Cold-rolled steel coil inner ring automatic spot welding machine and using method thereof

A spot welding machine and inner ring technology, applied in welding equipment, welding equipment, resistance welding equipment, etc., can solve the problems of restricting production rhythm, inconsistent production requirements, leading drooping, etc., to eliminate hidden dangers in operation, reduce hidden dangers, Guaranteed effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

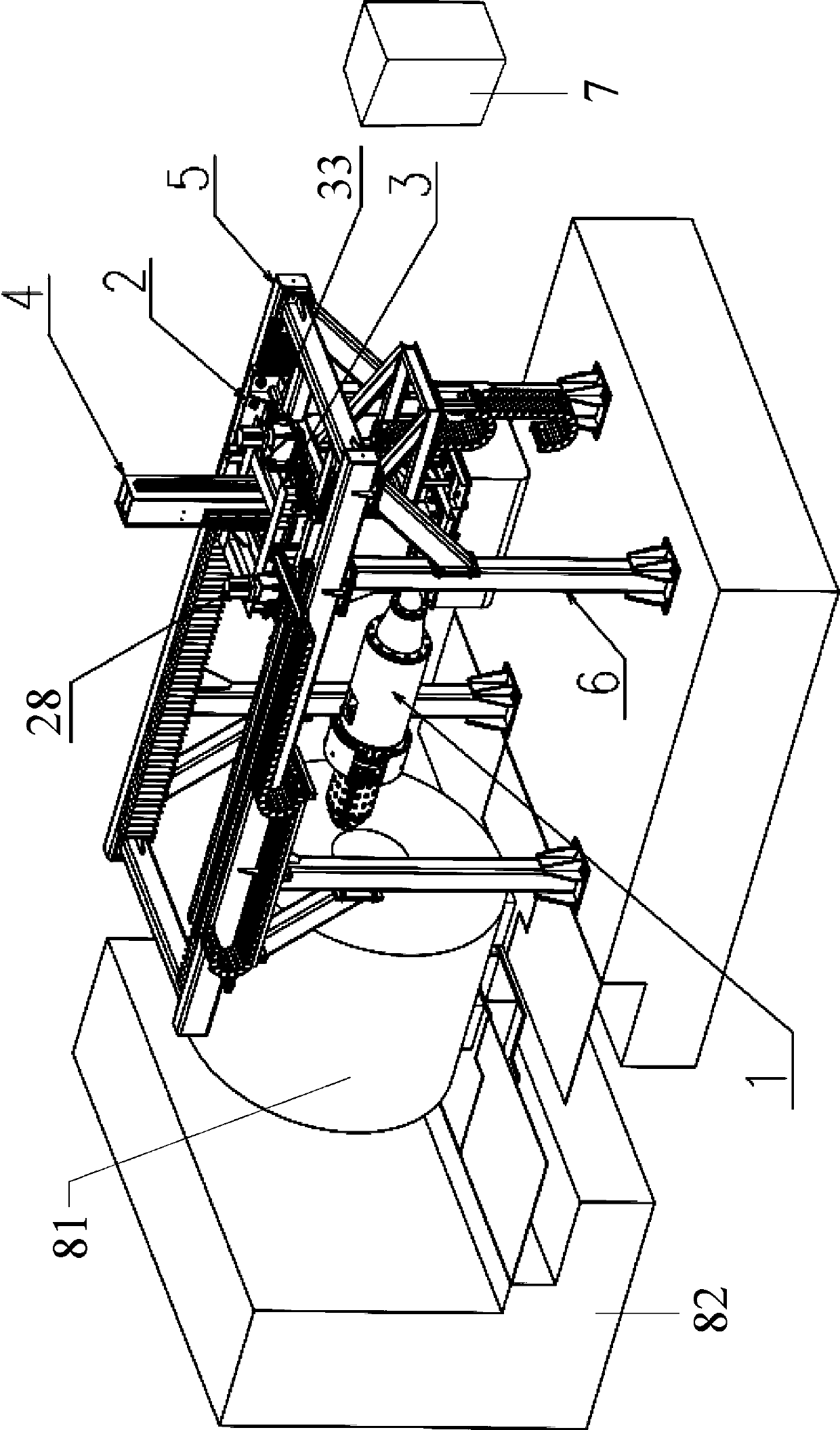

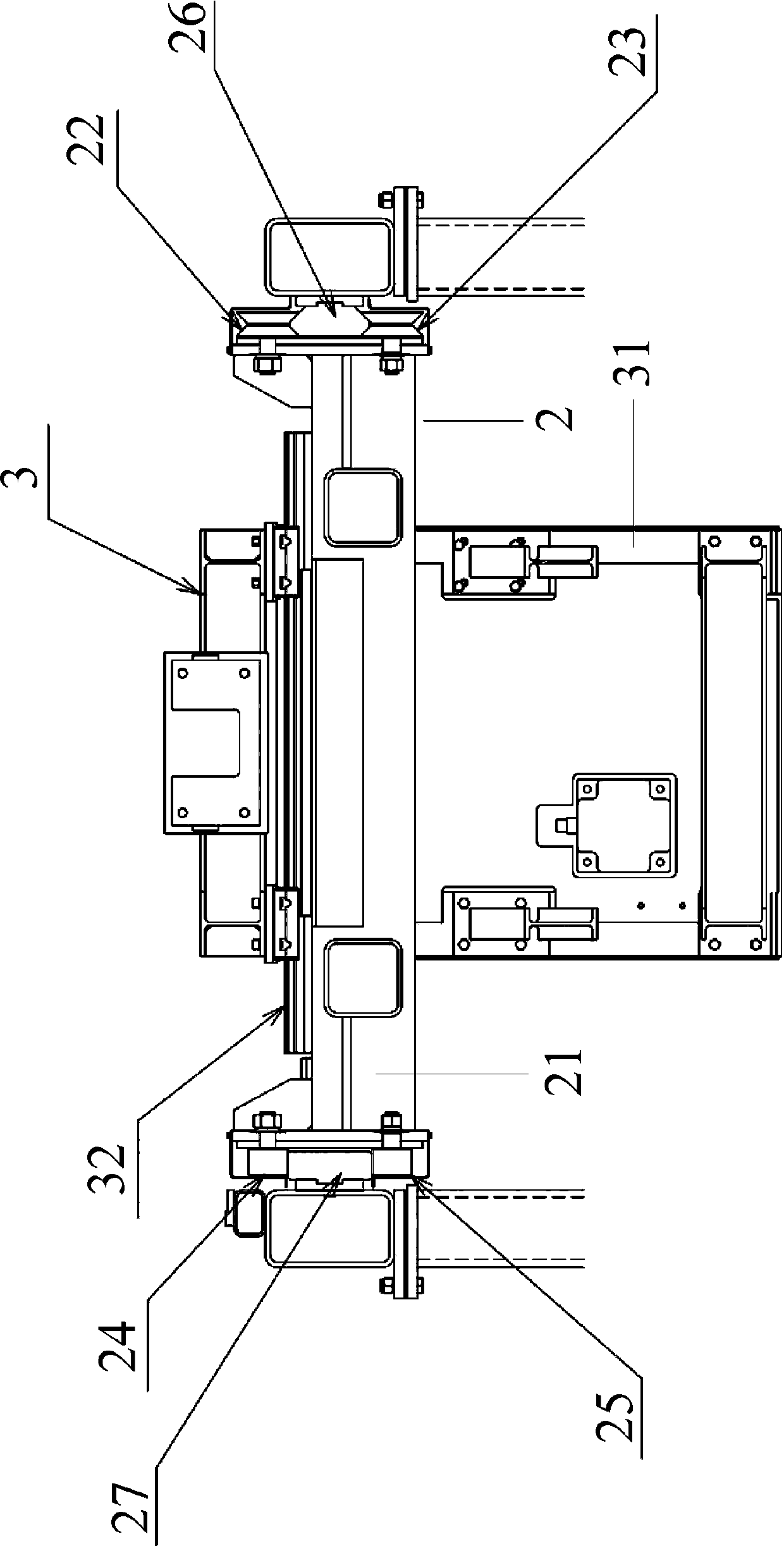

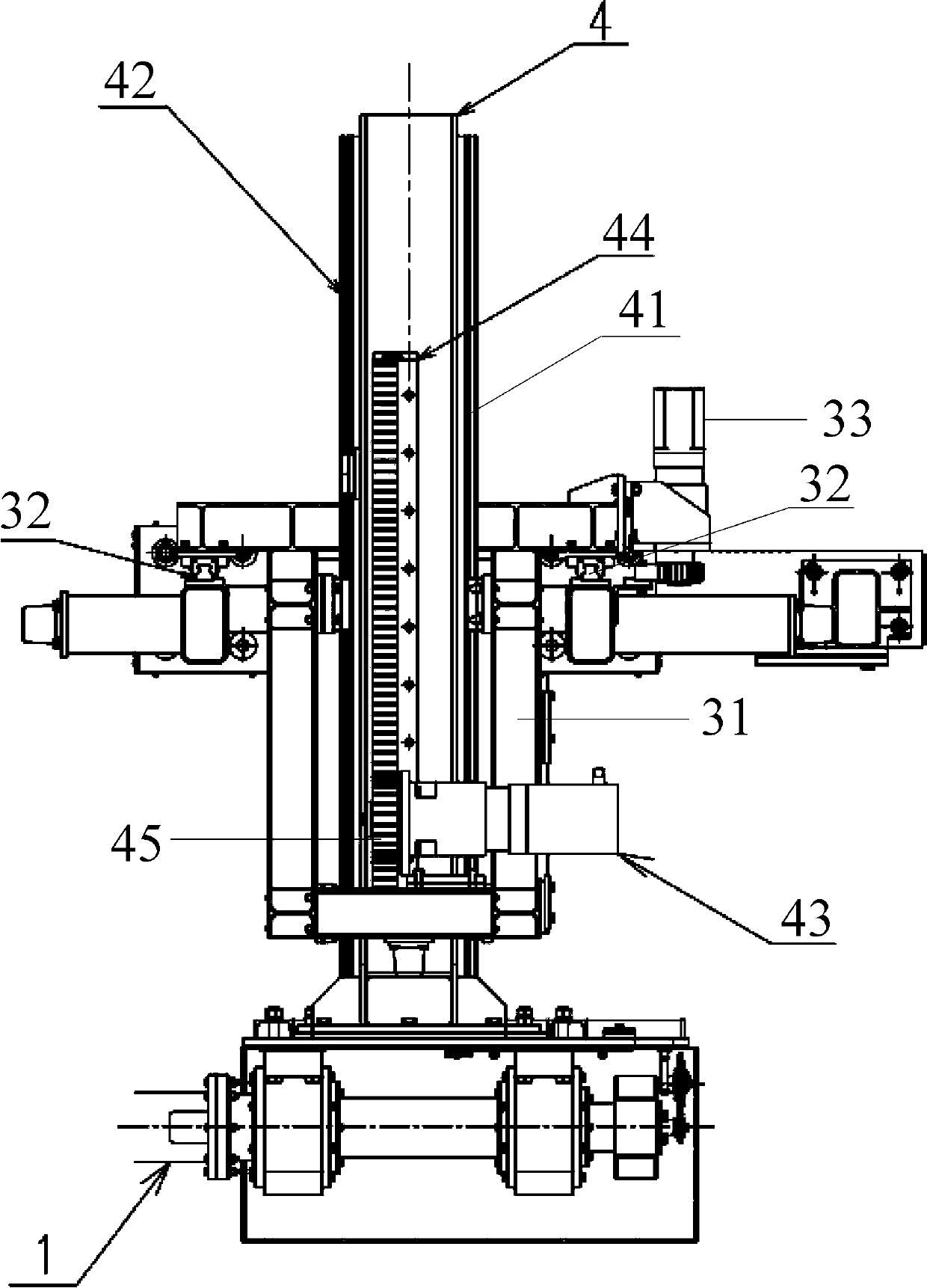

[0055] An automatic spot welding machine for the inner ring of a cold-rolled steel coil, including a spot welding machine component 1, a moving vehicle component 2 in the X direction, a moving vehicle component 3 in the Y direction, a moving vehicle component 4 in the Z direction, a beam frame 5, a supporting column 6 and a visual recognition system7, such as Figure 1 to Figure 7 As shown, the specific structure is:

[0056] Spot welding machine components 1 such as Figure 5 As shown: the spot welding machine assembly 1 includes an inner ring open-circuit reaming device 101, an inner ring tensioning device 102, a spot welding machine 103, a flange bracket 104, a connecting sleeve 105, a front bearing seat 106, a transmission spindle 107, and a rear bearing Seat 108, synchronous belt driven wheel 109, synchronous belt driving wheel 110, synchronous belt 111, gear motor 112 and rotation angle indexing plate 113,

[0057] Inner ring open circuit reaming device 101 such as I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com