Multi-effect siphon phase-change circular heat transfer system

A heat transfer system and siphon technology, which is applied in the field of mechanical siphon phase change cycle heat transfer system, can solve the problems of waste heat waste, waste heat lost by flash evaporation, low recovery rate, etc., and achieve the effect of improving cost performance, simplifying process and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

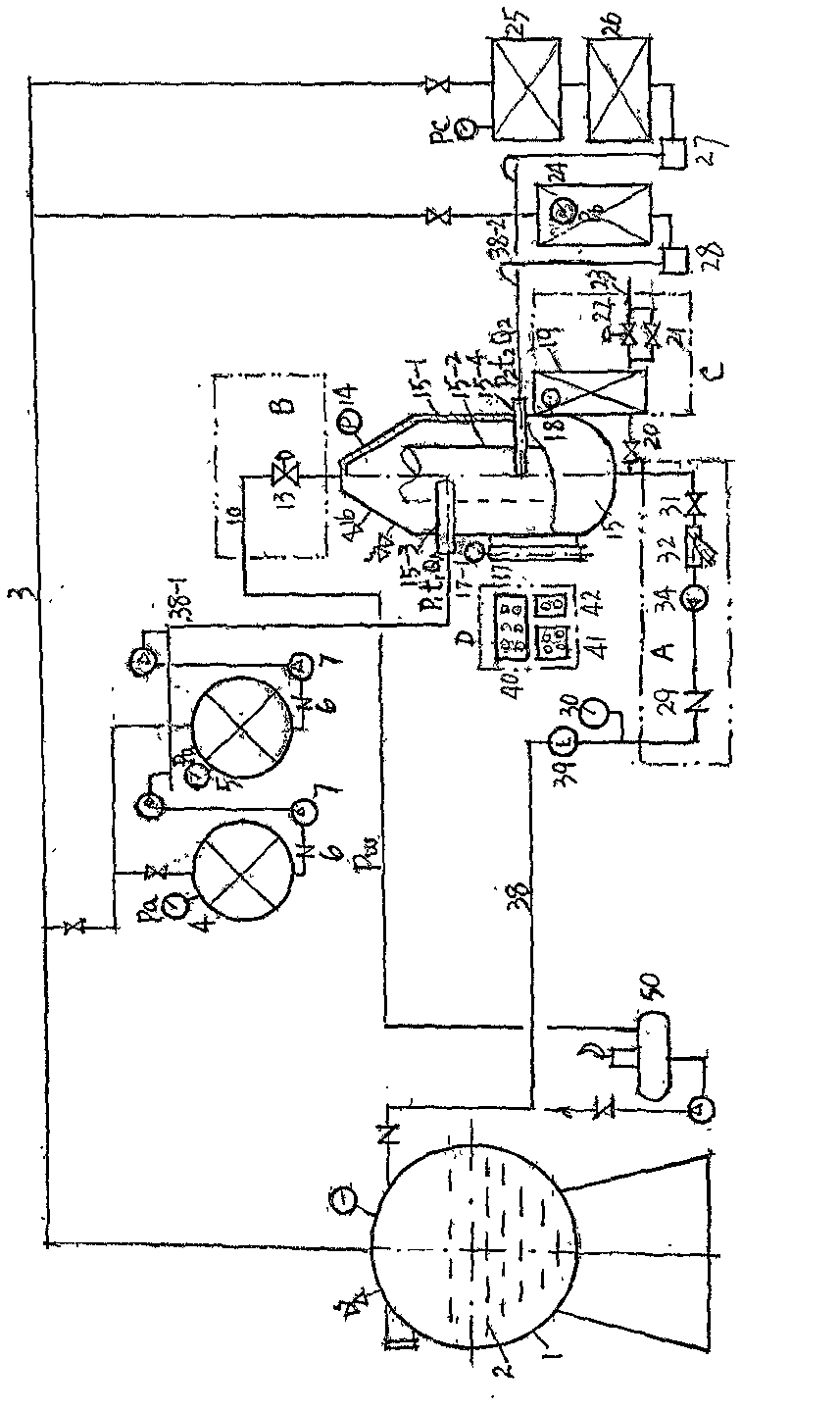

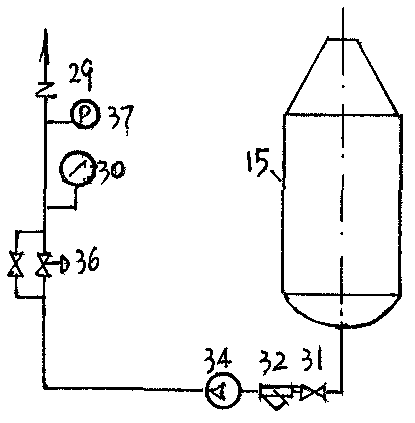

[0039] one, figure 1 The shown pump water siphon recovery device A consists of a storage tank 15, a IIIHx pump 34, a liquid level transmitter 17-1, and a frequency converter as a speed regulator 41 to form an intelligent pump water siphon recovery device. The transmitter 17-1 transmits the liquid level signal, and the operating speed of the pump 34 is adjusted by the frequency converter, thereby adjusting the instantaneous liquid infusion volume of the pump, so that the pump pumps and conveys condensed water in a continuous operation mode, and has a continuous pump water siphon effect. When the IIIHx pump 34 adopts a variable-speed motor, the variable-speed motor speed regulator is used as the speed regulator 41 and the liquid level transmitter 17-1 to form an intelligent pump water delivery siphon recovery device;

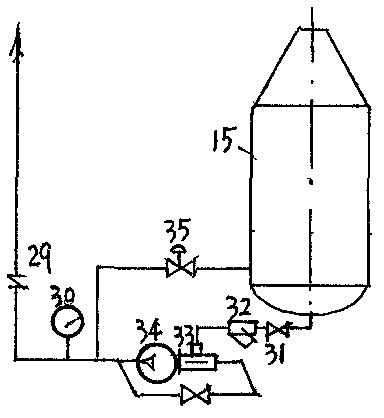

[0040] figure 2 The shown pump water siphon recovery device A consists of a storage tank 15, an intelligent regulating valve 36 and an intelligent pressure gaug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com