Phase change alloy material, phase change memory and preparation method of phase change alloy material

A phase-change memory and phase-change alloy technology, applied in electrical components and other directions, can solve the problems of the stability and reliability of phase-change memory devices, the inability to fully meet high-temperature use conditions, and the low temperature for ten-year data retention. Good amorphous stability and high thermal stability, reduce phase transition density difference, reduce the effect of working current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

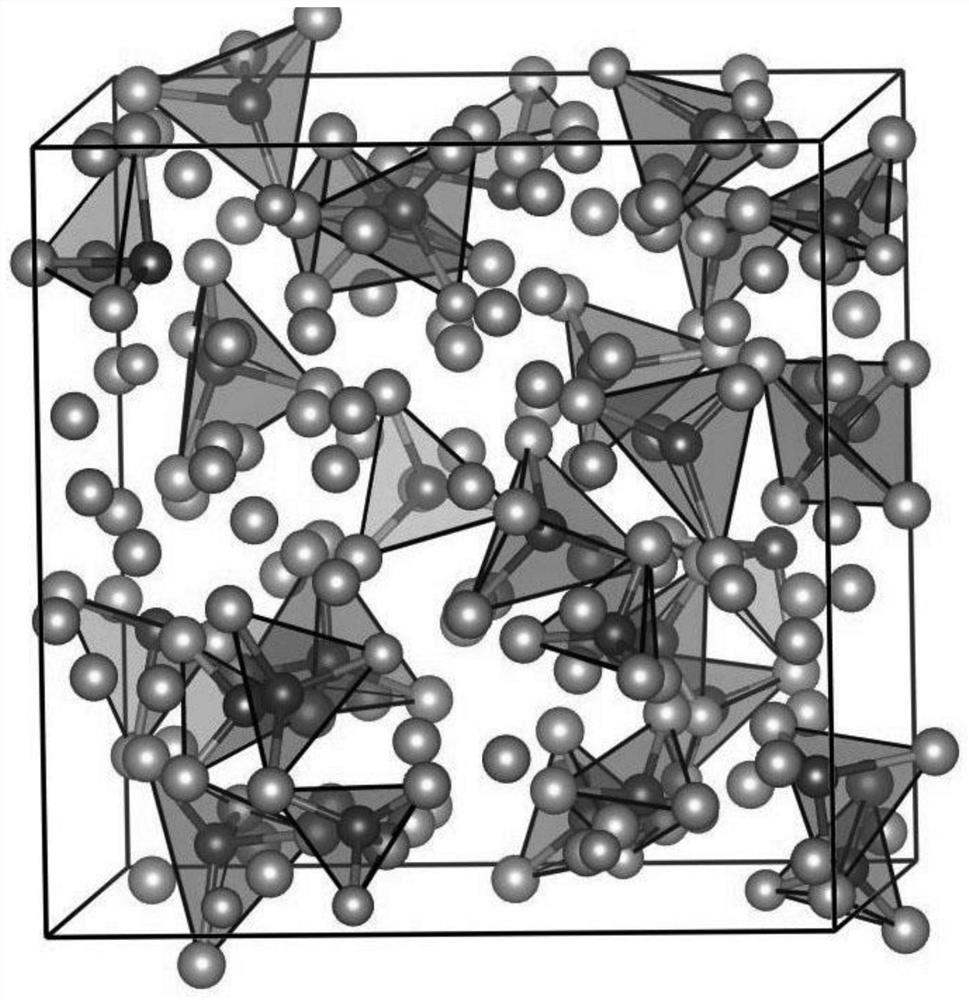

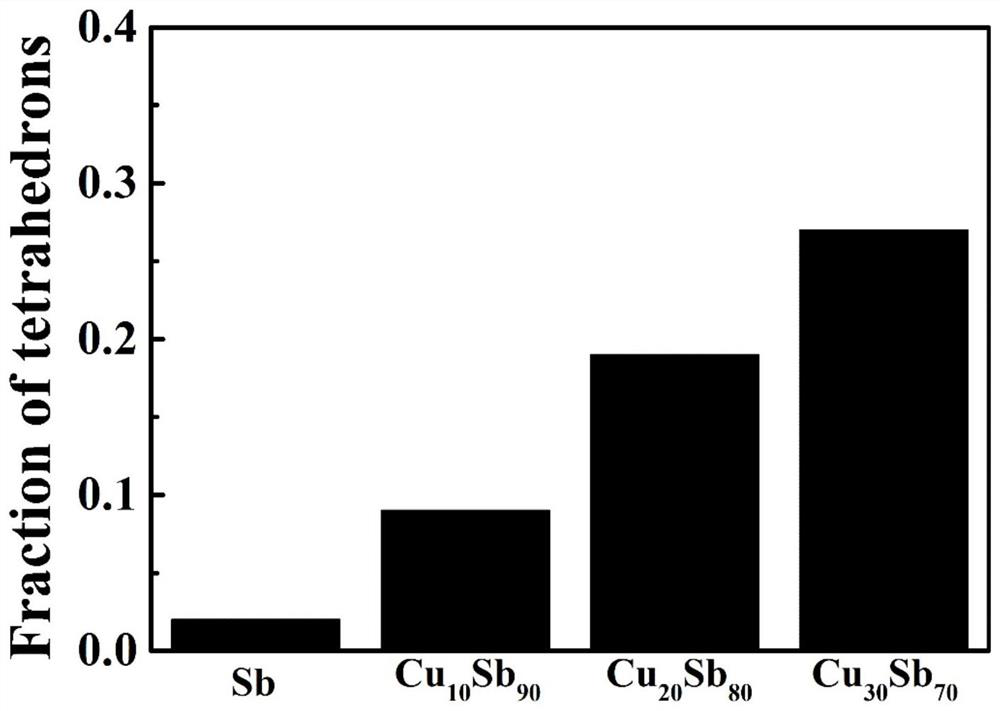

Method used

Image

Examples

Embodiment 1

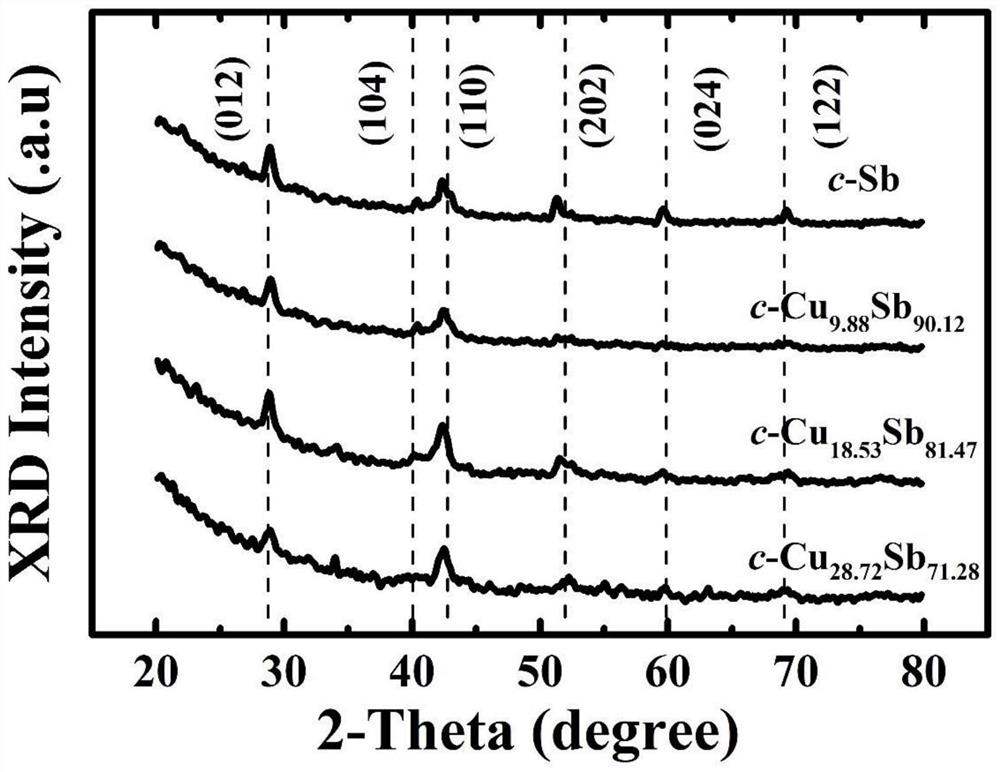

[0045] In this embodiment, the general chemical formula of the Cu-Sb phase change film material is Cu x Sb 100-x , where x=9.88.

[0046] The Cu—Sb nano film material in this embodiment is preferably prepared by magnetron sputtering. During preparation, high-purity inert gas (gas purity not less than 99.999%) is used as sputtering gas, for example, high-purity argon with gas purity not less than 99.999% is used as sputtering gas in a preferred embodiment, and the sputtering pressure is preferably The Sb target preferably uses a DC power supply with a power of 30W, and several copper sheets are placed on the etching ring of the Sb target for doping emission. Of course, when the Sb target adopts a different power source, such as an AC power source, the power of the power source can be adjusted accordingly, and the sputtering preparation of the Cu-Sb phase-change thin film material can also be completed correspondingly.

[0047] Specifically, Cu 9.88 Sb 90.12 The preparation...

Embodiment 2

[0062] In this embodiment, the preparation method of the Cu-Sb phase-change thin film material is the same as the above steps, the only difference is that the number of copper sheets placed at the etching ring on the surface of the Sb target in step S21 is five pieces of lcm×lcm size . After the above magnetron sputtering process, Cu-Sb phase change thin film materials with different thicknesses can be obtained according to the sputtering time. After quantitative analysis by X-ray photoelectron spectrometer (XPS), it can be known that the chemical composition formula of the film material obtained in the present embodiment is Cu 18.53 Sb 81.47 .

Embodiment 3

[0064] In this embodiment, the preparation method of the Cu-Sb phase-change thin film material is the same as the steps in the first embodiment, the only difference is that the number of copper sheets placed at the etching ring on the surface of the Sb target in step S21 is lcm×lcm The size of eight slices. After the above magnetron sputtering process, Cu-Sb phase change thin film materials with different thicknesses can be obtained according to the sputtering time. After quantitative analysis by X-ray photoelectron spectrometer (XPS), it can be known that the chemical composition formula of the film material obtained in the present embodiment is Cu 28.72 Sb 71.28 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com