Center sill free stainless steel foodstuff hopper wagon

A stainless steel, hopper car technology, applied in the direction of hopper cars, transport passenger cars, railway car body parts, etc., can solve the problems of unsuitable heavy-load operation, light load, small volume, etc., and achieve improved speed, unloading cleanliness, and dead weight. Light, bulky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

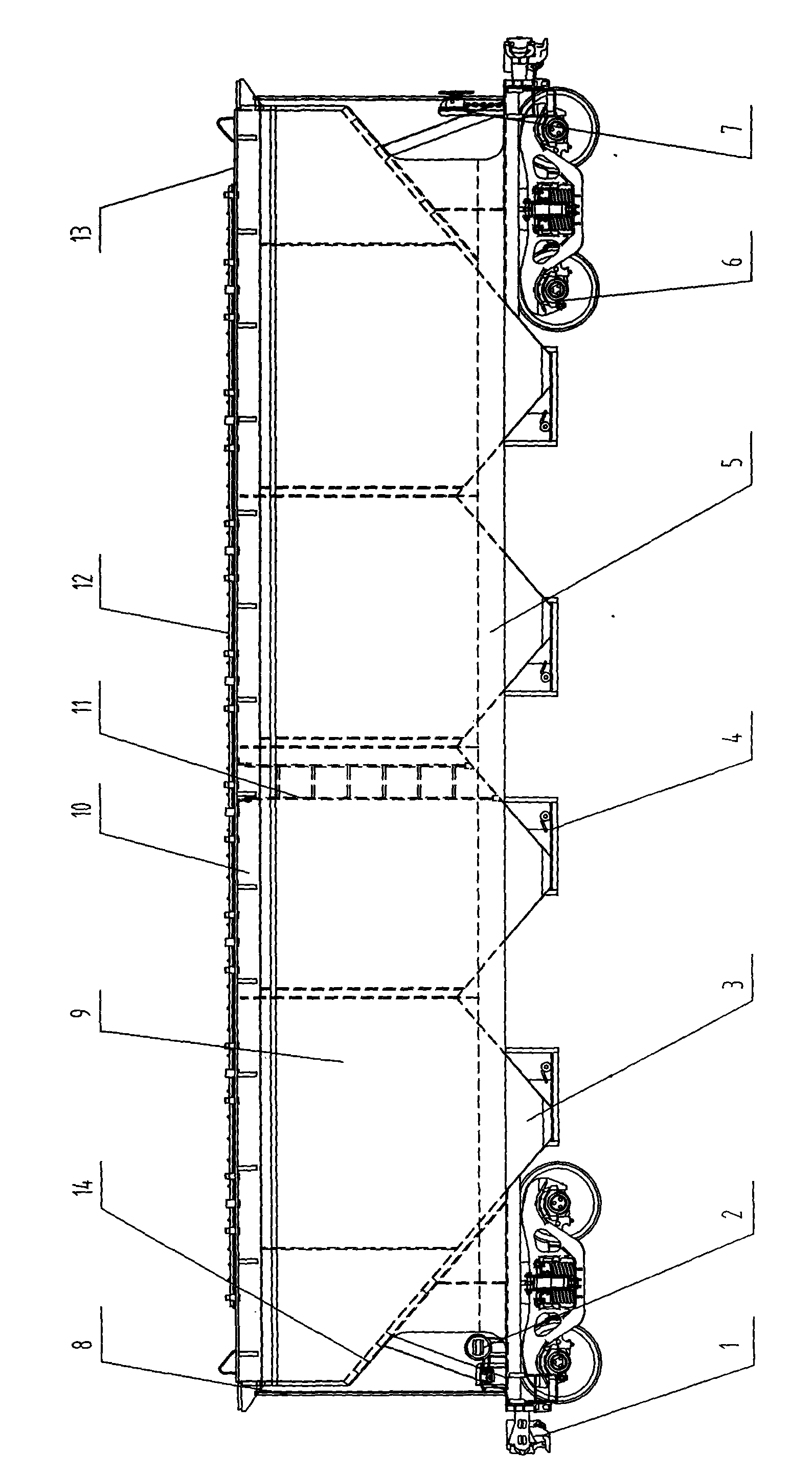

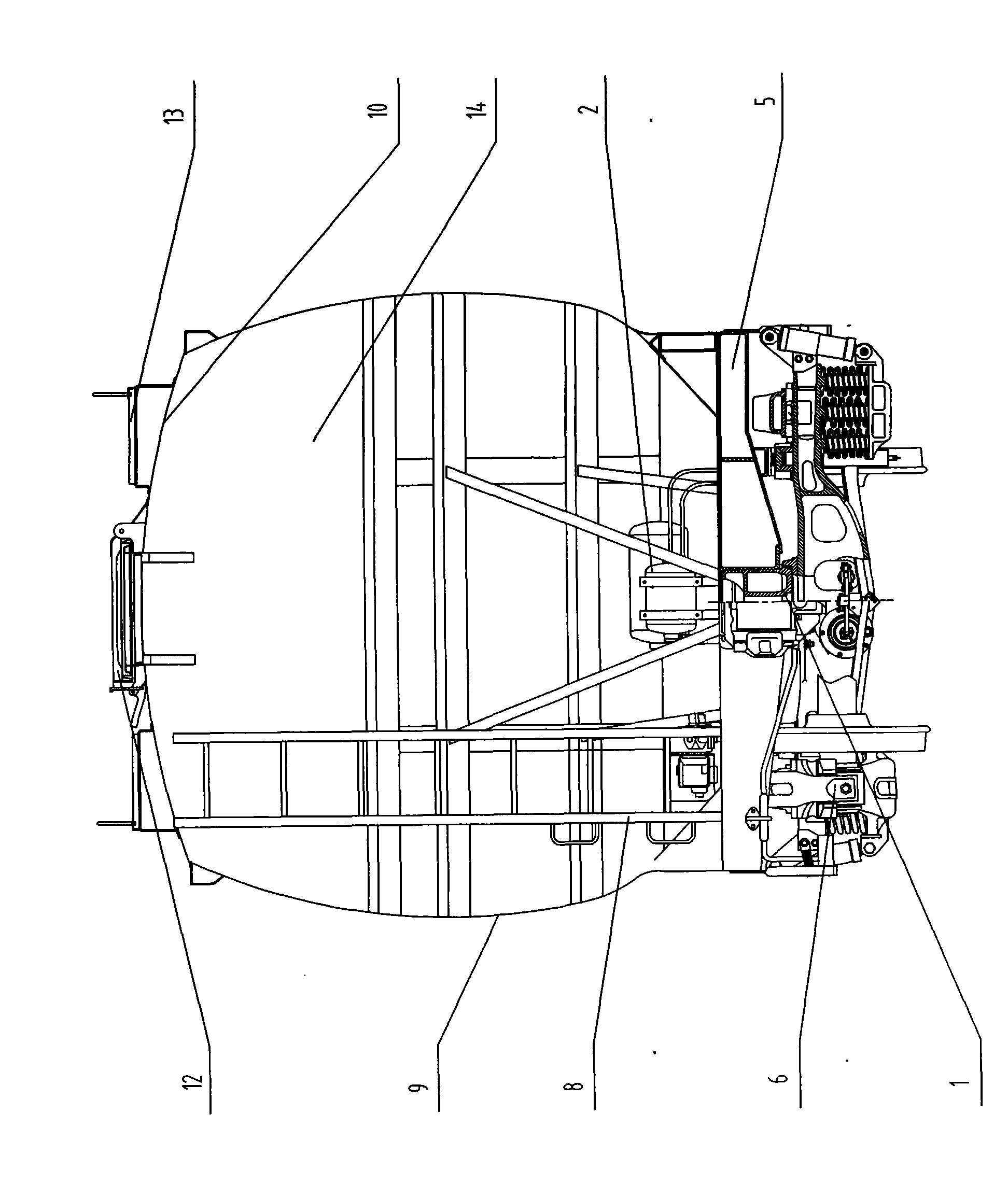

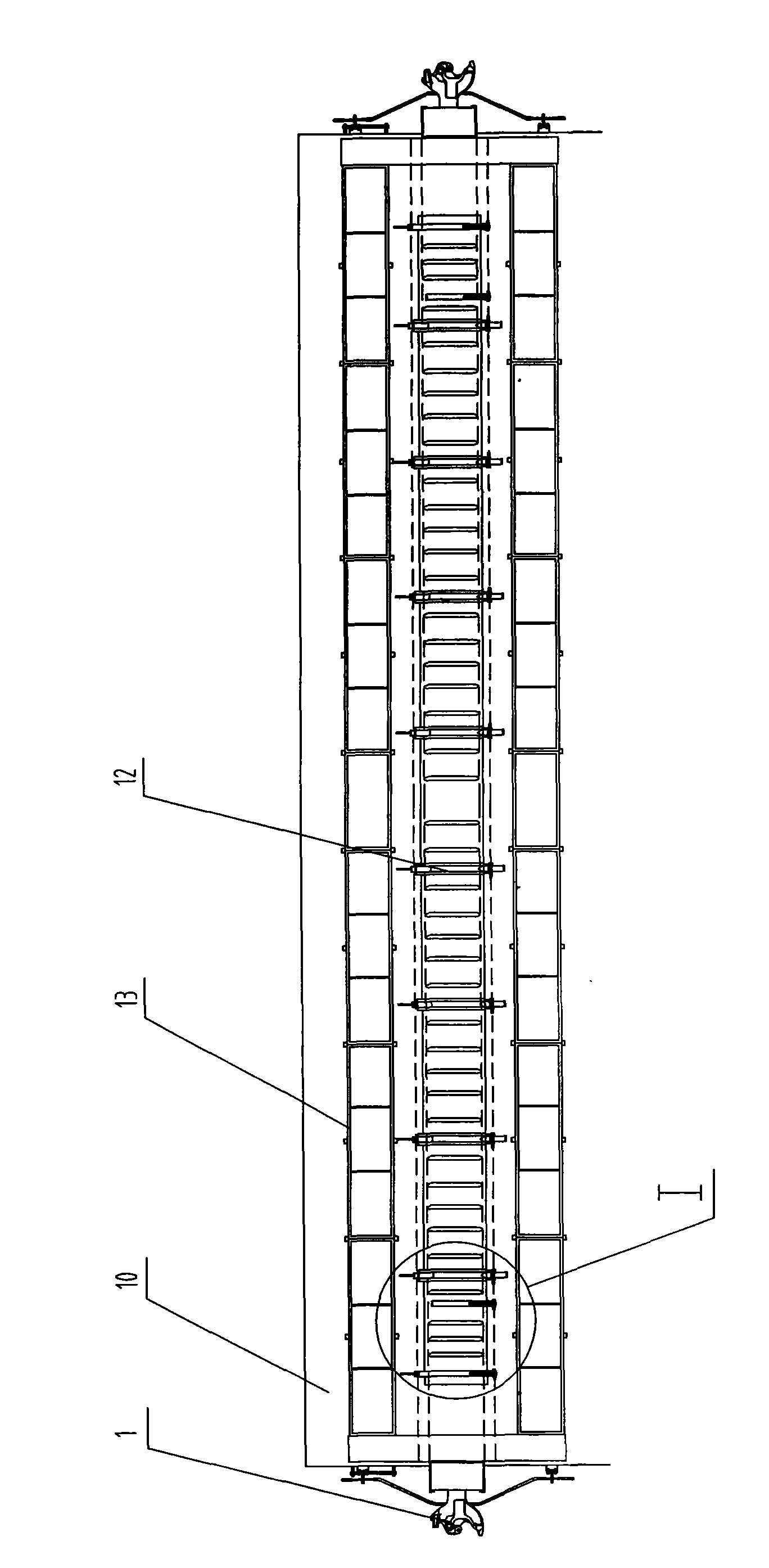

[0012] Stainless steel grain hopper car without center beam, including bogie 6, underframe 5, coupler buffer device 1, hand brake device 7, air brake device 2, car body, end ladder 8, funnel composition 3, bottom door assembly 4 and Walking platform 13, underframe 5 is installed on bogie 6, car body is installed on underframe 5, hand brake device 7 and air brake device 2 are installed on underframe 5, coupler buffer device 1 is installed on underframe 5 The two ends of the two ends, the funnel composition 3 is installed under the car body, the bottom door assembly 4 is installed under the funnel composition 3, and the walking platform 13 is installed on the car body, which is characterized in that the car body is installed with two side walls on the underframe 5 9 and the two end walls 14, the roof 10 is installed on the side wall 9 and the end wall 14, and four funnels are installed below the underframe 5 to form a 3, and the side panels of the funnel form 3 have an included a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com