Overhead line system maintenance electric ladder vehicle

A catenary, electric technology, applied in the direction of ladders, transport passenger cars, railway car body parts, etc., can solve the problems of inability to fold and retract, laborious operation to raise the height, and long folding ladder body parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

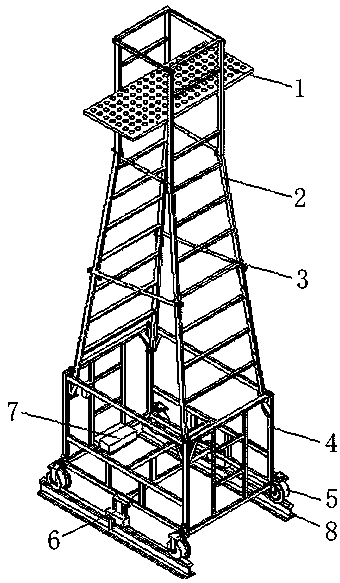

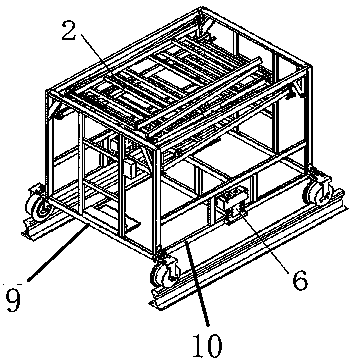

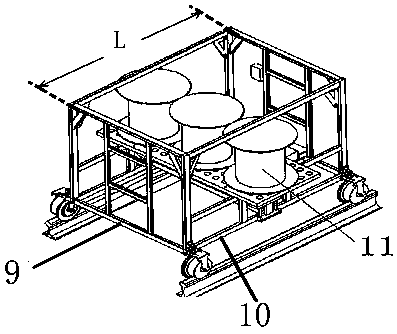

[0022] refer to figure 1 — Figure 9 , the catenary maintenance electric ladder car, including: a chassis, a working platform 1, a folding ladder body 2, a running device 5, the running device 5 is installed on the four bottom corners of the ladder seat 4, the chassis and the folding ladder body Ladder seat 4 is arranged between 2, and ladder seat 4 is fixed on the chassis, and the lower end of folding ladder body 2 is movably connected with the upper end of ladder seat 4;

[0023] The chassis is also equipped with a stabilizing device 6, and the stabilizing device 6 includes: a mounting seat 31, a permanent magnet 32, a positioning wheel 33, and the permanent magnet 32 and the positioning wheel 33 are installed inside the mounting seat 31, and the positioning wheel 33 is installed on the permanent magnet 32 On both sides, the stabilizing device mounting base 31 is installed on the chassis longitudinal bar 10 through the pin hole 34 and the pin shaft, and can rotate around ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com