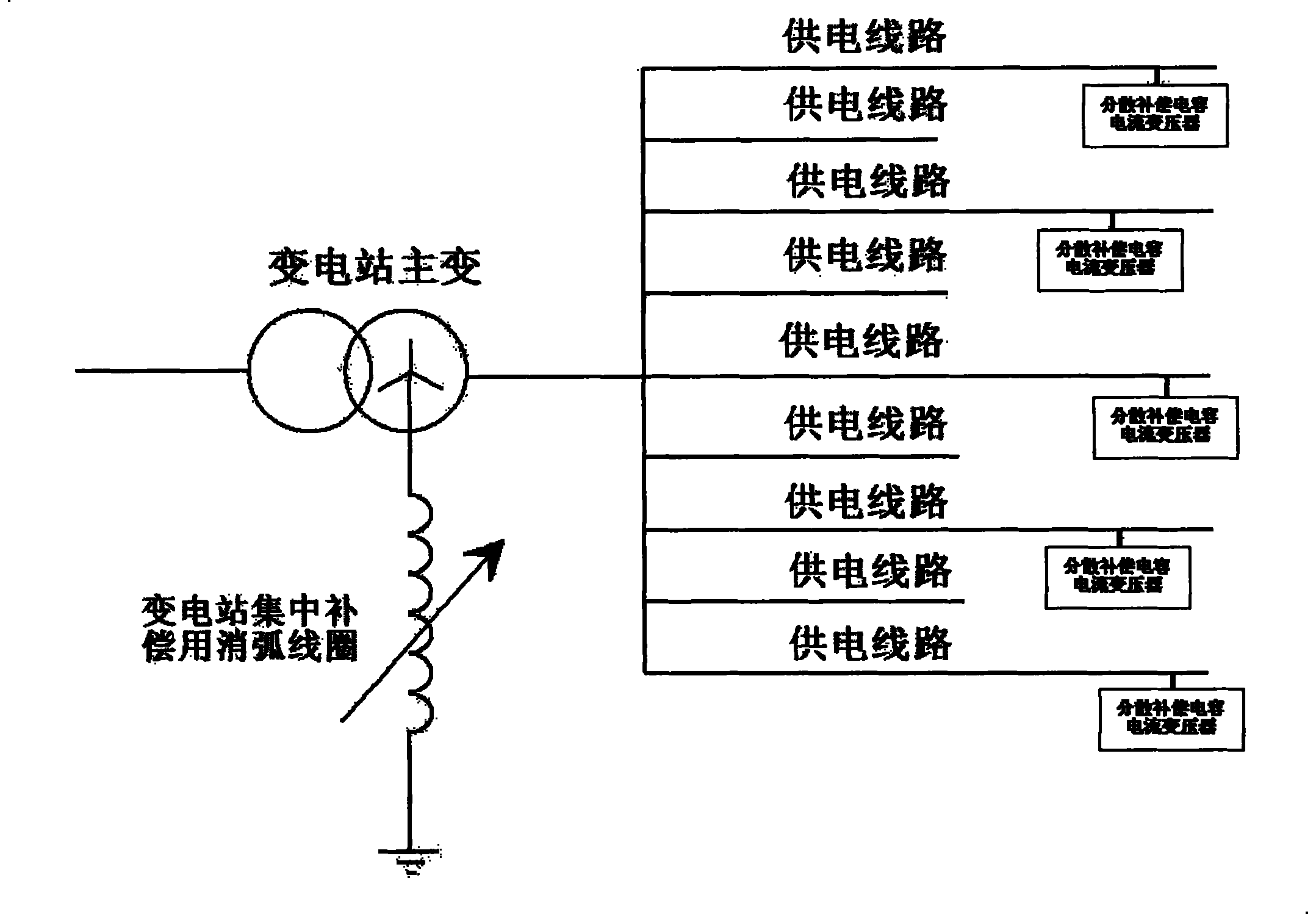

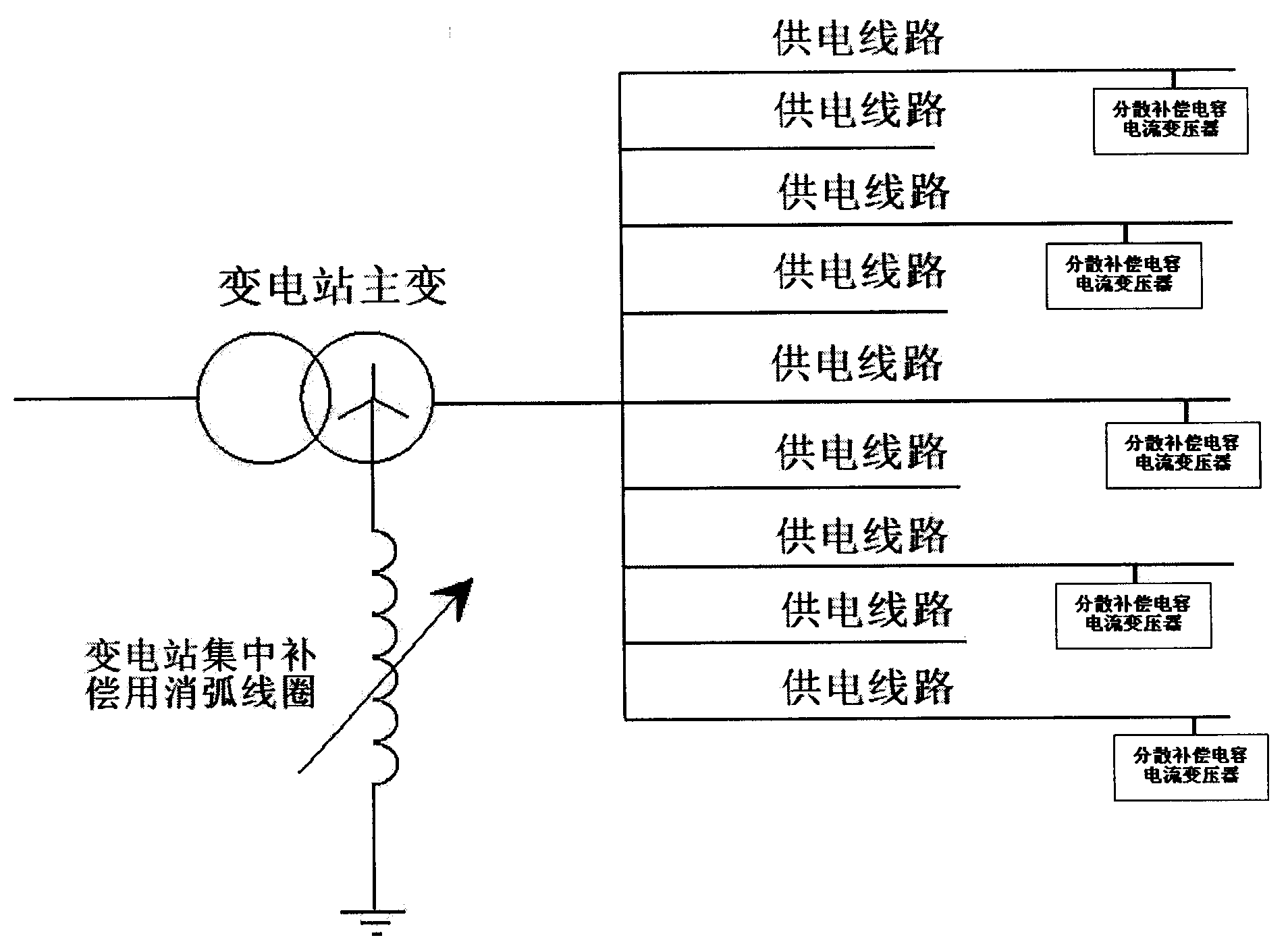

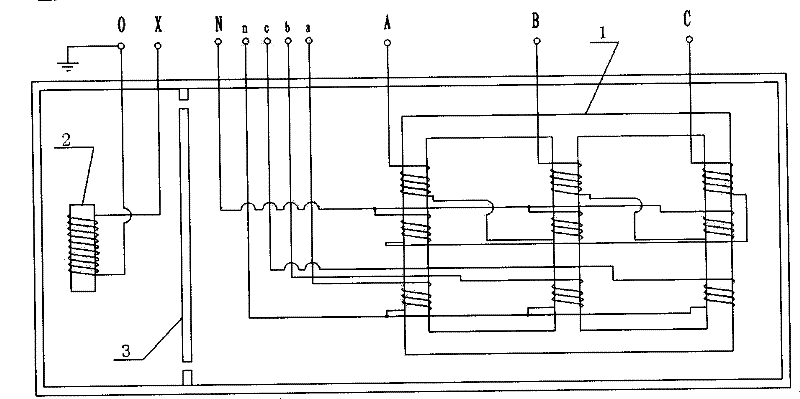

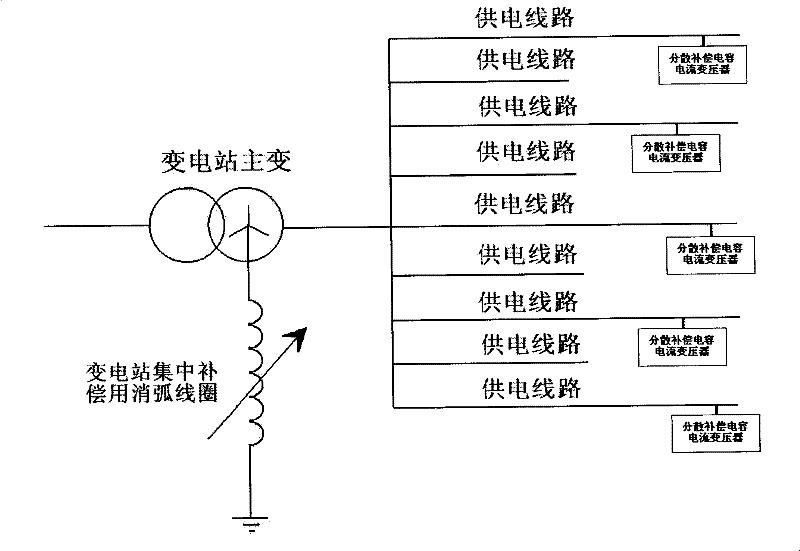

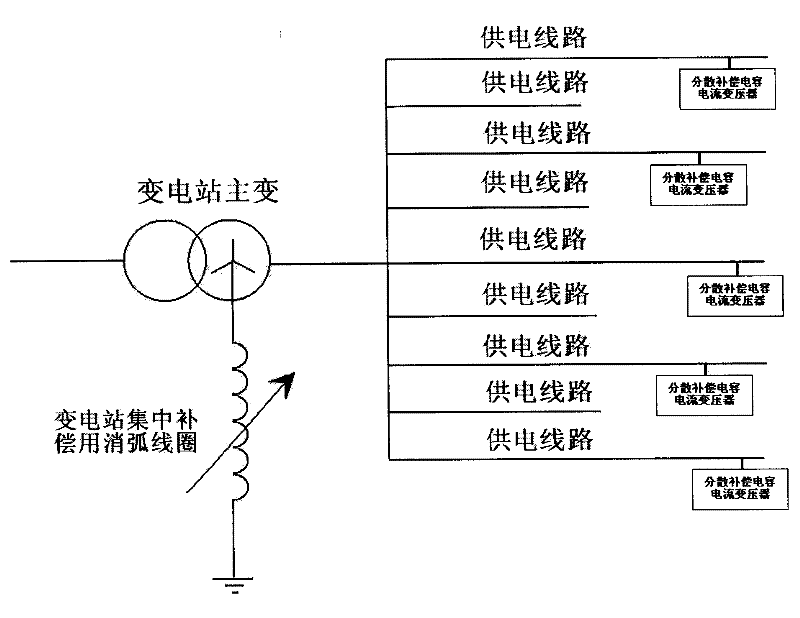

Capacitive grounding current distributed compensation method and device for medium-voltage power supply system

ActiveCN101872969AReduced ground inductanceReduce generationEmergency protective arrangements for limiting excess voltage/currentCapacitanceTransformer

The invention relates to a capacitive grounding current distributed compensation method for a medium-voltage power supply system, which belongs to the technical field of the capacitive grounding current compensation of a neutral non-grounding power supply system. In the method, capacitive grounding current distributed compensation transformers are arranged on lines, with relatively greater capacitive grounding currents, of the system in a distributed way, and only compensate the capacitive grounding currents of the corresponding lines, wherein the compensation capacity of each capacitive grounding current distributed compensation transformer is 1.1 times the capacitive grounding currents of the corresponding lines; and 40 to 60 percent of the capacitive grounding currents of the system is compensated by the capacitive grounding current distributed compensation of the whole power grid, and the other is comprehensively compensated by arc extinguishing devices of transformer substations. The capacitive grounding current distributed compensation method has the advantages that: the capacitive grounding current distributed compensation transformers are adopted, so arrangement is simple and maintenance is unnecessary; operation is simple and the capacitive grounding current is compensated in real time; and the power supply reliability of the power grid is radically improved.

Owner:JILIN PROVINCE ELECTRIC POWER RES INST OF JILIN ELECTRIC POWER CO LTD +2

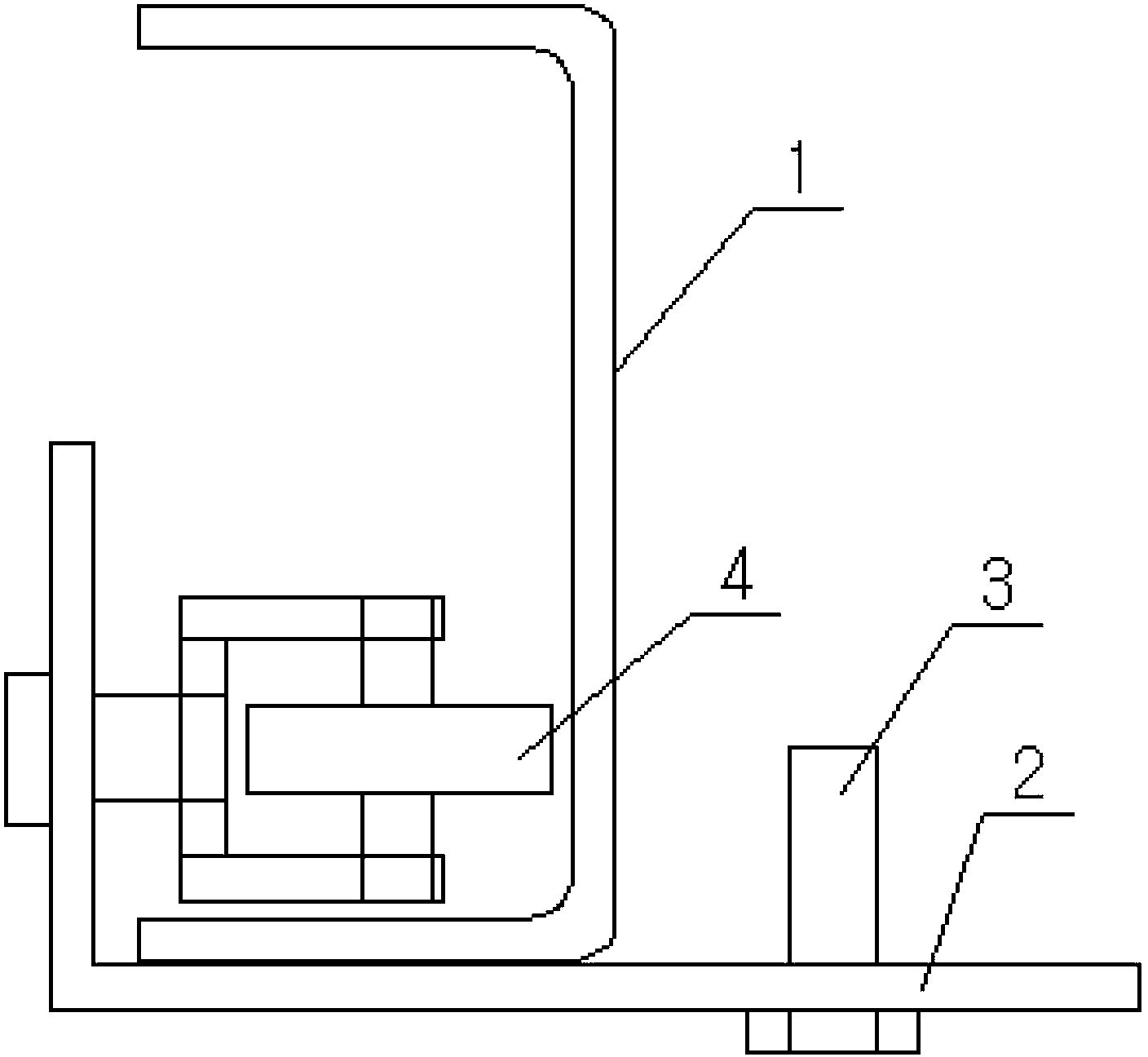

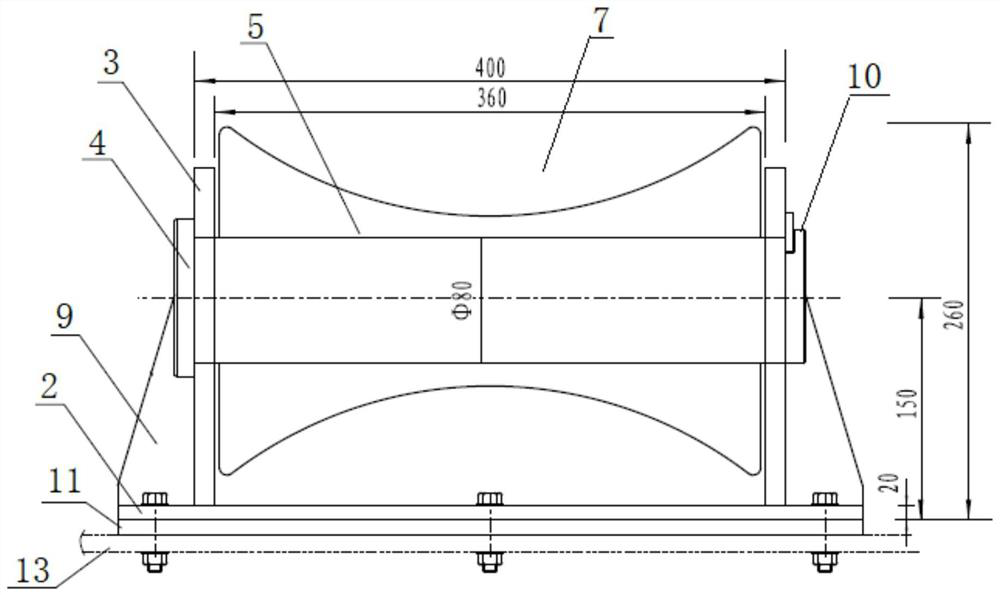

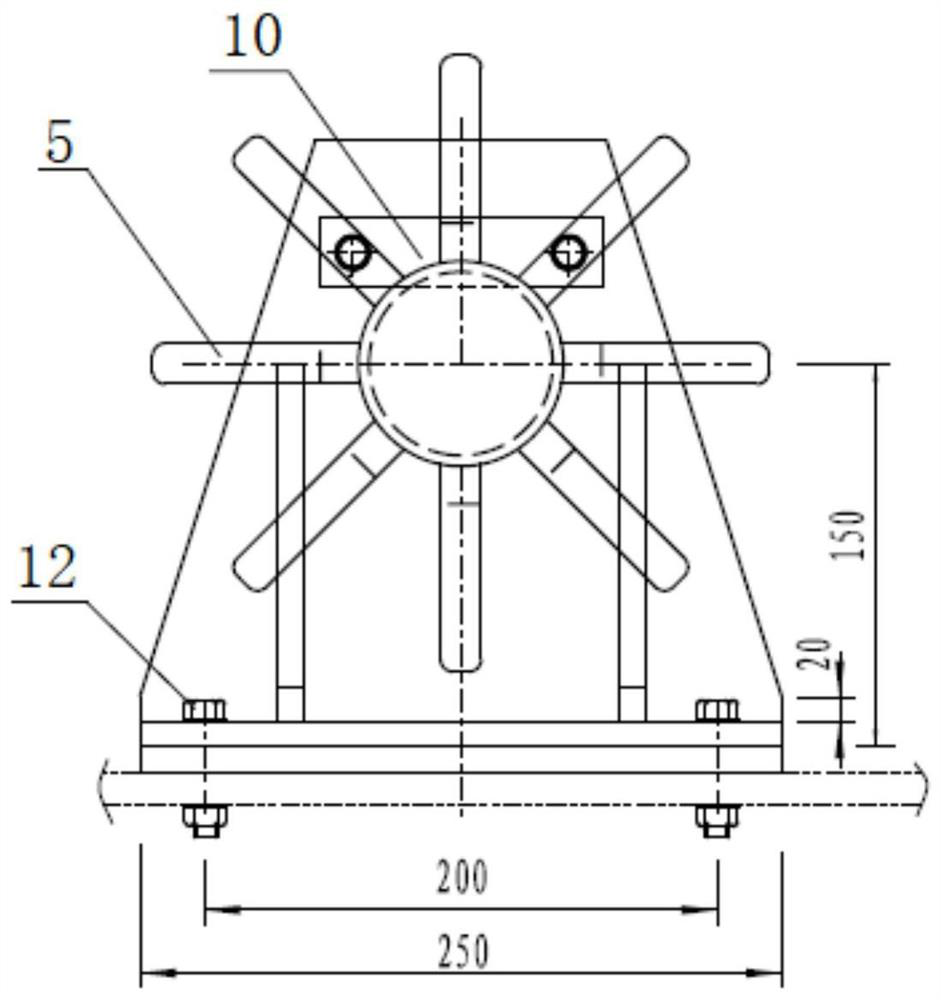

Pressure vessel barrel section assembling device

InactiveCN105834622ASolve the difficult problem of mechanized pairingImprove efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringCantilever

The invention relates to a pressure vessel barrel section assembling device which is characterized by comprising a guide rail, wherein roller carrier devices used for supporting and moving barrel sections are arranged on the guide rail, a cantilever lifting device is arranged at one side of the barrel sections, one end of the cantilever of the cantilever lifting device extends out towards the direction of the barrel sections, an internal clamp is arranged at the extending end of the cantilever, and the internal clamp keeps being concentric with the center of the barrel sections all the time. The pressure vessel barrel section assembly device is simple in structure, and easy to operate and realize, and can be used for assembly of barrel sections with different diameters and thicknesses, and due to the arrangement of the liftable internal clamp, the difficulty that mechanical assembly cannot be realized for thin barrel sections is solved, the assembling efficiency and assembling quality of the barrel sections are improved, the labor intensity is reduced, and the operation potential safety hazard of manual assembling can be eliminated.

Owner:YONGSHENG MACHINERY IND KUNSHAN

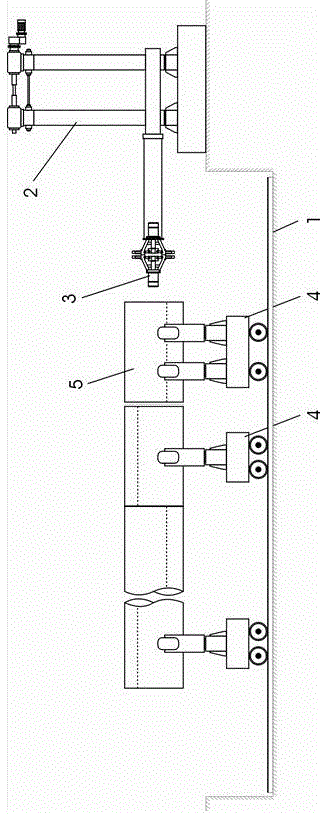

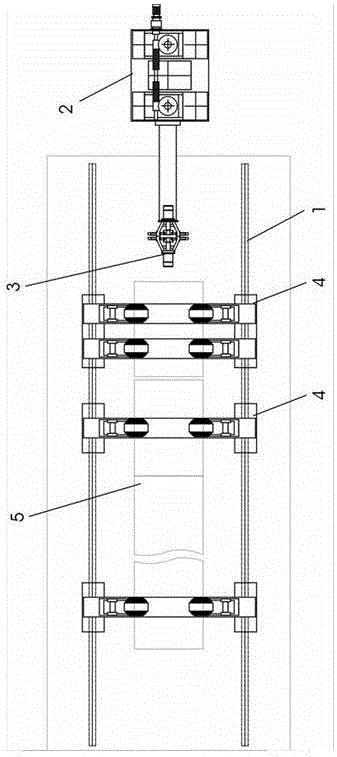

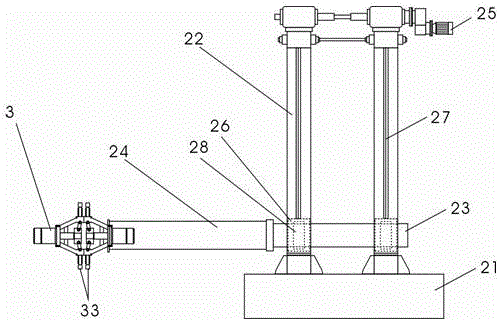

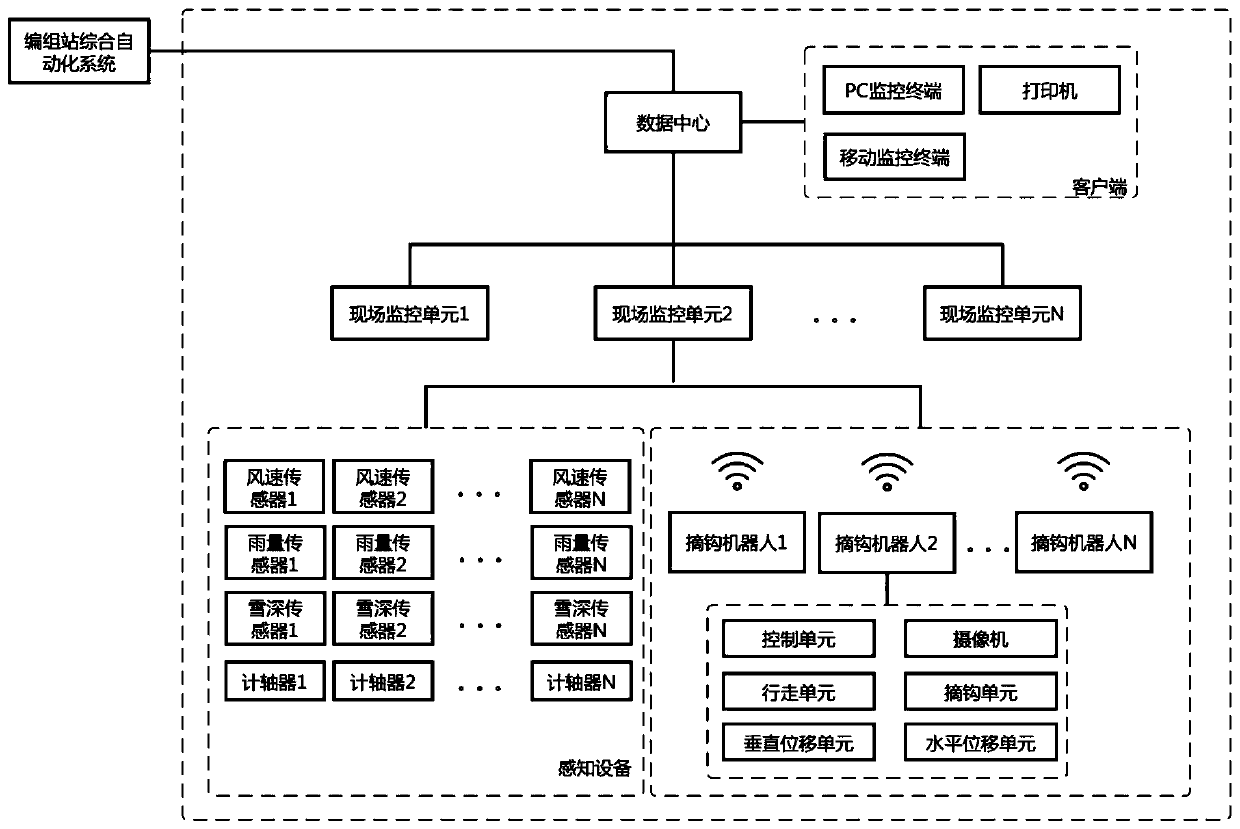

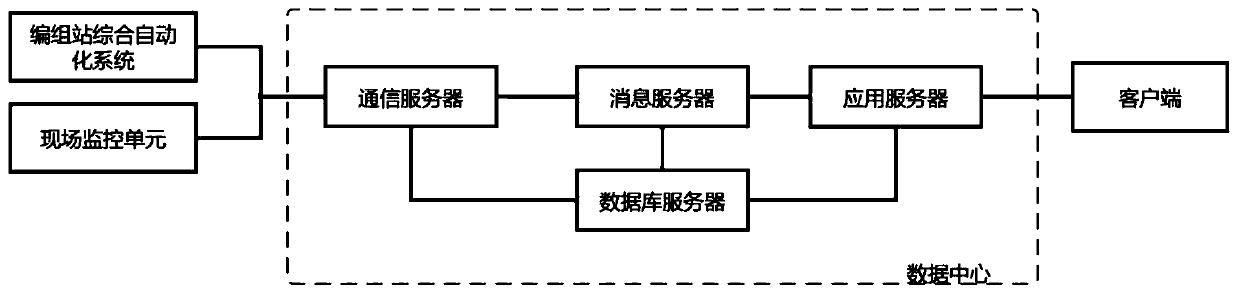

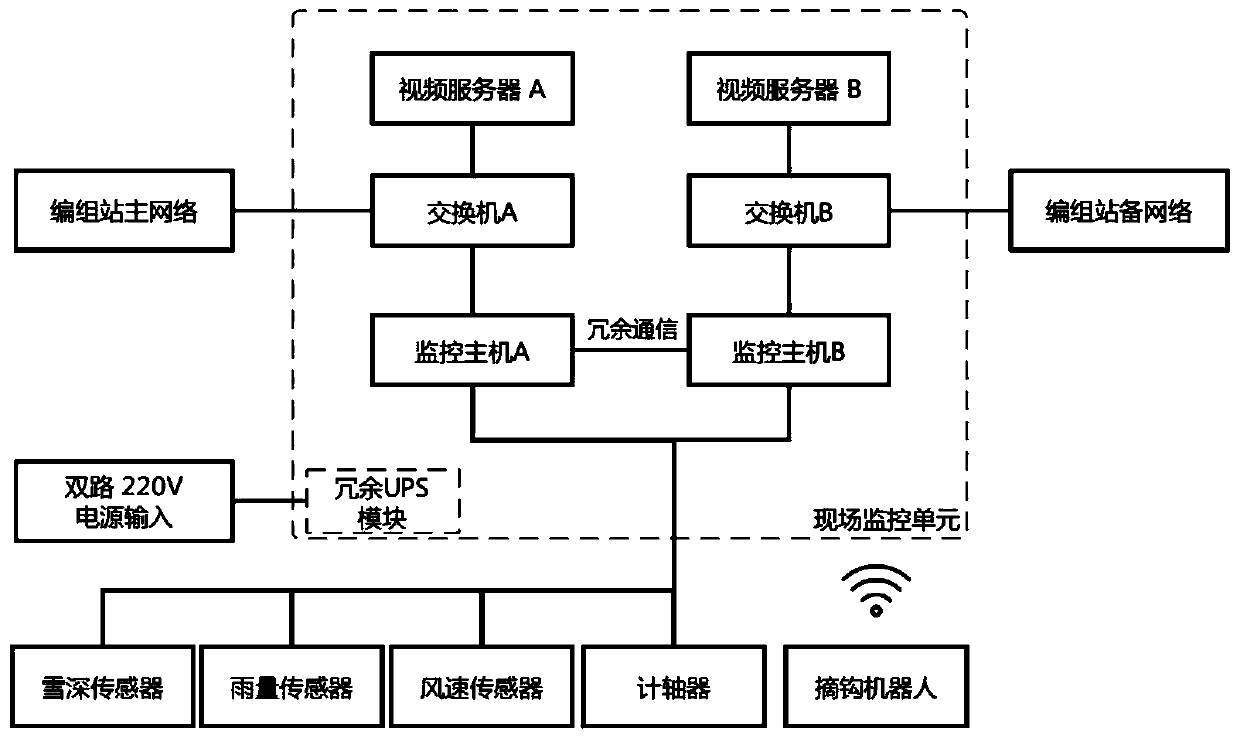

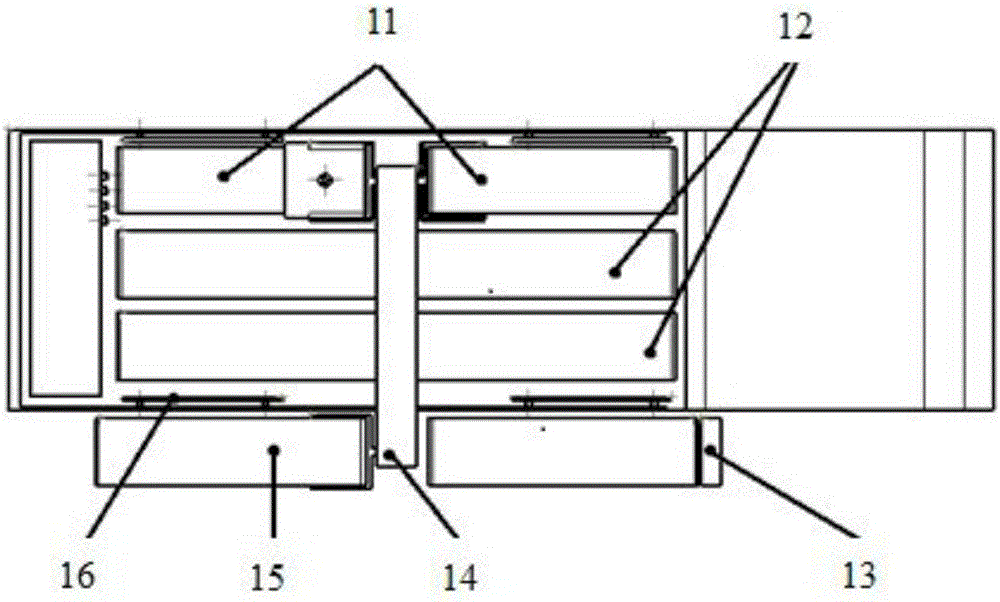

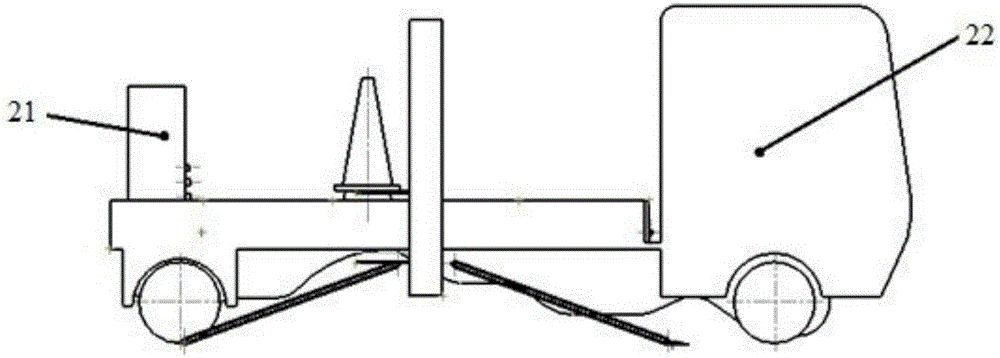

Intelligent unhooking system for railroad freight transportation and method

InactiveCN110386164AEliminate operational safety hazardsImprove work efficiencyProgramme controlComputer controlSite monitoringData center

The invention provides an automatic unhooking system for a draw gear connected with a disassembled carriage during railroad freight transportation and a method. The system comprises a data center, a client side, a site monitoring unit, a sensing device and an unhooking robot. During work, the site monitoring unit is in real-time communication with the data center, information such as disassembly operation notice orders and locomotive parameters is obtained through a comprehensive automation system interface of a marshalling station, the information collected by the sensing device is analyzed,an unhooking instruction is transmitted to the unhooking robot, and then all units of the unhooking robot cooperate to complete an unhooking task. The automatic unhooking system is ingenious in idea,reasonable in structure, convenient to use, flexible to adjust, high in universality and easy to maintain, the working efficiency of the marshalling station during railroad freight transportation is obviously improved, and the automatic unhooking system can be widely applied to various kinds of electrified railway construction.

Owner:大连谷瑞特科技有限公司

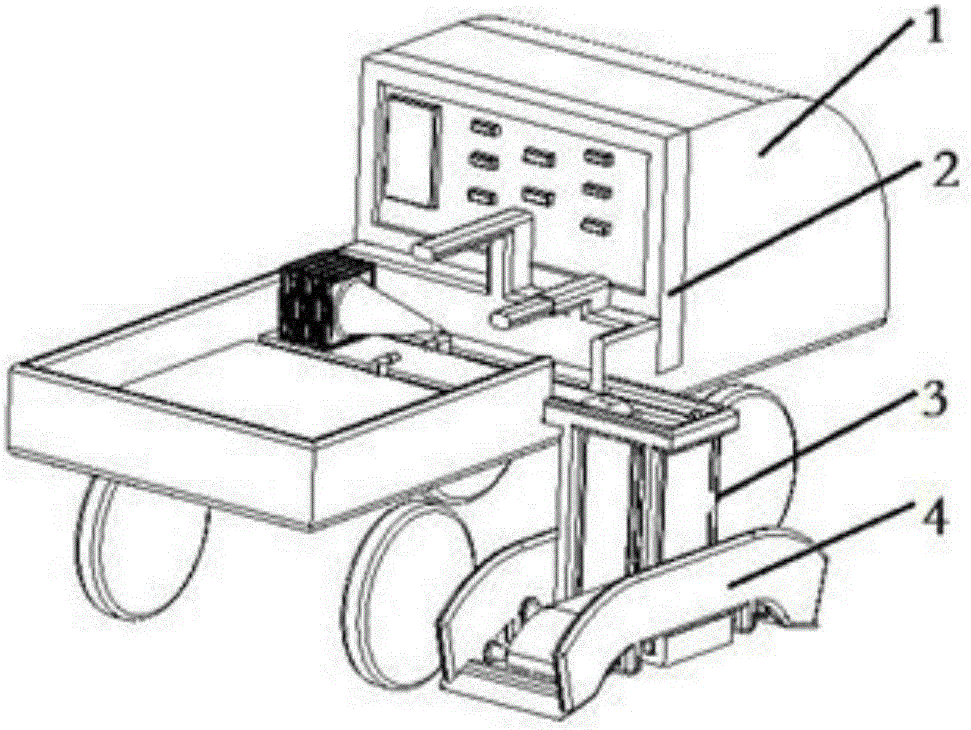

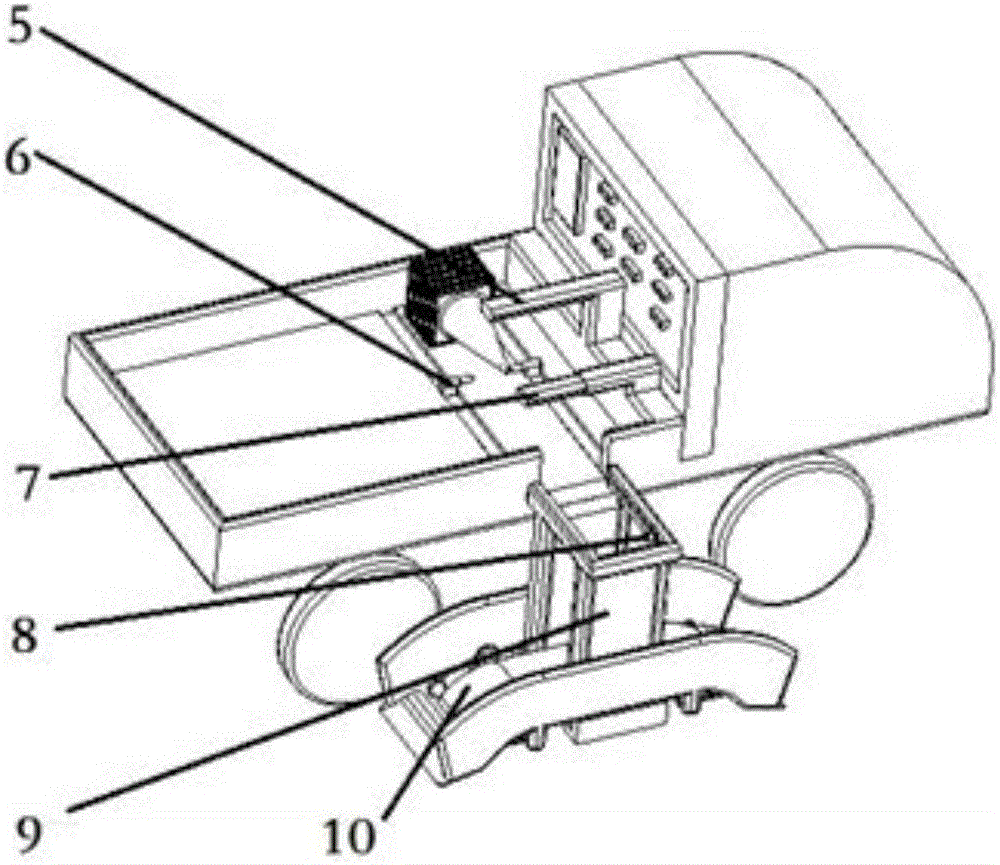

Gantry-type road cone automatically deploying and retracting device

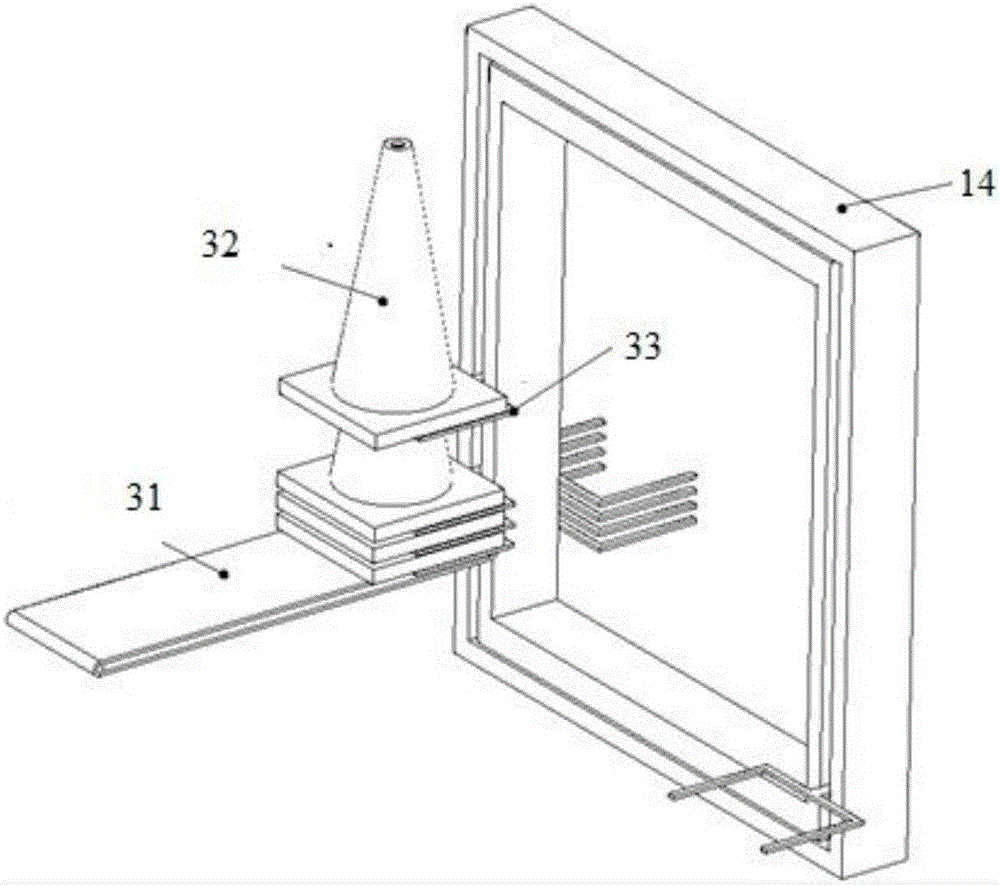

The present invention relates to a gantry-type road cone automatically deploying and retracting device. The gantry-type road cone automatically deploying and retracting device comprises a conveying device, a transporting device and a ground-connected conveying and placing device, wherein the transporting device also comprises push plates and a conveying crawler belt, and the push plates are installed on side baffles of a vehicle body while the conveying crawler belt is installed on a flat board of the vehicle body; the transporting device also comprises a track and support forks, and the support forks can move along the track; and the ground-connected conveying and placing device comprises a road cone deploying and retracting crawler belt forming a certain angle with the ground, and a micro poking and shoveling component. Manual replacement and recycling of the road cones during road maintenance is replaced, and full automation of road cone placement and recycling is realized. Risks of road operation are reduced, and personal safety of workers during working is raised. The road working efficiency is raised, and time is saved. Through constant-speed advancement of the vehicle and constant-speed movements of the device, equal-distance placement of the road cones is realized, and the aim of controlling distance among the road cones can be achieved by changing travelling speed of the vehicle.

Owner:SHANGHAI DIANJI UNIV

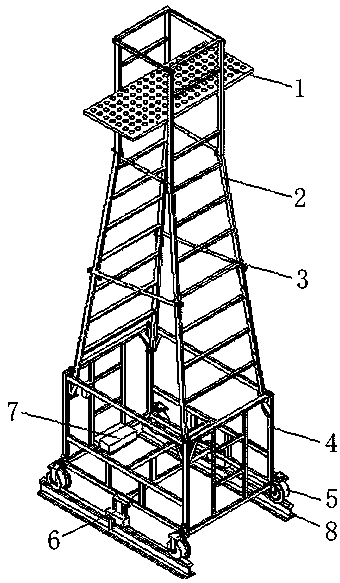

Overhead line system maintenance electric ladder vehicle

PendingCN108162807AShorten the lengthLower center of gravityTrolley linesCarriagesSystem maintenanceGravity center

The invention discloses an overhead line system maintenance electric ladder vehicle which comprises a chassis, an operating platform, a folding ladder body and walking devices. The walking devices areinstalled at the four bottom corners of a ladder base 4. The ladder base is arranged between the chassis and the folding ladder body and fixed to the chassis. The lower end of the folding ladder bodyis movably connected with the ladder base. A stabilizing device is arranged on the chassis, and comprises an installation base, a permanent magnet and positioning wheels, wherein the permanent magnetand the positioning wheels are installed in the installation base, the positioning wheels are installed on the two sides of the permanent magnet, and the installation base is installed on the chassisand can swing round a pin shaft. In the working state, the ladder body is shortened in height, low in gravity center and high in stability; the positioning wheels are supported on rails, the permanent magnets provide constant downward pressure, the ladder body is stable, and operating is safe; in the walking state, the ladder body is folded up, the installation base upward swings and turns over,the effect of magnetic force is eliminated, running is easy and saves energy, operations are easy and save labor, people can rest hands on a frame when moving together with the ladder vehicle, runningis safe, and the speed is increased to 10 km / h.

Owner:湖南亚太高岸铁路装备股份有限公司

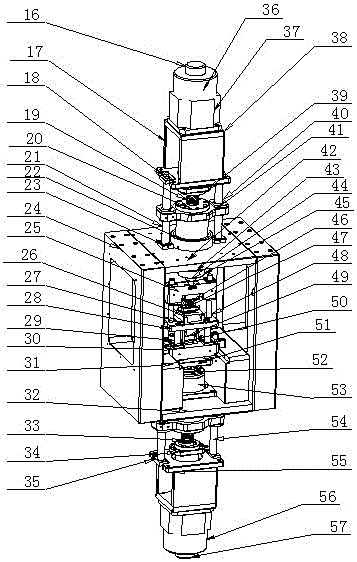

Multi-working-procedure integrated contact processing equipment

ActiveCN106975695AImprove processing efficiencyIncrease productivityShaping toolsElectric switchesEngineeringMechanical engineering

The invention discloses multi-working-procedure integrated contact processing equipment which comprises a base platform, guide posts fixed to the base platform and a movable platform installed on the guide posts in a vertically-movable mode. The multi-working-procedure integrated contact processing equipment further comprises a contact plate blank feeding mechanism, a contact lower die plate fixedly arranged on the base platform and a contact upper die plate fixedly arranged on the movable platform. The contact lower die plate is provided with a stamp die assembly comprising multiple stamp dies. The contact upper die plate is provided with a punch assembly comprising multiple punches. The stamp die assembly on the contact lower die plate comprises a contact hole stamp die and a cut-off stamp die. The punch assembly is correspondingly provided with a contact hole punch and a cut-off punch. The movable platform drives the contact upper die plate to move downwards, accordingly, the punch assembly and the stamp die assembly are matched in a stamping mode for stamping multiple contact finished products from the contact plate blank, the contact point punch and the contact hole stamp die are matched for punching contact holes in the contact plate blank, the cut-off punch and the cut-off stamp die are matched to cut off the contact plate blank, and contact processing efficiency is effectively improved.

Owner:ZHEJIANG CHINT ELECTRIC CO LTD

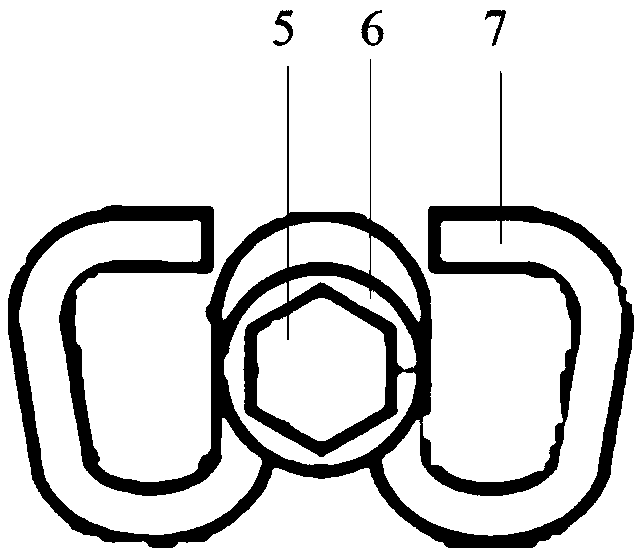

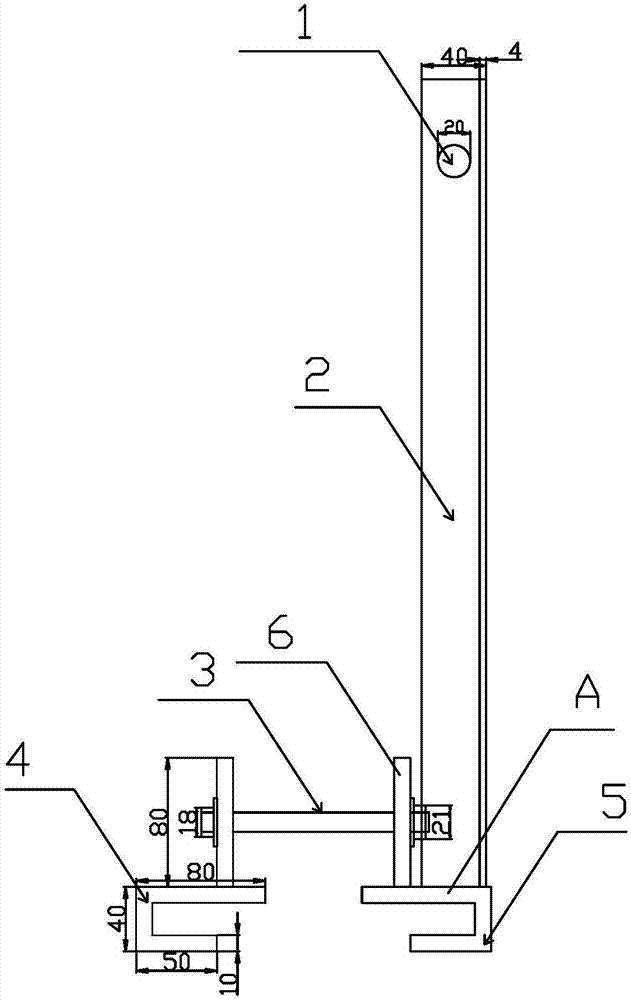

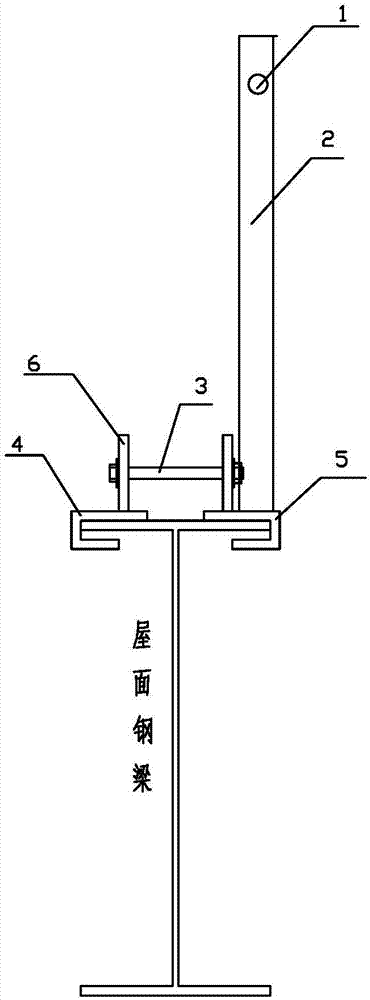

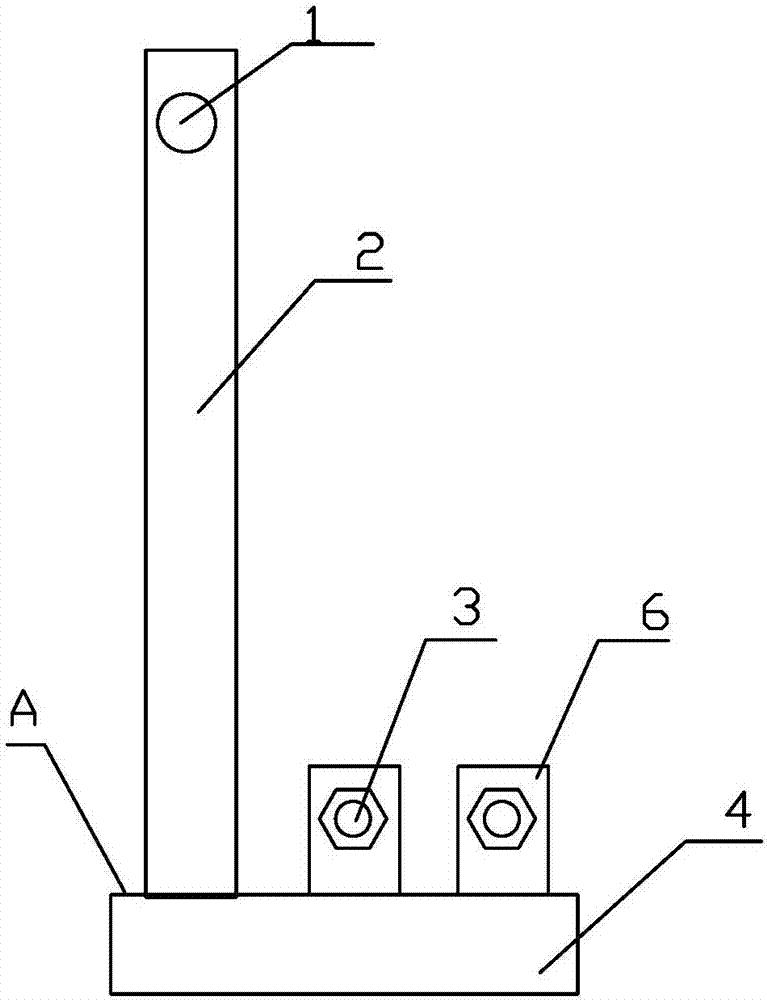

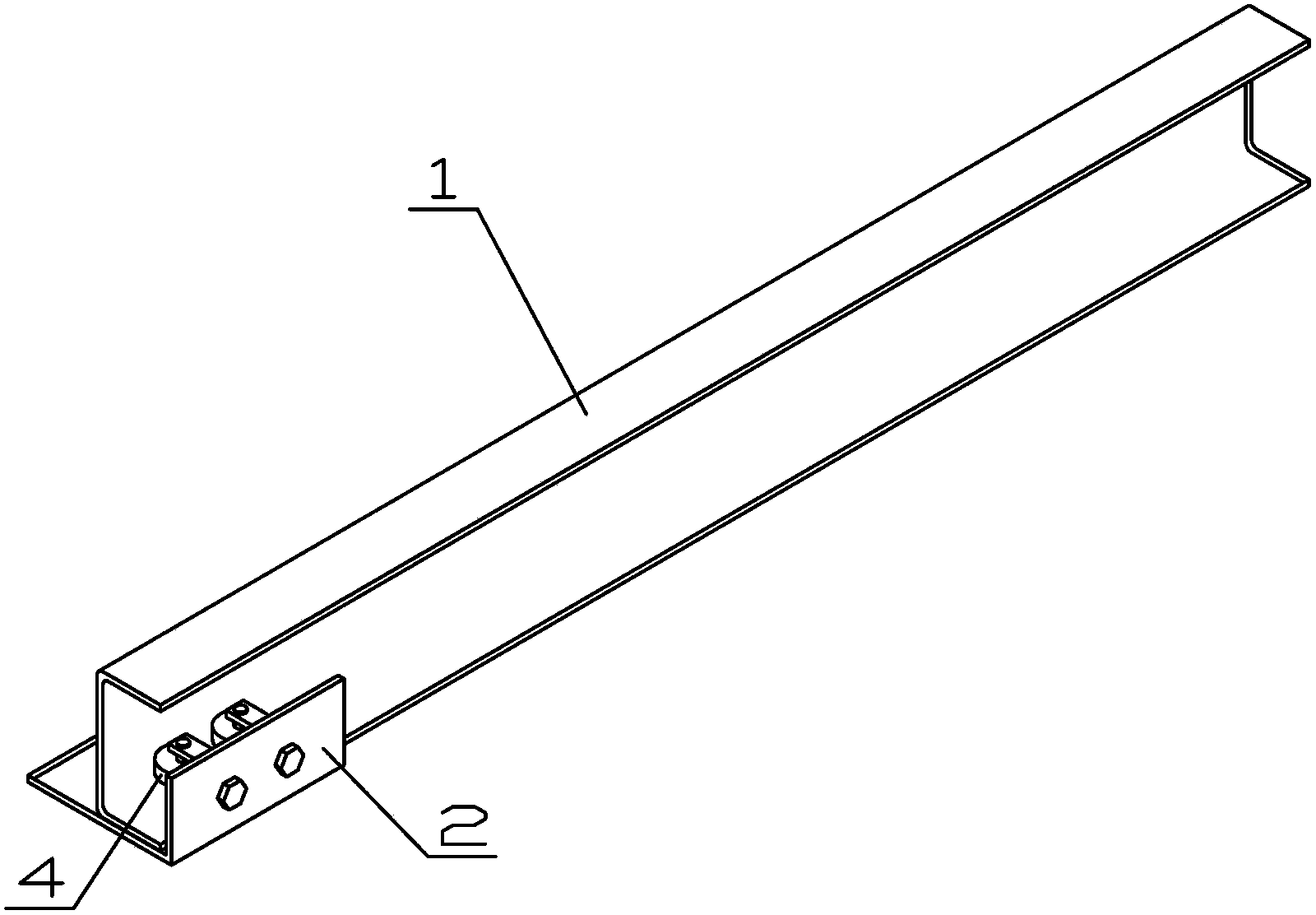

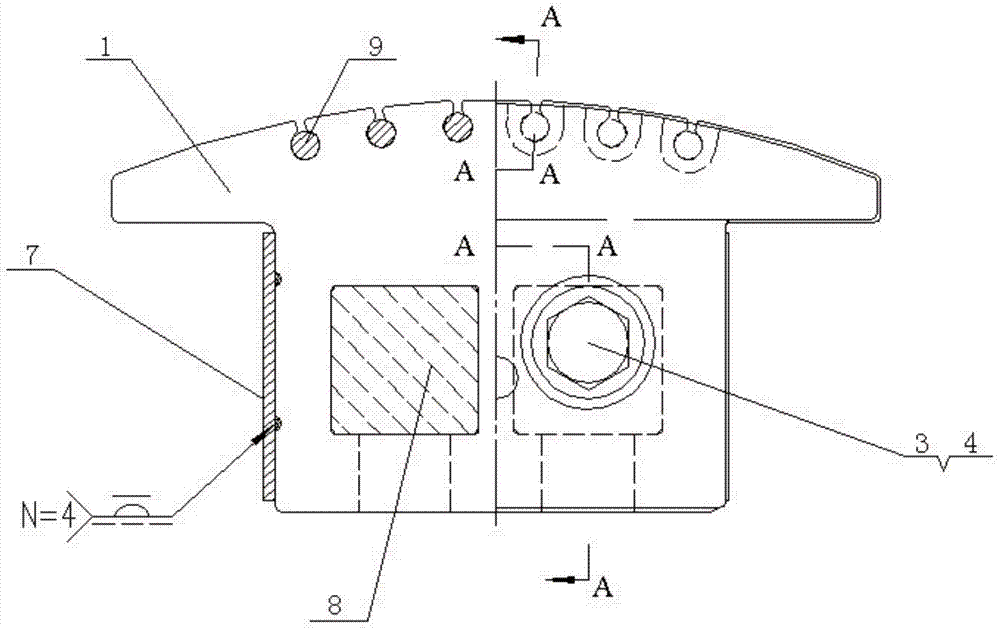

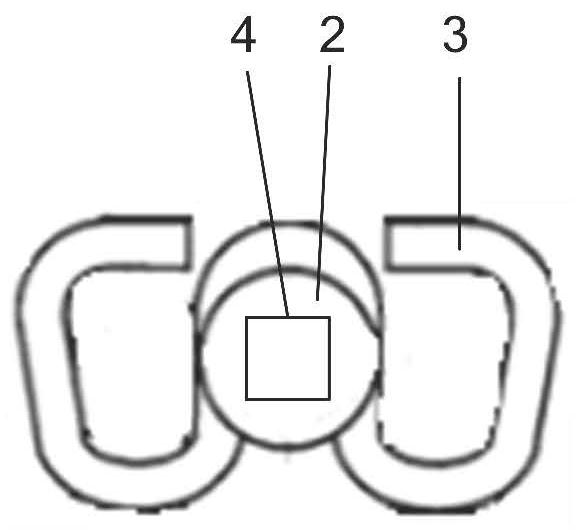

Life rope fixator

The invention discloses a life rope fixator, comprising clamps 4 and 5 having a U-shaped vertical section; the outer side of one end of each of the clamps 4 and 5 is provided with connection plate 6 vertically fixed to the end, the outer side of the end A of the clamp 4 or 5 is also provided with steel angle 2 vertically fixed to the end, the steel angle 2 is provided with life rope insertion hole 1, and the connection plates 6 on the clamps 4 and 5 are connected in releasable manner. In use of the life rope fixator, a roof steel beam is placed in U-shaped openings of the clamps 4 and 5, the clamps 4 and 5 are then fastened in releasable manner, the roof steel beam is firmly fixed in the two opposing U-shaped openings, a life rope is passed through the life rope insertion hole 1, and accordingly the life rope is fixed. When the life rope fixator is idle, the clamps 4 and 5 are separated. The life rope fixator is simple in structure, convenient to operate, low in cost and convenient to use, is suitable for long-term use after single investment, is friendly to the surface of a steel beam, and may serve as a good life rope fixing manner for the industry of modern buildings.

Owner:CHINA MCC5 GROUP CORP

Retractable movable lifting platform and ships including the same

ActiveCN105752271BTurnaround steps savedImprove lifting efficiencyCargo handling apparatusVessel partsMarine engineeringMultiple platform

The invention discloses a retractable type movable hoisting platform and a ship comprising the same.The retractable type movable hoisting platform comprises a portal frame, a platform and a retractable system.The platform is arranged at one end of the portal frame, and multiple platform lug plates are hinged to the end, close to the portal frame, of the platform.The retractable system is installed between the portal frame and the platform and used for enabling the platform to rotate relative to the vertical portal frame, so that the platform is switched between a horizontal state and a vertical state.The ship comprises a cabin wall and a storeroom deck.The storeroom deck extends outwards from the cabin wall.The ship comprises the retractable type movable hoisting platform.By adopting the retractable movable hoisting platform, great convenience is brought for achieving safe goods hoisting.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD +1

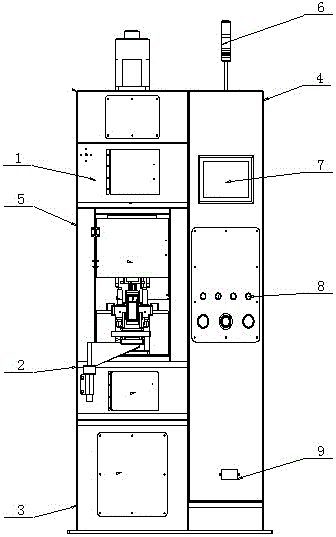

High-precision powder forming machine

The invention discloses a high-precision powder forming machine and relates to the technical field of powder forming machines. A cabinet is arranged at the left half part of the front side of a power forming machine, an electric cabinet is arranged at the right half part of the front side of the powder forming machine, the cabinet is connected with the side edge of the electric cabinet to form the powder forming machine, a side support plate is mounted on the side surface of the cabinet, an overshooting motor and an upper servo motor are mounted in a rack I, a powder flow distributing device is mounted on the side edge of the overshooting motor and located behind the electric cabinet, a vertical linear pressing device is mounted in a rack II, a feeding device is transversely mounted at the side edge of the vertical linear pressing device, an undershooting motor and a lower servo motor are mounted in a rack III. The high-precision powder forming machine has the following benefits: die filling is convenient and quick; the pressure is stable and data display is realized; ultraminiature and irregularly-shaped products can be produced by pressing; adopted operating parts are fully-enclosed, so that potential safety hazards caused during operation are eliminated; the rotational speed is high, the one-outlet multi-mode purpose is achieved, the operation ratio is high, produced dies are low in loss, and products are burr-free; the high-precision powder forming machine can work in a natural environment; the energy consumption is low; oil and material leakage is prevented and no noise is generated.

Owner:GUANGZHOU JINGCHENGDA PRECISION MACHINERY CO LTD

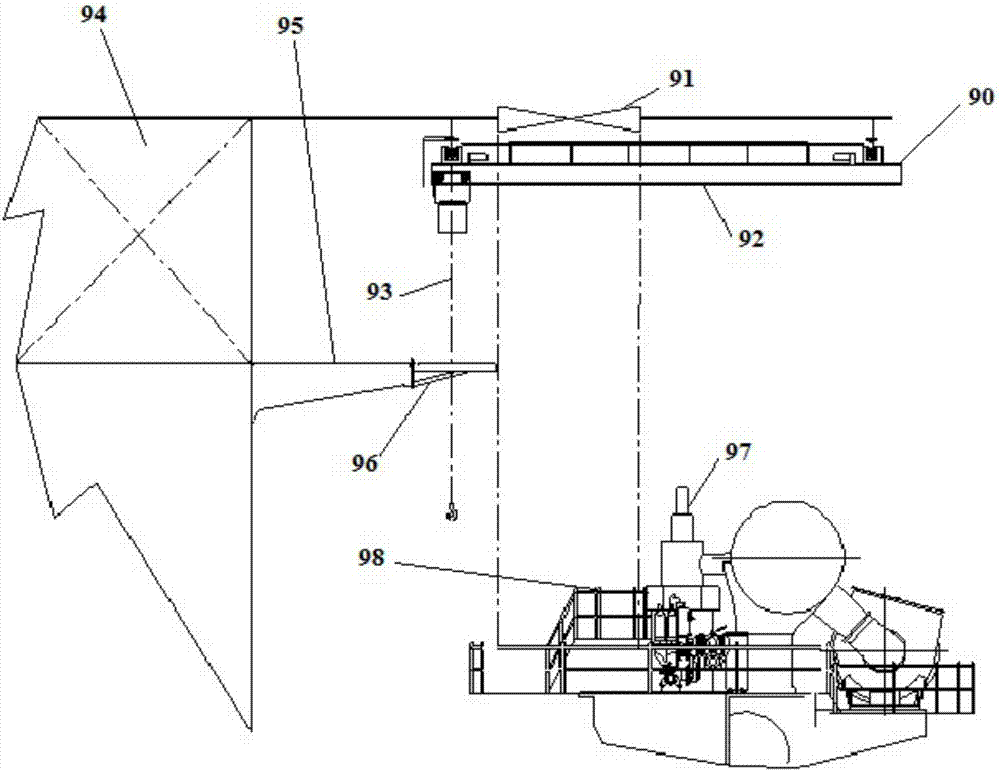

Method and device for replacing wheel group of bridge crane

ActiveCN103043531BSimplify work stepsReasonable structural designLoad-engaging elementsDrive wheelJackscrew

The invention relates to a method for replacing a wheel group of a bridge crane. The method comprises the following steps: jacking up a crane body by using a jack and placing a crane body support; returning the crane body to the crane body support; disassembling the wheel group and a connecting screw of a drive wheel; welding a channel steel guide rail on an end beam of the crane; locking a transverse beam and a sliding plate of the wheel group by using a locking bolt and pulling out the wheel group; carrying the wheel group to the ground and entrucking; disassembling a joint and a saddle of the old wheel group and assembling on the new wheel group; and hoisting the wheel group to a walking platform of the crane. Compared with the prior art, the method has the benefits that the characteristics of reasonable structural design and high safety are achieved; the walking wheel group moves along the guide rail through the sliding plate and the guide rail, so the wheel group can move with balance; the operation steps of replacing the wheel group of the bridge crane are simplified; the work intensity and the complex degree are effectively reduced; the production time is saved; the potential safety hazard of the work is eliminated; and personal injury accidents are avoided.

Owner:ANSHAN IRON & STEEL GROUP CORPORATION

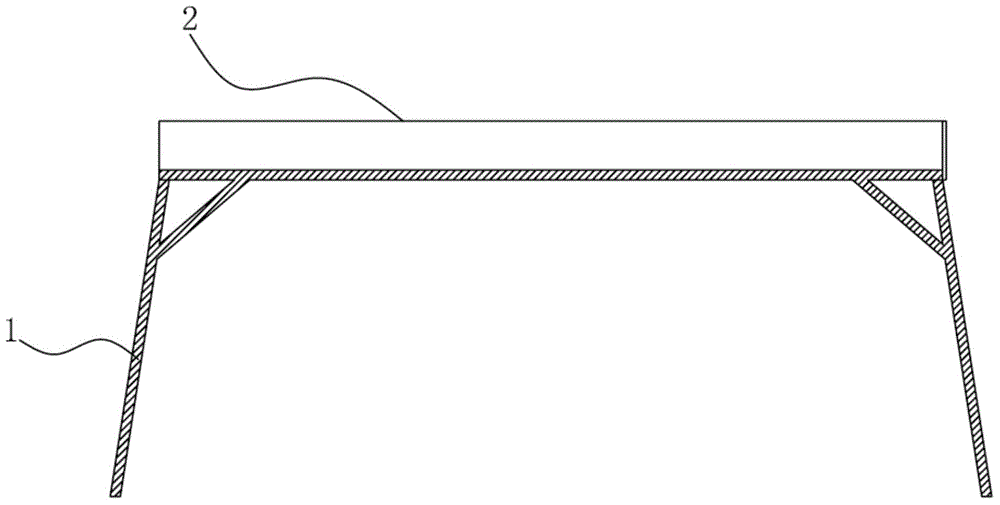

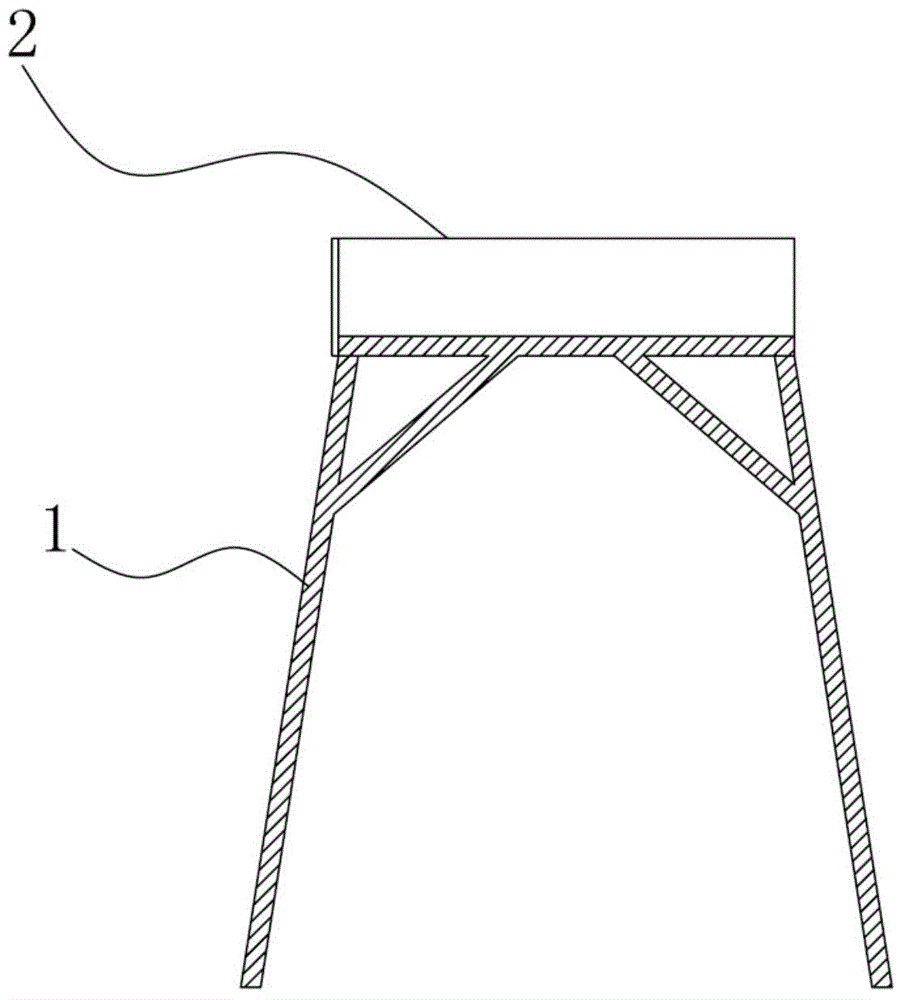

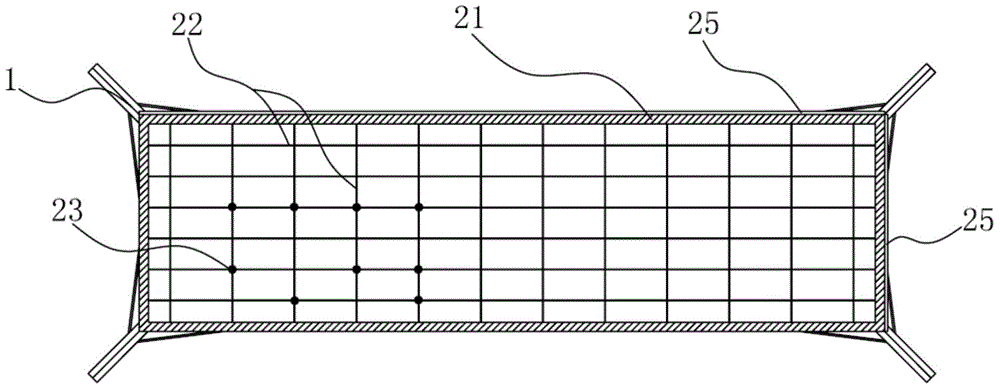

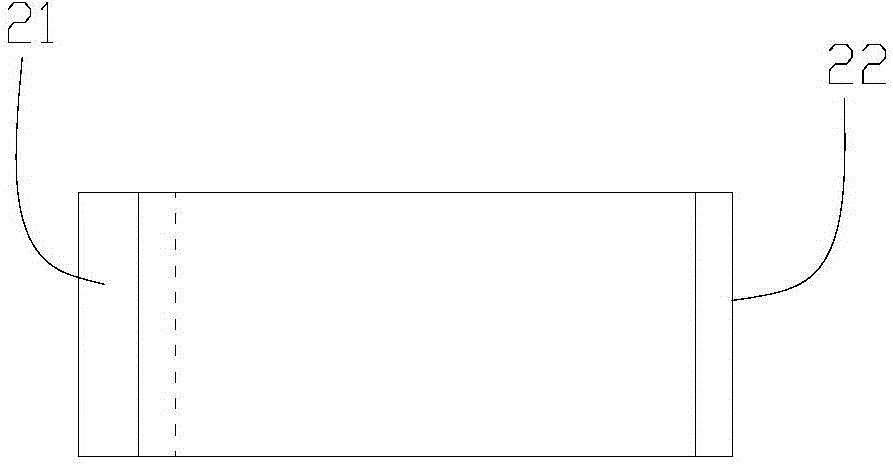

Novel stone sheet processing table

The invention discloses a novel stone sheet processing table comprising a supporting part and a table-board arranged on the supporting part. The table-board comprises an outer frame which is fixedly arranged on the supporting part, a plurality of strip bodies that is installed inside the outer frame by means of intersecting with one another both longitudinally and transversely, and a plurality of supporting units having cross-type slots at their bottoms, wherein the supporting units are clamped at the intersections of the plurality of strip bodies through the cross-type slots. Comparing with the prior art, the problems that the potential safety hazard is caused due to the fact that the table-board is carelessly cut, cooperation is required during the cutting, the sheet at the cut-off portion is easy to fall off when the cutting is finished, and the stone sheet needs to be held in the prior art can be solved, thereby the convenience of using the stone sheet processing table and the working efficiency of single-person operations can be effectively increased.

Owner:NANTONG INST OF TECH

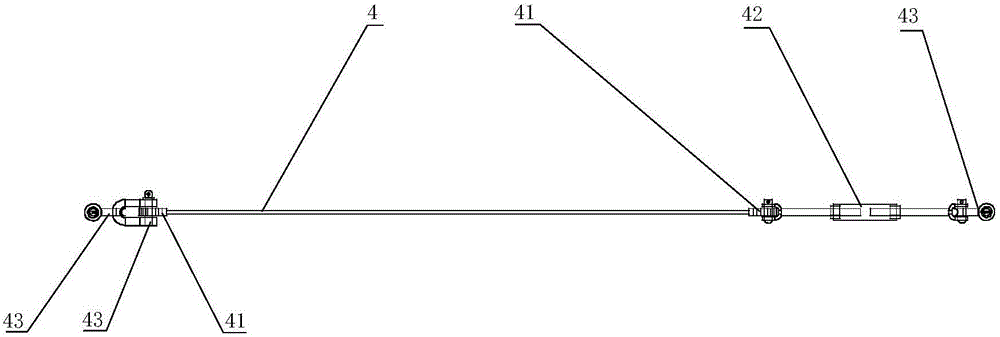

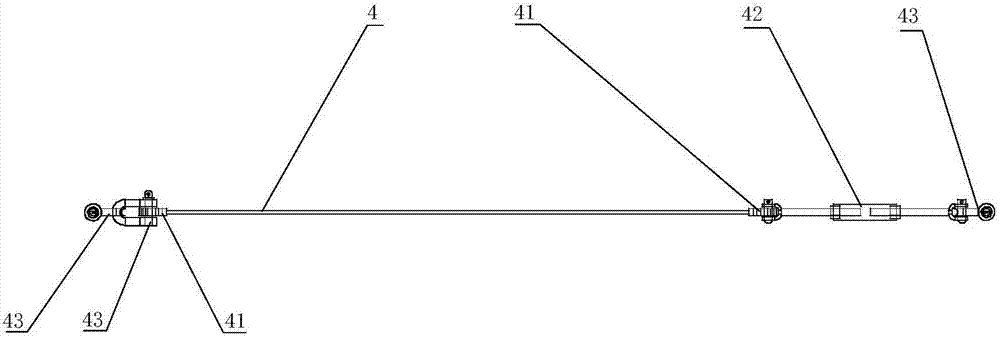

Stabilizing device for frog system

ActiveCN104532693AEnsure application stabilityEnsure transportation safetyRailsRail switchesEngineeringSystem parameters

The invention provides a stabilizing device for a frog system. The stabilizing device comprises a tie rod and a plurality of buckling claws, wherein the two ends of the tie rod are used for being connected with a guard rail and a basic rail, the middle of the tie rod is used for being connected with a frog, and the buckling claws are adjustably arranged on the tie rod and provided with openings for steel rail bottoms of the guard rail, the basic rail and the frog to be embedded therein and used for fixedly connecting the guard rail, the basic rail and the frog to the tie rod. The stabilizing device is used for guaranteeing the application stability of the frog system, the abrasion and impact to the system and the system parameter change caused when a locomotive passes are avoided, and the running potential safety hazards of the locomotive are eliminated. The corresponding parameters can be adjusted at any time according to the abrasion situation of the guard rail. The integral stability of the system is ensured, and the rail transportation safety is guaranteed.

Owner:SHANDONG IRON & STEEL CO LTD

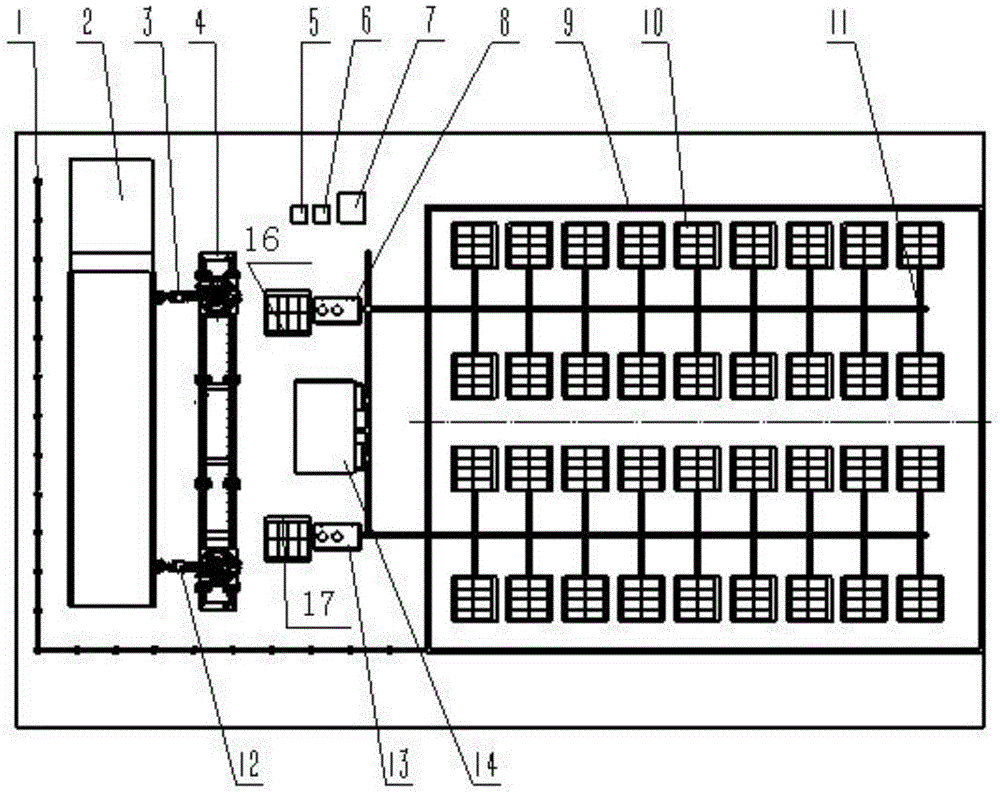

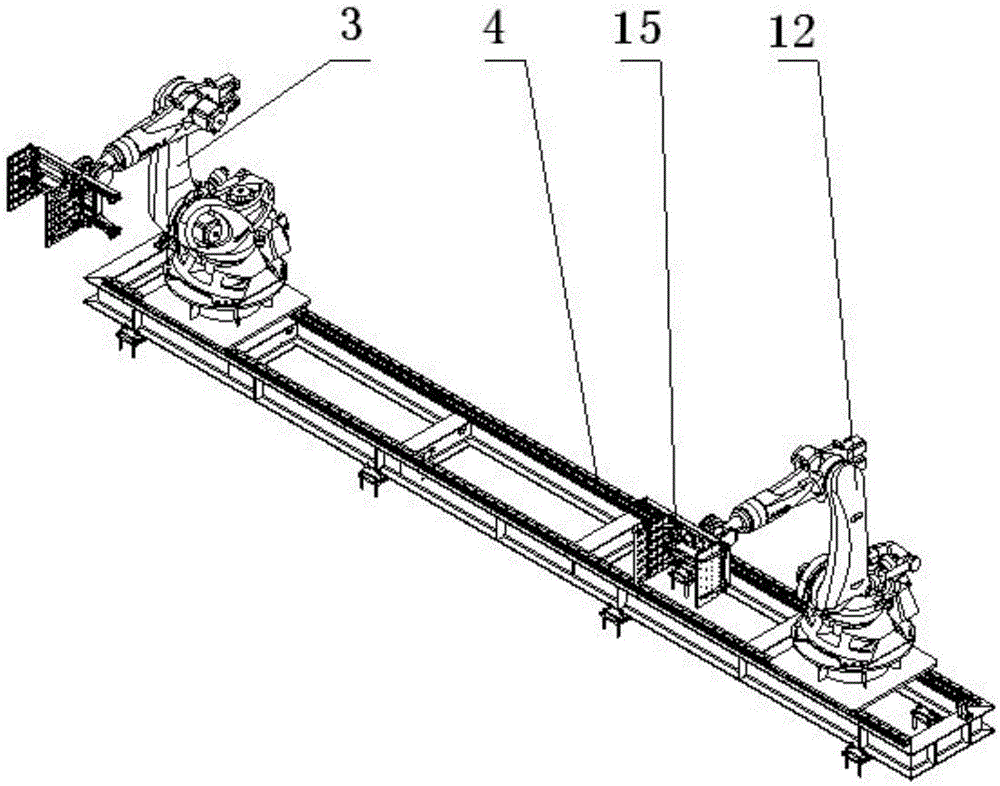

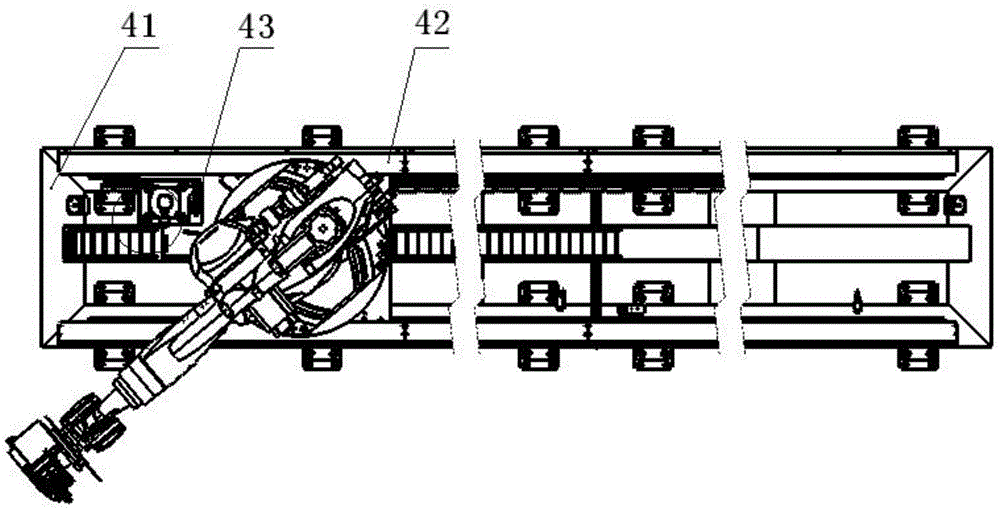

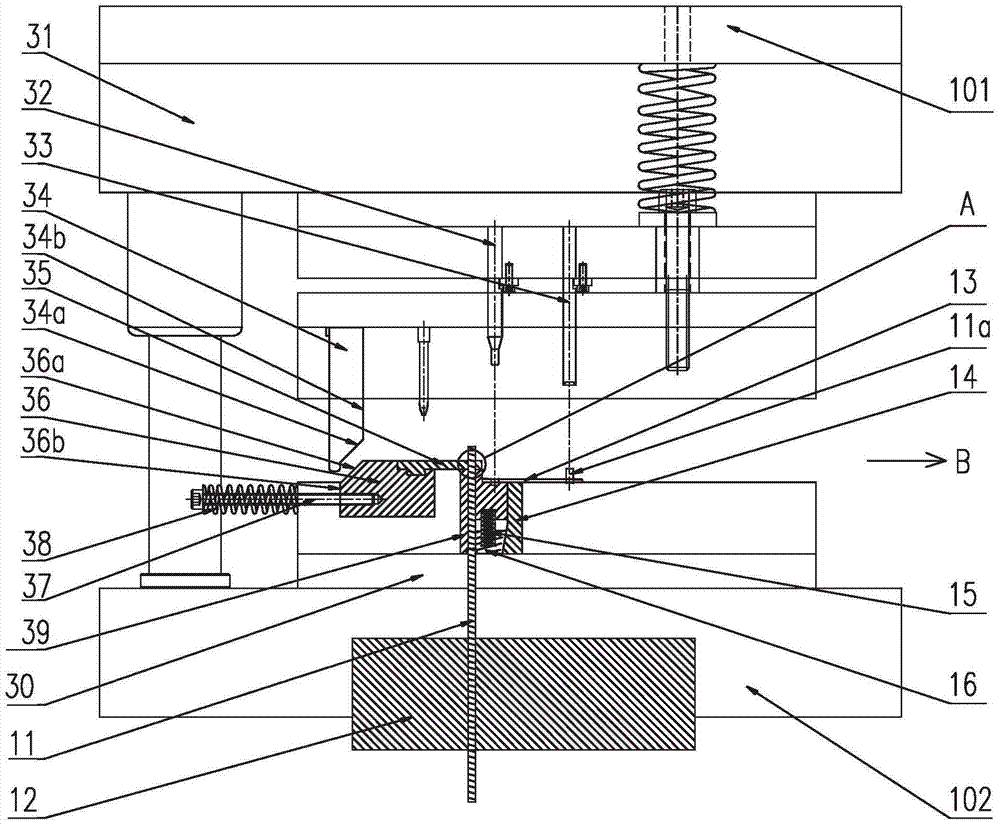

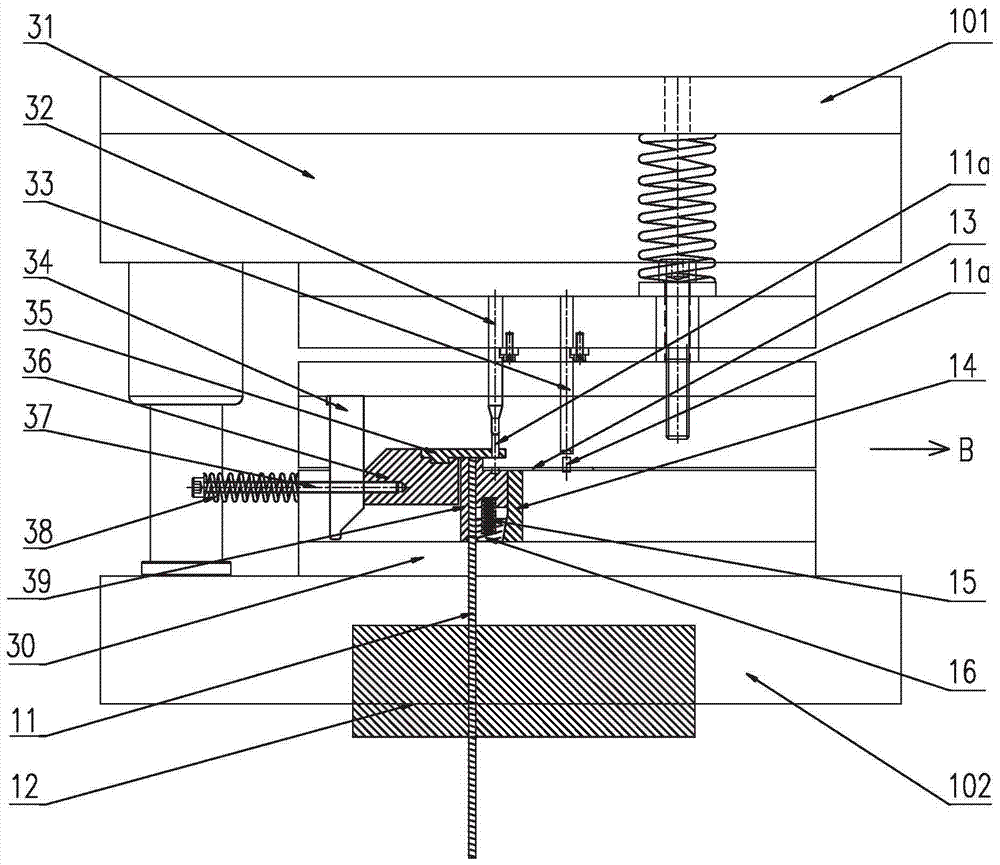

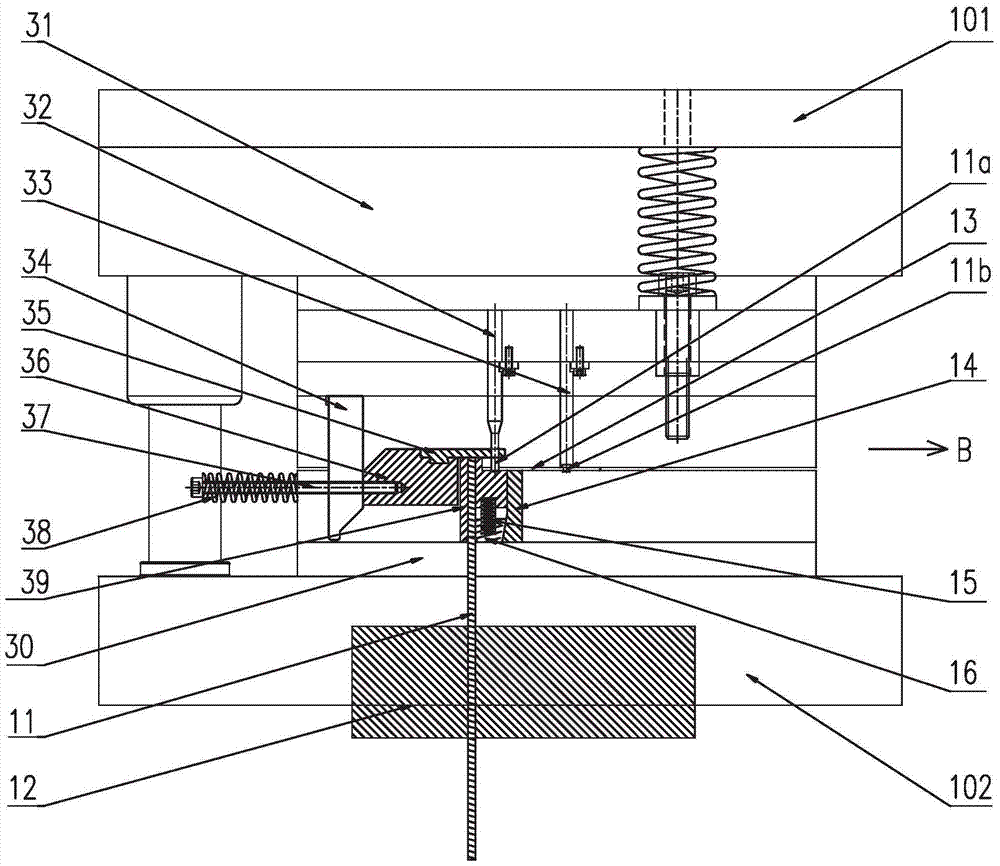

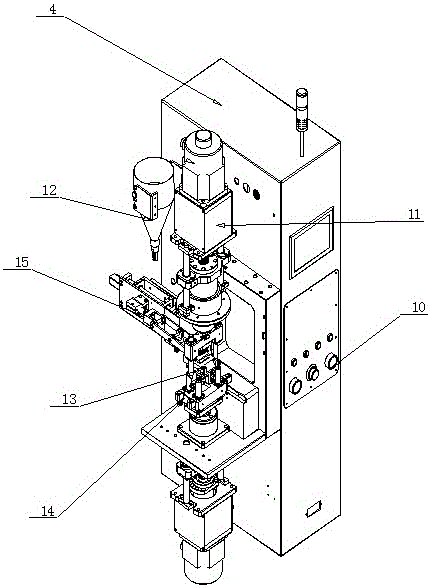

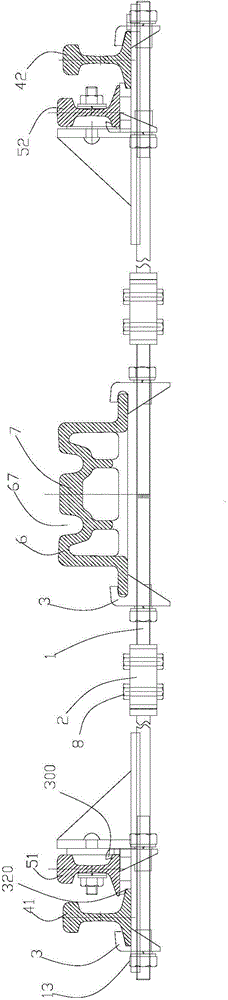

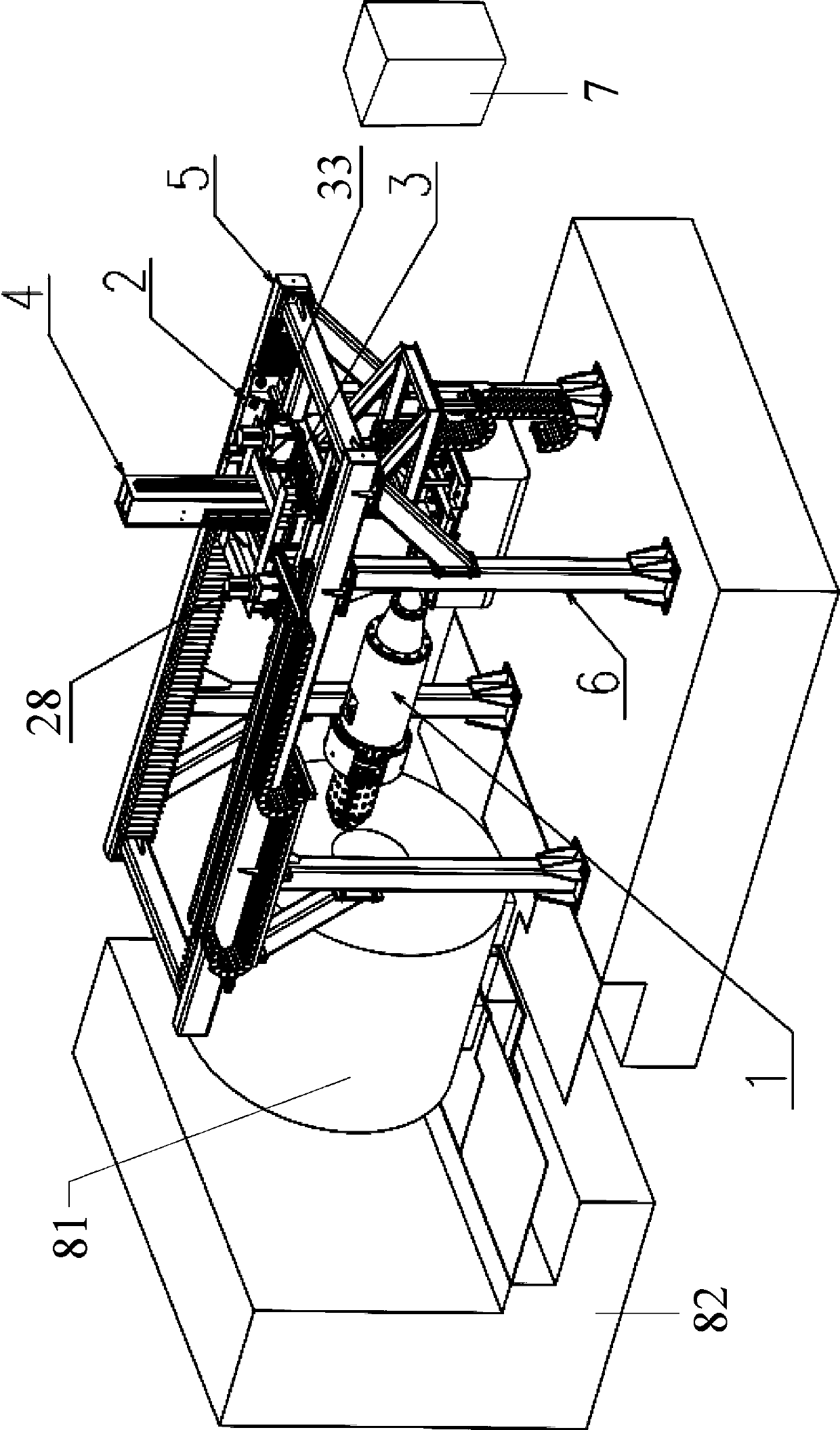

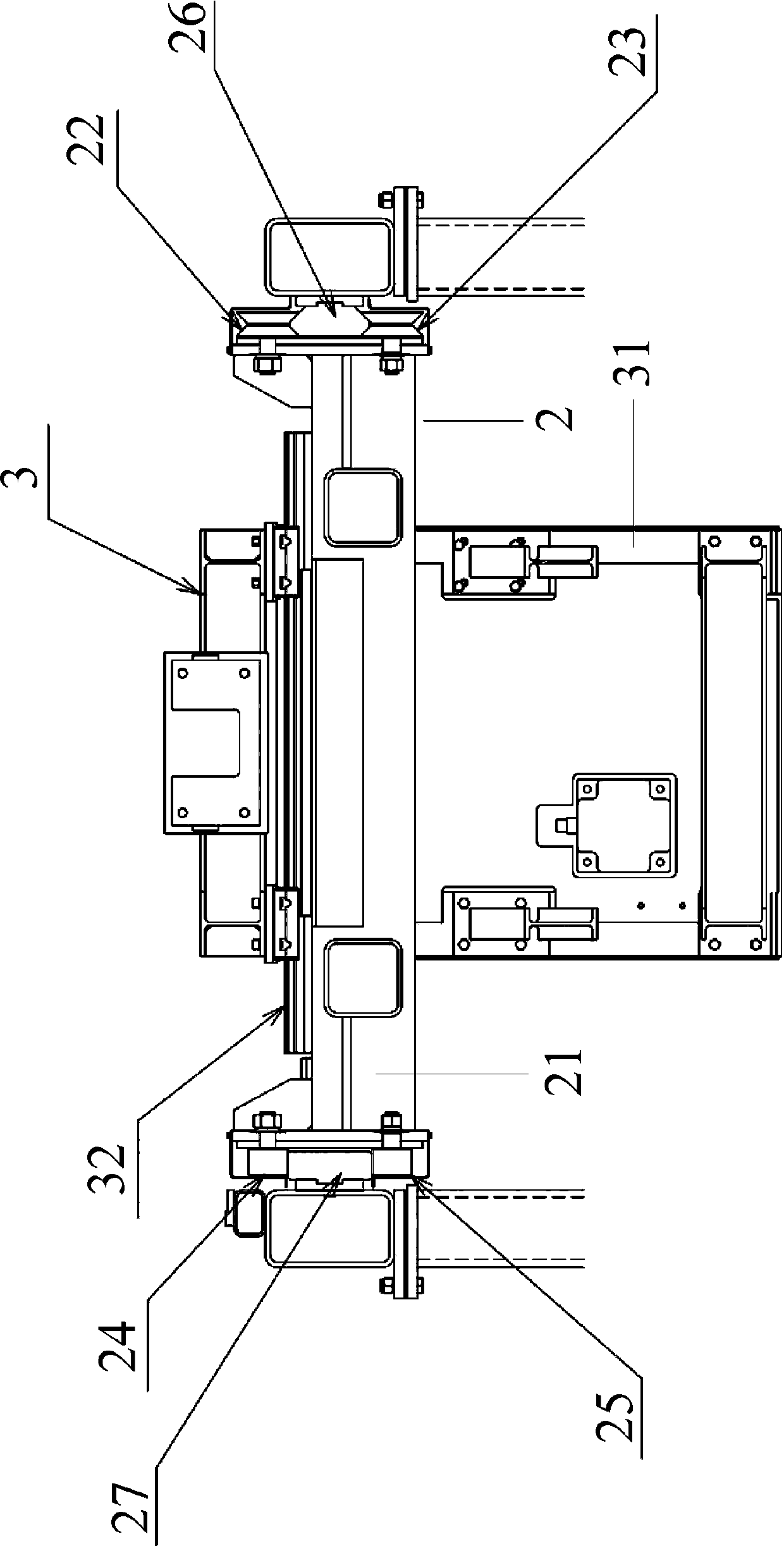

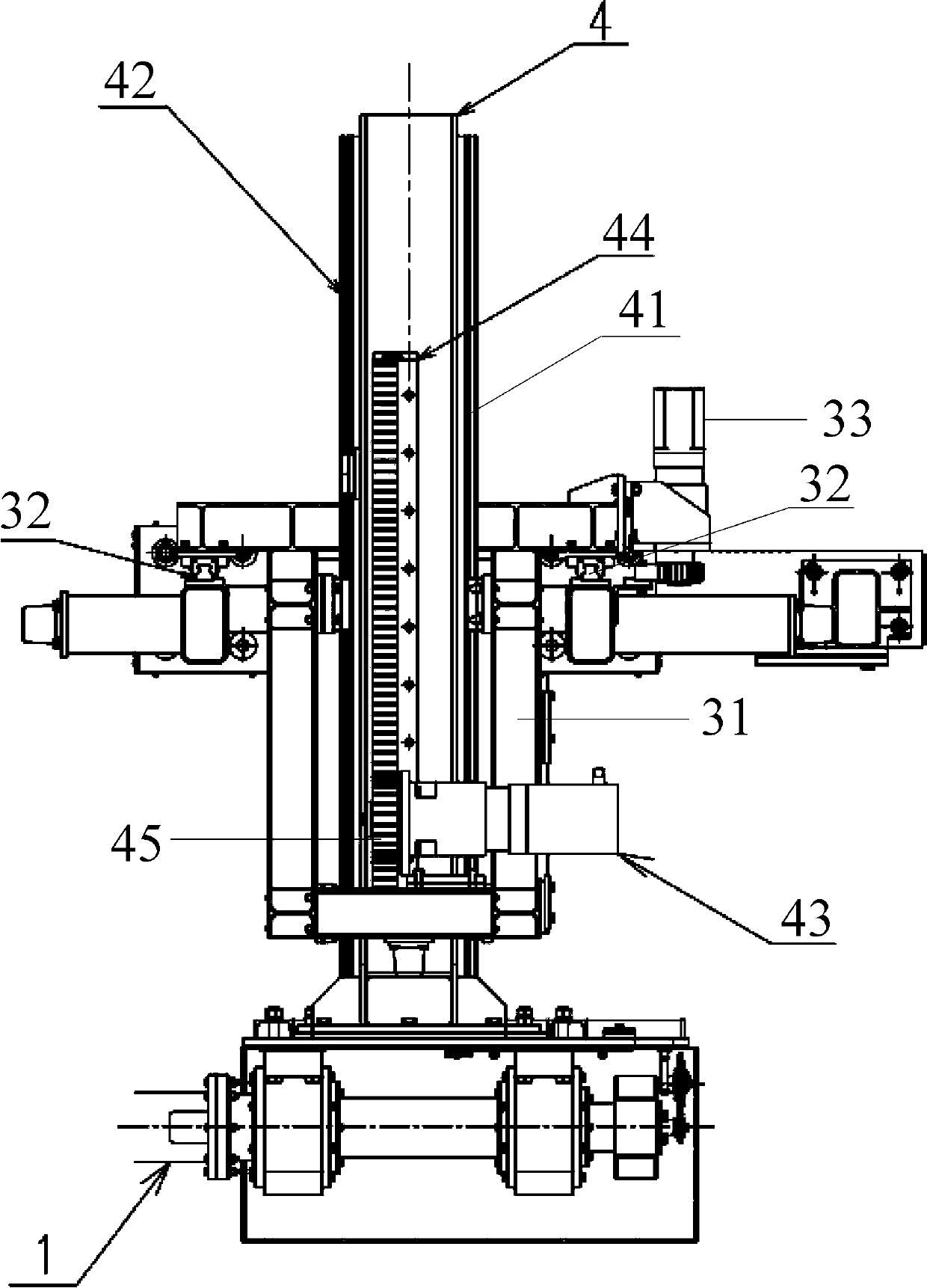

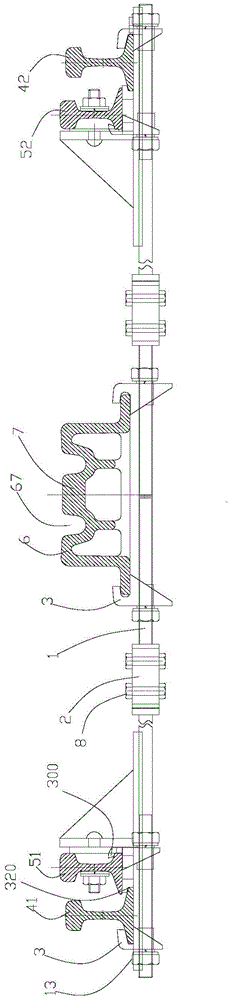

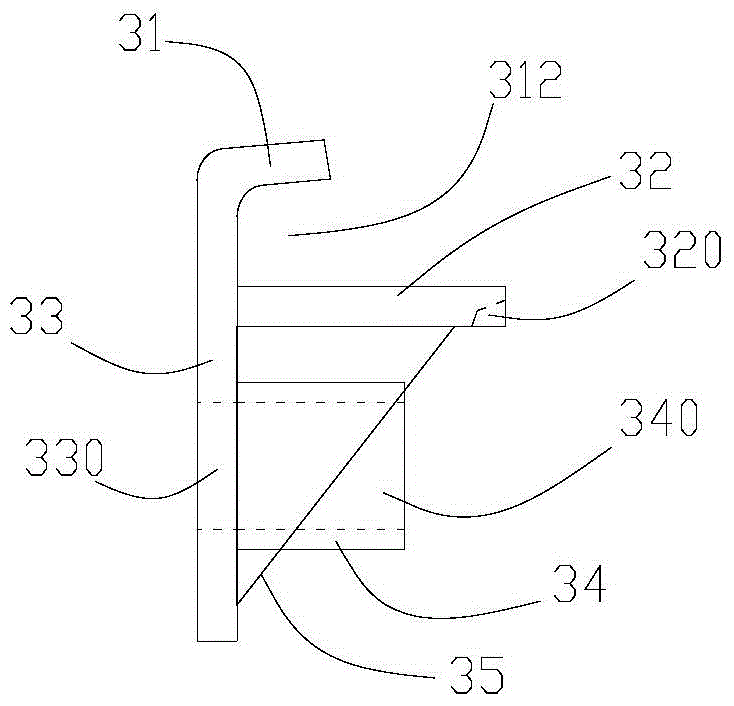

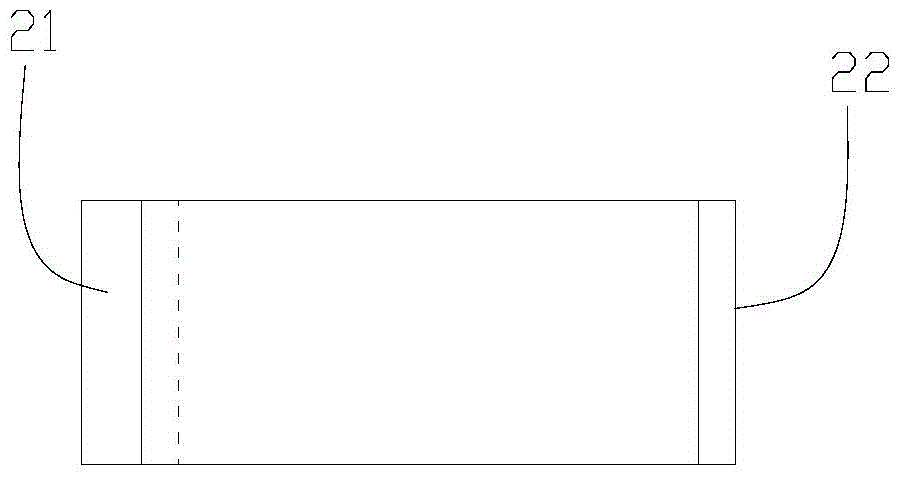

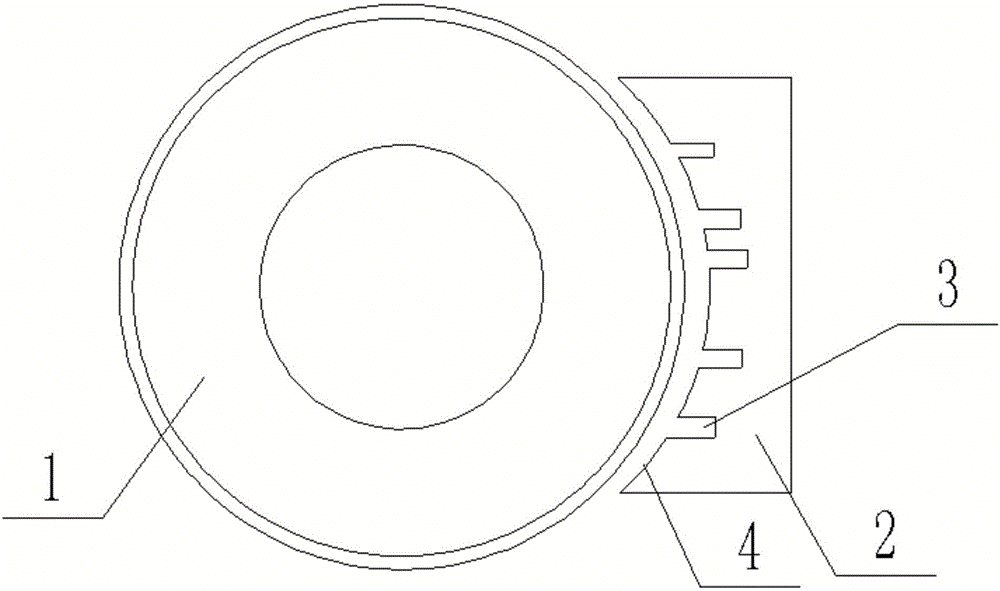

Cold-rolled steel coil inner ring automatic spot welding machine and using method thereof

PendingCN111112817ASolve automatic spot weldingSolve runnabilityResistance electrode holdersWelding/cutting auxillary devicesMetal stripsMetallic materials

The invention relates to the field of unwinding or uncoiling of metal lines, metal strips or other flexible metal materials, in particular to a cold-rolled steel coil inner ring automatic spot weldingmachine and a using method thereof. The cold-rolled steel coil inner ring automatic spot welding machine comprises a spot welding machine component (1), and is characterized by further comprising a X-direction moving vehicle component (2), a Y-direction moving vehicle component (3) and a Z-direction moving vehicle component (4), and the like, wherein the spot welding machine component (1) comprises an inner ring open-circuit reaming device (101), an inner ring tensioning device (102), the spot welding machine (103), a transmission main shaft (107), a synchronous belt driven wheel (109), a synchronous belt driving wheel (110) and the like. The using method of the cold-rolled steel coil inner ring automatic spot welding machine is characterized by comprising the following steps of (1) identifying; (2) moving; (3) stretching; (4) supporting; (5) detecting; (6) welding; and (7) repeating. The cold-rolled steel coil inner ring automatic spot welding machine is high in automation degree, safe and reliable.

Owner:BAOSTEEL ENG & TECH GRP

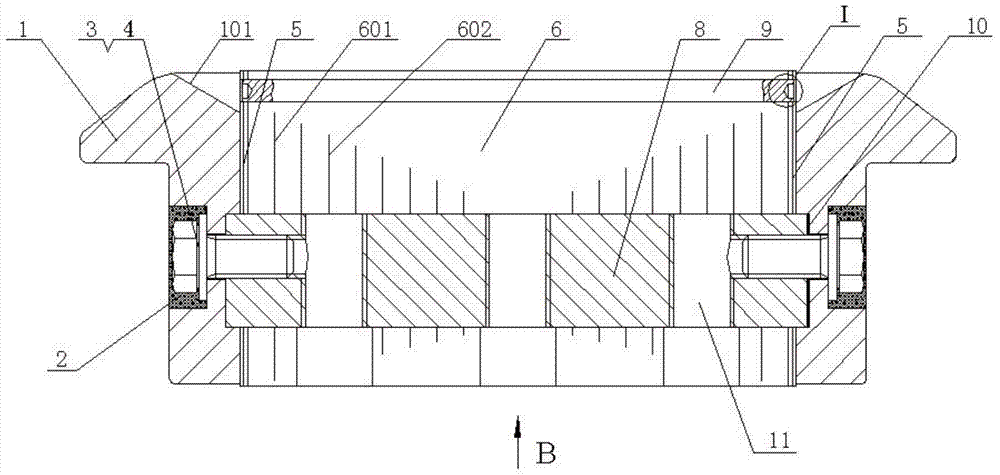

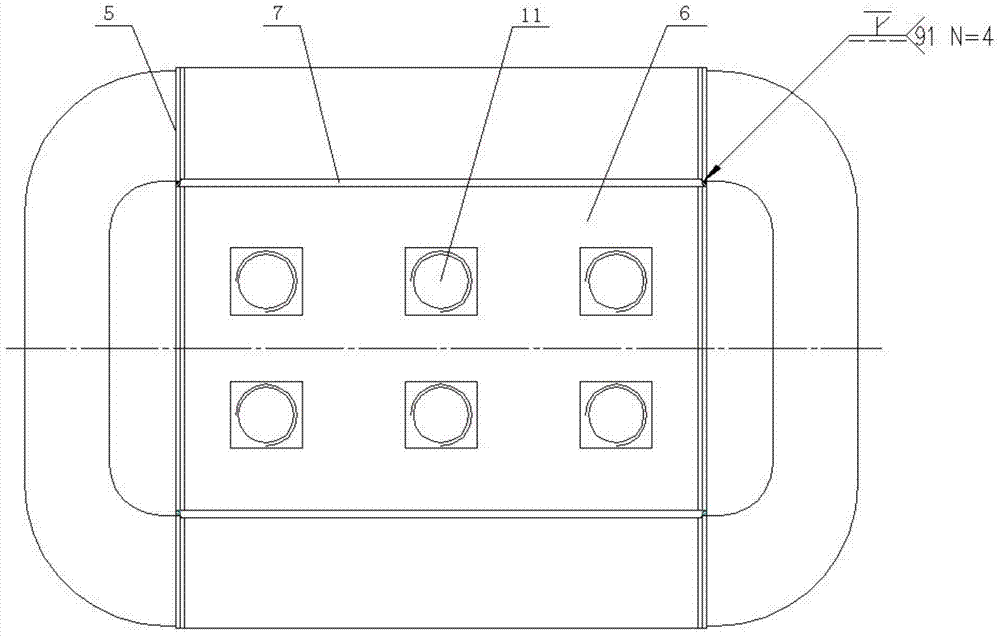

A magnetic pole core with damping strips for a high-speed rotating salient pole generator

ActiveCN104505959BAvoid the problem of unsymmetrical operation of three-phase loadsImprove overvoltageSalient polesPunchingMagnetic poles

The invention provides a magnetic pole core with a damping bar for a high-speed rotating salient pole generator, which mainly includes a magnetic pole pressing plate, a magnetic pole punching set, a punched short circuit ring installed between the magnetic pole pressing plate and the magnetic pole punching set, a damping plate and Magnetic pole tie rod and damping strip, the magnetic pole pressing plate is fixedly connected with the magnetic pole pulling rod, the magnetic pole punching set is compressed between the magnetic pole pressing plate and the magnetic pole tie rod, and the damping strip is installed in the damping strip mounting hole on the magnetic pole punching set Inside, the damping plate is electrically connected to the punched short-circuit ring, and the punched short-circuit ring is short-circuited to the damping bar. The invention is suitable for high-speed rotating salient pole generators when the three-phase load is asymmetrical or the load changes suddenly, and can well avoid the problem of asymmetric operation of the three-phase load of the generator caused by the sudden load change, and improve the asymmetry of the generator The excessively high operating voltage weakens the negative-sequence magnetic field and reduces the sinusoidal distortion rate of the waveform, improving the safety and reliability of the generator.

Owner:CHENGDU CRRC ELECTRIC MOTOR CO LTD

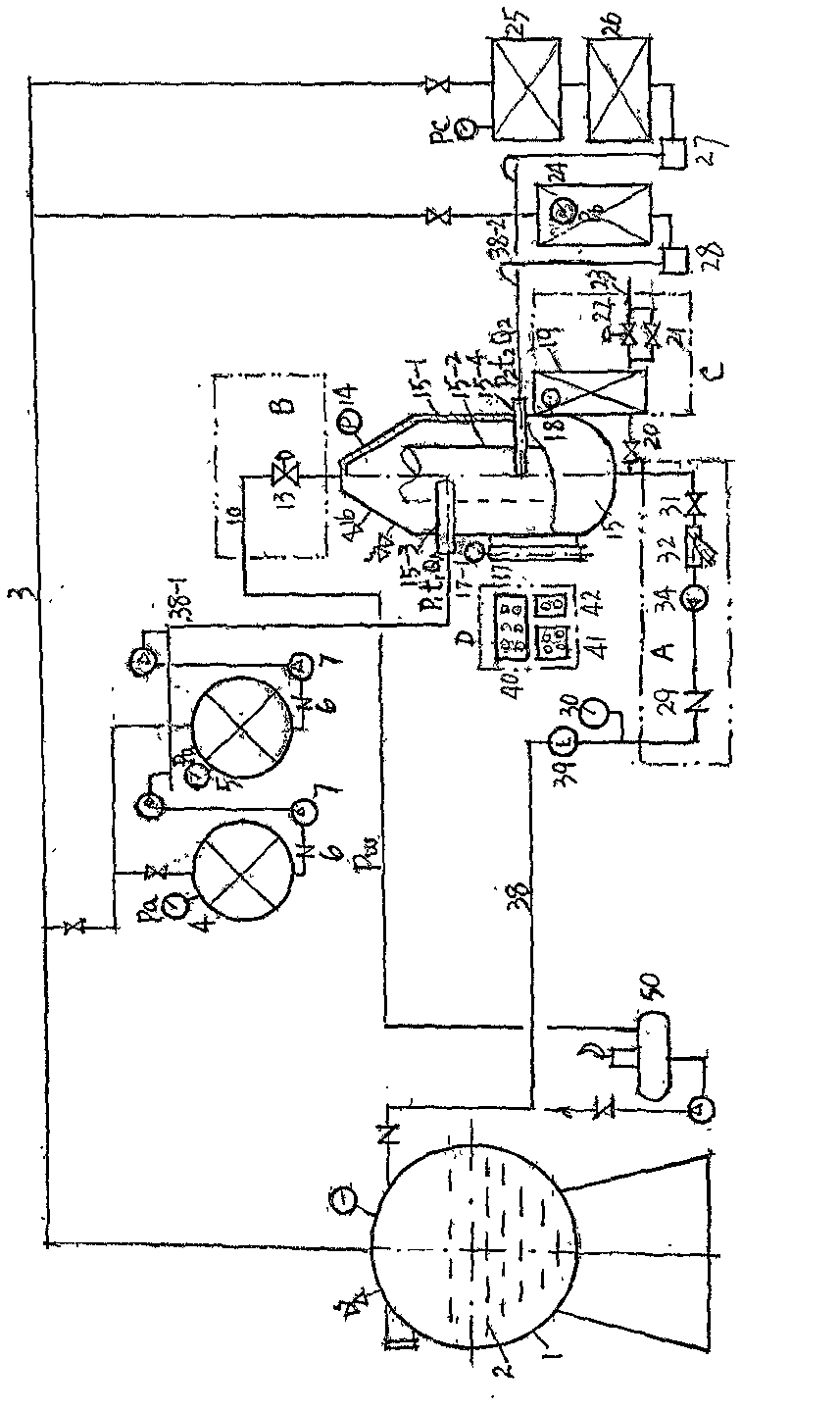

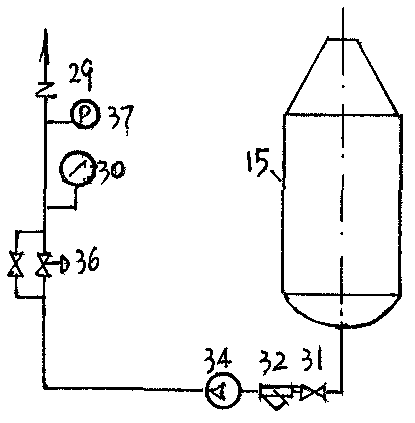

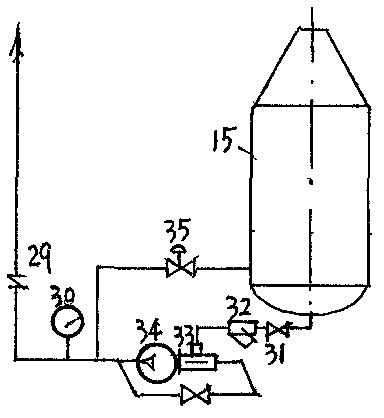

Multi-effect siphon phase-change circular heat transfer system

The invention discloses a multi-effect siphon phase-change circular heat transfer system, belongs to closed boiler heat supply systems, and relates to a boiler heat tube system, a mechanical siphon phase-change circular heat transfer system and a closed condensate water recovering system; intelligent multi-effect siphon condensate water and steam recovering machines are mounted on condensate water passages; the system is selectively equipped with a net-in device and gathering steam traps by a hot process; a traditional trap is eliminated; a gathering drain controller is used as a safety device; a compound storage tank is used for separating resurgent vapor efficiently; a special pump resists high temperature, prevents cavitation and remains seal; condensate water is recovered to a boiler through pump siphon; the resurgent vapor is recovered to be used stage by stage through exhaust stream backpressure / stream-jet siphon; continuous variable-flow water delivery is carried out to adapt to the variable working condition; the intelligent control is achieved; the condensate water is smoothly transferred; no waste heat is discharged; phase-change circular operation is realized to an isobaric / anisotonic boiler heat supply system, so that the isobaric / anisotonic boiler heat supply system becomes a real closed recovery system, and the energy saving and emission reducing effects are excellent. If waste heat is recovered to non-pressure equipment such as a deaerator / softened water tank to be heated, the pump is not used. The remote control operation is carried out through an operation platform of an internet of things.

Owner:HAIMEN ZHUOWEI TEXTILE CO LTD

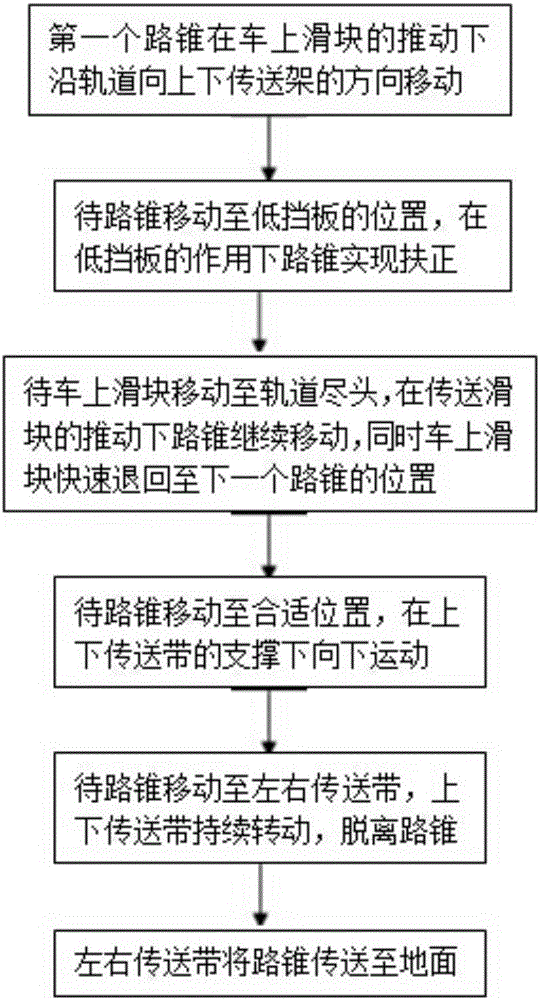

Automatic retractable method of track-type road cone

InactiveCN104894993BFully automatedImprove the manual placement of road conesTraffic signalsRoad signsEngineeringAutomation

The invention relates to a method and device for automatically deploying and retracting a track type road cone. The method comprises the following steps: in the step 1, a first road cone is pushed by a vehicle sliding block to move towards an up and down transferring frame along a track; in the step 2, when the road cone moves to the position of a low baffle, the road cone is righted under the effect of the low baffle; in the step 3, when the vehicle sliding block moves to the end of the track, the road cone is pushed by a transferring sliding block to continuously move, and at the same time, the vehicle sliding block quickly returns to the position of a next road cone; in the step 4, when the road cone moves to an appropriate position, the road cone moves downwards under the supporting of an up and down transferring belt; in the step 5, when the road cone moves to a left and right transferring belt, the up and down transferring belt continuously rotates and is away from the road cone; in the step 6, the road cone is transferred to the ground by the left and right transferring belt. Through the innovation of a road cone deploying system, requirements for labor intensity, efficiency, safety, automation, continuity of deploying the road cones and the like are met during operation of the road cones by people, and the defects existing in a conventional method for deploying the road cones are overcome to a greater extent.

Owner:SHANGHAI DIANJI UNIV

Stabilizers for Frog Systems

ActiveCN104532693BEnsure application stabilityEnsure transportation safetyRailsRail switchesEngineeringSystem parameters

The invention provides a stabilizing device for a frog system. The stabilizing device comprises a tie rod and a plurality of buckling claws, wherein the two ends of the tie rod are used for being connected with a guard rail and a basic rail, the middle of the tie rod is used for being connected with a frog, and the buckling claws are adjustably arranged on the tie rod and provided with openings for steel rail bottoms of the guard rail, the basic rail and the frog to be embedded therein and used for fixedly connecting the guard rail, the basic rail and the frog to the tie rod. The stabilizing device is used for guaranteeing the application stability of the frog system, the abrasion and impact to the system and the system parameter change caused when a locomotive passes are avoided, and the running potential safety hazards of the locomotive are eliminated. The corresponding parameters can be adjusted at any time according to the abrasion situation of the guard rail. The integral stability of the system is ensured, and the rail transportation safety is guaranteed.

Owner:SHANDONG IRON & STEEL CO LTD

Capacitive grounding current distributed compensation method and device for medium-voltage power supply system

ActiveCN101872969BReduced ground inductanceReduce generationEmergency protective arrangements for limiting excess voltage/currentTransformerElectric capacity

The invention relates to a capacitive grounding current distributed compensation method for a medium-voltage power supply system, which belongs to the technical field of the capacitive grounding current compensation of a neutral non-grounding power supply system. In the method, capacitive grounding current distributed compensation transformers are arranged on lines, with relatively greater capacitive grounding currents, of the system in a distributed way, and only compensate the capacitive grounding currents of the corresponding lines, wherein the compensation capacity of each capacitive grounding current distributed compensation transformer is 1.1 times the capacitive grounding currents of the corresponding lines; and 40 to 60 percent of the capacitive grounding currents of the system iscompensated by the capacitive grounding current distributed compensation of the whole power grid, and the other is comprehensively compensated by arc extinguishing devices of transformer substations.The capacitive grounding current distributed compensation method has the advantages that: the capacitive grounding current distributed compensation transformers are adopted, so arrangement is simple and maintenance is unnecessary; operation is simple and the capacitive grounding current is compensated in real time; and the power supply reliability of the power grid is radically improved.

Owner:JILIN PROVINCE ELECTRIC POWER RES INST OF JILIN ELECTRIC POWER CO LTD +2

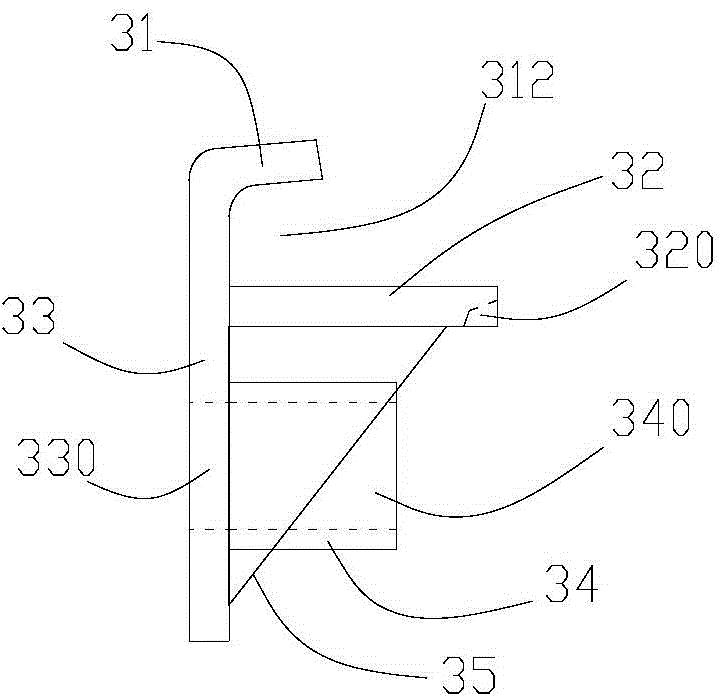

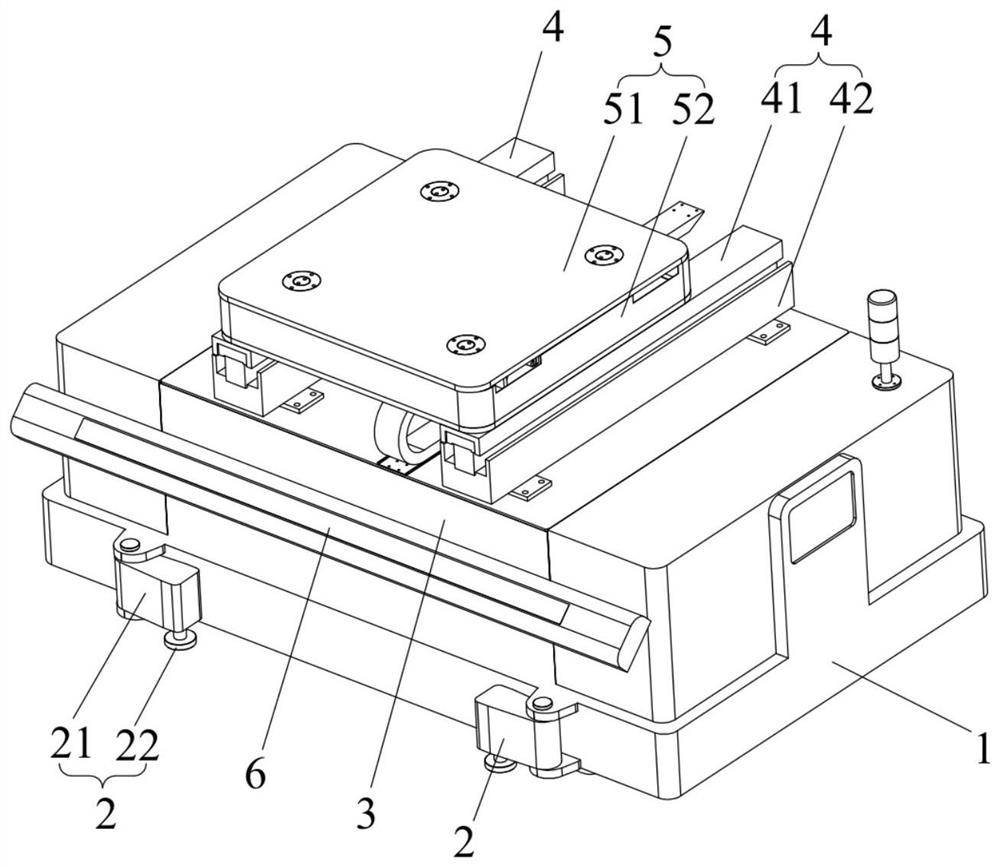

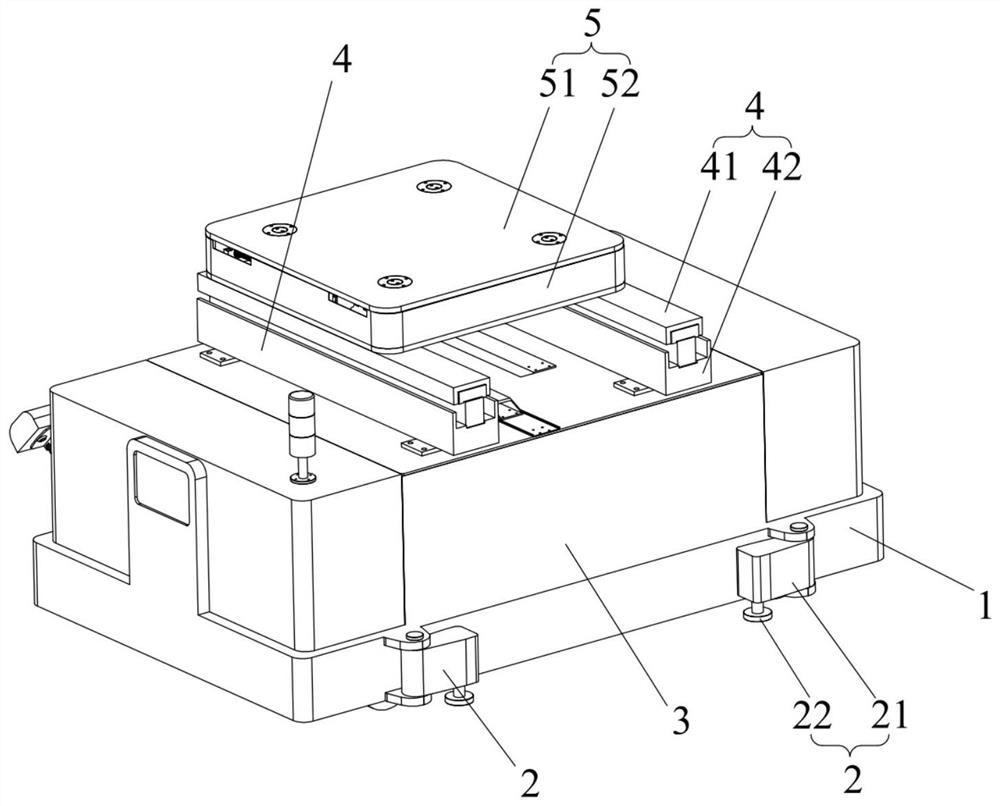

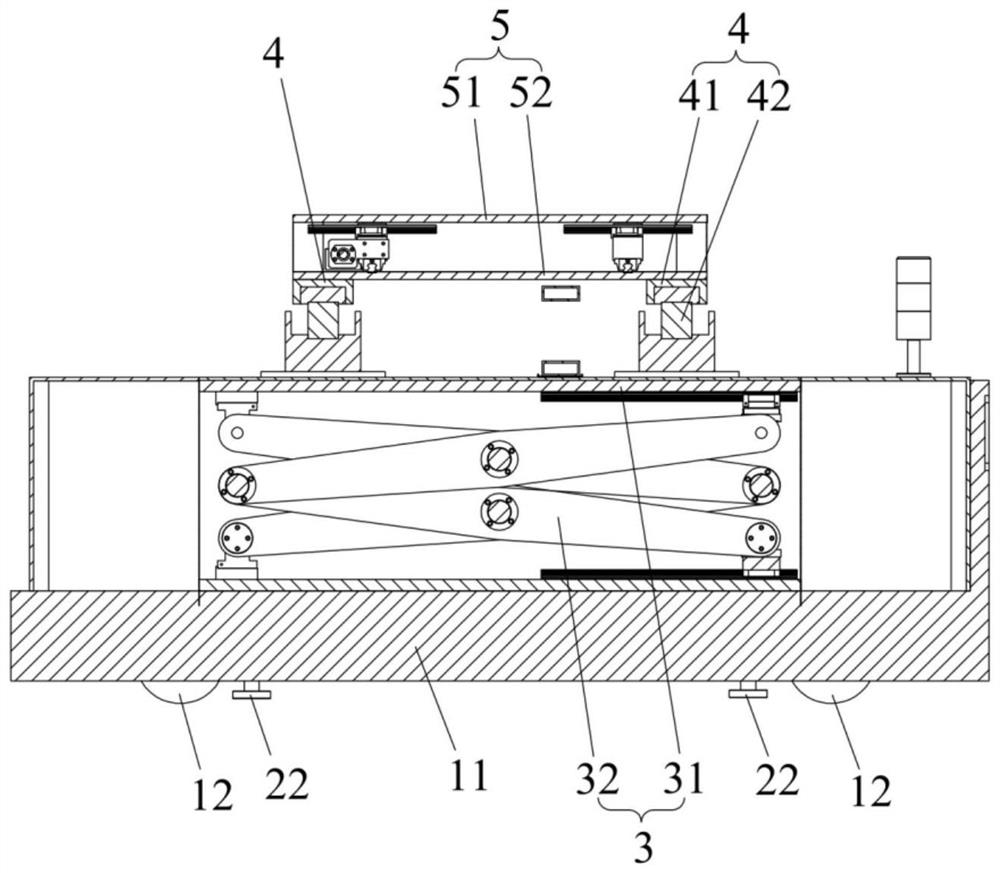

Dismounting and mounting device

PendingCN113955673ASimple and fast operationReduce volumeLifting framesAutomationElectrical and Electronics engineering

The invention relates to the technical field of EMU train maintenance, and discloses a dismounting and mounting device. The dismounting and mounting device comprises a walking unit, a supporting unit, a lifting unit, a telescopic unit and an alignment unit, the supporting unit is arranged on the walking unit and used for supporting the walking unit, the lifting unit is arranged on the walking unit in a height-adjustable manner, the telescopic unit is arranged on the lifting unit in a sliding manner, and the alignment unit is arranged on the telescopic unit and used for bearing to-be-dismounted and to-be-mounted parts. The dismounting and mounting device is easy and convenient to operate, small in size and high in automation degree, the dismounting and mounting efficiency is improved, the number of operators is reduced, and potential safety hazards of operation are eliminated.

Owner:BEIJING RAILWAY INST OF MECHANICAL & ELECTRICAL ENG

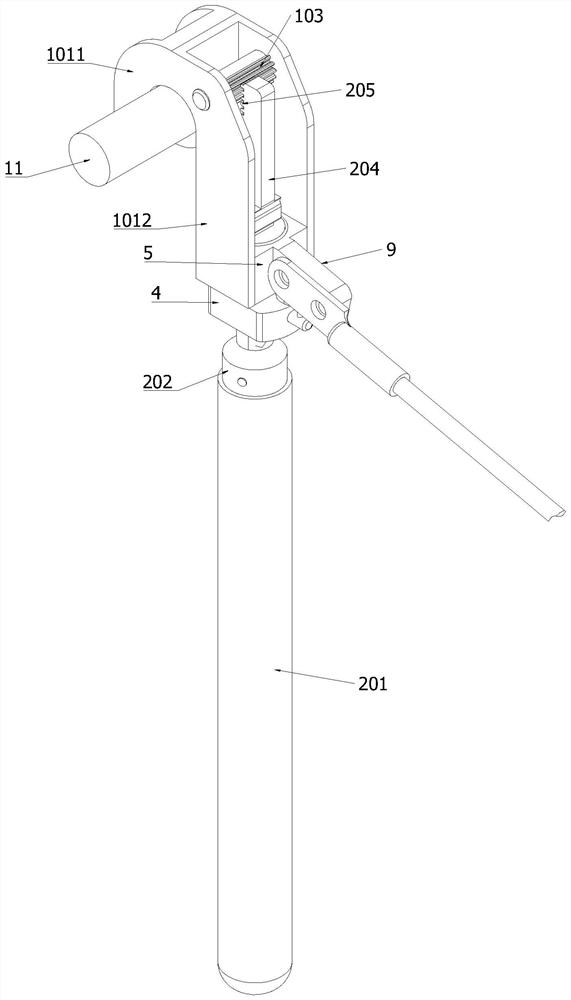

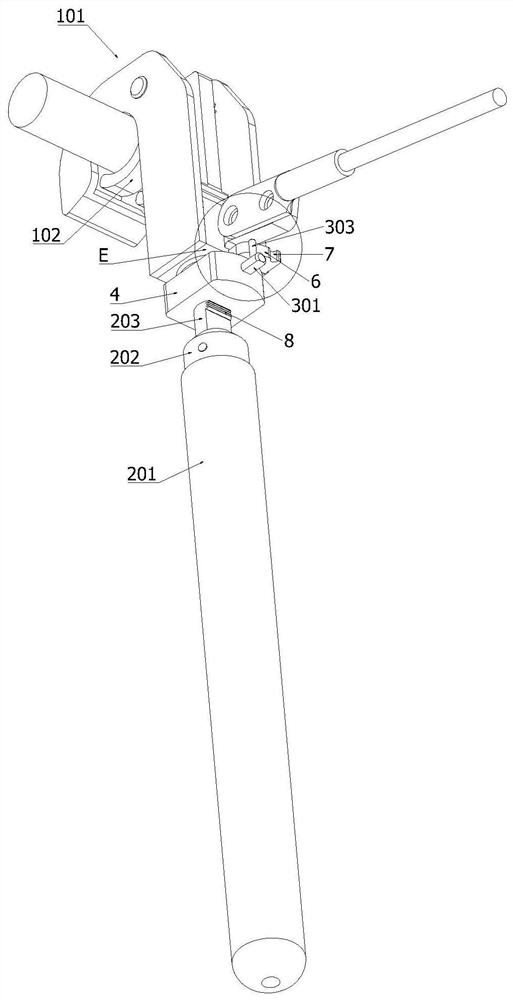

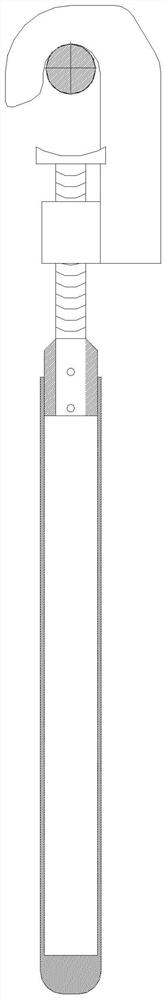

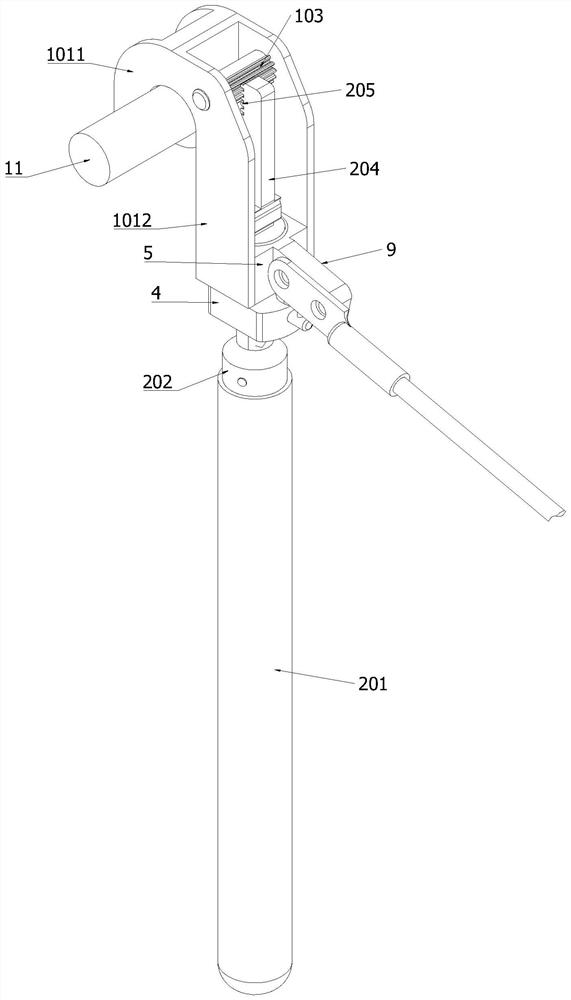

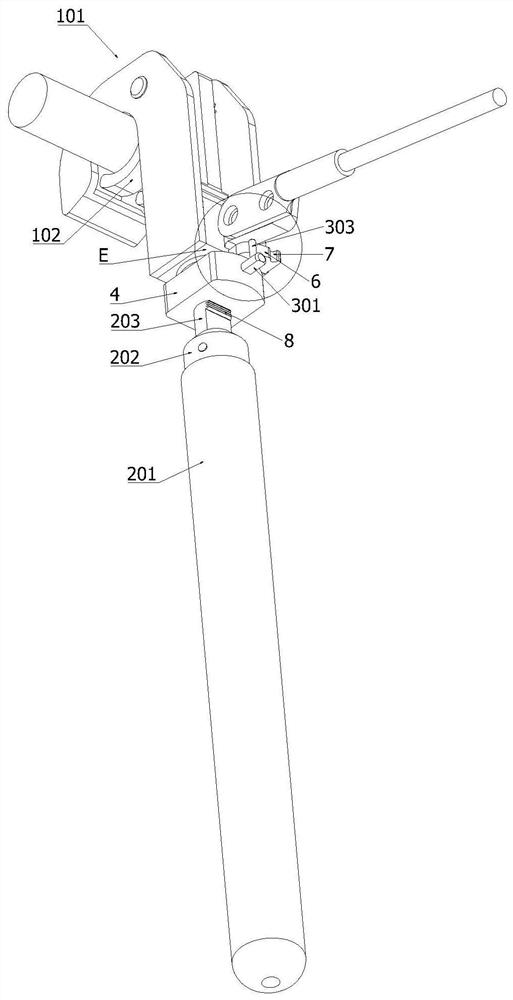

Universal push-pull micro-torsion type grounding wire device

ActiveCN112038796AHanging highImprove the efficiency of disassembly workElectric connection structural associationsReciprocating motionControl theory

The invention relates to the technical field of power grounding wire clamps, and provides a universal push-pull micro-torsion type grounding wire device, which comprises a clamping part, a poking piece and a locking piece, wherein the clamping part comprises a fixed claw and a movable claw which can be opened and closed relative to the fixed claw; the poking piece is movably connected with the clamping part and can slide in a reciprocating mode in the direction where the axis of the poking piece is located to poke the movable claw to rotate relative to the fixed claw so as to achieve opening and closing of the clamping part; and the locking piece can move back and forth to be close to or far away from the poking piece, so that the locking piece and the poking piece are propped against eachother and separated from each other. The grounding wire can be conveniently and rapidly assembled and disassembled, the clamping stability and the wire clamp anti-falling performance are reliable, and the problems of inconvenient operation, high labor intensity, long time consumption, potential safety hazard and the like generally existing in the process of assembling and disassembling the grounding wire are thoroughly solved.

Owner:EXTRA HIGH VOLTAGE POWER TRANSMISSION NANJING OF CHINA SOUTHERN POWER GRID +1

Method for welding connector on stiff tubular column

ActiveCN106493478AReduce labor costsEliminate operational safety hazardsWelding/cutting auxillary devicesAuxillary welding devicesRebarEngineering

The invention relates to a method for welding a connector on a stiff tubular column. The method comprises the following steps: inputting data of the stiff tubular column and data of each rebar on a beam column joint into a drawing tool at equal proportions, determining the position, angle and elevation of the connector; drawing a connector positioning template in the drawing tool according to the data of the stiff tubular column and the data of position, angle and elevation of the connector; machining and forming the connector positioning template through a numerically-controlled machine tool; welding the connector positioning template on the corresponding position of the stiff tubular column; placing the connector on the corresponding position of the connector positioning template, welding the connector on the stiff tubular column; dismounting the connector positioning template. The investment on the labor charges is reduced; the potential safety hazard caused by operation in a narrow space by a constructor is avoided, the construction quality is strengthened, the mechanization of the building construction and instrumentalization of finished products are realized, the welding of the connector is not needed on the construction site, and the work amount of field welding is reduced.

Owner:中铁十六局集团城市建设发展有限公司 +1

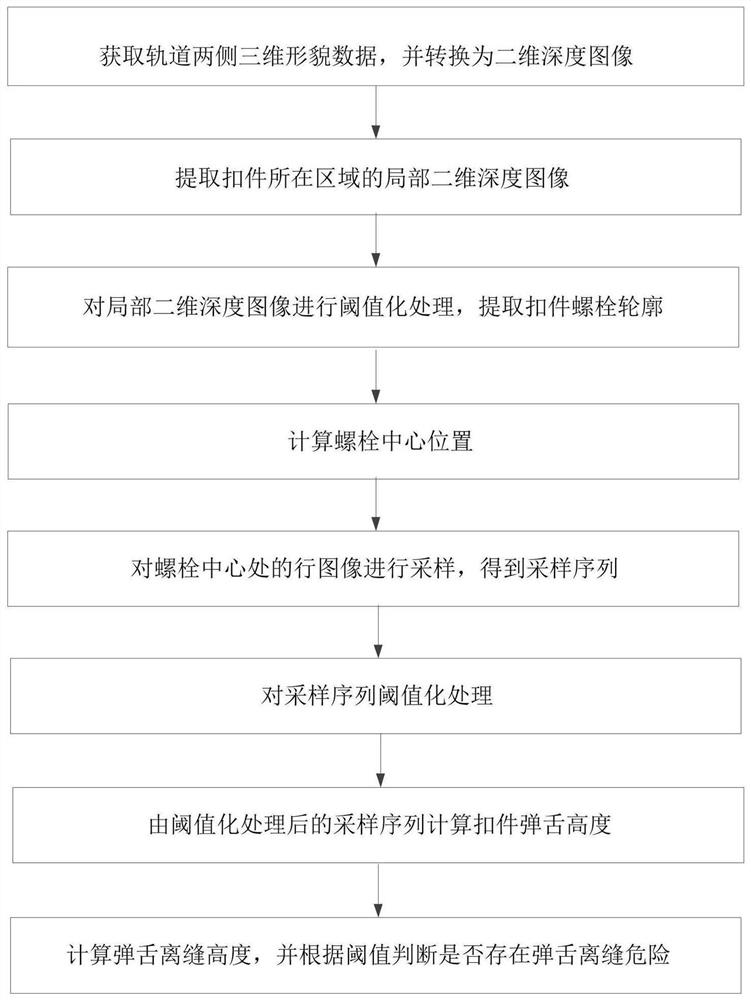

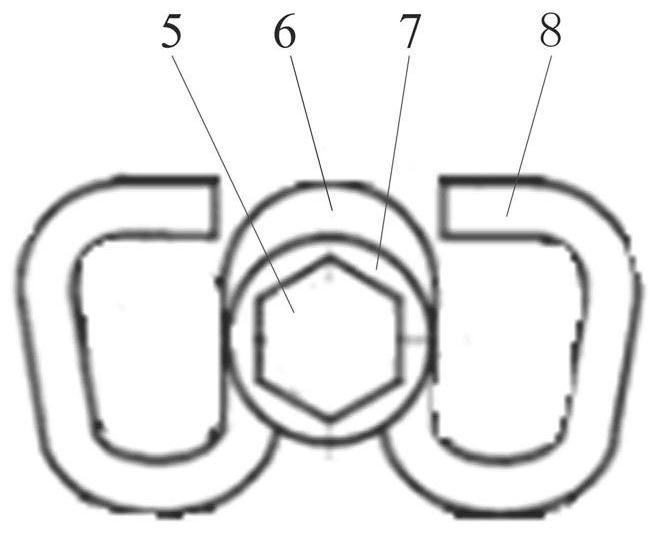

A method for detecting the seam separation of the spring tongue of a fastener

ActiveCN110567397BOvercoming the difficulty of detecting spring tongue separationEliminate operational safety hazardsUsing optical meansImage extractionTrackway

The invention discloses a method for detecting the seam separation of a spring tongue of a fastener, which belongs to the field of railway infrastructure detection. The main steps of the present invention are: acquire the three-dimensional shape data on both sides of the track through the three-dimensional data acquisition system, convert it into a two-dimensional depth image, extract the local two-dimensional depth image of the area where the fastener is located, and perform thresholding on it Processing, extracting the fastener bolt contour, calculating the bolt center position, and starting from the bolt center, sampling to the side of the rail, and then thresholding the sampling sequence to calculate the height of the fastener spring tongue and the distance between the spring tongue and the seam. And according to the threshold value, it is judged whether there is a danger of the tongue leaving the seam. The detection method proposed by the invention can automatically and effectively detect the separation of the spring tongue of the fastener, and timely eliminate hidden dangers of train operation safety.

Owner:成都精工华耀科技有限公司

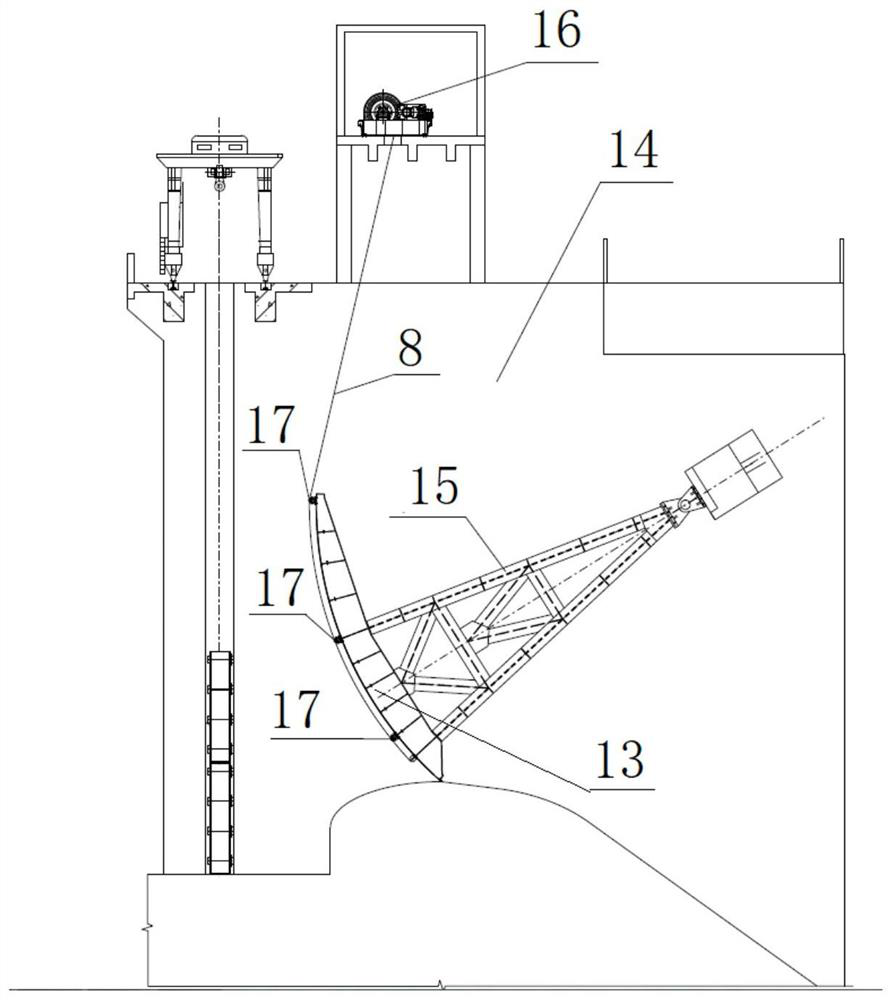

Tooth type guide device for steel wire rope of top-exposed type radial gate and mounting structure of tooth type guide device

PendingCN113026683AAvoid cutsEliminate operational safety hazardsBarrages/weirsEngineeringRelative space

The invention relates to the technical field of metal structures of water conservancy and hydropower engineering, and discloses a tooth type guide device for a steel wire rope of a top-exposed type radial gate. The tooth type guide device comprises a base, wherein the base comprises a bottom plate; two supporting plates are mounted on the bottom plate; holes are formed in the two supporting plates; the two ends of a wheel shaft are separately positioned in the holes of the supporting plates; at least three guide steel plates are uniformly welded on the wheel shaft; the length direction of the guide steel plates is parallel to that of the wheel shaft; the extension line of the short side of each guide steel plate points to the circle center of the cross section of the wheel shaft; the outer side surface of each guide steel plate is sunken towards the inner side to form a groove with radian; and the steel wire rope is positioned in the grooves. The invention further discloses a mounting structure of the tooth type guide device for the steel wire rope of the top-exposed type radial gate. According to the tooth type guide device for the steel wire rope of the top-exposed type radial gate and the mounting structure of the tooth type guide device disclosed by the invention, the problem that the steel wire rope is cut by the gate top as the relative space position arrangement of the gate and a hoist is not reasonable is solved, and abrasion of the steel wire rope is reduced.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

A general-purpose push-pull micro-twisting grounding wire device

ActiveCN112038796BHanging highImprove the efficiency of disassembly workElectric connection structural associationsReciprocating motionControl theory

The present invention relates to the technical field of power grounding wire clips, and provides a general-purpose push-pull micro-twisted grounding wire device, the clamping part includes a fixed claw and a movable claw that can be opened and closed relative to the fixed claw; The clamping part is movably connected, and the toggle part can reciprocate and slide along the direction of its own axis to move the movable claw to rotate relative to the fixed claw to realize the opening and closing of the clamping part; the locking part can reciprocate to approach or away from the toggle member to realize the abutment and disengagement between the lock member and the toggle member; The abutment and disengagement between the stop assembly and the toggle piece. The invention can not only realize convenient and fast assembly and disassembly of the grounding wire, but also has reliable clamping and stabilization performance and wire clip anti-off performance, which completely solves the common problems of inconvenient operation, high labor intensity and energy consumption when installing and disassembling the grounding wire. long time and there are safety hazards and other issues.

Owner:EXTRA HIGH VOLTAGE POWER TRANSMISSION NANJING OF CHINA SOUTHERN POWER GRID

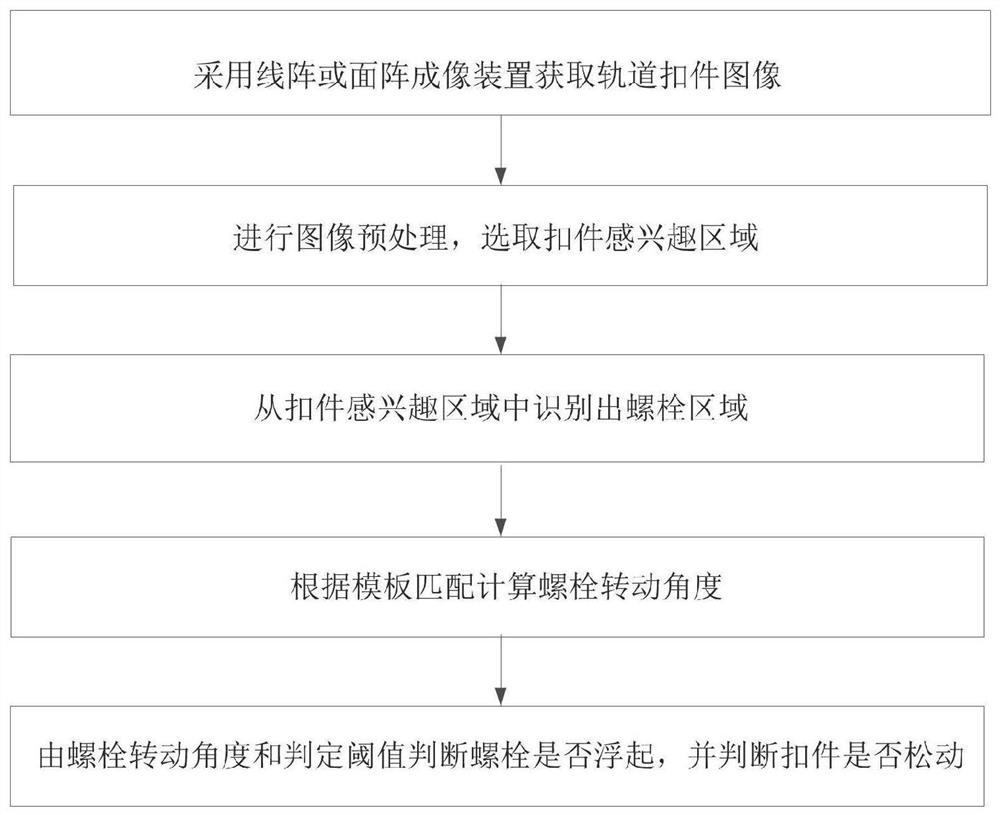

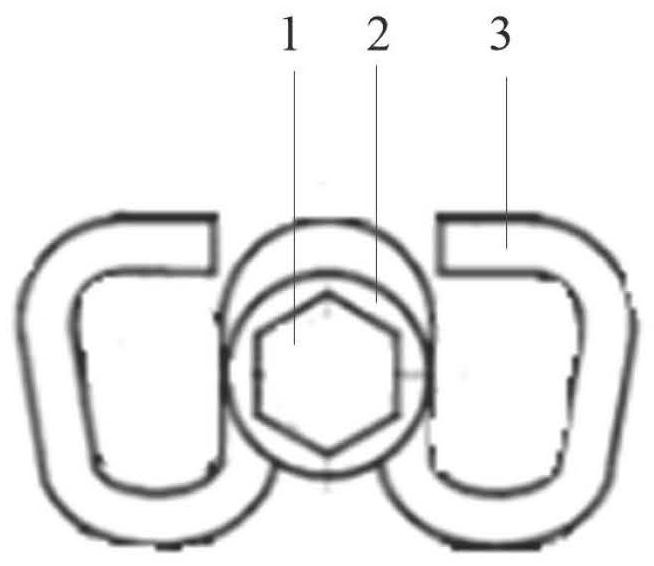

A Loose Detection Method for Rail Fasteners Based on Angle Comparison

ActiveCN110567680BPrevent looseningEliminate operational safety hazardsImage analysisCharacter and pattern recognitionTemplate matchingThresholding

The invention discloses a method for detecting loose rail fasteners based on angle comparison, which belongs to the field of railway infrastructure detection. The main steps of the present invention are as follows: using a linear array or area array imaging device to acquire the image of the rail fastener, performing image preprocessing, selecting the area of interest of the fastener, identifying the bolt area therefrom, performing template matching, calculating the bolt rotation angle, and according to the threshold value The angle judges whether the bolt rotates and floats, and then judges whether the track fastener is loose. The detection method proposed by the invention is easy to use, does not change the structure of the existing railway fasteners, and can judge whether the rail fasteners are loose by detecting whether bolts or nuts of various types of fasteners rotate and float.

Owner:成都精工华耀科技有限公司

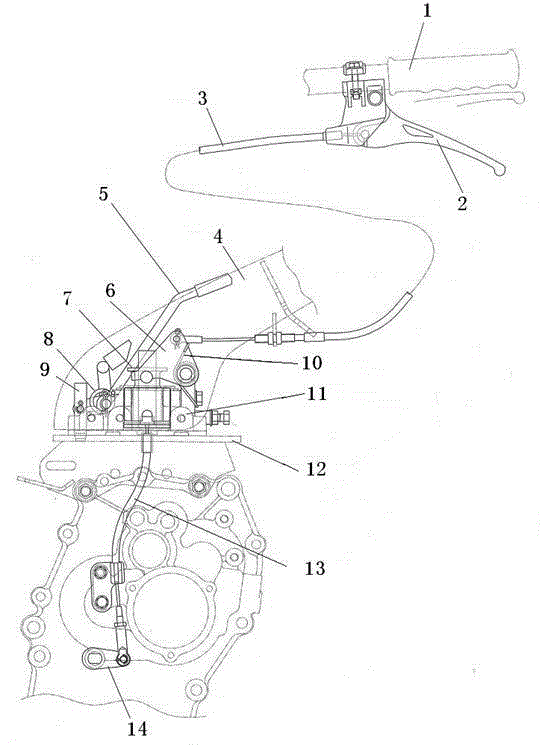

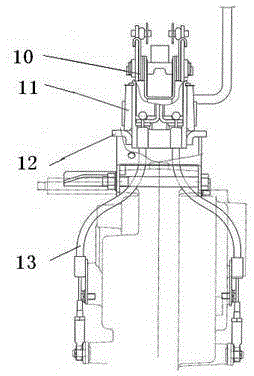

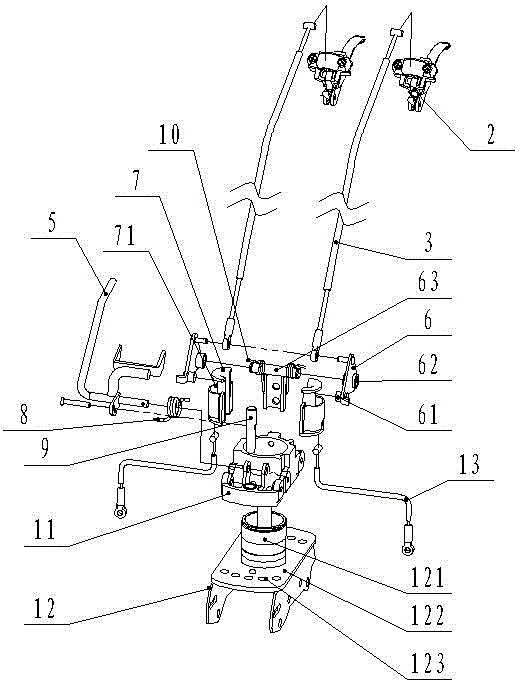

Steering clutch mechanism for field management machine

InactiveCN102963249BEnsure safetyCompact structureVehicle mounted steering controlsControl devicesEngineeringClutch

The invention provides a steering clutch mechanism ensuring that a right clutch and a left clutch of a field management machine automatically switch when an armrest rack of the field management machine steers, and a clutch handle always controls the clutching of wheel shafts on the same side. The steering clutch mechanism comprises the clutch handle arranged on the armrest rack and the clutches arranged on a machine body, wherein the clutch handle is connected and transmitted with the clutches by clutch pull wires. The steering clutch mechanism is characterized in that the clutch pull wires comprise clutch rotating pull wires and clutch fixed pull wires; the clutch rotating pull wires are connected with the clutch handle; the clutch fixed pull wires are connected with the clutches; and an automatic clutch switching mechanism is arranged among the clutch rotating pull wires and the clutch fixed pull wires, and can rotate horizontally around the machine body on the armrest rack to allow the clutch handle to always control the clutching of wheel shafts on the same side. The steering clutch mechanism is compact in structure and convenient to operate.

Owner:江苏久泰农业装备科技有限公司

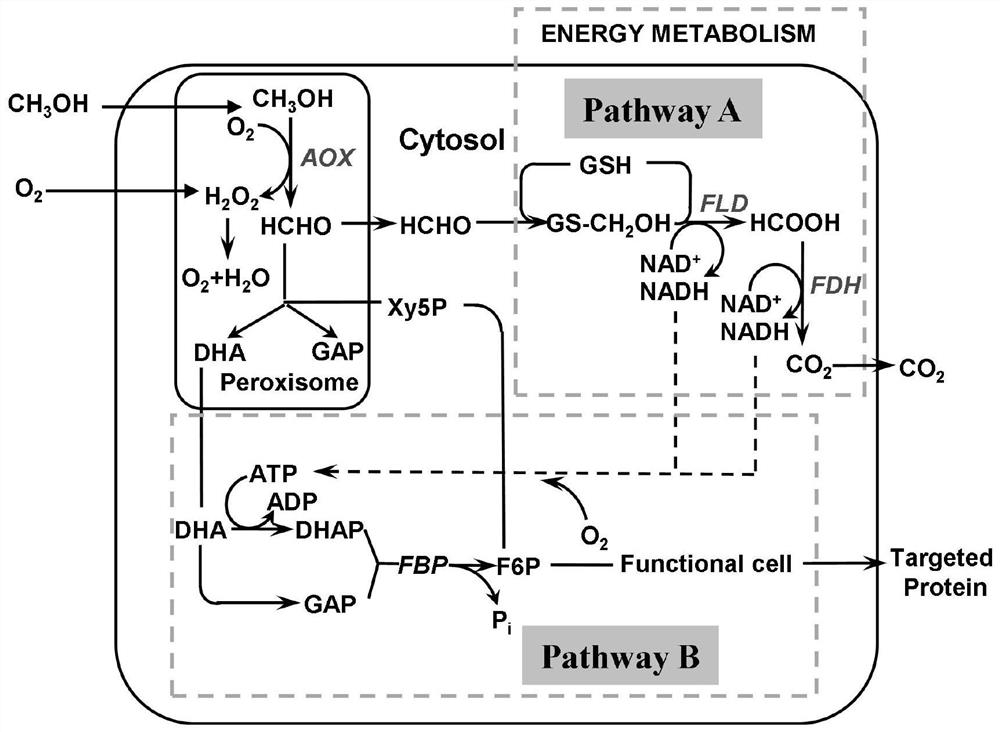

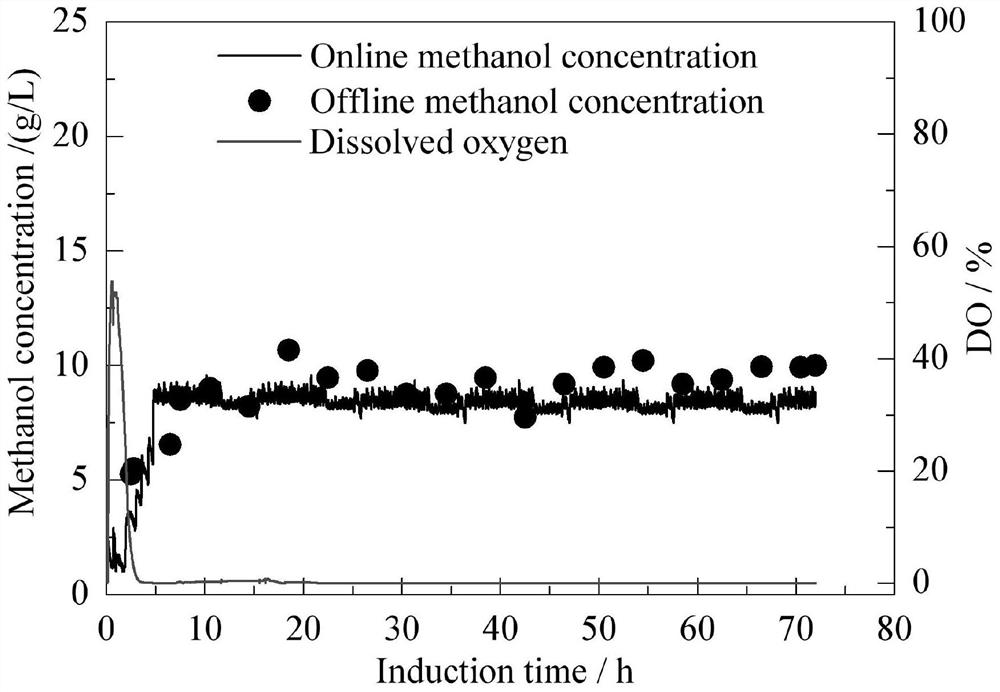

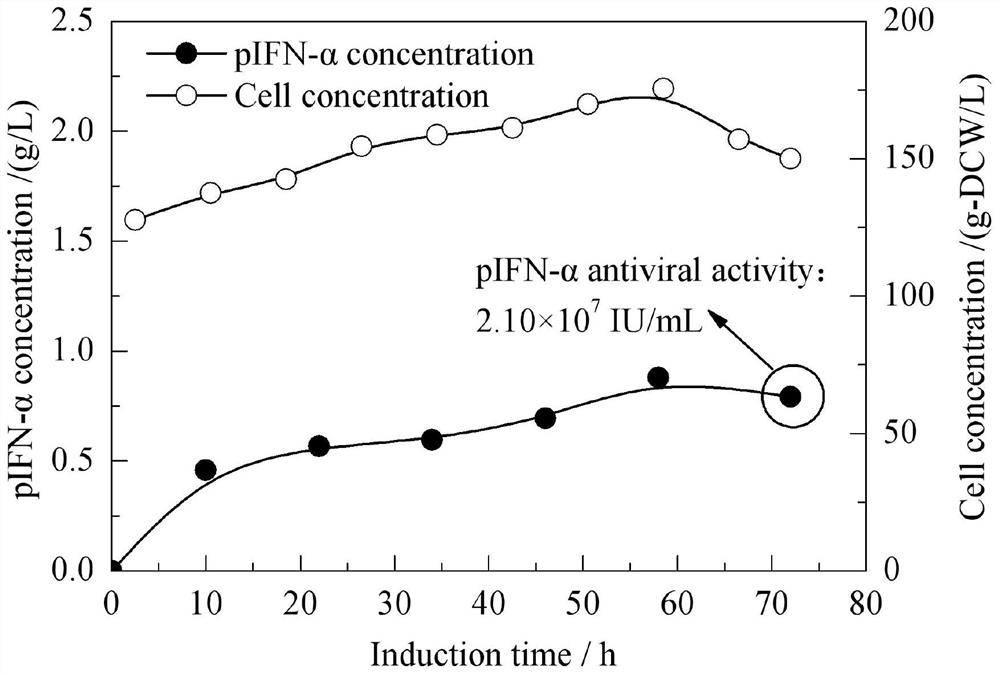

a reinforcement mut s Method for expressing heterologous protein in Pichia pastoris

ActiveCN109402039BMetabolic Activity Restoration/IntensificationQuick useMicroorganism based processesFermentationPichia pastorisHeterologous

The invention discloses a method for intensifying expression of heterologous protein by MutS type pichia pastoris, and belongs to the technical field of fermentation engineering. According to the method disclosed by the invention, the methanol concentration and the dissolved oxygen (DO) concentration in a methanol induction process of MutS type pichia pastoris are switched back and forth between high / low level and low / high level according to different cycle lengths so as to improve the metabolic activity of the MutS type pichia pastoris and the specific consumption speed of methanol, reduce the accumulation of intracellular methanol and remarkably improve the concentration and activity of the heterologous protein; by adopting the method, the expression level of heterologous protein by theMutS type pichia pastoris is increased by about 1.5 times over traditional high methanol concentration / low DO induction strategy and relatively low methanol concentration / high DO induction strategy.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com