A magnetic pole core with damping strips for a high-speed rotating salient pole generator

A technology of high-speed rotation and magnetic pole core, applied in the field of magnetic pole core, can solve problems such as uneven load symmetry, damaged generator, uneven symmetry, etc., to eliminate hidden dangers of operation safety, improve operation safety, and improve over-high voltage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the present invention will be described in detail below with reference to the drawings and specific embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

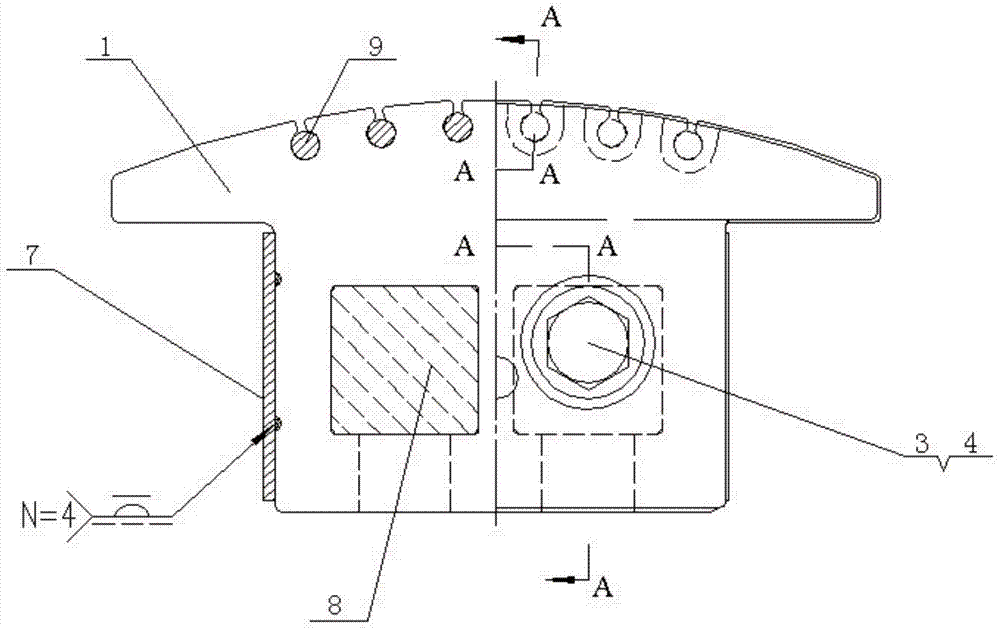

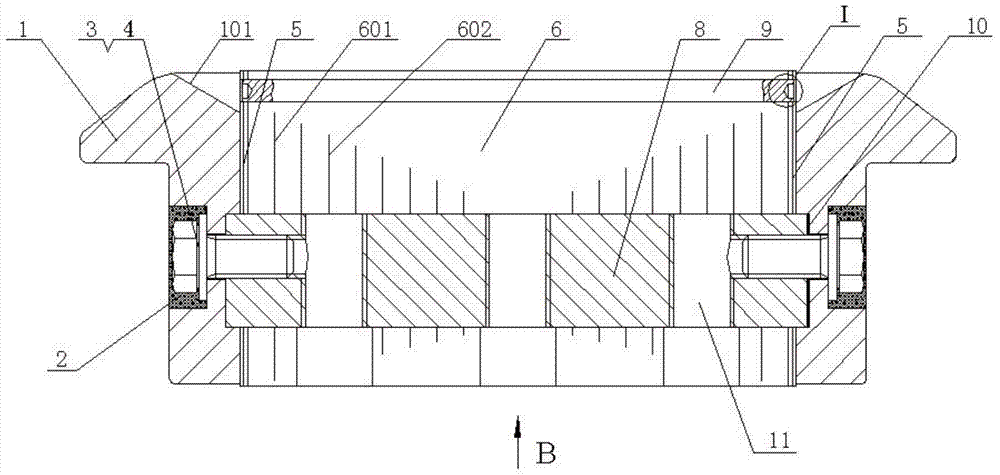

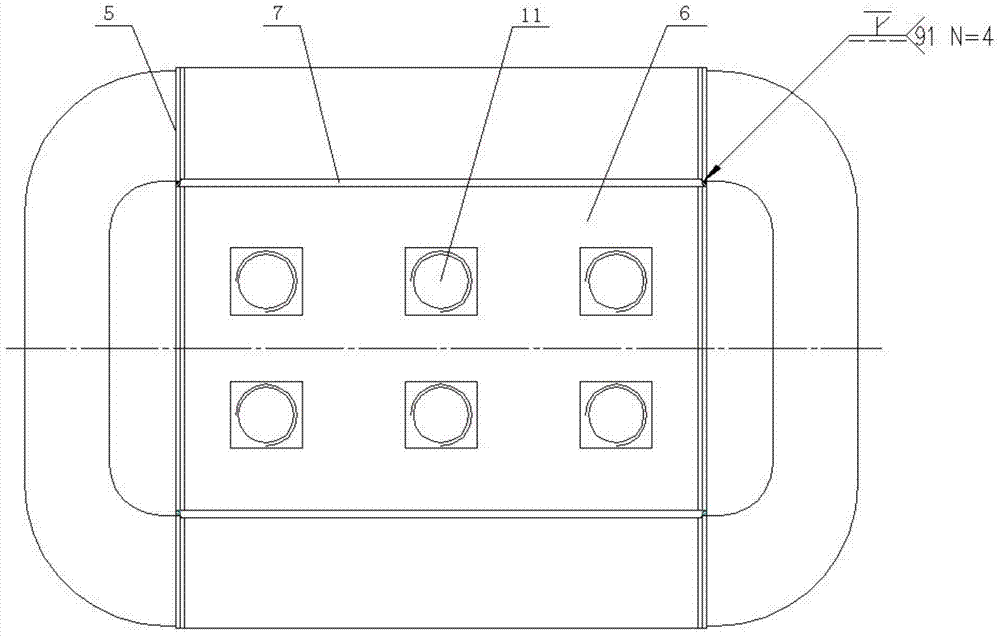

[0031] Such as figure 1 , figure 2 , image 3 The magnetic pole core with damping strips of a high-speed rotating salient pole generator shown mainly includes two magnetic pole pressure plates 1, a punching short-circuit ring 5, a magnetic pole punching set 6, a damping plate 7, and two magnetic pole pull rods 8 and There are six damping strips 9, two of which are located at the two ends of the pole pull rod 8, and their width is usually slightly larger than the cross-section width of the magnetic pole punch group 6 in the same direction to facilitate the installation of the damping plate 7. The magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com