Method and device for replacing wheel group of bridge crane

An overhead crane and wheel set technology, applied in the field of machinery, can solve the problems of the wheel set and the balance beam assembly being large in weight and dimensions, endangering the safety of operators, difficult in actual operation, etc., so as to prevent personal injury accidents and simplify operation steps. , the effect of reducing the intensity and complexity of the work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

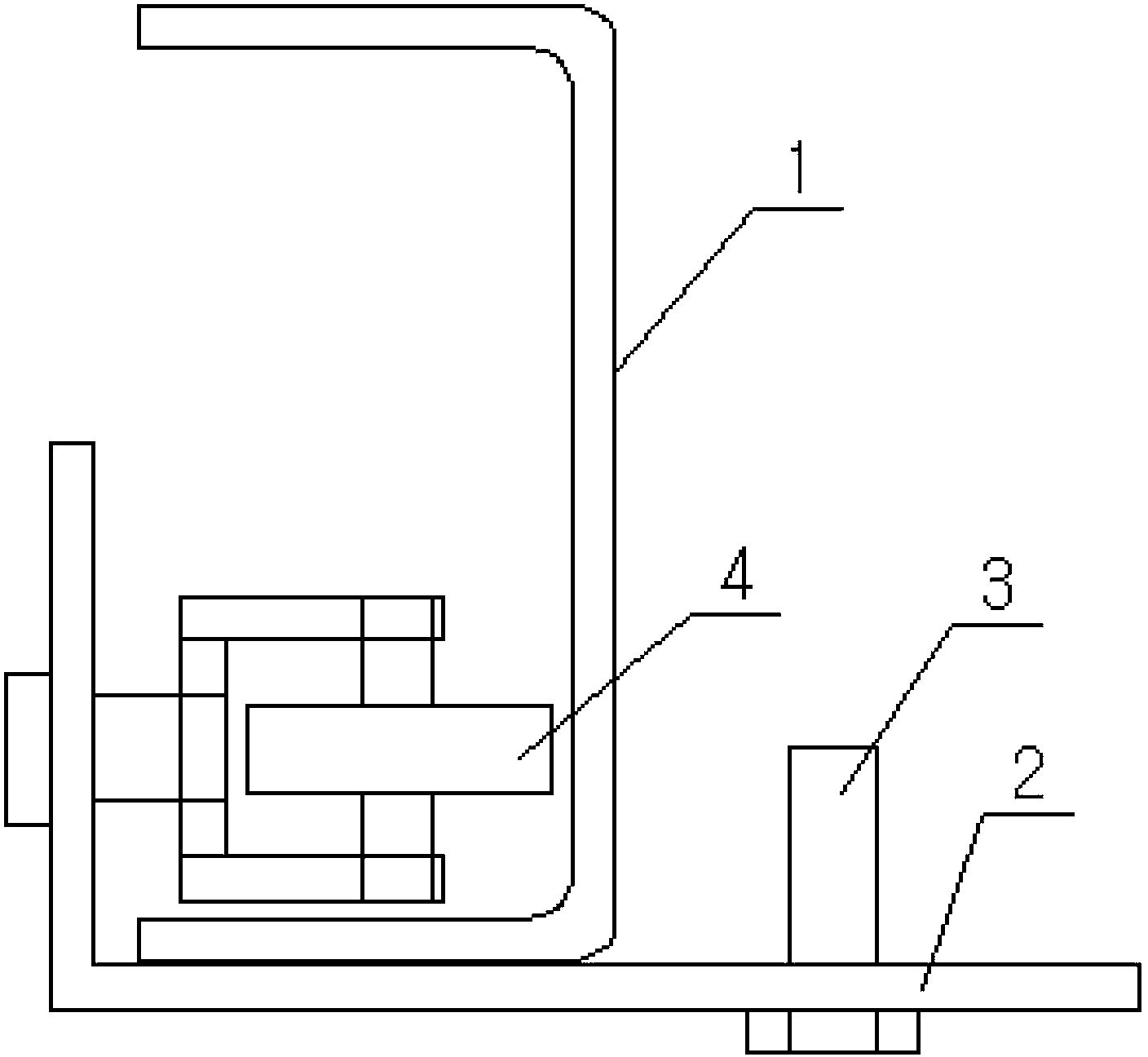

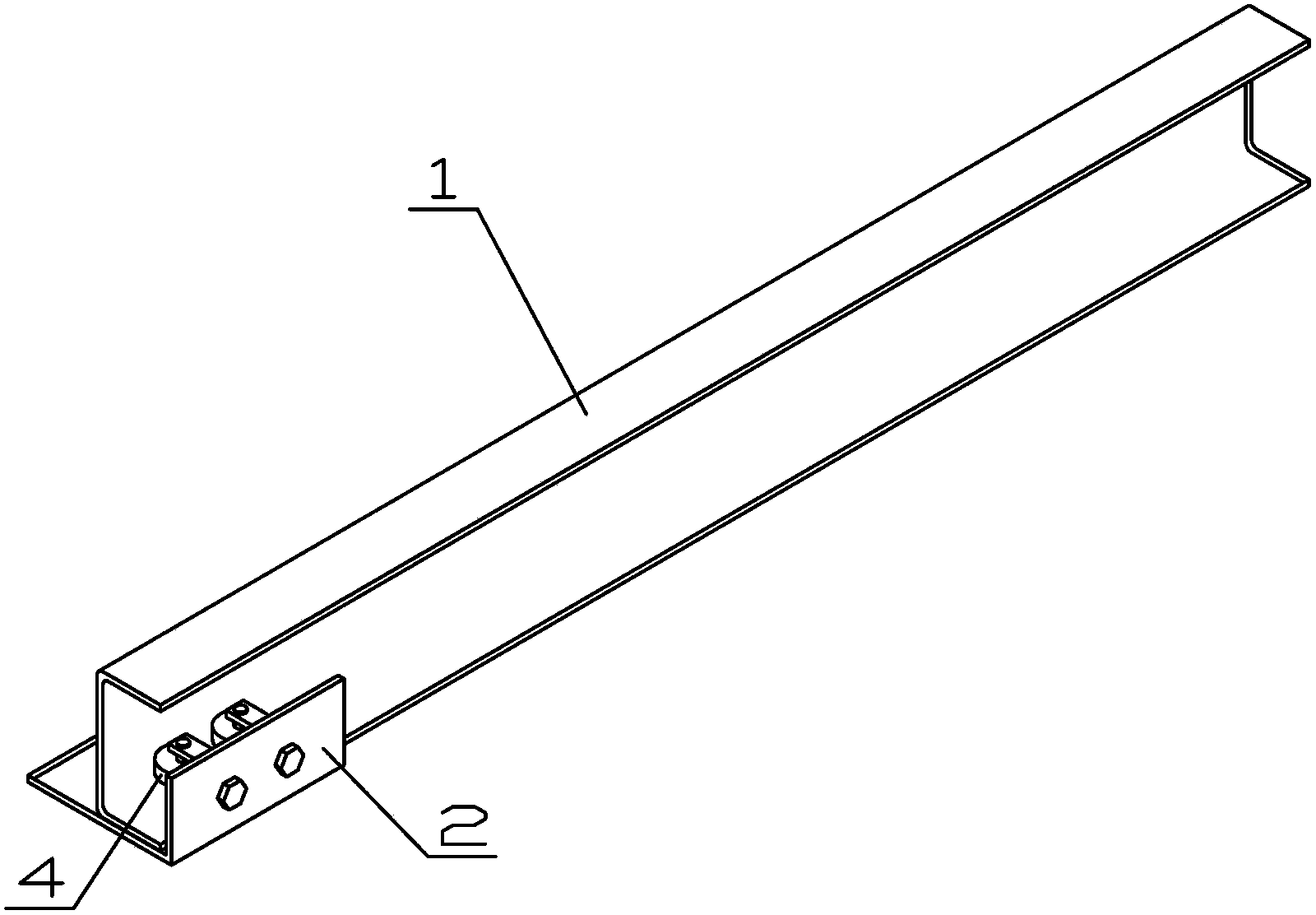

[0022] The present invention as figure 1 with figure 2 As shown, a device used in a method for replacing the wheel set of an overhead crane includes a channel steel guide rail 1 and a slide plate 2, the channel steel guide rail 1 and the slide plate 2 are combined together, the slide plate 2 is an L-shaped plate, and the slide plate 2 A locking bolt 3 is provided on the long board surface of the slide plate 2, and a guide pulley 4 is provided on the short board surface of the slide plate 2, and the slide plate 2 is fixedly connected with the guide pulley 4.

[0023] A method for replacing a wheel set of an overhead crane is completed according to the following steps:

[0024] 1) Use a jack to jack up the car body. After the car body is lifted by 300mm, place the car body support on the inner side close to the wheel set;

[0025] 2) Take back the ja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com