Overpressure-assisted gravity bending method device suitable therefor

A bending and gravity technology, applied in the device field of this method, can solve the problems of long bending time and increased production cost, and achieve the effect of reducing damage risk and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

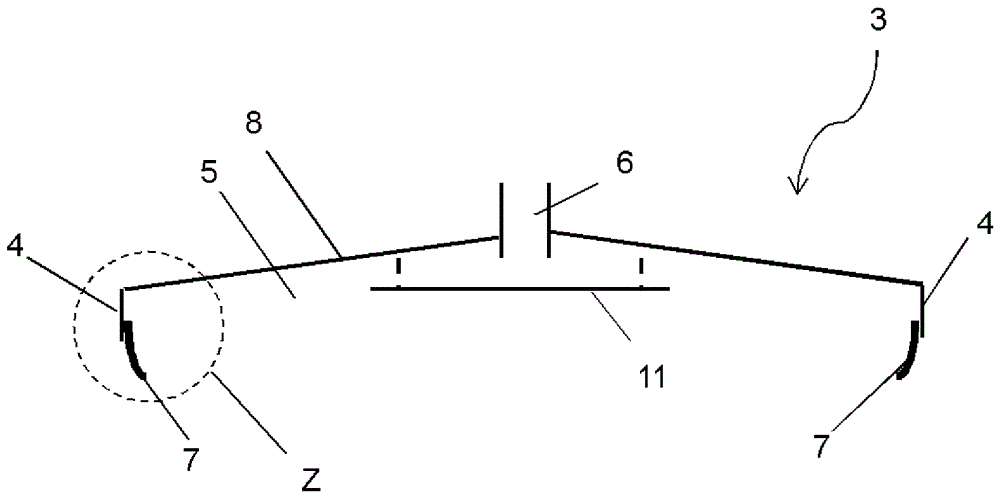

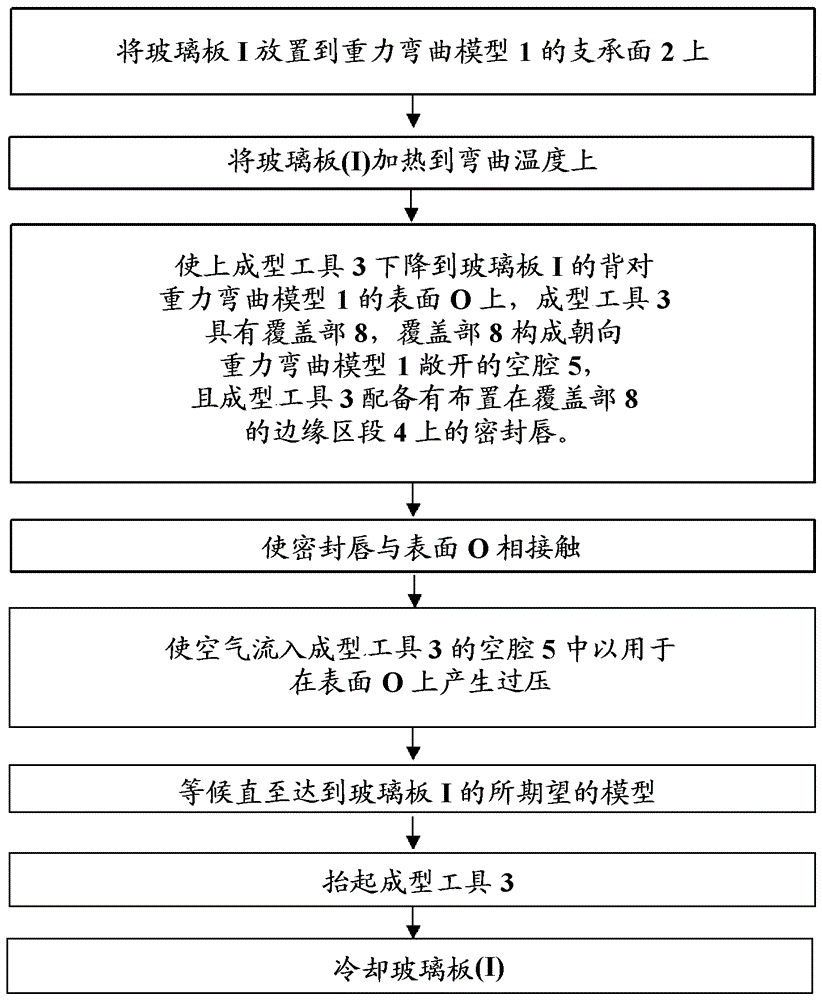

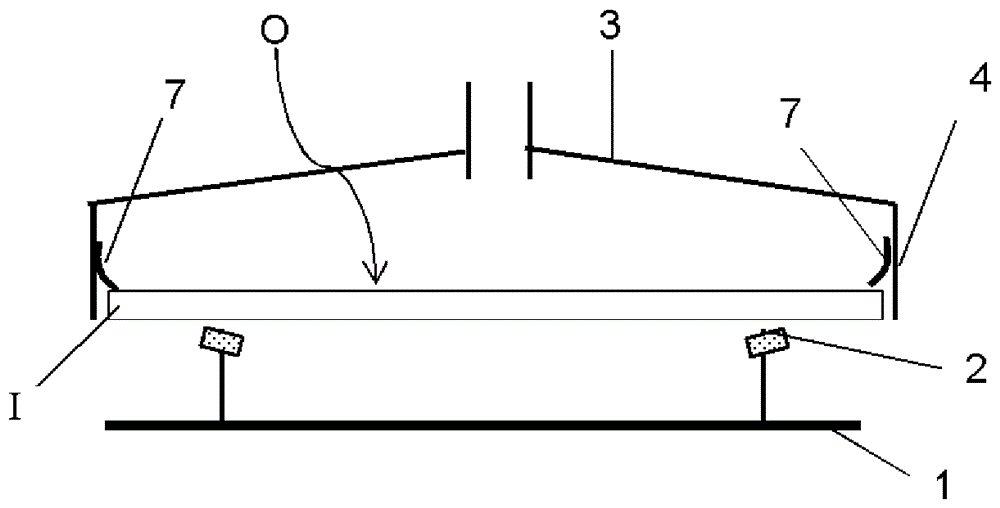

[0064] figure 1The device according to the invention is shown during the method according to the invention for bending a glass pane I. In the initial state a flat glass plate 1 is placed on the frame-like support surface 2 of the gravity bending model 1 ( figure 1 a). As usual in gravity bending, the glass pane I is heated to a bending temperature which at least corresponds to the softening temperature. Subsequently, the softened glass sheet 1 is pressed against the support surface 2 under the influence of gravity ( figure 1 b).

[0065] According to the invention, gravity bending is assisted by an upper forming tool 3 which generates an overpressure on the upwardly directed surface O of the glass pane 1 facing away from the support surface 2 . The upper forming tool 3 is a bell-shaped or cup-shaped tool with a cavity 5 facing the glass sheet 1. The upper forming tool 3 is brought into contact with the upper surface O of the glass pane 1 via a surrounding sealing lip, so ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com