Side wall structure for hopper car

The technology of a side wall structure and a hopper car is applied in the direction of a hopper car, a railway car body, a transport passenger car, etc., and can solve the problems of increasing the weight and cost of rivets, unutilized space of the side column, and reducing the strength of the side wall panel, etc. Achieve the effect of improving the assembly process, eliminating the assembly process and simplifying the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

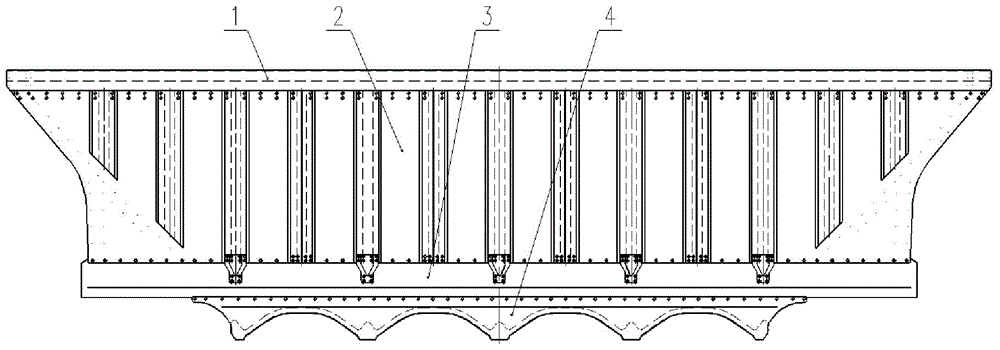

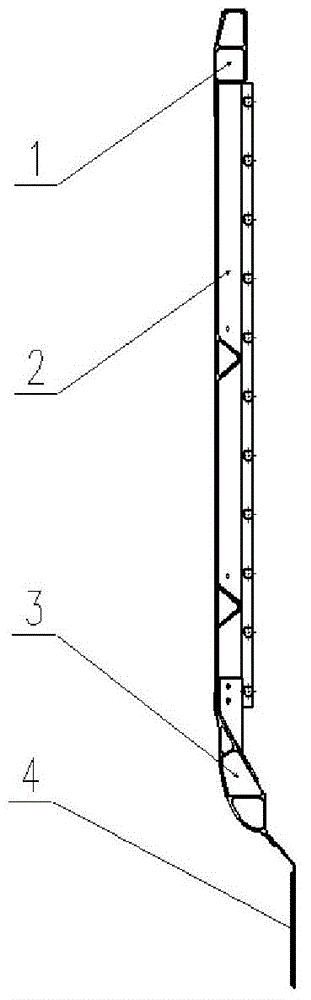

[0018] see Figure 1-Figure 7 As shown, the side wall structure of the railway coal hopper car provided by the embodiment of the present invention includes: an integrally formed upper side beam 1, an integrated side wall panel 2, an integrally formed lower side beam 3 and a lower side wall 4; The beam 1 is riveted with the integrated side wall panel 2 below; the side wall panel 2 is riveted with the integrally formed lower side beam 3 below; Inside the vehicle body; the lower side beam 3 is riveted with the lower side wall 4 below.

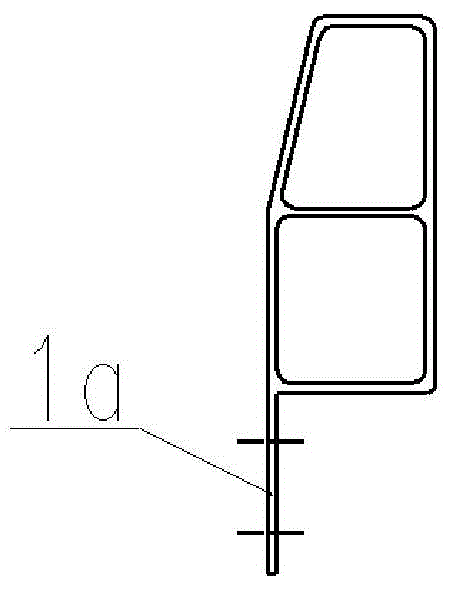

[0019] The lower part of the upper side beam 1 is provided with a wing edge 1a; the wing edge 1a is riveted with the side wall panel 2 . The upper side beam 1 is an integrally formed box beam of aluminum alloy material. The side wall panel 2 includes a side panel 2a, a side column 2b and a side column 2c with a triangular cross-section and wings. The side plates 2a are equidistant and alternately provided with side columns 2b with triangular cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com