Multi-working-procedure integrated contact processing equipment

A processing equipment, multi-process technology, applied in metal processing equipment, forming tools, manufacturing tools and other directions, can solve the problems of high labor intensity, high processing cost and high cost of operators, eliminate hidden dangers in operation safety, improve production efficiency, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

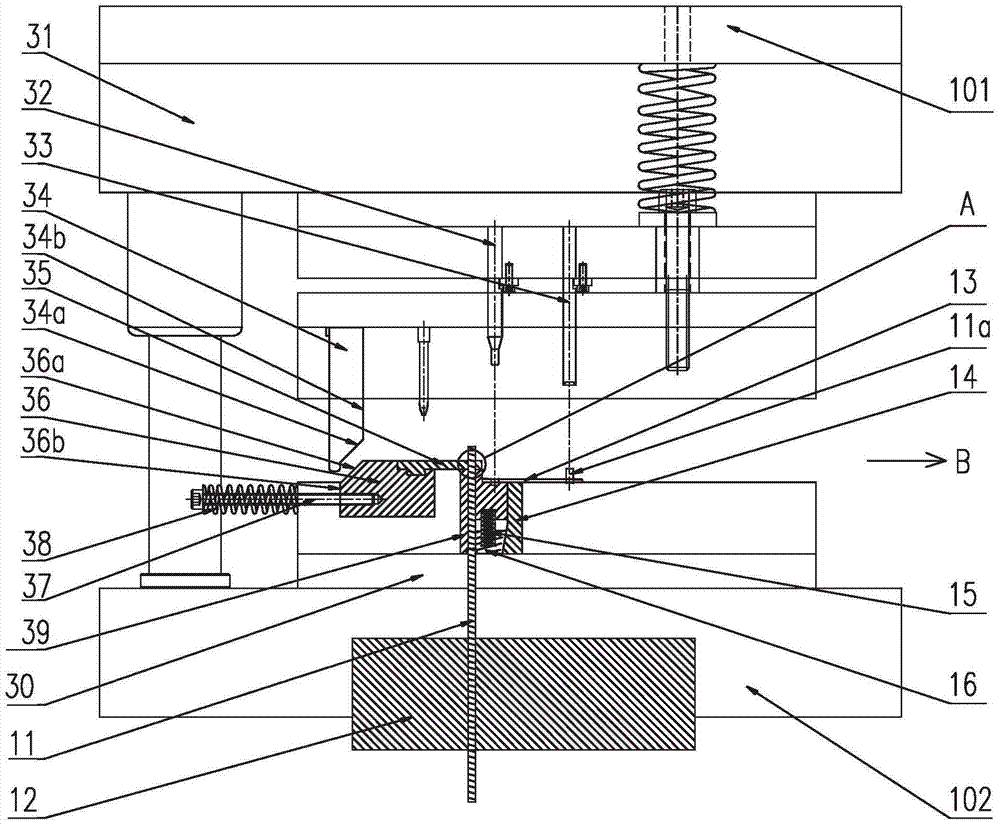

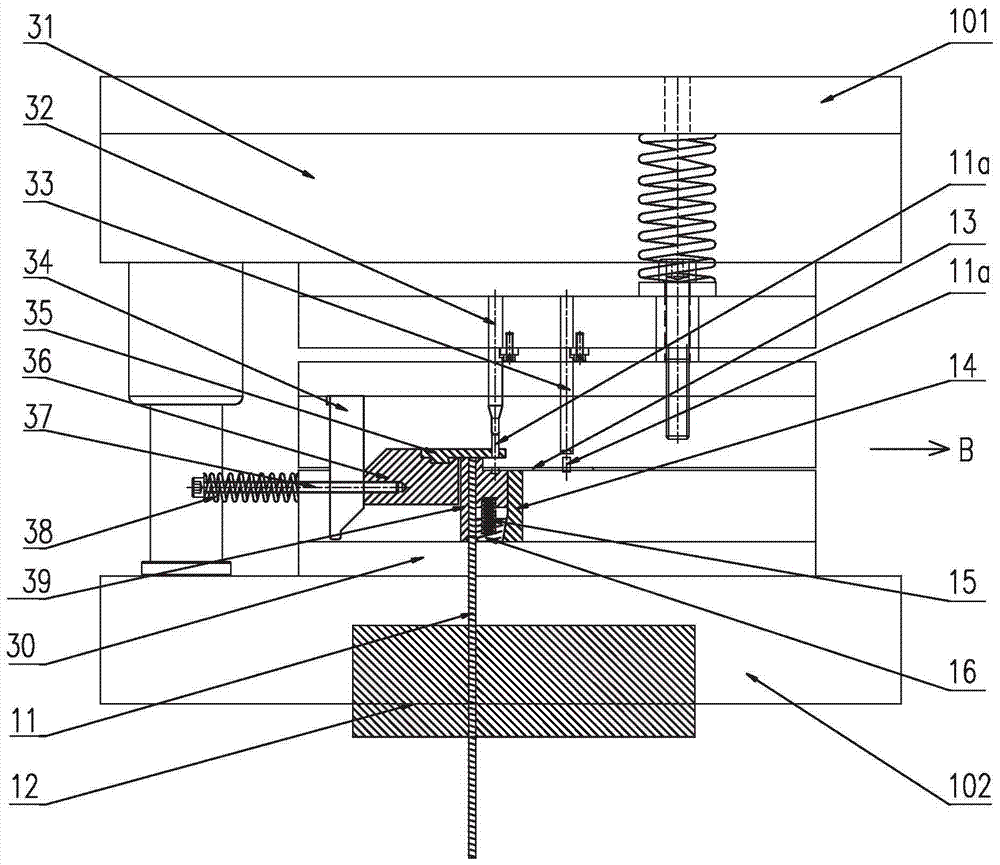

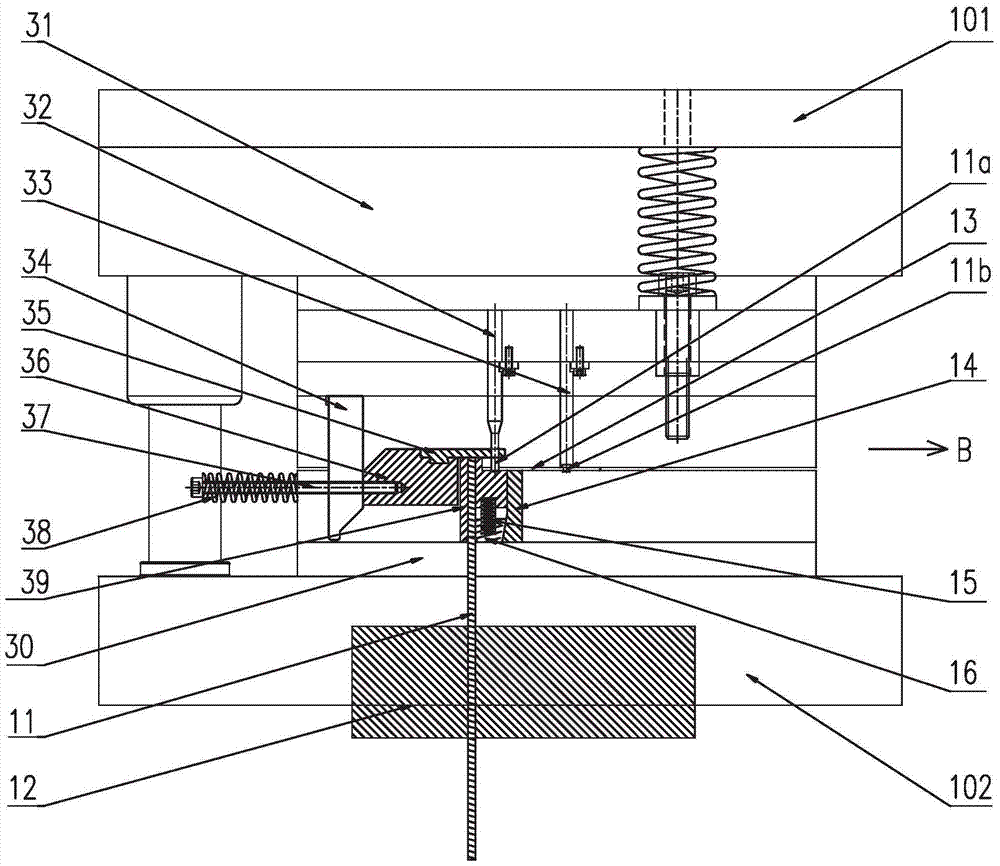

[0035] The following combination Figure 1 to Figure 21 The given examples further illustrate the specific implementation of the in-mold automatic riveting molding die for riveting contact points of the present invention. The in-mold automatic riveting forming mold for riveting contacts of the present invention is not limited to the description of the following embodiments.

[0036] The stamping equipment applicable to the in-mold automatic riveting molding die for the riveting contact point of the present invention can adopt general equipment such as common stamping machine tools, and these equipments all have a movable platform 101 that can move up and down and are located under the movable platform 101. The base platform 102, the moving platform 101 can provide stamping force in the stamping process of downward movement; And processing equipment, and realize the processing and riveting of contacts at the same time. The present invention will combine Figure 1-10Illustrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com