Wind power/manual linkage apparatus for discharge of railway freight transport hopper wagon

A railway freight and linkage device technology, applied in hopper cars, railway car body parts, transport passenger cars, etc., can solve problems such as pneumatic misoperation, achieve reliable operation, eliminate potential safety hazards, and eliminate the effect of pneumatic misoperation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

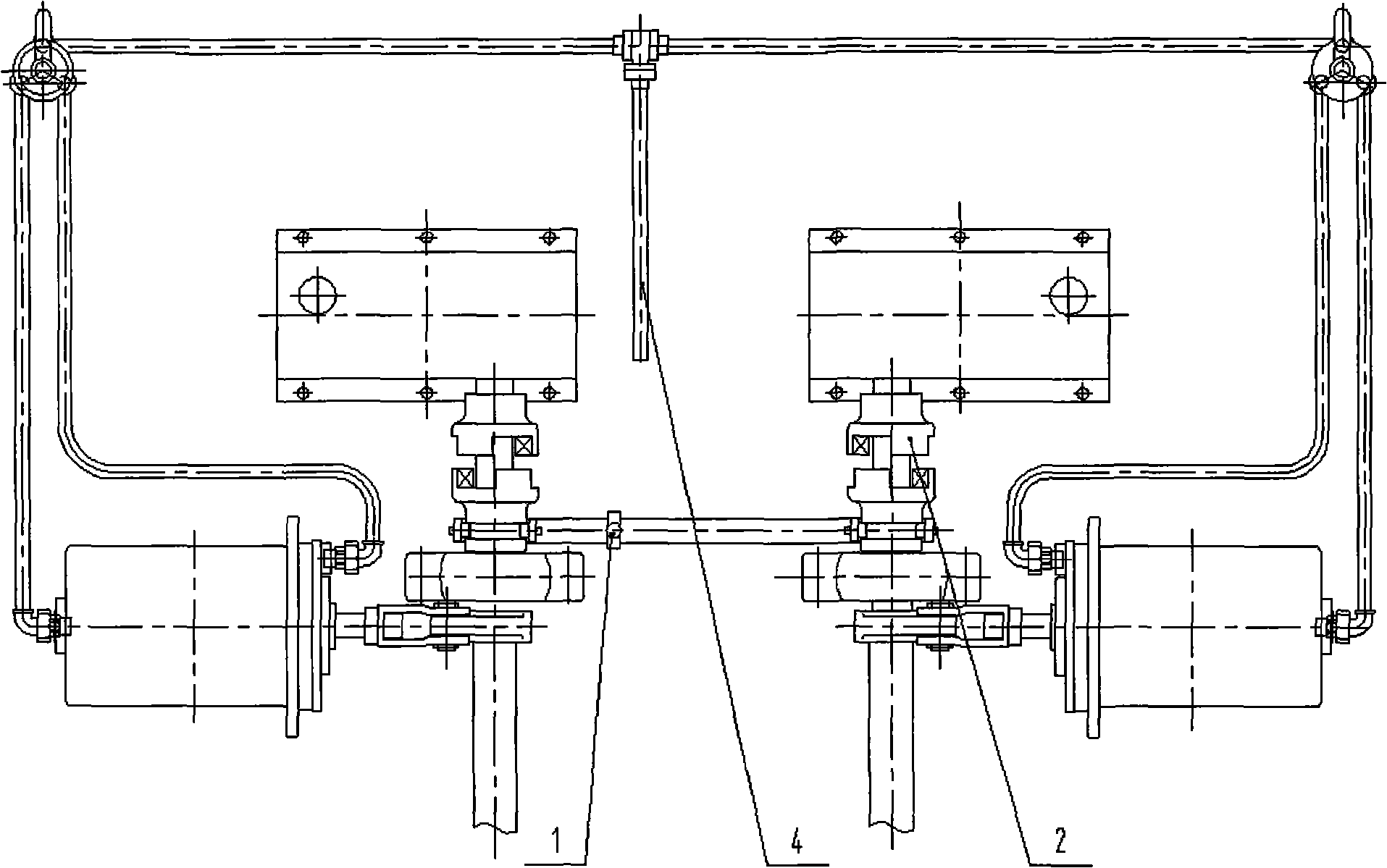

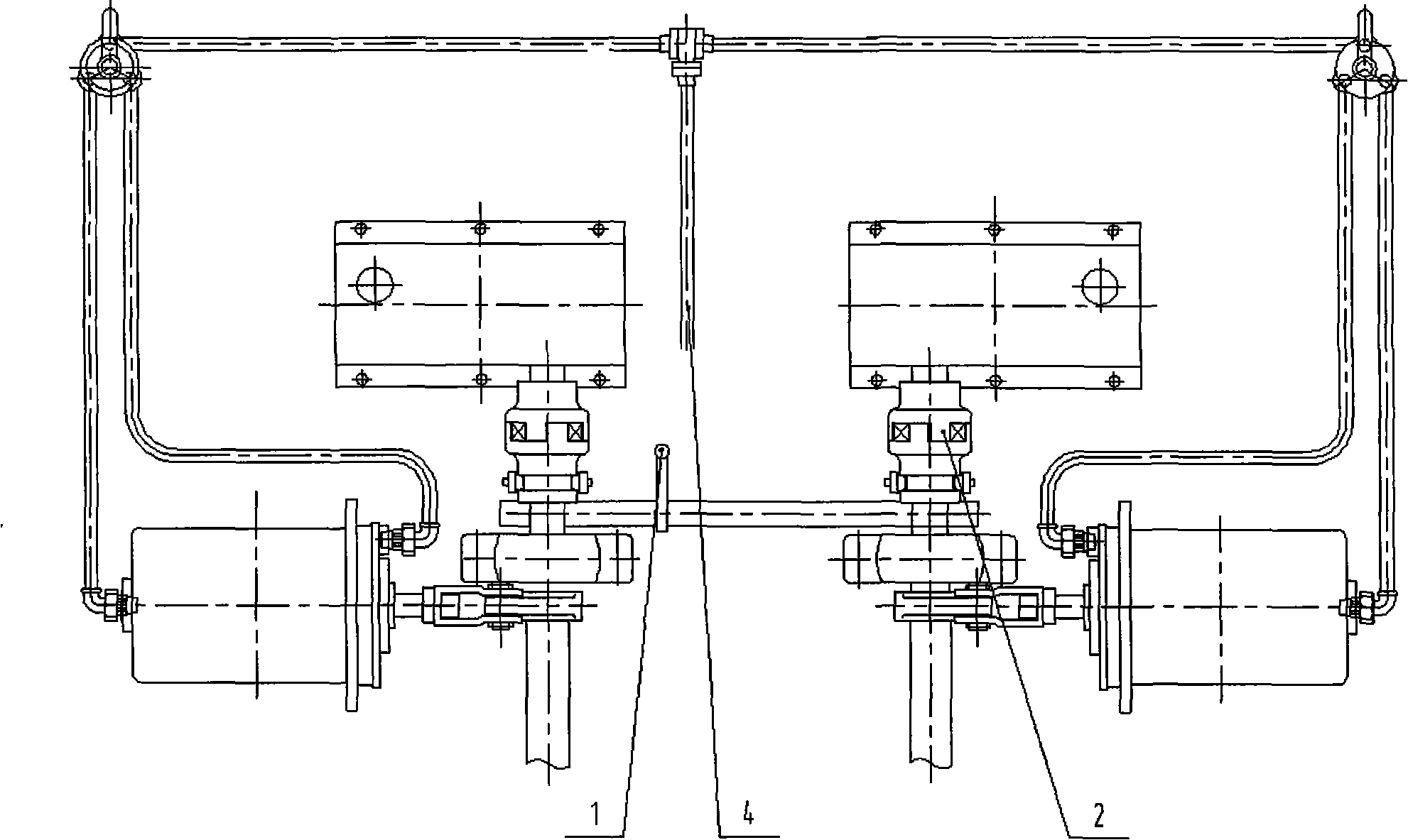

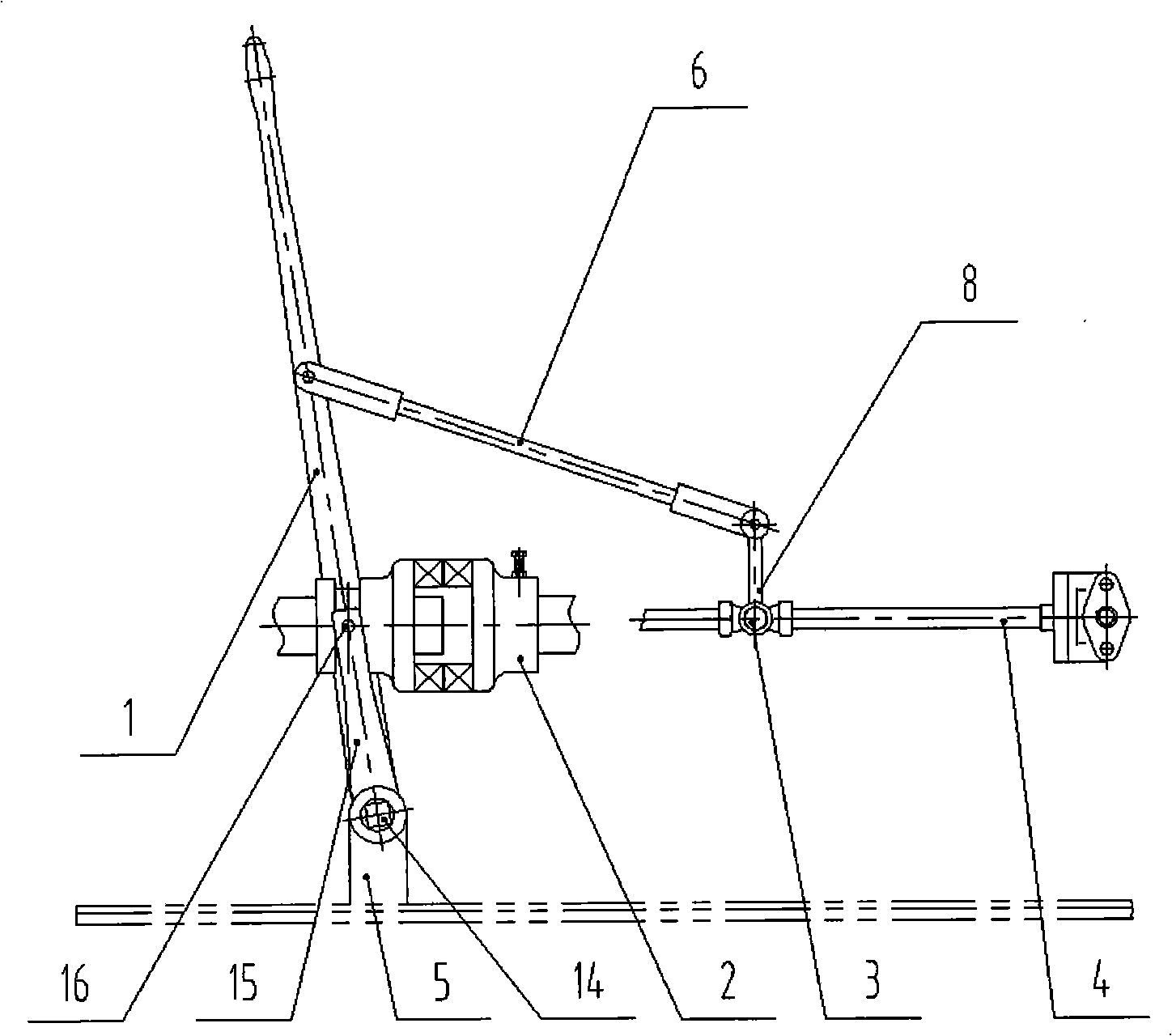

[0012] see image 3 , Figure 4 , Figure 5 , the present invention includes a clutch 2 and a main air duct 4 of the pneumatic system, the clutch 2 is installed on a shift fork 15, a toggle pin 16 is arranged on the shift fork 15, the shift fork 15 is installed on the main transmission shaft 14, and the main transmission shaft 14 is installed on the On the bearing 5, a handle is housed on the main transmission shaft 14, and the bearing 5 and the main air duct 4 of the pneumatic system are all fixed on the car body. Its key technology is to connect the connecting rod 6 on the handle 1, the other end of the connecting rod 6 is connected to the conversion plug 3, and the conversion plug 3 is installed on the main air duct 4 of the pneumatic system. The conversion plug 3 has a cavity 13 in the valve body 10, a ball core 11 with a central hole 12 is arranged in the cavity 13, an axle 7 is installed on the ball core 11, and a handle 8 is installed at the end of the axle 7. The ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com