Pressure vessel barrel section assembling device

A technology of pressure vessel and cylinder joints, which is applied in the field of pressure vessel cylinder joint assembly devices, to achieve the effects of eliminating hidden dangers of operation safety, reducing labor intensity and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the drawings and specific implementations:

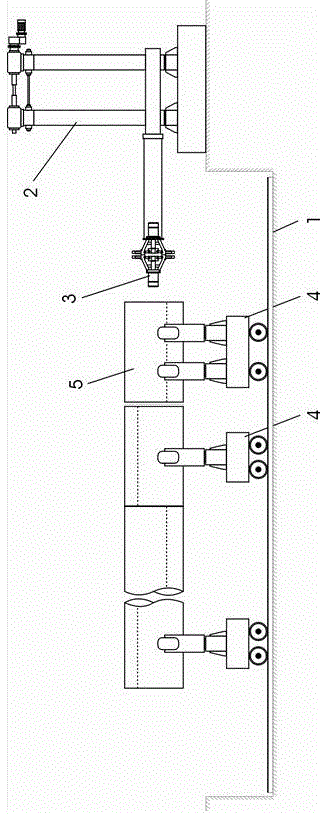

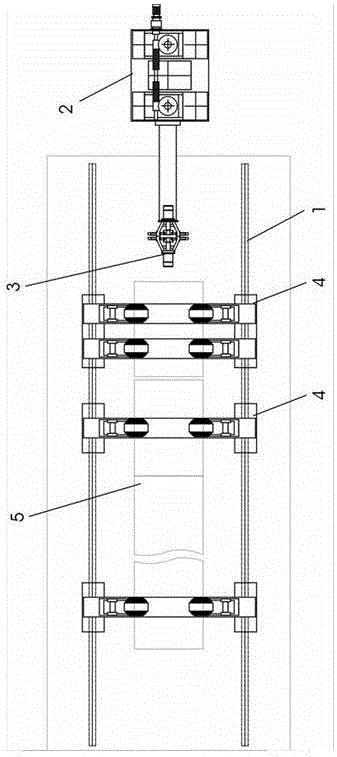

[0026] according to figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 The illustrated pressure vessel tube section pairing device includes a guide rail 1, on which a roller frame device 4 for supporting and moving the tube section 5 is provided, and a cantilever lifting device 2 is provided on one side of the tube section 5, One end of the cantilever 24 of the cantilever lifting device 2 extends in the direction of the tube section 5, and the protruding end of the cantilever 24 is provided with a mouthpiece 3, and by adjusting the lifting of the cantilever 24, the mouthpiece 3 is always kept concentric with the center of the tube section 5 .

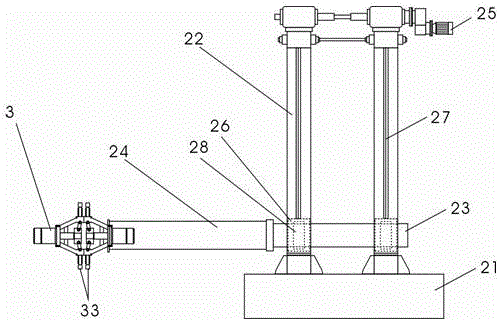

[0027] according to image 3 As shown, the cantilever lifting device 2 includes a frame base 21, a frame 22, a cantilever spindle 23, a cantilever 24, and a driving device 25. The frame 22 is fixed on the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com