Stabilizing device for frog system

A technology for stabilizing devices and frogs, which is applied in the field of railway equipment maintenance, can solve problems such as easy changes in technical parameters of frogs, and achieve the effects of eliminating potential safety hazards in locomotive operation, avoiding wear and tear, and ensuring application stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

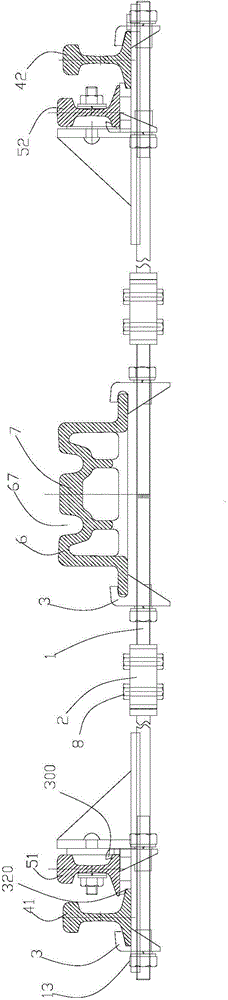

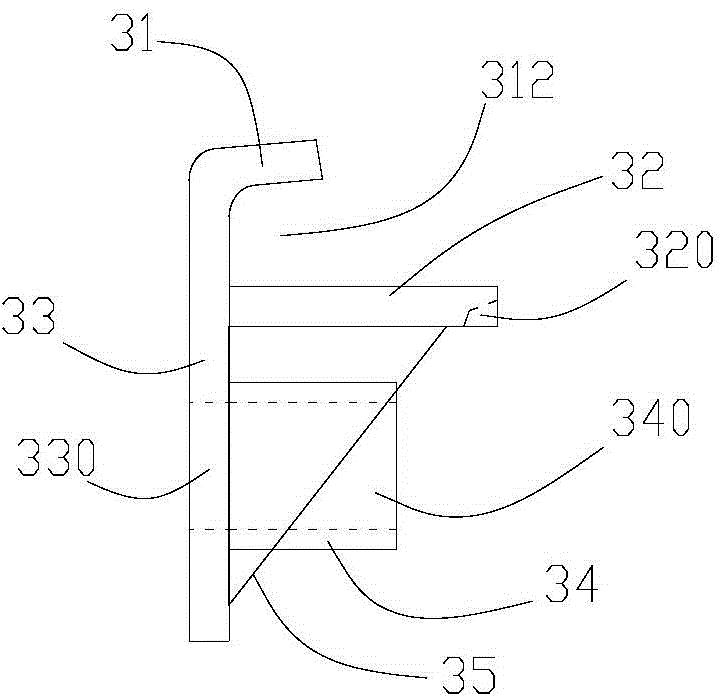

[0021] figure 1 The structure of the embodiment of the present invention is schematically shown. In order to clearly describe and disclose the function and structure of the embodiment of the present invention and its various parts, figure 1 It also shows the positional relationship, connection structure, etc. of the basic rail 41 , the basic rail 42 , the guard rail 51 , the guard rail 52 and the frog when the embodiment of the present invention is applied. Among them, the frog is an integral structure, which includes a core rail 7 and a wing rail 6, and between the core rail 7 and the wing rail 6, a rim groove 67 for passing the wheel rim is provided.

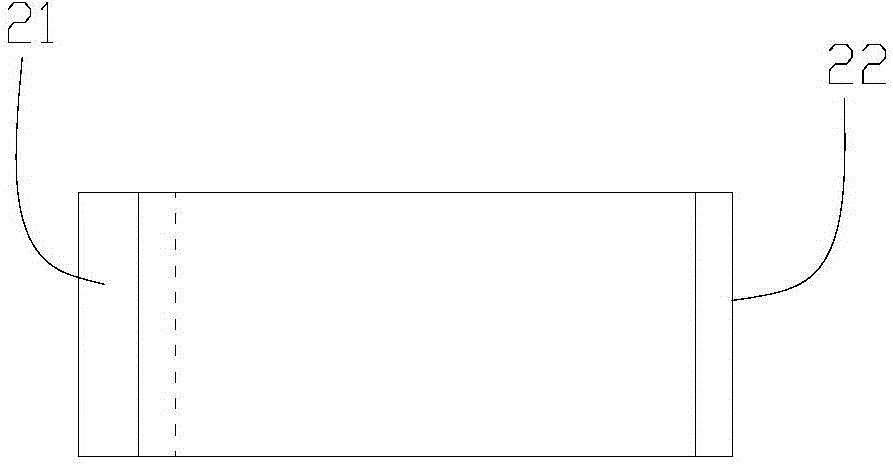

[0022] For this embodiment, it includes a gauge rod 1 , a plurality of claws 3 and claws 300 . The two ends of the gauge rod 1 are connected to the guard rail 51 and the guard rail 52...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com