Life rope fixator

A technology of life rope and fixing frame, which is applied in the direction of construction, building structure, and building material processing, etc. It can solve the problems that the safety rope cannot be used for high-hanging and low-hanging, cannot meet the needs of high-altitude operations, and increase labor and material costs. , to achieve good promotion and application prospects, eliminate hidden dangers of operation safety, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

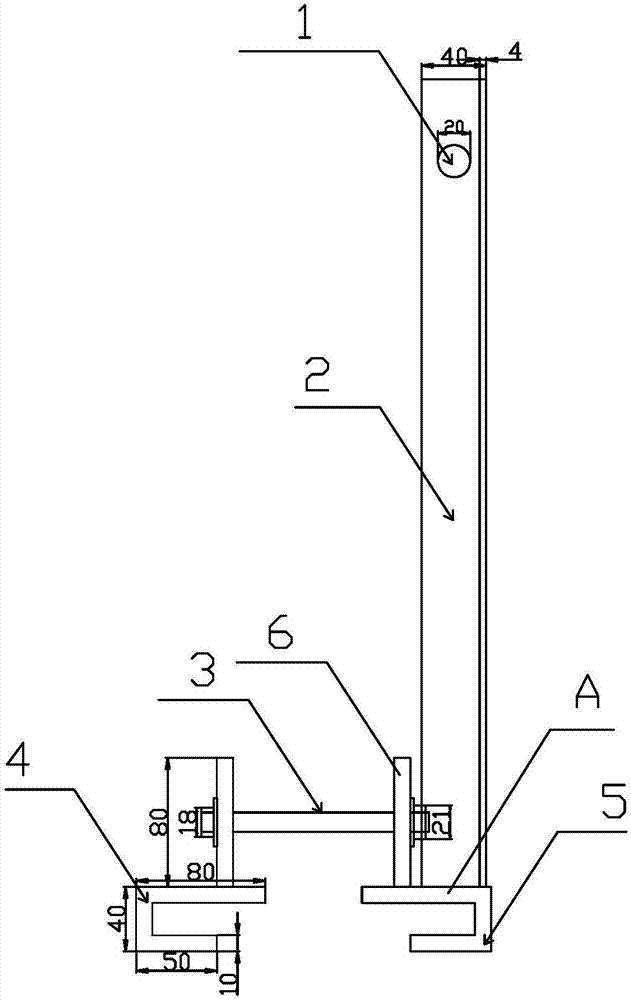

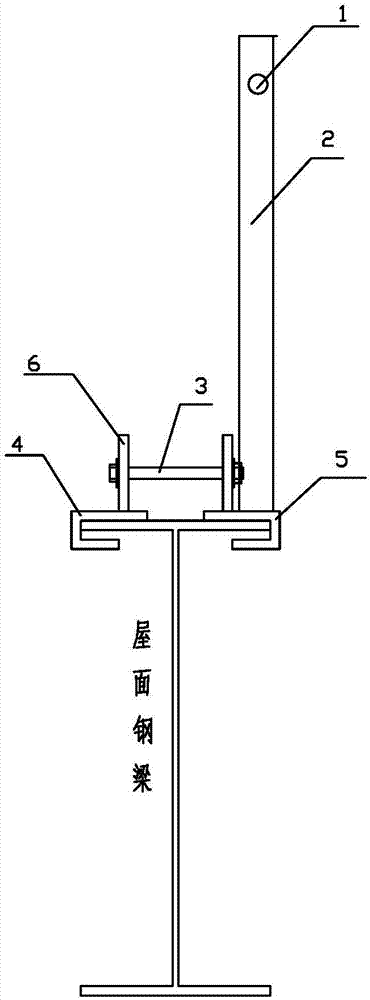

[0023] see figure 1 , the lifeline fixture of this embodiment includes clamps 4 and 5 with a U-shaped vertical section, each of the clamps 4 and 5 has a connecting plate 6 welded vertically to the end surface A on the outside of each of the clamps 4 and 5. The positions of the connecting plates correspond to each other and are provided with corresponding holes. The outside of the end face A of the clamp 5 also has an angle steel 2 welded vertically to the end face. The life rope penetration hole 1 is opened on the angle steel 2 . When in use, use the state diagram to see figure 2 , put the roof steel beams in the U-shaped openings of fixtures 4 and 5, select bolts 3 of appropriate size to fix the connection plate 6 through the holes on it, and insert the life rope into the life rope penetration hole 1, thus completing the installation of the life rope fixed. After the fastening is completed, it can be put into use. After waiting for use, take off the bolt 3, and the fixing...

Embodiment 2

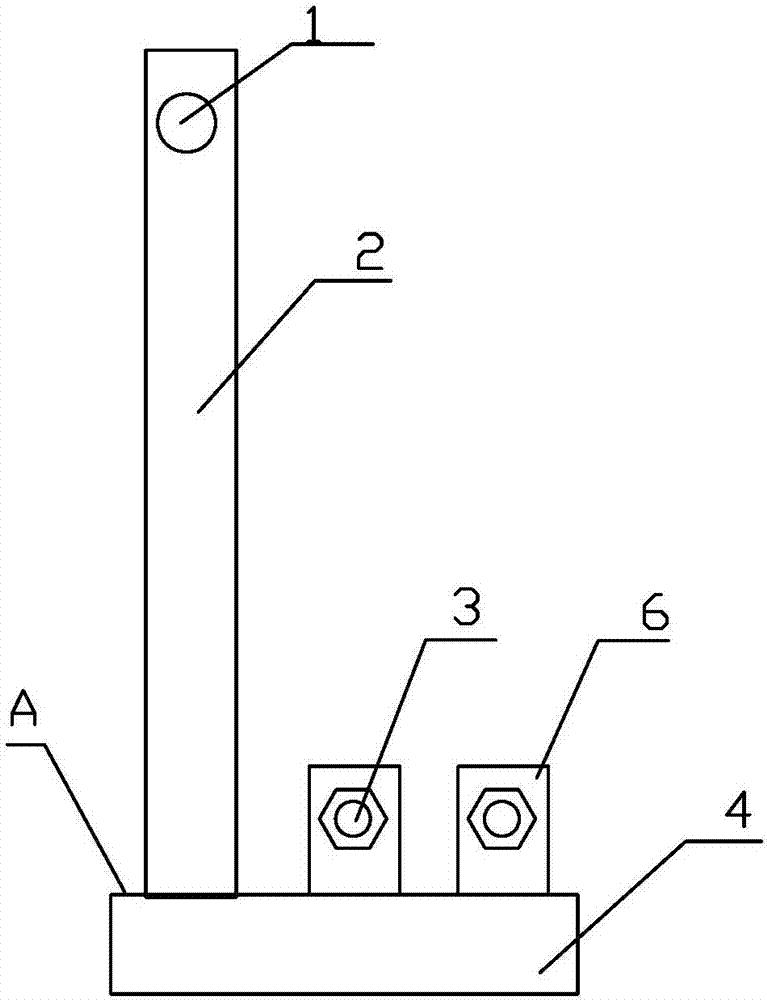

[0025] see figure 1 and image 3 , the life rope holder of the present embodiment, the clamps 4 and 5 have the same structure and shape, and the upper end surface A of each clamp has two (or more than two) connecting plates 6 vertically welded to the end surface, and the clamps 4 and 5 The positions of the connecting plates are corresponding, and corresponding holes are provided. There is also an angle steel 2 vertically welded to the end surface on the outside of the end face A. The life rope penetration hole 1 is opened on the angle steel 2. The angle steel 2 on the clamps 4 and 5, And the life rope piercing hole 1 on the angle steel 2 is relatively. When in use, the roof steel beams are placed in the U-shaped openings of the fixtures 4 and 5, and the two pairs of connecting plates 6 are fixedly connected with the bolts 3 of appropriate sizes through the holes on them respectively, and the life ropes penetrate the life ropes of the two angle steels 2. Enter hole 1, promptl...

Embodiment 3

[0027] see Figure 4 The difference between the life rope fixing frame of this embodiment and Embodiment 1 is that the clamps 4 and 5 are respectively connected by the upper end face splint A-1 and the lower end face splint A-2 through bolts 3 to form a U-shaped vertical section. Fixture, all the other are identical with embodiment 1. See embodiment 1 and 2 for using process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com