Patents

Literature

54results about How to "Extrusion realization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

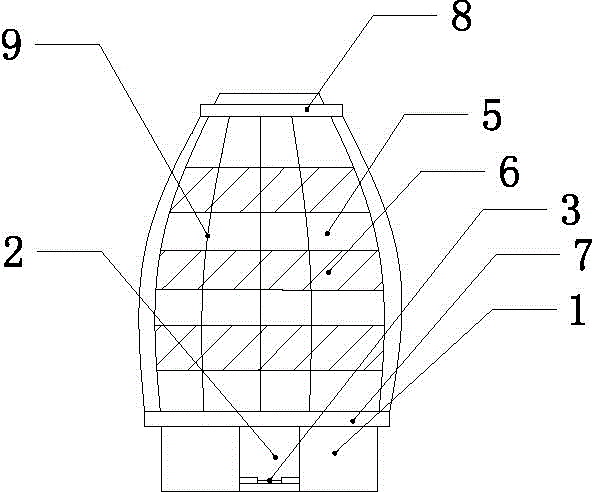

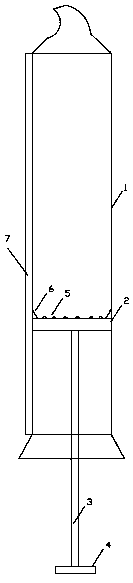

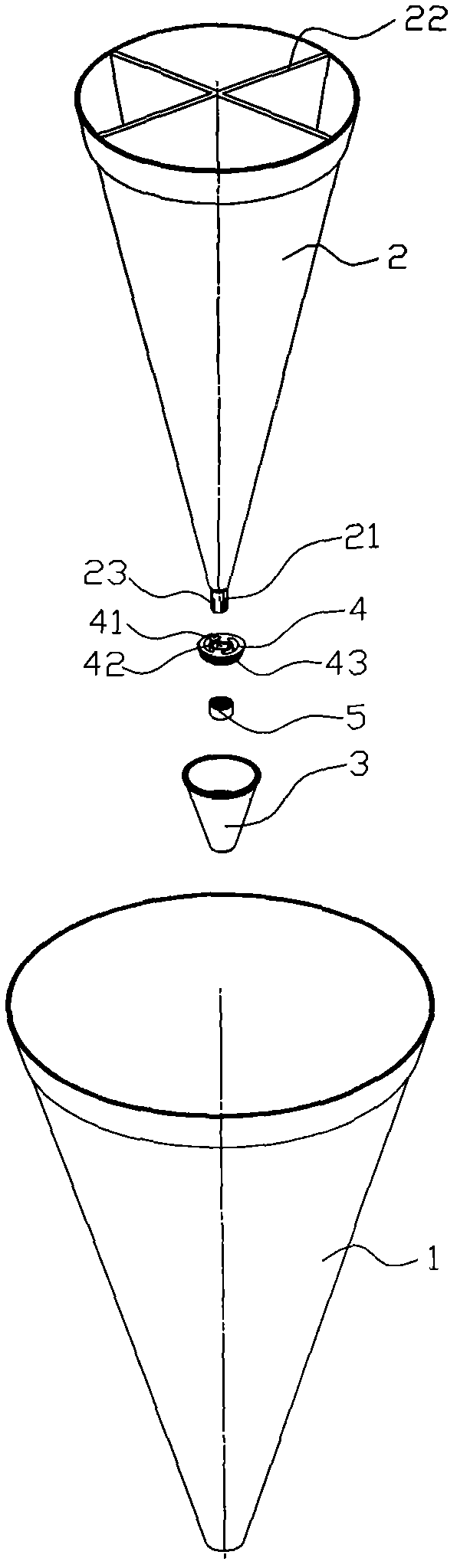

Rural water-saving and odorless ecological toilet for separation and collection of faeces and urine

InactiveCN107296561AImprove fertilityGuaranteed nutritionBathroom accessoriesSpecial buildingEngineeringFermentation

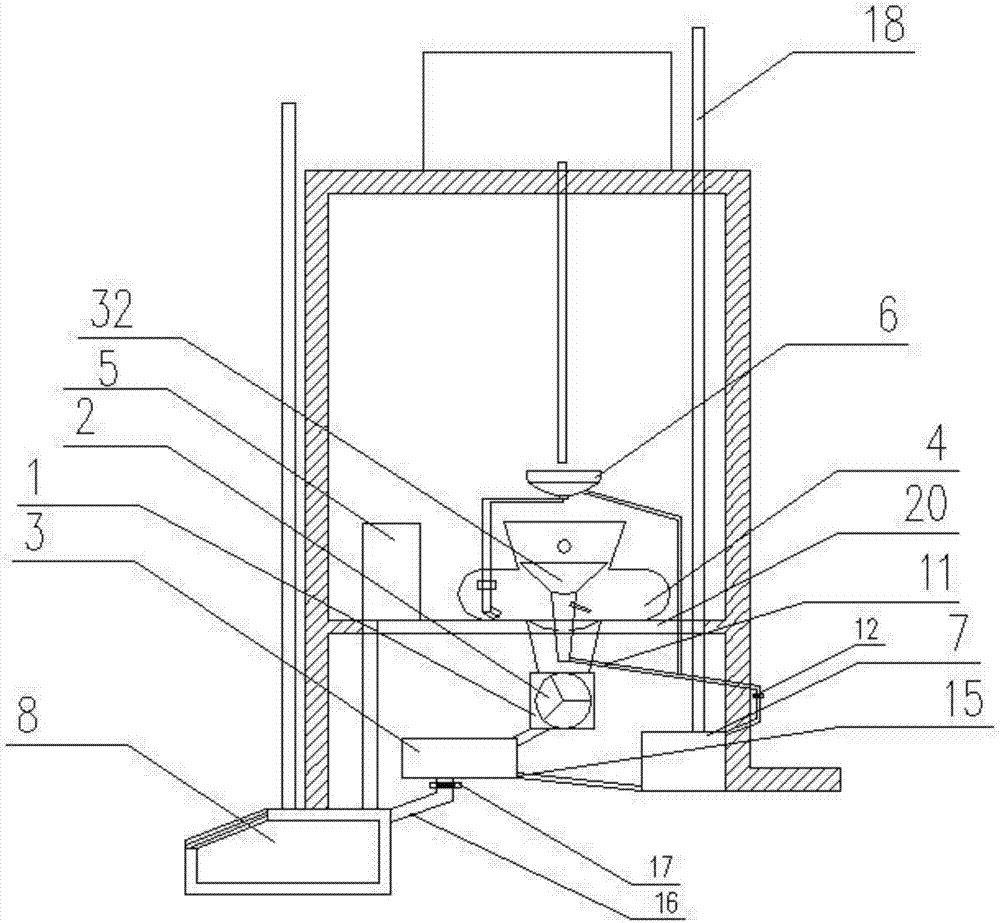

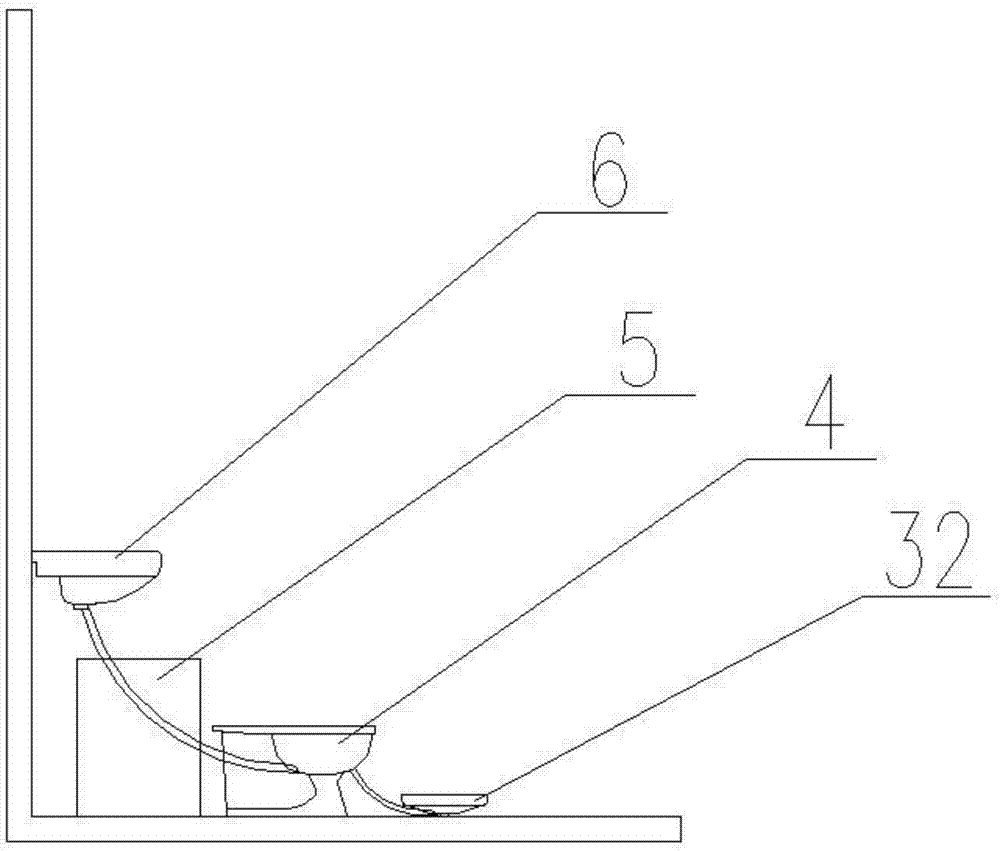

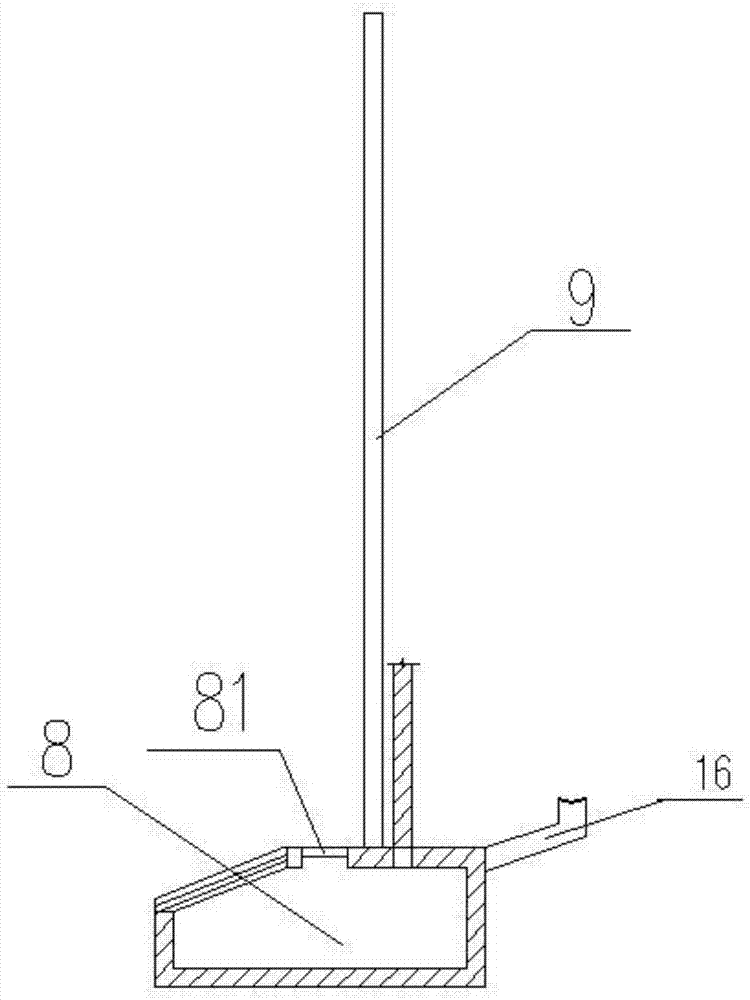

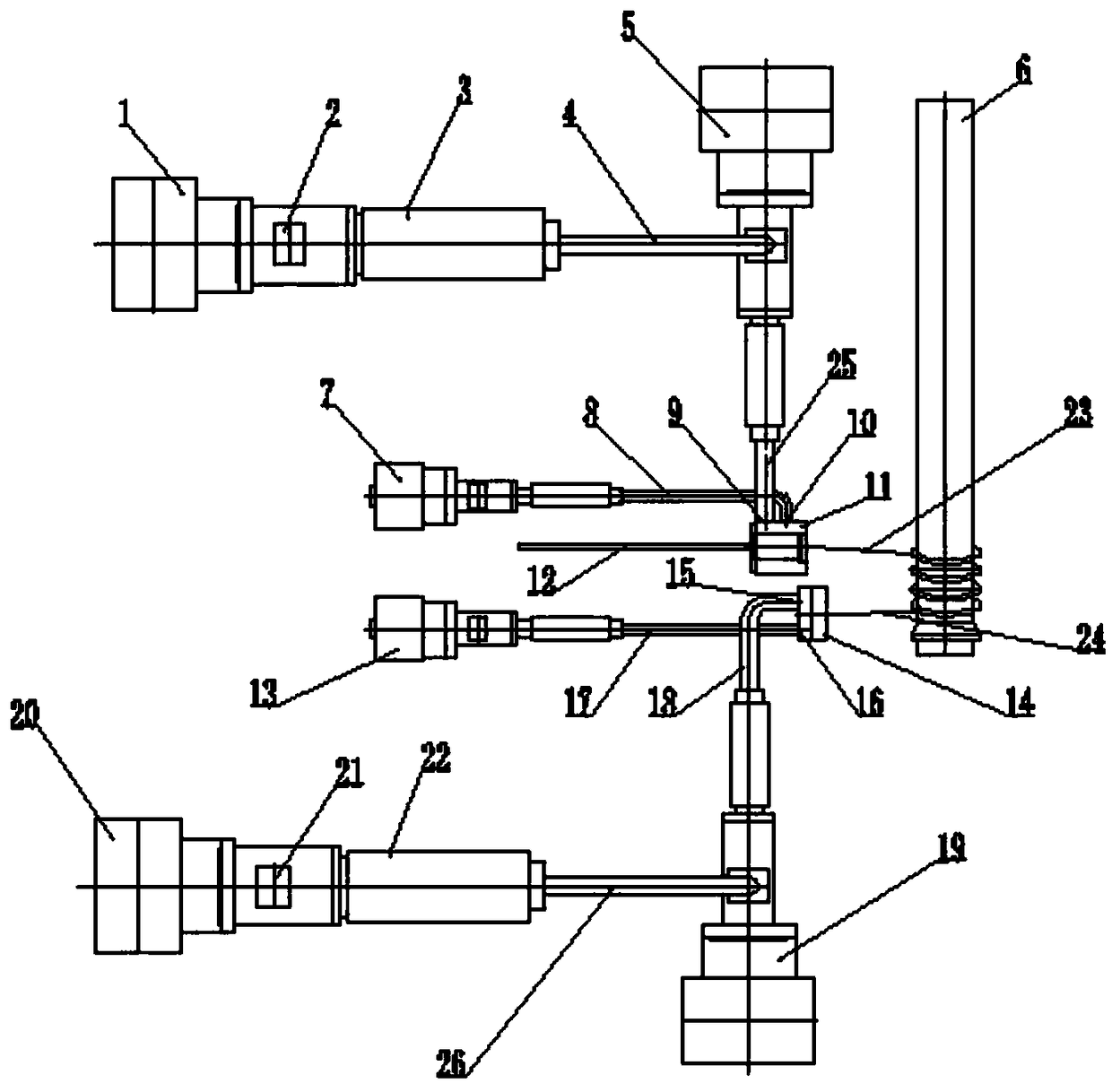

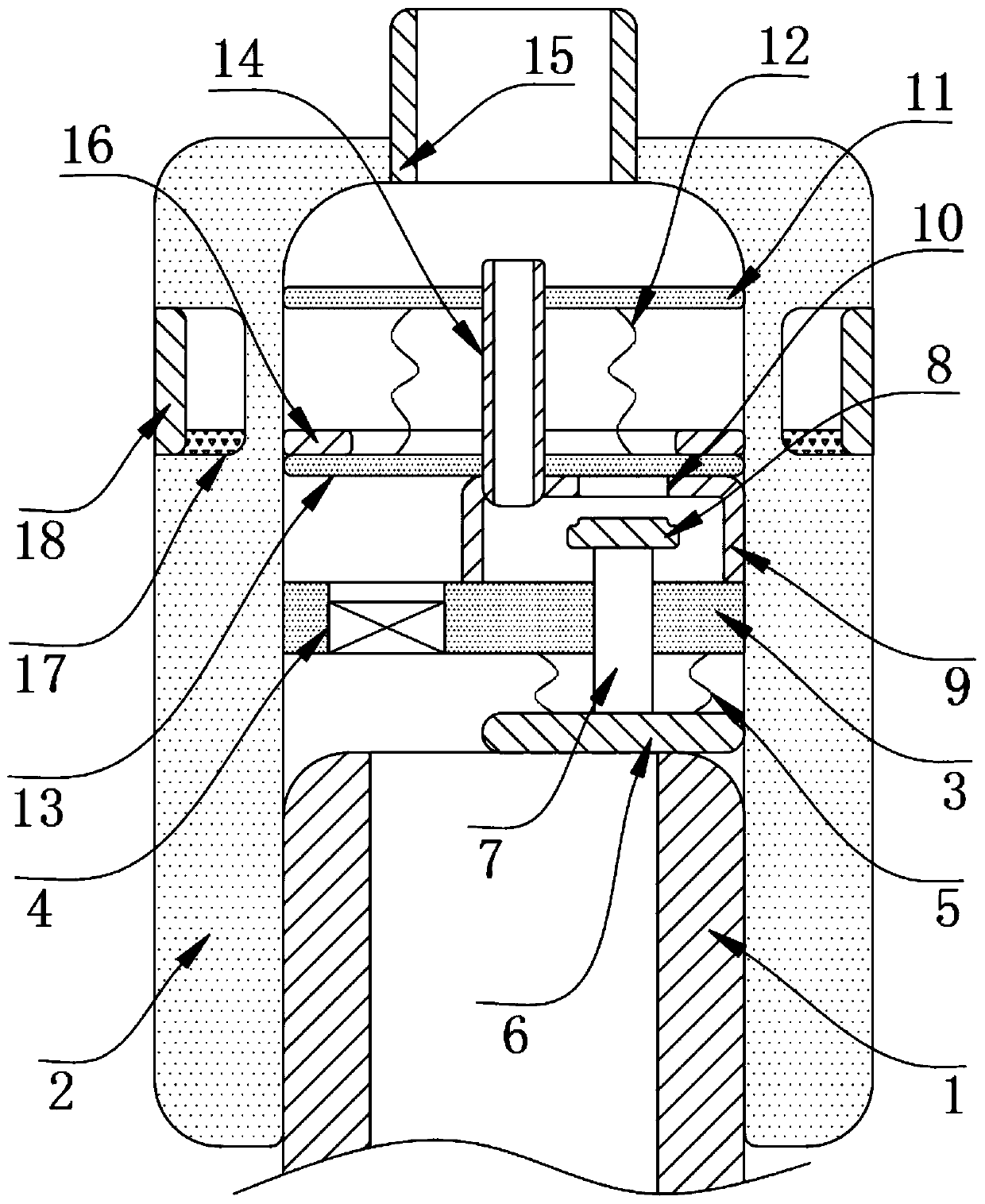

The invention discloses a rural water-saving and odorless ecological toilet for separation and collection of faeces and urine. The rural water-saving and odorless ecological toilet for separation and collection of the faeces and urine comprises a faeces pool and a tank body, wherein a bottom plate is arranged in the tank body, and the tank body is divided into an upper part and a lower part through the bottom plate; a toilet bowl is arranged at the upper part of the interior of the tank body, and the faeces pool is arranged below the outside of the tank body; the toilet bowl is communicated with the faeces pool, and the faeces pool is also connected with a dry faeces chamber; the dry faeces chamber is internally provided with a drying device, and the faeces pool is internally provided with a faeces processing device; a rainwater box and a control device are arranged on the top of the outer surface of the tank body, and a solar battery panel is arranged on the control device. Since a bio-fermentation chamber, a liquid fertilizer pool and a dry faeces pool are connected with the faeces pool, every time a toilet user finishes an excrement, separation of the faeces and the urine is conducted firstly, then the faeces in the faces pool is subjected to bio-degradation and temperature-raising dehydration, and solid faeces are processed into faeces blocks or granules which are then stored in the dry faeces pool for weathering and drying; the emitting amount of odor of the faeces after dehydration is greatly reduced, so that the surrounding environment is protected.

Owner:CHINA MCC17 GRP

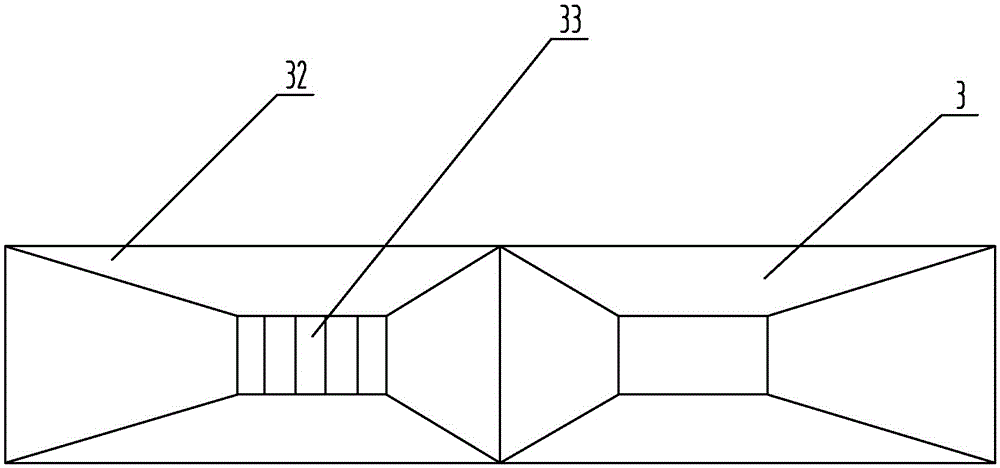

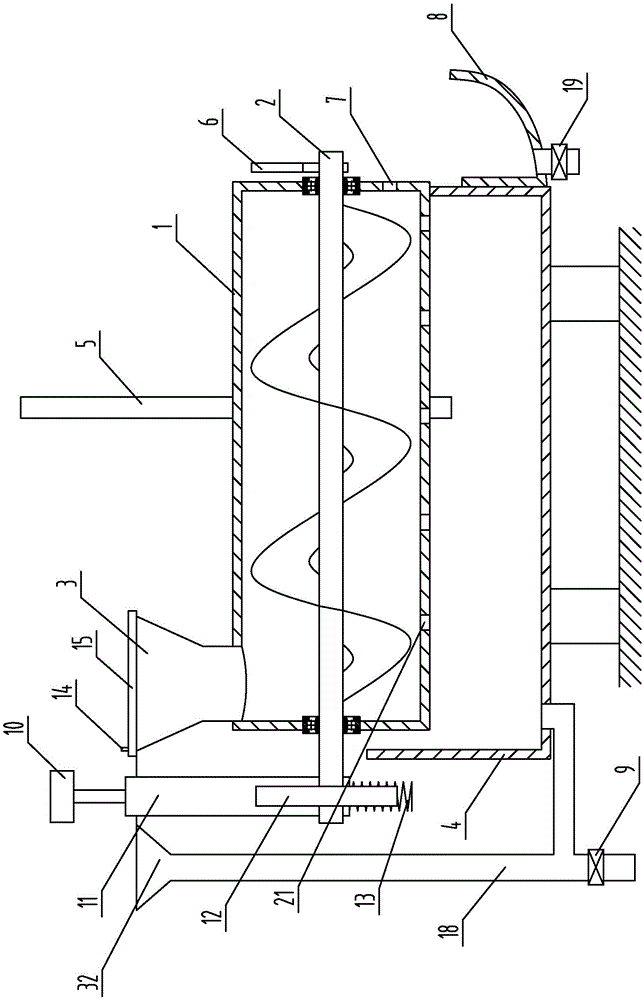

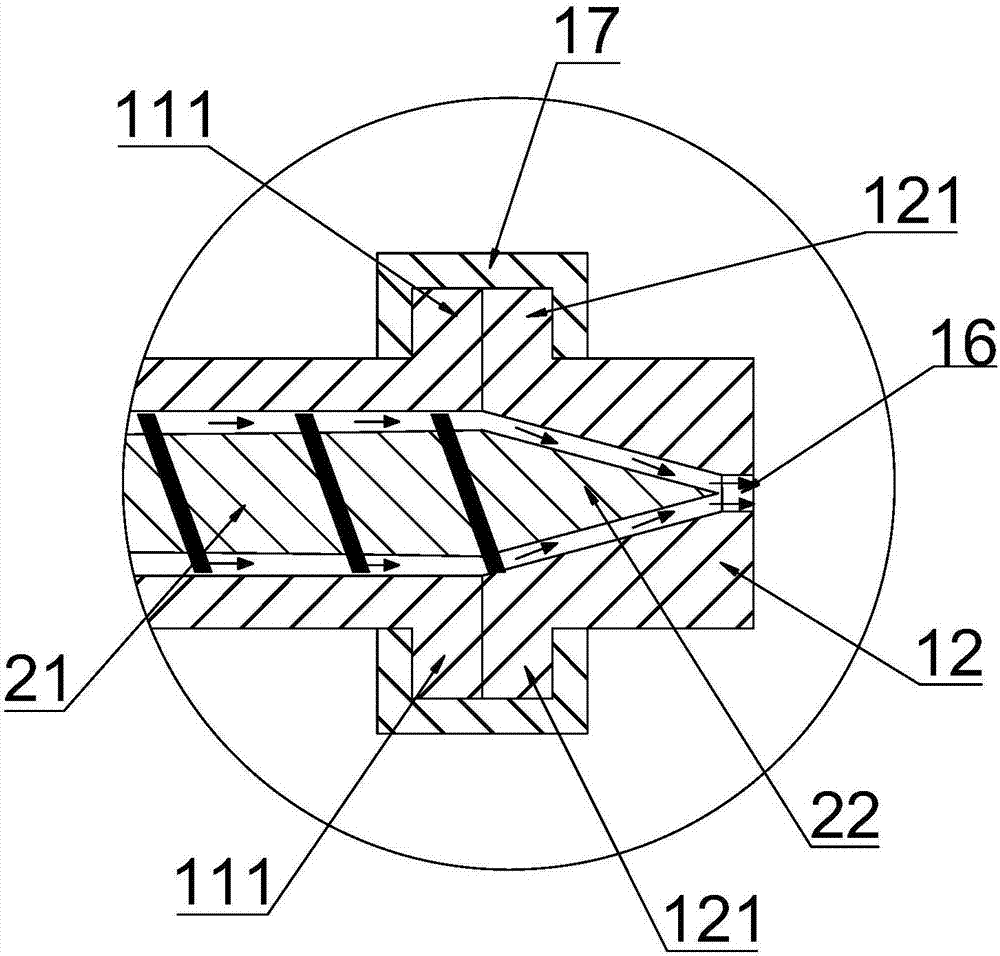

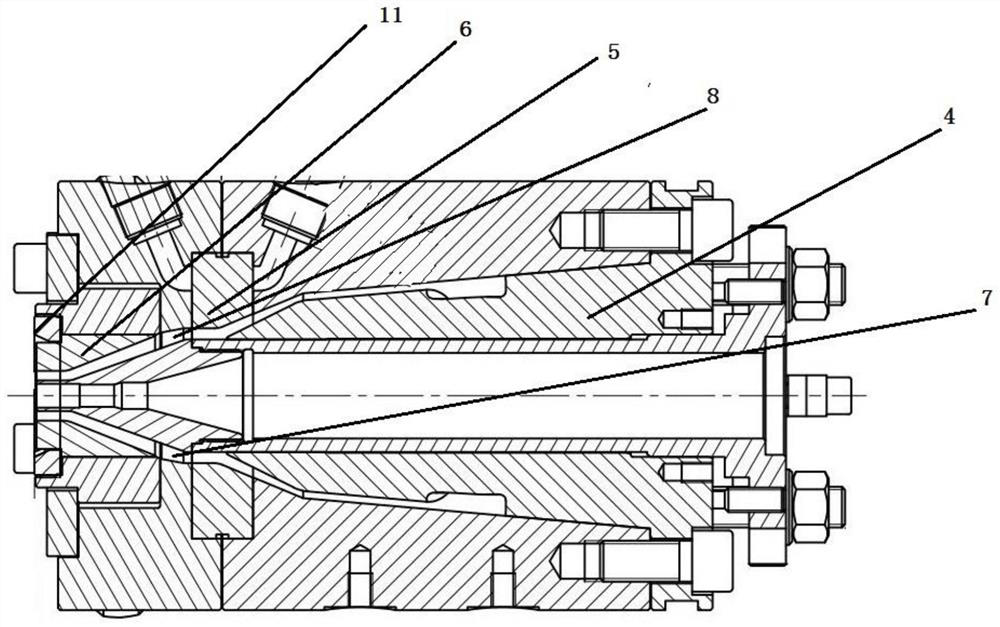

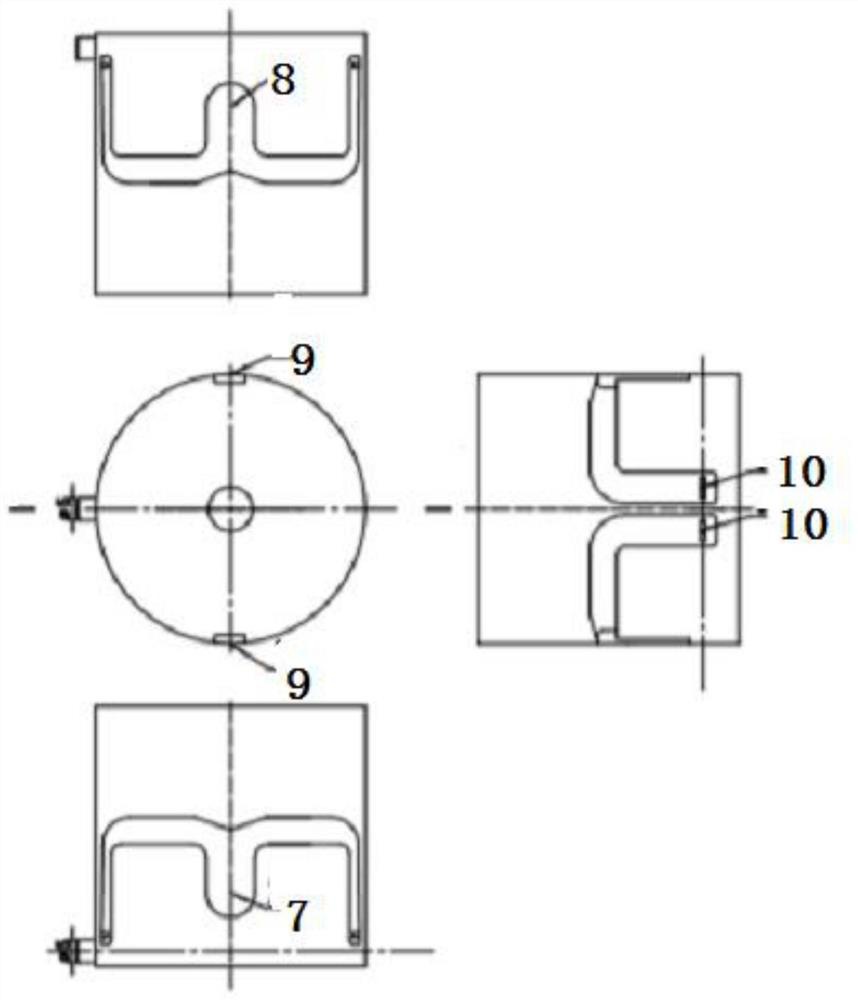

Machine barrel for extruding UHMWPE (Ultra High Molecular Weight PolyEthylene)

The invention discloses a machine barrel for extruding UHMWPE (Ultra High Molecular Weight PolyEthylene), and aims to solve the problems of high viscosity, poor fluidity, and susceptibility to fracture and degradation during the manufacturing process of the UHMWPE. The machine barrel of an extruder adopts a groove machine barrel; pins are arranged on the machine barrel; a copper sheathing is mounted around each pin. The extruder machine barrel provided by the invention can increase the friction between material and the machine barrel to guarantee strong forward transportation capacity, and is easy to plasticize and mix; the pins can be replaced conveniently; the copper sheathings outside the pins can achieve the functions of sealing, positioning and adjustment, so as to increase the extruding efficiency of the extruder and the mass of the UHMWPE.

Owner:江苏联冠高新技术有限公司

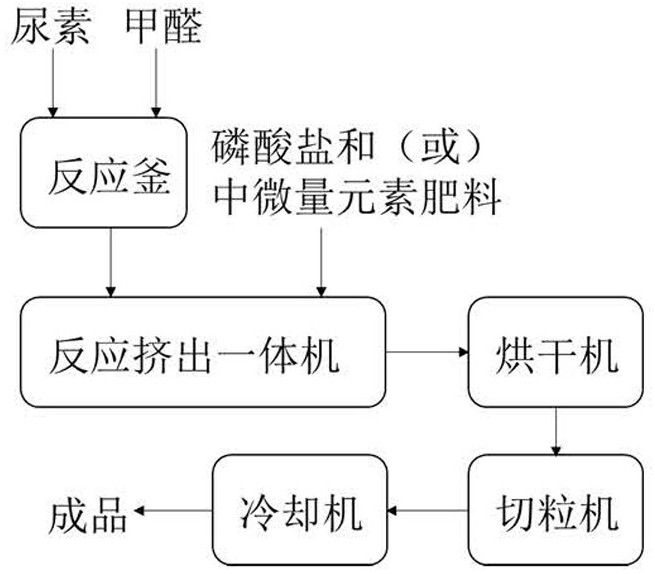

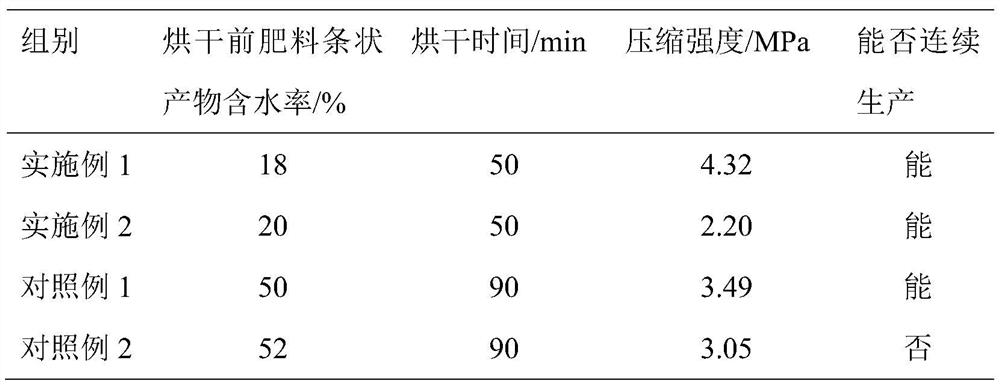

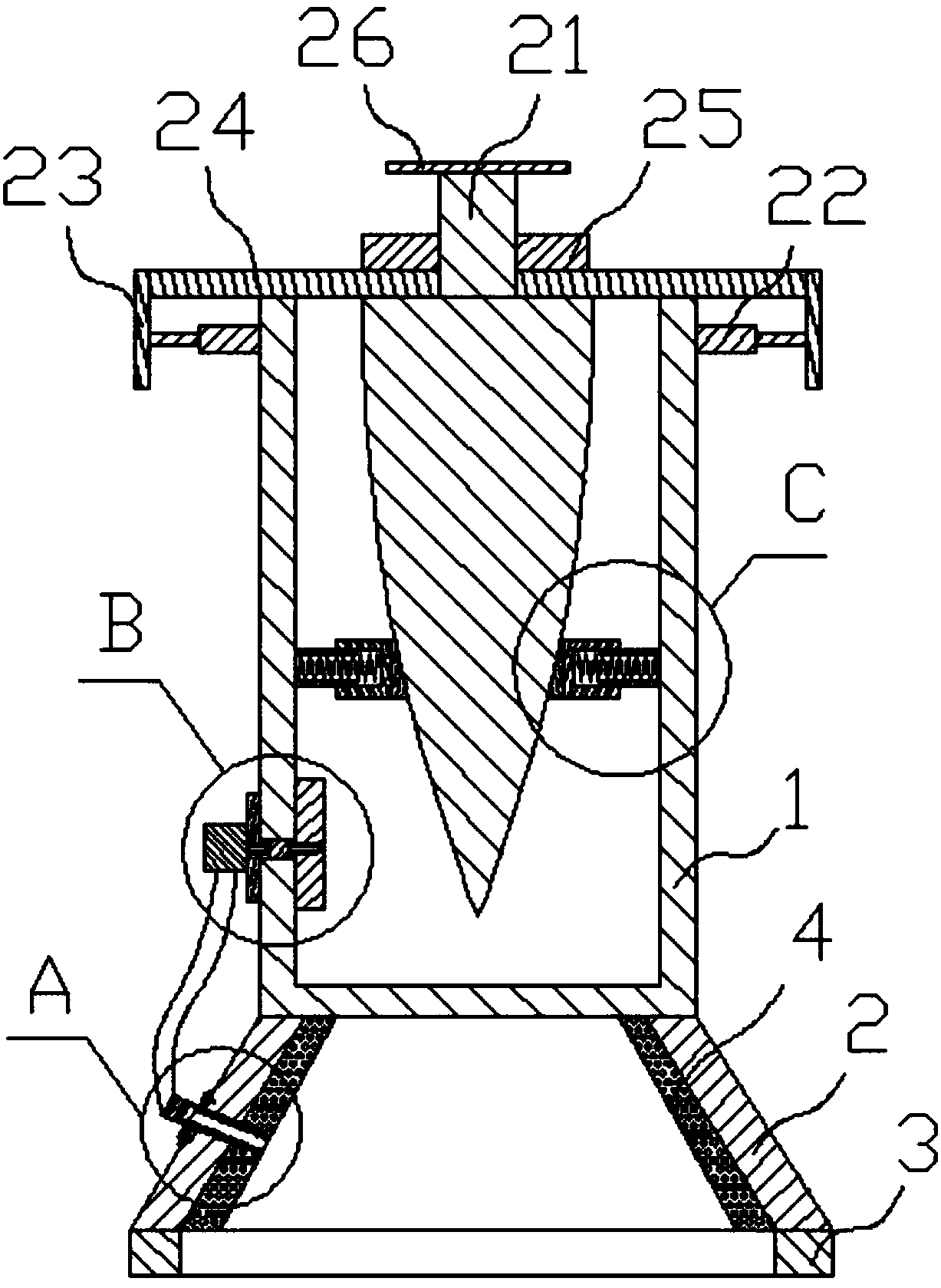

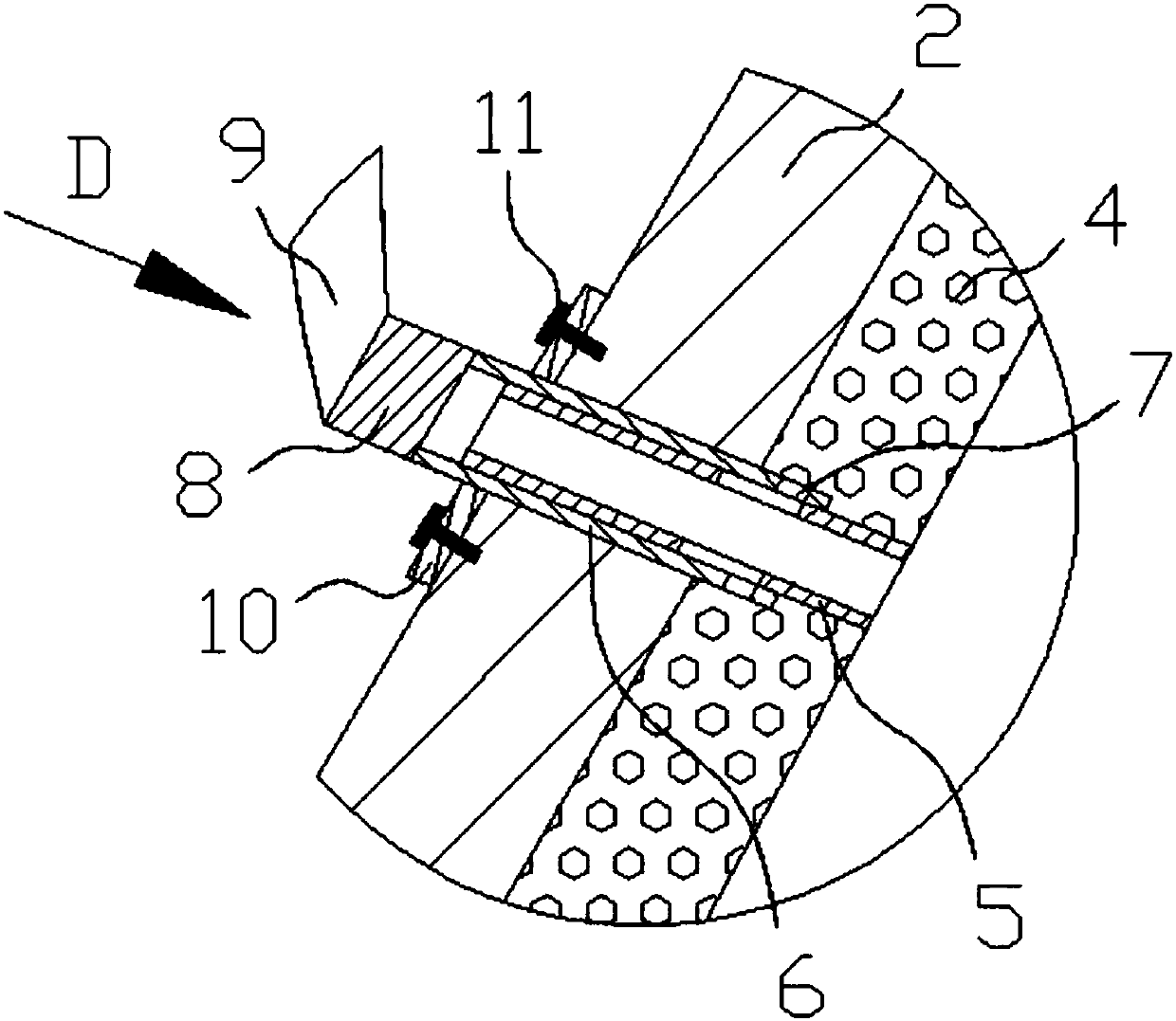

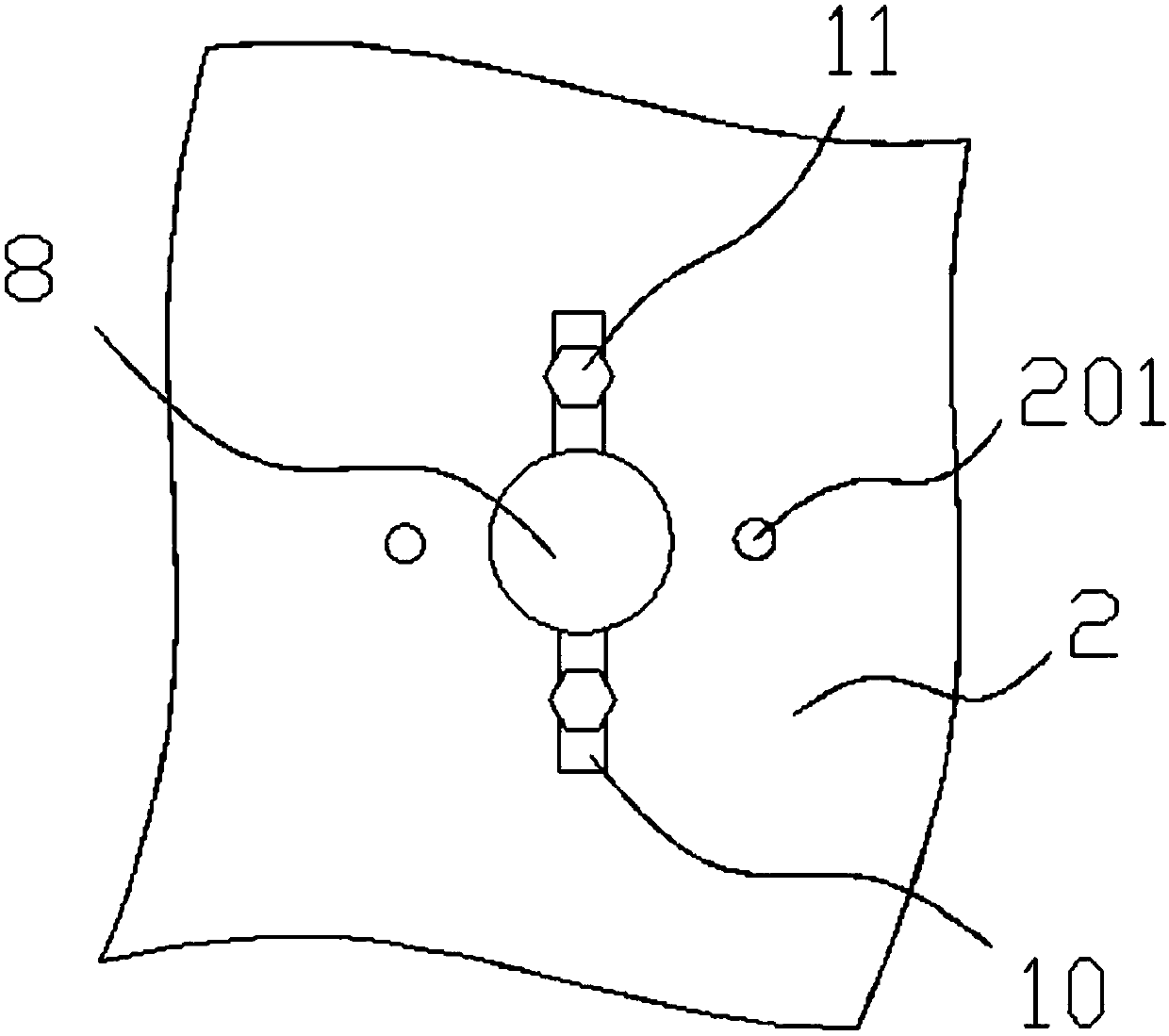

Efficient environment-friendly reactive extrusion integrated continuous processing technology of urea aldehyde and derivatives thereof

ActiveCN112898053ARealize forced dischargeRealize continuous productionAlkali orthophosphate fertiliserChemical industryPhosphateProcess engineering

Owner:ZHONGBEI UNIV +1

Toothpaste extruding mechanism capable of facilitating decoration and mounting

InactiveCN107837021ARealize automatic extrusionEasy to useHolders and dispensersUnpacking by expelling contentsAir pumpToothpaste

The present invention relates to the field of daily life mechanical equipment, in particular to a toothpaste extruding mechanism that can be easily decorated and installed. The extrusion device, the lower part of the extrusion cylinder is connected with a square installation cone seat, the lower part of the installation cone seat is provided with an installation seal ring, and the installation cone seat is provided with a suction pipe passing through the wall of the cone seat, and the suction pipe passes through the installation ventilation hose The ventilation pump is connected, and the ventilation pump is installed on the extrusion cylinder through the ventilation pump installation block, and the extrusion device and the ventilation pump are connected to the controller; the present invention places the toothpaste in the extrusion cylinder, and cooperates with the extruding cylinder in the extrusion cylinder. The output device realizes the automatic extrusion of toothpaste. Through the installation part set at the lower part of the extrusion cylinder, the extrusion cylinder can be fixed on the washstand, which not only facilitates the use of toothpaste, but also can cooperate with the washstand to achieve a decorative and beautiful effect.

Owner:DONGGUAN UNIV OF TECH

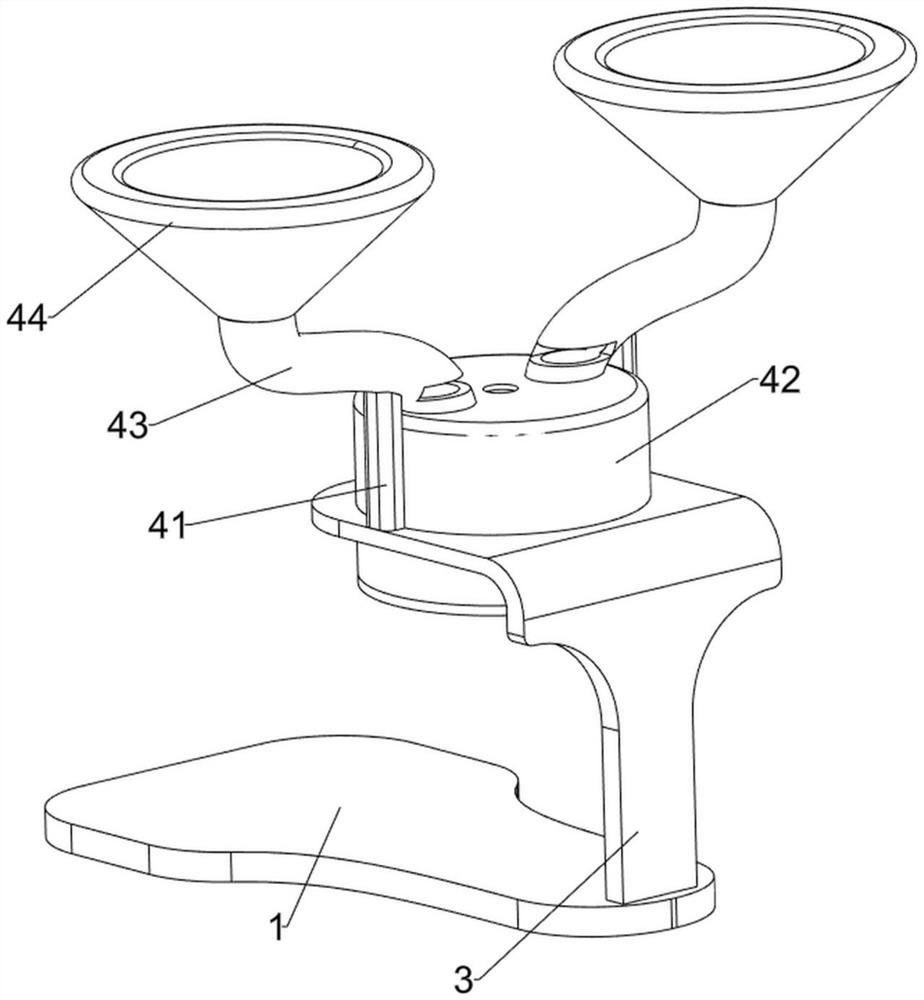

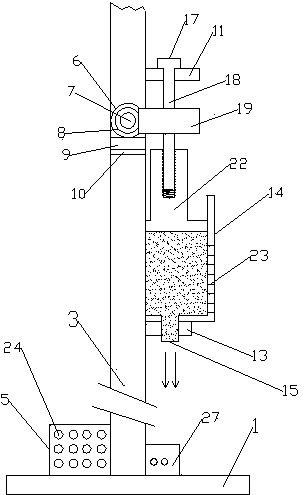

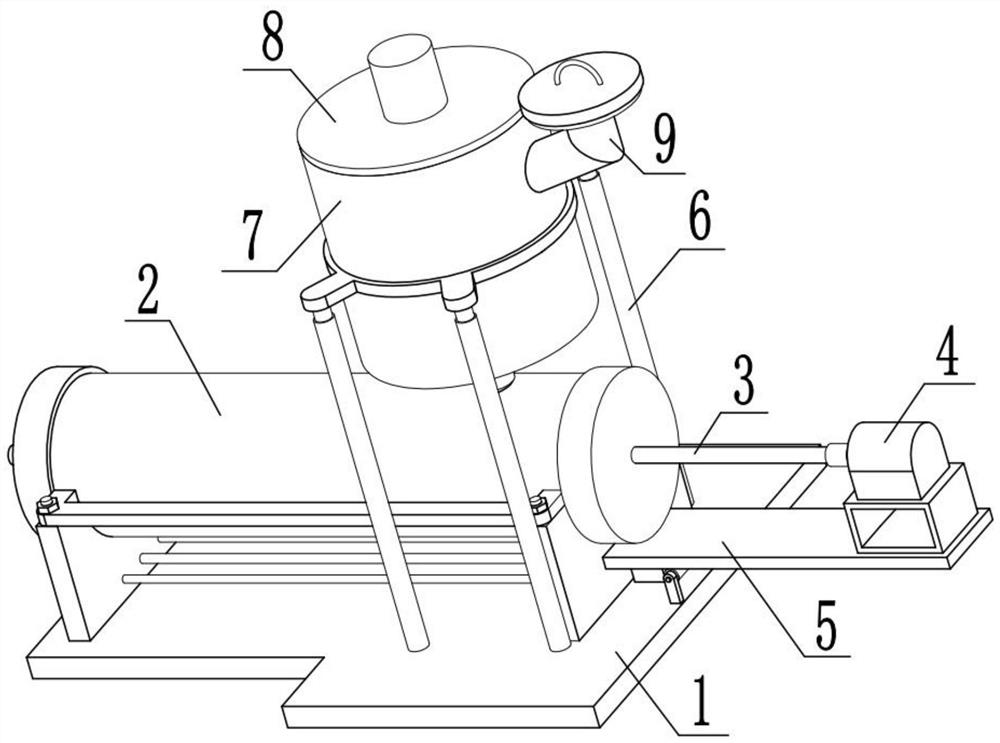

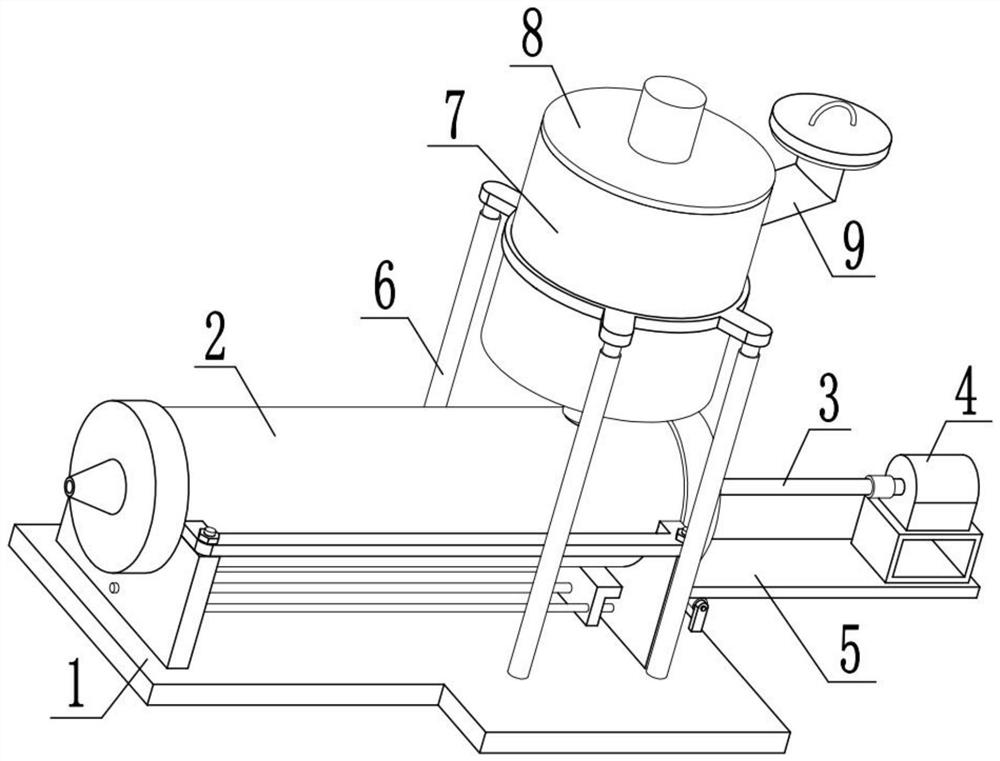

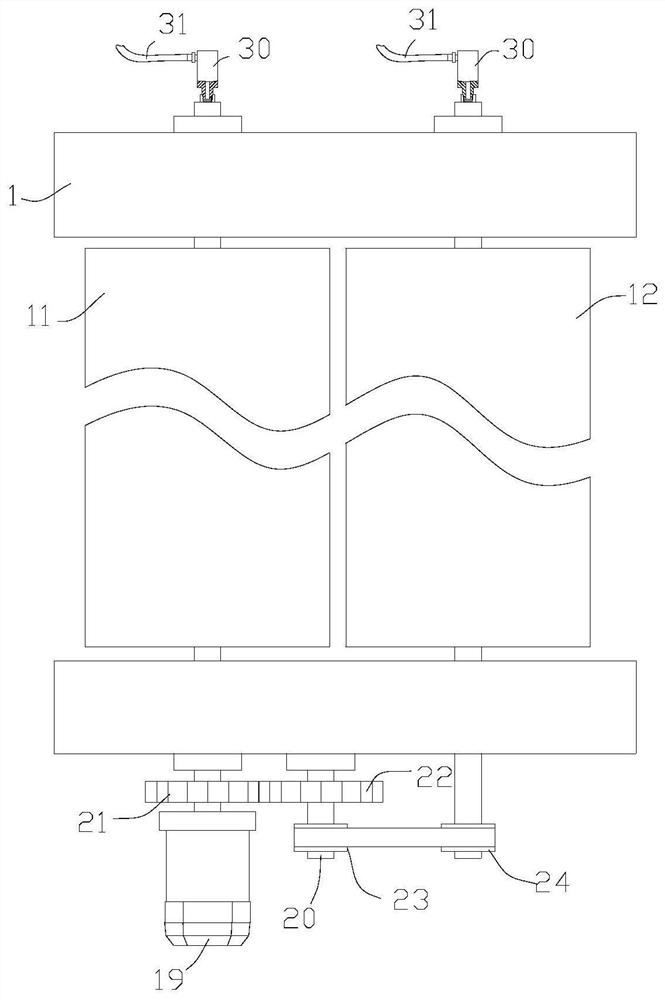

Particle extrusion device for modified starch processing

ActiveCN112497551ARealize the blanking effectStirring effect is evenSievingScreeningEngineeringMechanical engineering

The invention relates to a particle extrusion device, in particular to a particle extrusion device for modified starch processing . The particle extrusion device for modified starch processing provided by the invention is uniform in mixing and good in extrusion effect. The particle extrusion device for modified starch processing comprises a base, a supporting seat, a feeding mechanism, a rotatingmechanism and a reciprocating mechanism. A first supporting column is arranged on the base; the supporting seat is arranged on the base; the feeding mechanism is arranged at the upper part of the supporting seat; the rotating mechanism is arranged on the feeding mechanism; and the reciprocating mechanism is arranged at the lower part of the feeding mechanism, and is connected with the rotating mechanism in a sliding manner. According to the particle extrusion device for modified starch processing provided by the invention, modified starch is discharged through a discharging frame and slides into a stirring box through a discharging pipe, so that the discharging effect is achieved; and by arranging a collecting mechanism, the purified modified starch is collected by the collecting mechanismand is convenient for people to take and use.

Owner:DONGXIANG HEDA IND CO LTD

Multifunctional paint sprayer

InactiveCN103358805ASimple structureEasy to operateOther artistic work equipmentsElectric machineryMotor shaft

The invention relates to a multifunctional paint sprayer. A motor support frame is arranged between support rods; at least a motor is mounted above the motor support; a worm is mounted on a motor shaft of each motor; a mounting groove is formed in the motor shaft between each worm and each motor; a fastening bolt is movably mounted in the mounting groove; a turbine support frame is movably mounted below the motor support frame, and is mounted on the side surfaces of the support rods through positioning cotter pins; cotter pins positioning holes matched with the positioning cotter pins are formed in the support rods; the lower part of the turbine connecting rod is sleeved with a sliding nut matched with a bolt head; an extruding catch is arranged below the sliding nut, and is sleeved with a paint buckle; a reinforcing fixing connecting rod is arranged between a paint support rod and the turbine support frame; a control panel and an exterior power plug are arranged on the base. The paint sprayer is multifunctional, and has a high level of mechanization.

Owner:PINGDINGSHAN UNIVERSITY

Color mixing device for graphic design

InactiveCN110901285AExtrusion realizationAvoid drippingOther artistic work equipmentsElectric machineryEngineering

The invention discloses a color mixing device for graphic design. The color mixing device comprises a supporting mechanism for supporting and fixing, a transmission mechanism, a detection mechanism, acase and a stirring barrel, wherein the supporting mechanism is arranged above the case, the transmission mechanism is arranged below the supporting mechanism, the detection mechanism is arranged inthe case, and the stirring barrel is arranged in front of the case. The color mixing device further comprises discharging mechanisms used for extruding pigments. According to the color mixing device for graphic design of the invention, each first electric telescopic rod is used for pushing a plunger rod to move in a cylinder barrel, so that a pigment in the cylinder barrel can be extruded into thestirring barrel; a whole first supporting frame is driven to rotate through a material changing motor, so that cylinder barrels of other pigments can be switched, and therefore, the extrusion of different pigments is achieved; the downward dripping of the pigments can be prevented through springs and leakage-proof rods; and the weights of the pigments in the stirring barrel are detected through apressure sensor, and then the pigments in the stirring barrel can be stirred through a stirring motor and a stirring shaft.

Owner:CHONGQING COLLEGE OF ELECTRONICS ENG

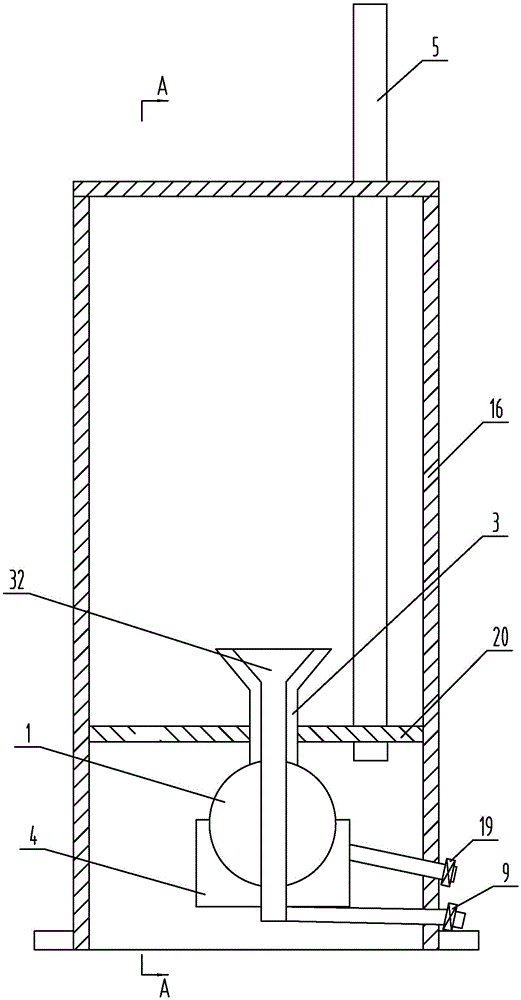

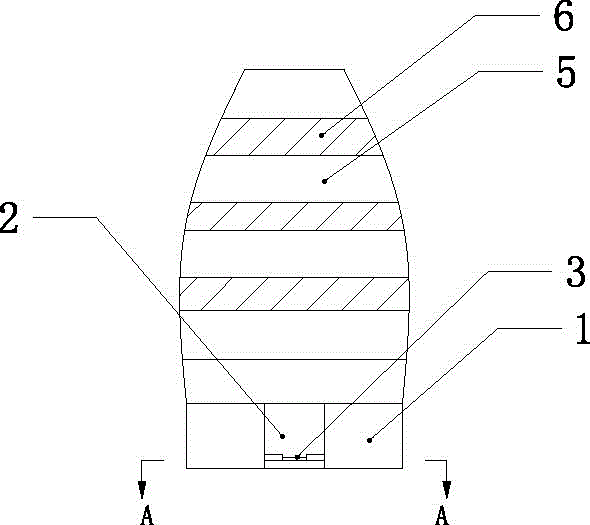

Water-free public toilet for scenic region of village

ActiveCN105520676AEasy to collect and useEmission reductionBathroom accessoriesRural areaReduction treatment

The invention discloses a water-free public toilet for a scenic region of a village, belonging to the technical field of dry pail latrines. The water-free public toilet comprises a faeces pit, and is characterized by further comprising a housing, wherein the space defined by the housing is provided with the floor which separates the space into an upper part and a lower part; a defecating pan is arranged above the floor, the faeces pit is arranged below the floor, and the defecating pan is communicated with the faeces pit; the faeces pit is connected with a faeces drying pit, and a faeces processing device is arranged in the faeces pit; a control device is arranged in the space defined by the housing or on a shell of the housing, and can drive the faeces processing device to act. According to the water-free public toilet, the faeces can be subjected to water reduction treatment, so that the emission amount of the peculiar smell of the faeces can be greatly reduced, the surrounding environment is protected, and the urine and faeces can be conveniently collected and utilized; in addition, after the faeces form the granular shape, the superficial area is increased, and the airing drying is accelerated; the faeces do not need to be washed by water, so that other impurities such as water are eliminated, further, the high-fidelity nutrition of the faeces is guaranteed, and the faeces can be taken as the fertilizer for agricultural production.

Owner:东台果蔬椒乡农业科技发展有限公司

Organic silicon extrusion device

PendingCN111791528APrevent solidificationExtrusion realizationShaping pressPhysical chemistryPower apparatus

The invention relates to the technical field of organic silicon, in particular to an organic silicon extrusion device. The organic silicon extrusion device comprises an extrusion bearing fixing frame,an organic silicon storage device, a stirring extrusion device, a stirring power device, a sliding linkage device, a lifting support frame body, a solid silicon melting bucket, a shielding stirring device and a solid silicon adding port, wherein solid organic silicon is added into a processing bucket by a transfer inclined tube, a heating ring is started to heat the solid organic silicon and a plurality of stirring plates stir the solid organic silicon; when the solid organic silicon becomes liquid organic silicon, the liquid organic silicon is transferred into a storage cavity through a liquid discharge pipe and a feed pipe; a motor II is started to drive an extrusion sliding plate, a fixed plate and an elastic spiral plate to rotate, so that the organic silicon can be stirred, and the solidification of the organic silicon is prevented; a motor I is started to drive a support sliding plate to slide leftwards, so that the extrusion sliding plate can be driven to slide leftwards, at the moment, the organic silicon located in the storage cavity can be discharged through an extrusion port, and the extrusion of the organic silicon is realized.

Owner:张建华

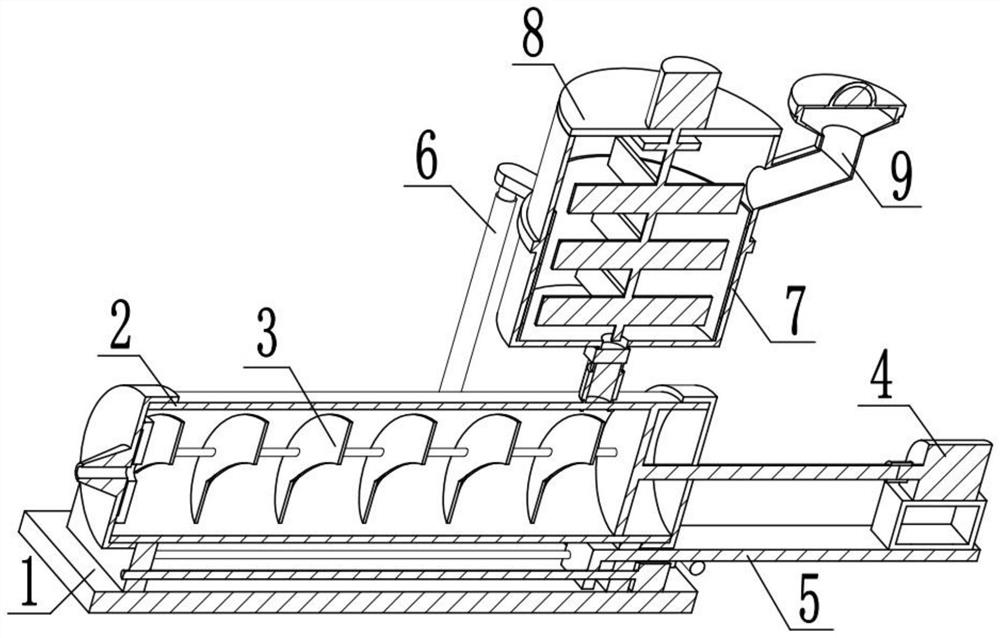

Extrusion, tabletting and crushing device for preparing powder coating

PendingCN112549624AExtrusion realizationRealize automated productionLighting and heating apparatusGrain treatmentsTabletingPowder coating

The invention provides an extrusion, tabletting and crushing device for preparing a powder coating. The extrusion, tabletting and crushing device comprises a conveying belt, and a tabletting mechanism, a cooling mechanism and a crushing mechanism which are arranged along the conveying belt, and an extruder is arranged above the tabletting mechanism. The tabletting mechanism, the cooling mechanismand the crushing mechanism are arranged along the conveying belt, thermosetting powder in the extruder is extruded into the tabletting mechanism from a discharged material to be pressed into flaky materials, the flaky materials fall onto the conveying belt to be conveyed to the crushing mechanism to be crushed into granular materials, and meanwhile when the flaky materials are conveyed on the conveying belt, the cooling mechanism cools the flaky materials on the conveying belt, and automatic production of extrusion, tabletting and smashing is achieved, and the production efficiency and the production reliability can be guaranteed.

Owner:ANHUI SUNROAD ENVIRONMENT PROTECTIVE NEW MATERIALS

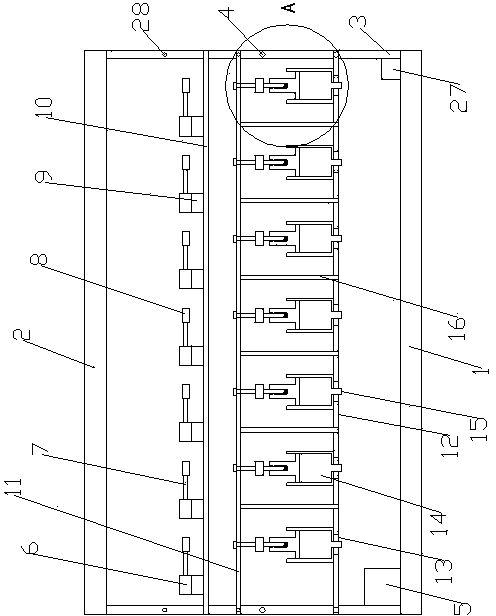

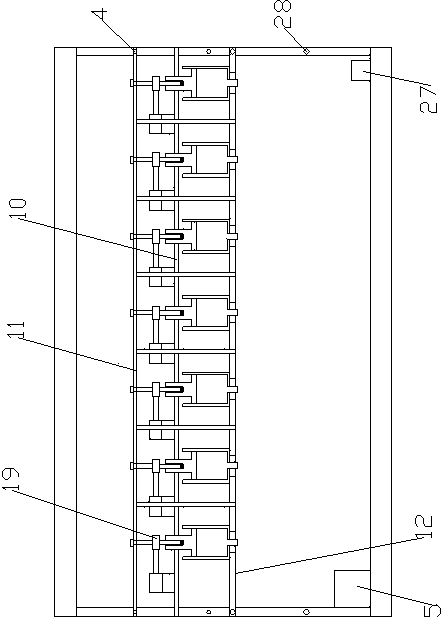

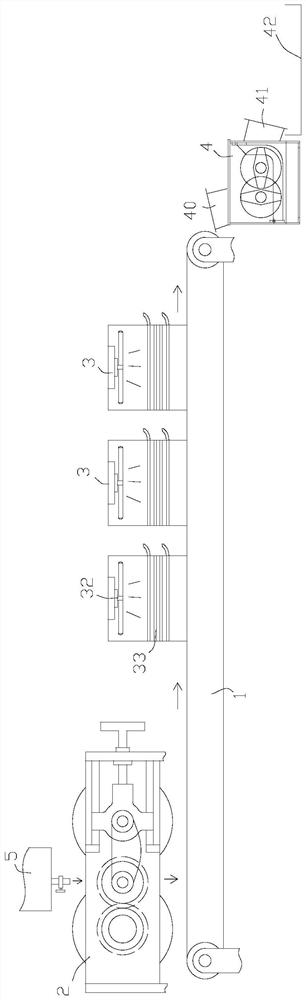

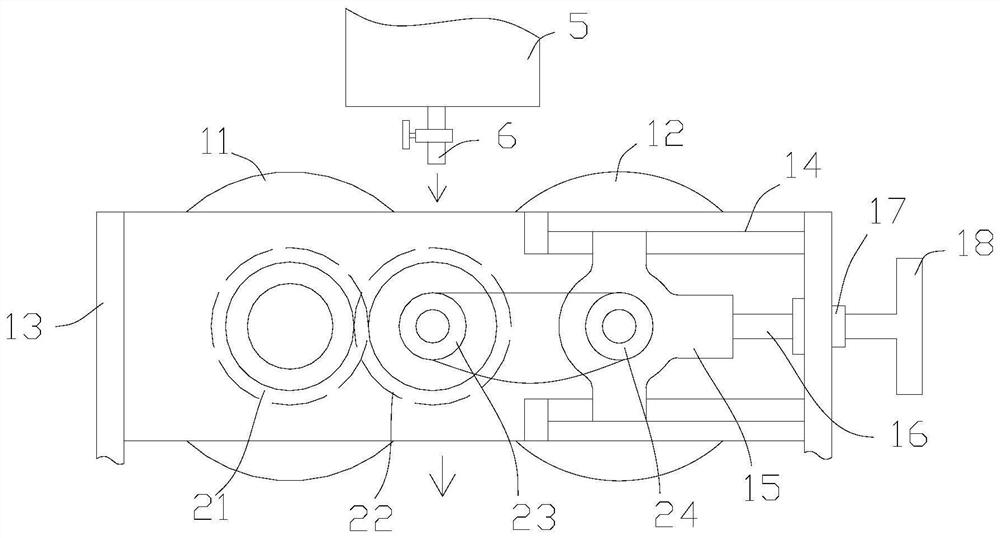

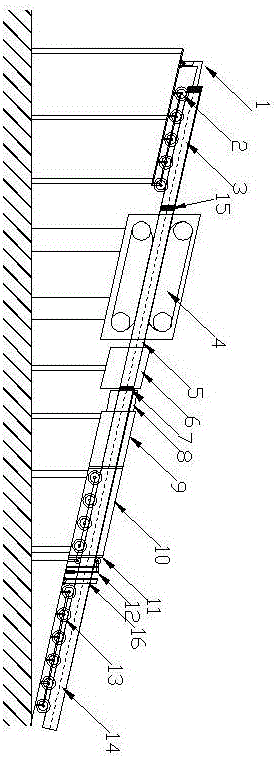

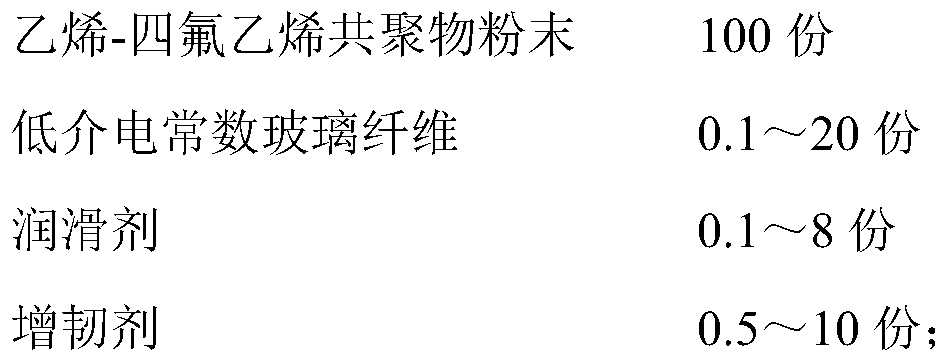

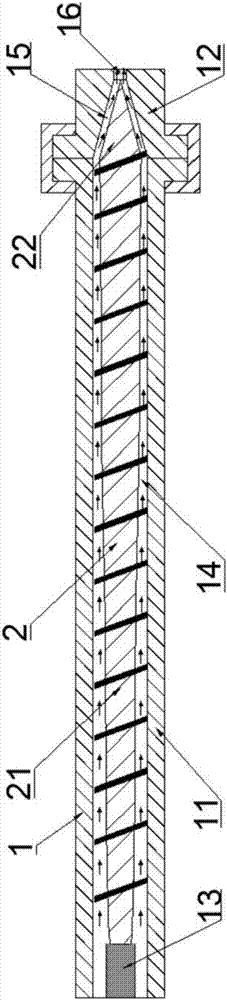

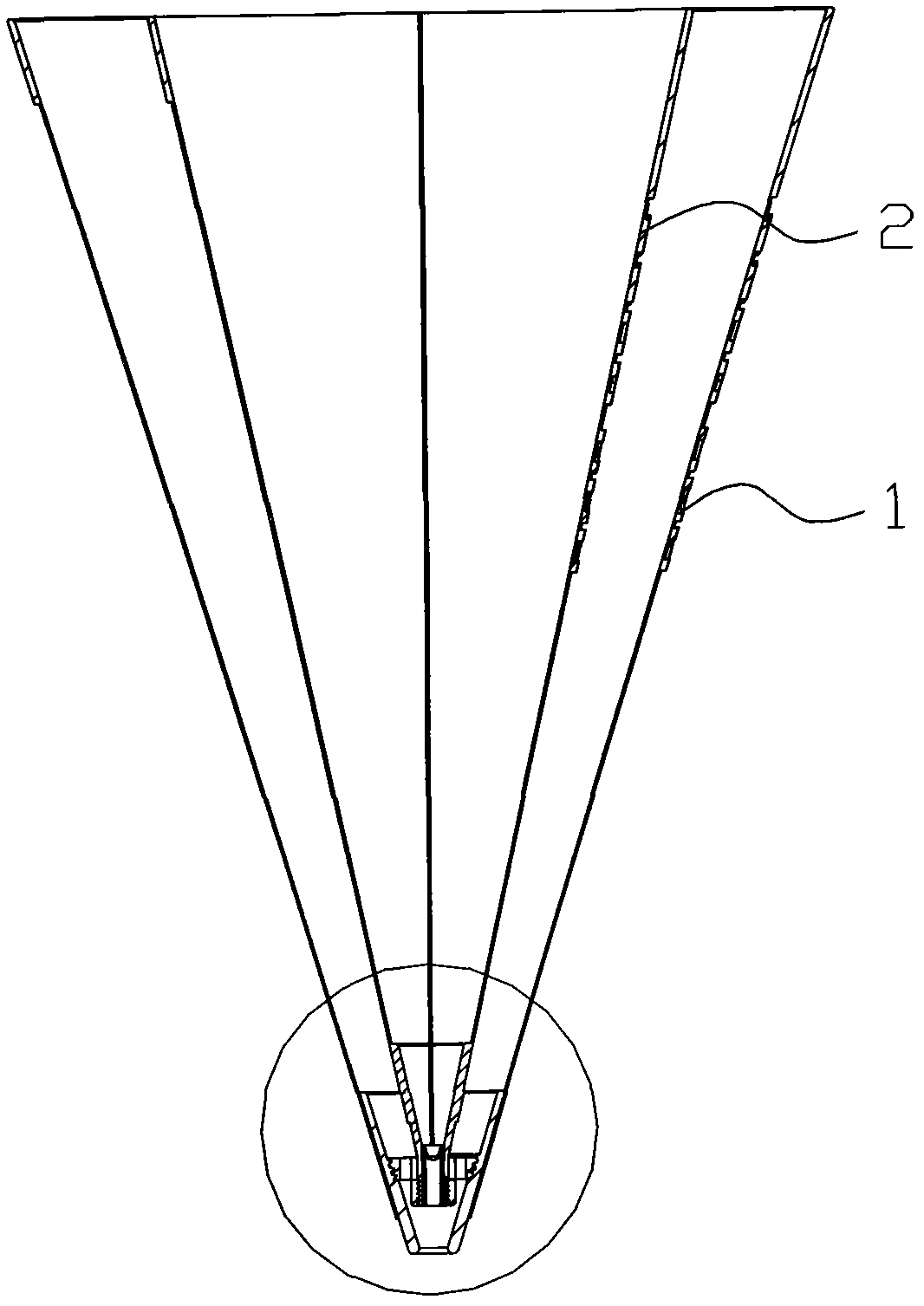

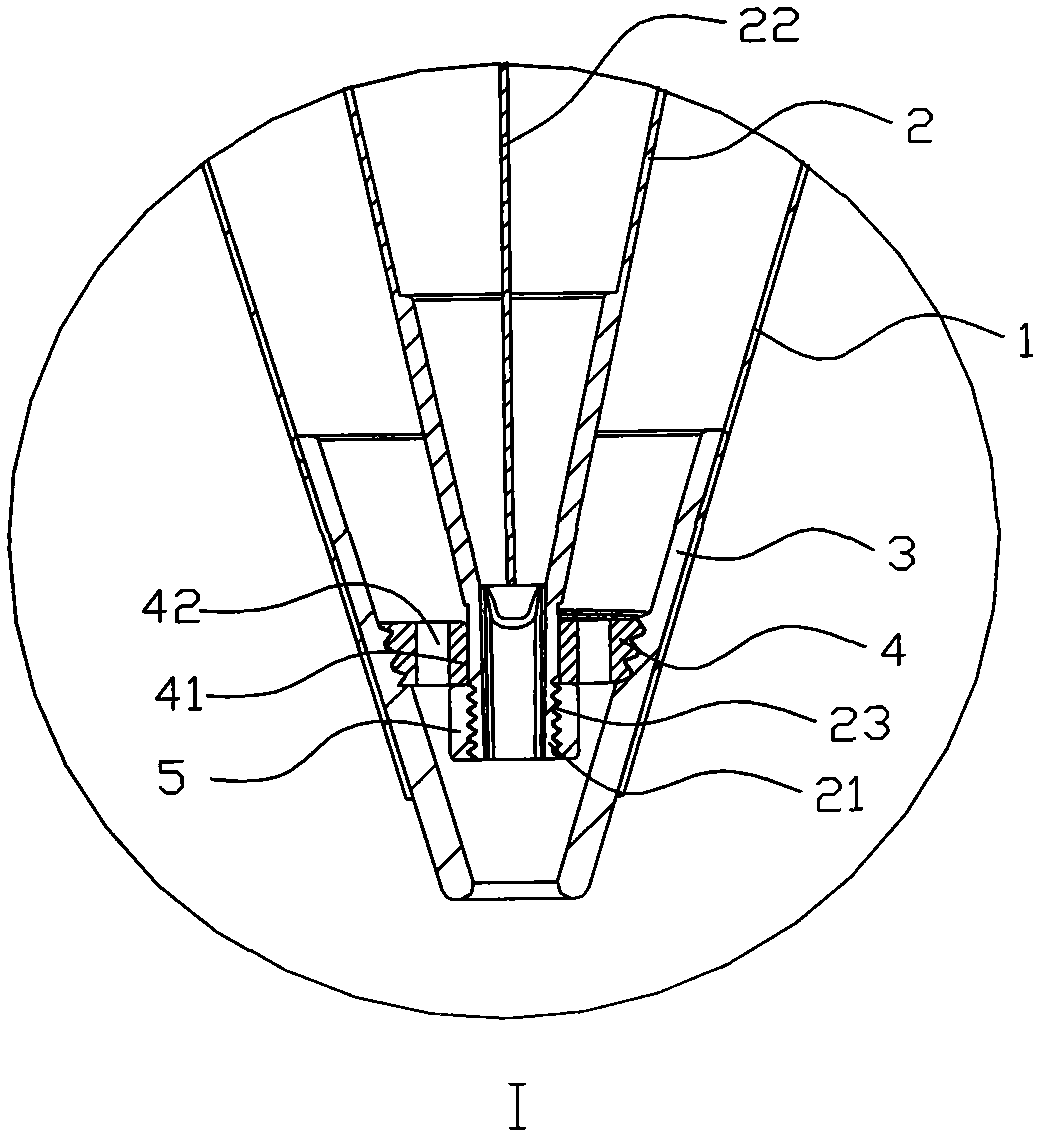

Insulation pipe type busbar three-layer coextrusion continuous vulcanization production equipment and production process

InactiveCN106003648AExtrusion continuousExtrusion realizationInsulating conductors/cablesProduction lineVulcanization

The invention discloses insulation pipe type busbar three-layer coextrusion continuous vulcanization production equipment and a production process. The equipment comprises a conductor pipe connecting auxiliary pushing car, a conductor pipe connecting platform, conductor pipe connecting pins, an air-pressure track pusher, a three-layer coextrusion machine head, an upper closer, a vulcanization pipe, a cooler, a lower closer, an air-pressure pressing device, an insulation stripping cutter and a stripping cutting platform positioned on the same inclined surface from high to low in sequence. The production process comprises the following steps: single conductor pipes are connected continuously by the connecting pins to satisfy the continuous extrusion and continuous vulcanization technical requirements; a production line is aslant arranged to eliminate the gravity dropping influence of the conductor pipes for free insulation vulcanization; the pressing device is used for eliminating aslant downward sliding force of the conductor pipes and improving the extrusion stability; and the scheme satisfies the continuous extrusion and continuous vulcanization production requirements of high-voltage-grade insulation pipe type busbars.

Owner:周龙刚

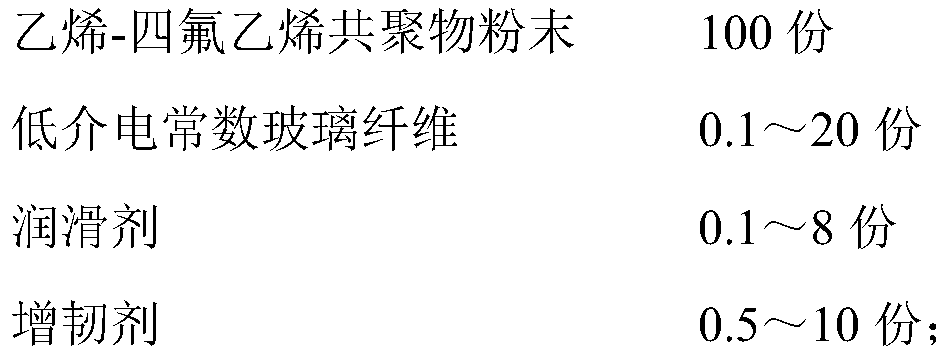

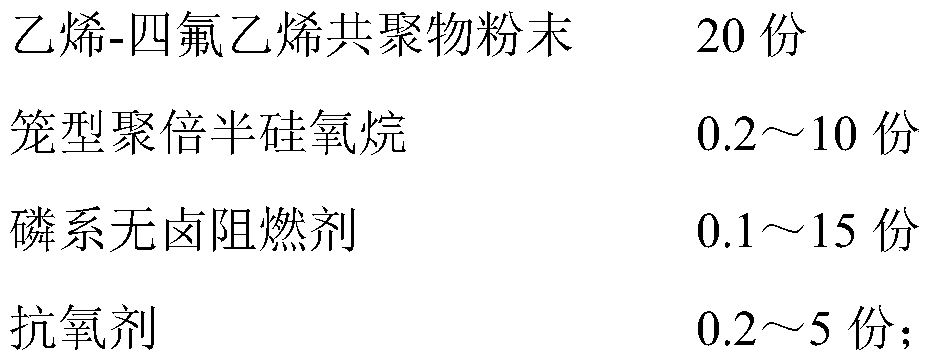

Outer coating cable material for high-frequency and high-speed communication cables and preparation method of cable material

InactiveCN110760121ALow dielectric constantImprove mechanical propertiesPlastic/resin/waxes insulatorsChemical industryAntioxidantEngineering

The invention belongs to the technical field of high polymer materials, and specifically relates to an outer coating cable material for high-frequency and high-speed communication cables and a preparation method of the cable material. The outer coating cable material comprises the following raw materials in parts by weight: a component A: 100 parts of ethylene-tetrafluoroethylene copolymer powder,0.1 to 20 parts of low-dielectric-constant glass fiber, 0.1 to 8 parts of a lubricant and 0.5 to 10 parts of a toughening agent; a component B: 20 parts of ethylene-tetrafluoroethylene copolymer powder, 0.2 to 10 parts of cage polysilsesquioxane, 0.1 to 15 parts of a phosphorus halogen-free flame retardant and 0.2 to 5 parts of an antioxidant; and a component C: 0.1 to 3 parts of an ultraviolet absorbent. By using the ethylene-tetrafluoroethylene copolymer with a low dielectric constant to be blended with a dielectric additive, so that the outer coating cable material has a low dielectric constant and good mechanical properties, and the preparation method provided by the invention is simple to operate, energy-saving and environment-friendly.

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

Fluoroplastic extrusion equipment

Fluoroplastic extrusion equipment comprises an extruder. A cavity is formed in the extruder. The cavity comprises a machine body cavity and a machine head cavity which are in communication. A first screw is arranged in the cavity and is opposite to an extrusion hole of the extruder. The first screw comprises a rod body and a head part which are connected in an end-to-end manner. The rod body and the head part are located in the machine body cavity and the machine head cavity correspondingly so as to form a dead-angle-free streamline channel. The machine head cavity of the extruder is in a conical shape, the head part of the first screw is also in a conical shape, and the angle of the taper angle of the head part of the first screw is matched with the angle of the taper angle of the machine head cavity. According to the fluoroplastic extrusion equipment, the head part of the first screw directly stretches into the machine head cavity, and accordingly the staying time of XETFE fusion bodies in the machine head cavity is prevented from being too long; and through the dead-angle-free streamline channel, the extrusion insulation quality of the XETFE material can be guaranteed.

Owner:ANHUI PACIFIC CABLE CO LTD

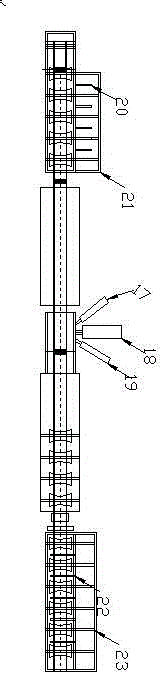

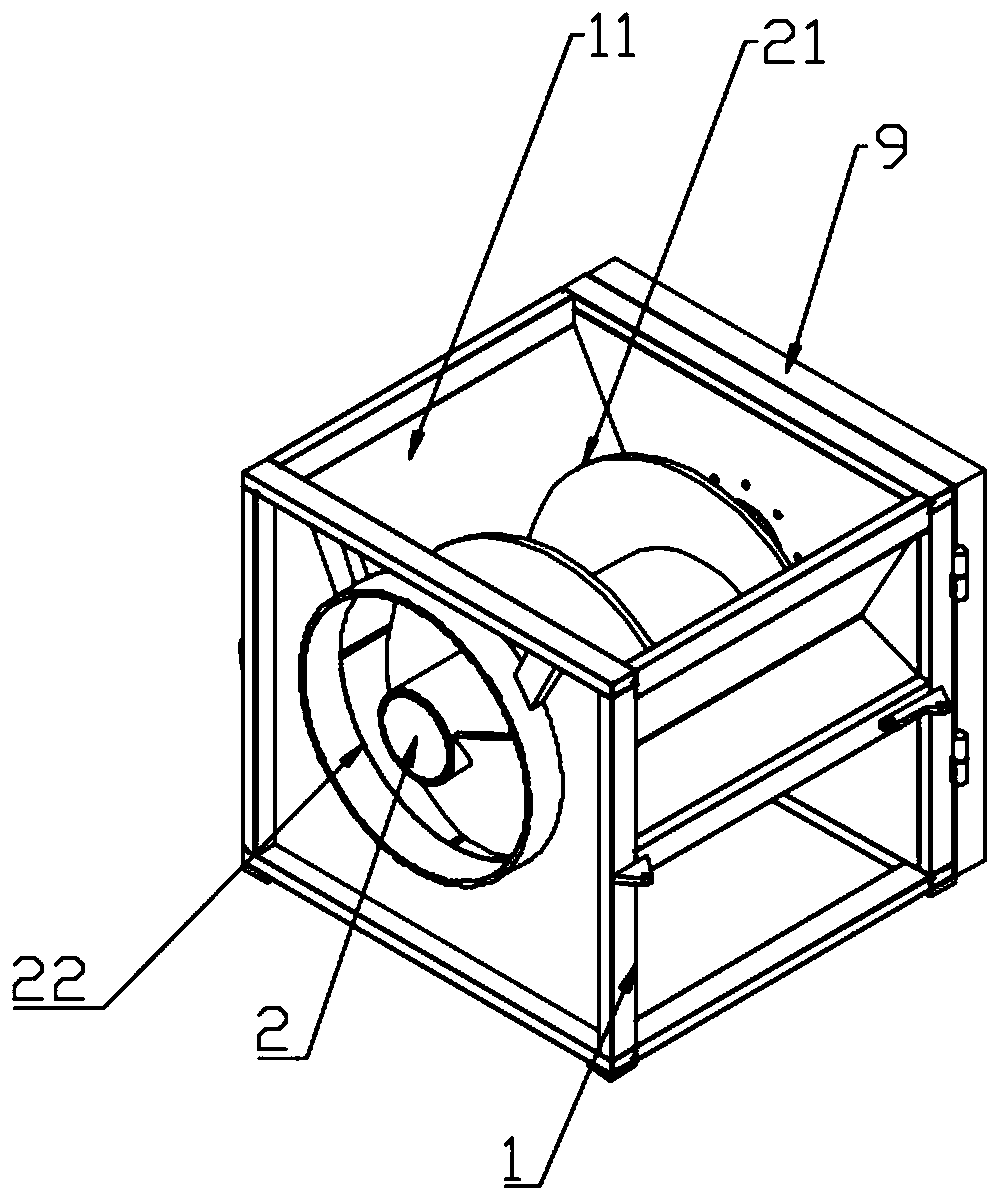

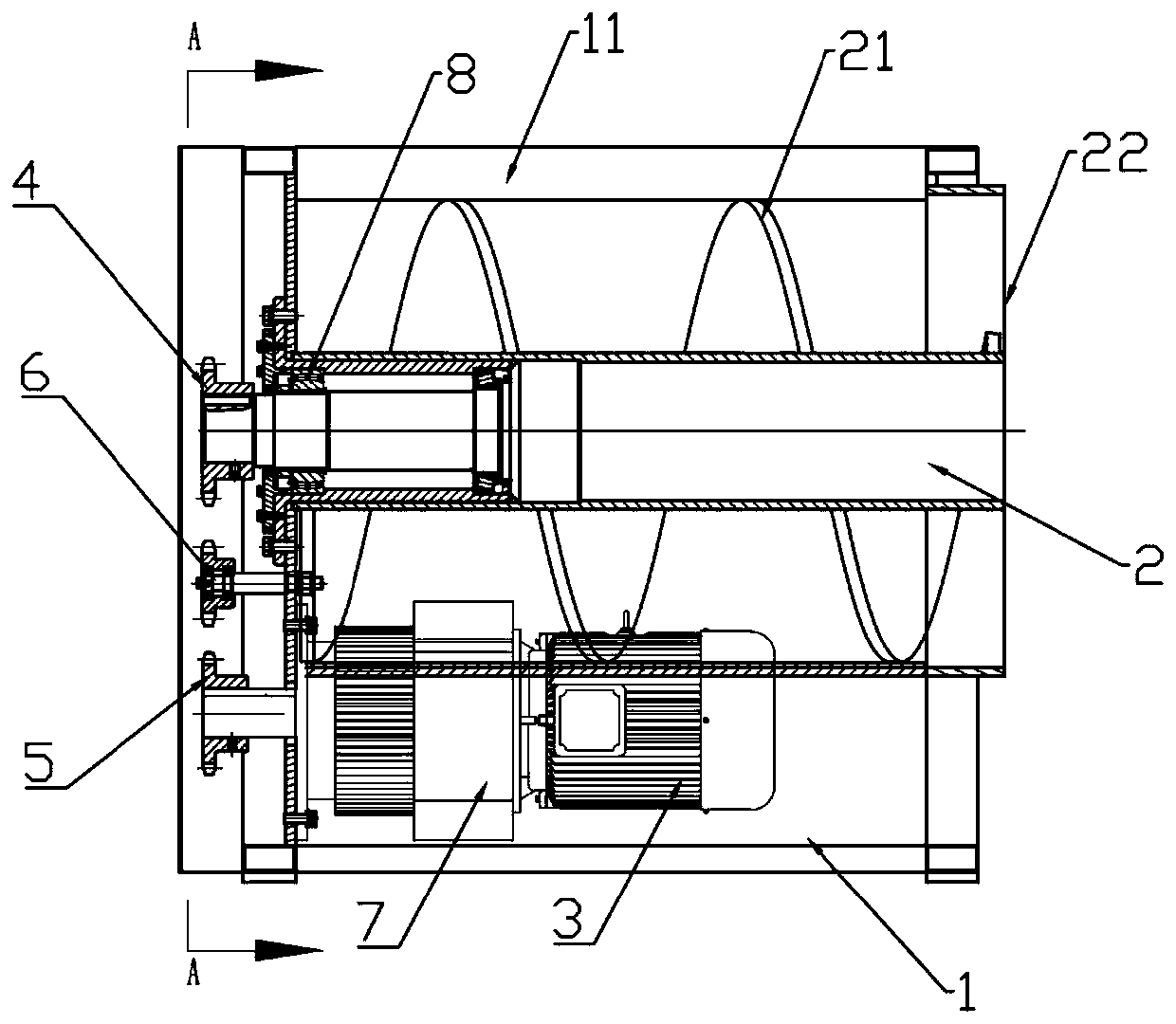

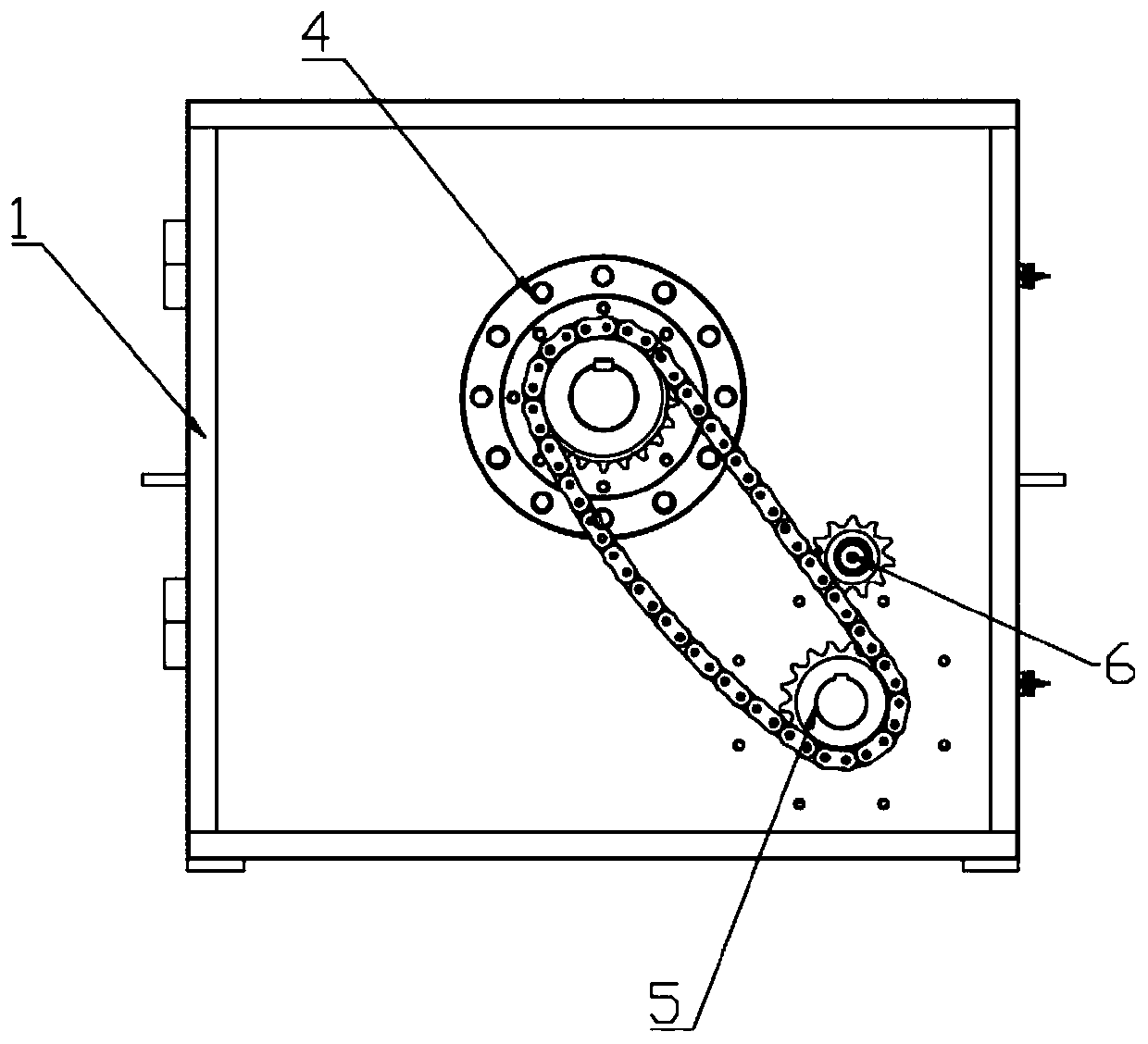

Screw extruder

PendingCN110215880ANo wavy jitterExtrusion realizationGranulation by material expressionSprocketEngineering

The invention discloses a screw extruder. The screw extruder comprises a machine body, an opening in the top of the machine body is a material inlet, the interior of the machine body is provided witha reamer shaft and a motor, and the material inlet is located above the reamer shaft; the reamer shaft is provided with a single-screw conveying reamer group, one end of the reamer shaft is a materialoutlet, the other end of the reamer shaft is provided with a first chain wheel, the rotating shaft of the motor is provided with a second chain wheel, and the first chain wheel is in drive connectionwith the second chain wheel through a chain; and the outer side of the chain is provided with a tension chain wheel, and the tension chain wheel is connected to the machine body. The screw extruder provided by the invention has the advantages of a simple structure, convenient operation and high production efficiency.

Owner:GUANGZHOU 3E MACHINERY

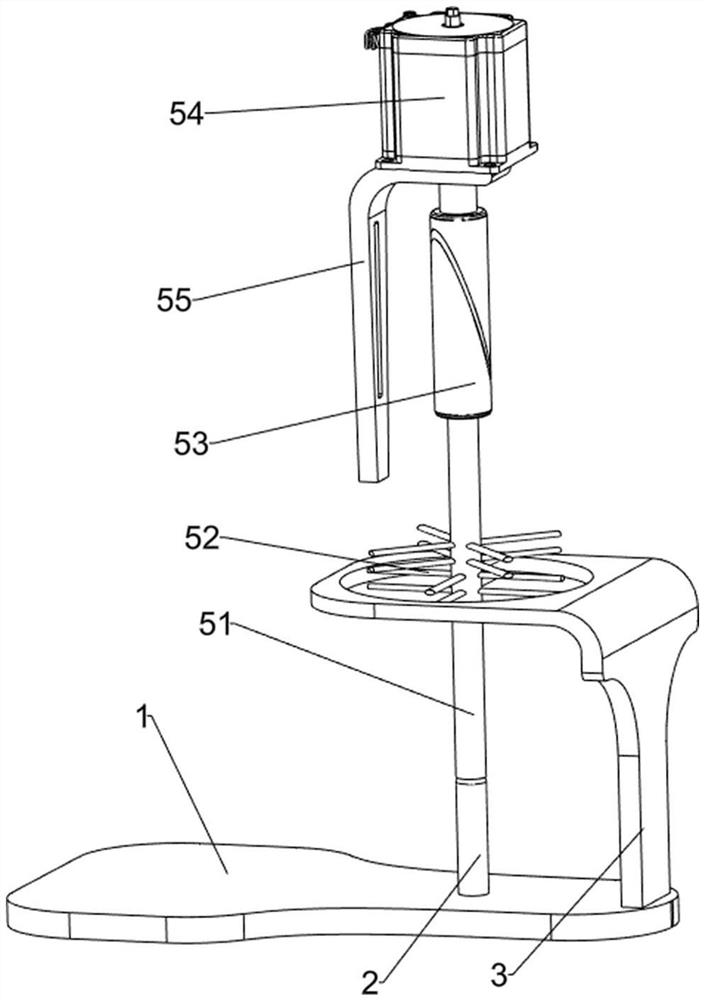

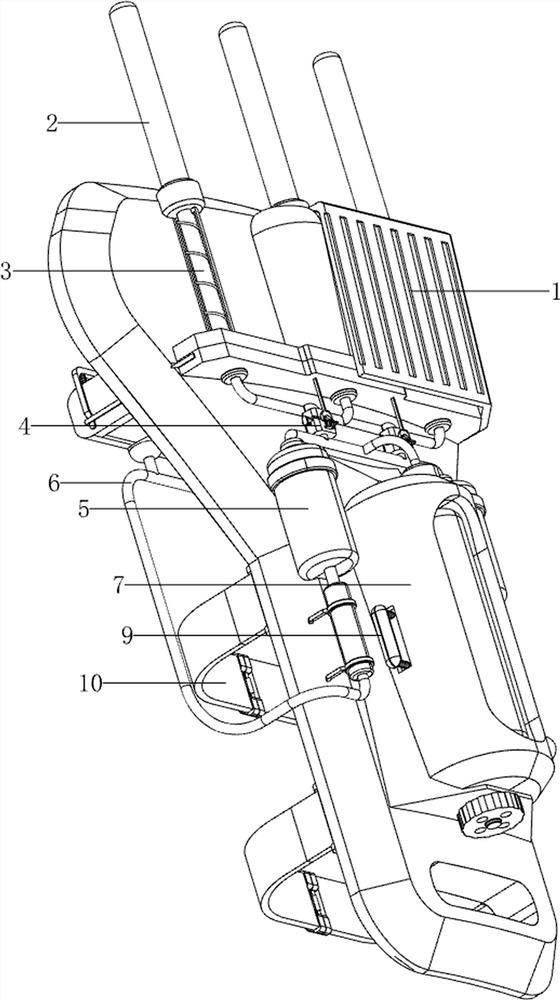

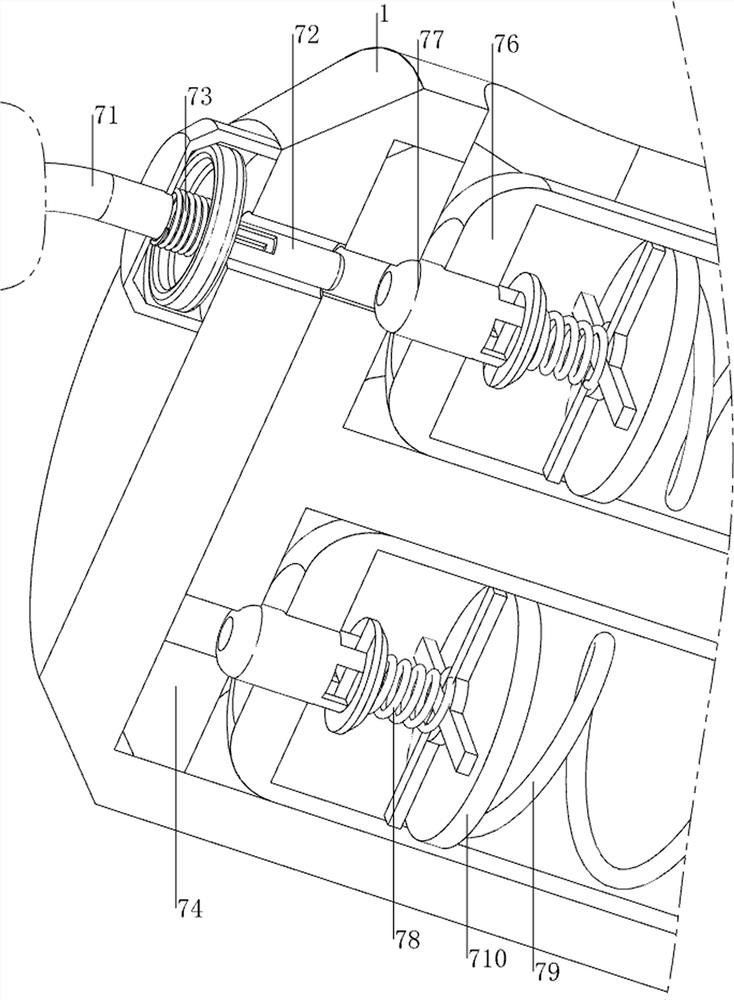

Sewage collection device for environmental science research

PendingCN113933106AEasy to controlRealize the effect of absorbing sewageWithdrawing sample devicesStream flowEngineering

The invention relates to a sewage collection device and particularly relates to a sewage collection device for environmental science research. The invention provides a sewage collection device for environmental science research, which is convenient to carry and can automatically control the sewage collection amount. The sewage collection device for environmental science research comprises a shell, an extension mechanism, a flow control mechanism and a suction mechanism, wherein three suction pipes are arranged on the shell in a sliding mode; the extension mechanism is arranged on the shell; the flow control mechanism is arranged on the shell; and the suction mechanism is arranged in the middle of the shell. After a sliding block moves backwards to be separated from a flow baffle, a third spring is reset, so the flow baffle is driven to move backwards to the outer side, a valve block channel is opened by the flow baffle, the flow baffle controls the flow of sewage, and the effect that the flow baffle controls the flow of the sewage is achieved.

Owner:袁文琪

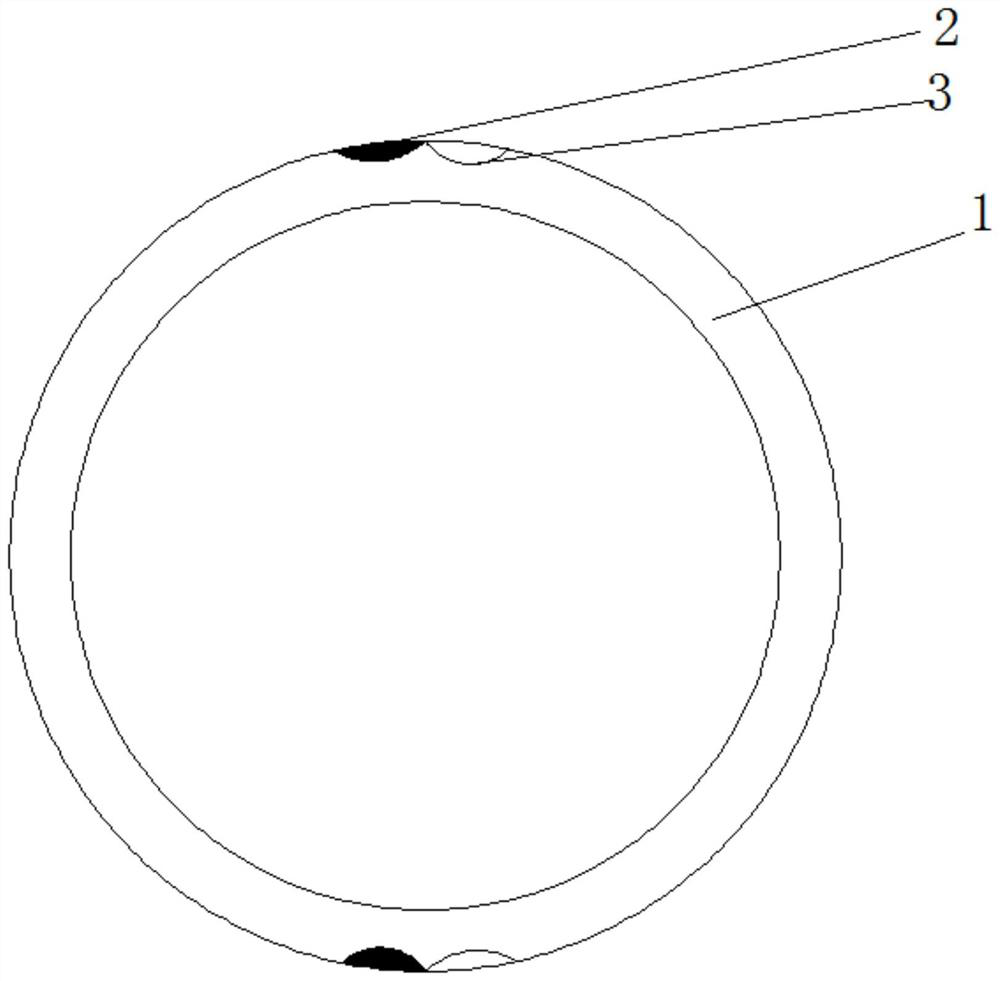

Double-colored strip sheath and its extrusion die

ActiveCN112192823BWell formedImprove visibilityFibre mechanical structuresStructural engineeringMechanical engineering

The invention discloses a double-different-color strip sheath and an extrusion die thereof. The double-different-color strip sheath includes a sheath body, and two pairs of double-different-color strips arranged in parallel are embedded on the outer side of the sheath body. Symmetrically arranged; the extrusion die includes a mold core, a color stripe diverter cone, and a color stripe mold sleeve. The two color stripe flow channels, the flow channel inlets of the first color stripe flow channel and the second color stripe flow channel are respectively connected with the diversion outlets of the two color stripe flow channels, and the first color stripe flow channel and the second color stripe flow channel are separated from each other by The bifurcation at the entrance of the mold sleeve extends to both sides of the color stripe mold sleeve. The first color stripe flow channel and the second color stripe flow are both provided with two flow channel outlets, and the flow channel outlets are symmetrically arranged on both sides of the color stripe mold sleeve. . The present invention proposes a color stripe form different from conventional single color stripes and multiple color stripes, improves recognition, and proposes a special mold for producing the color stripe form.

Owner:JIANGSU HENGTONG PHOTOELECTRIC

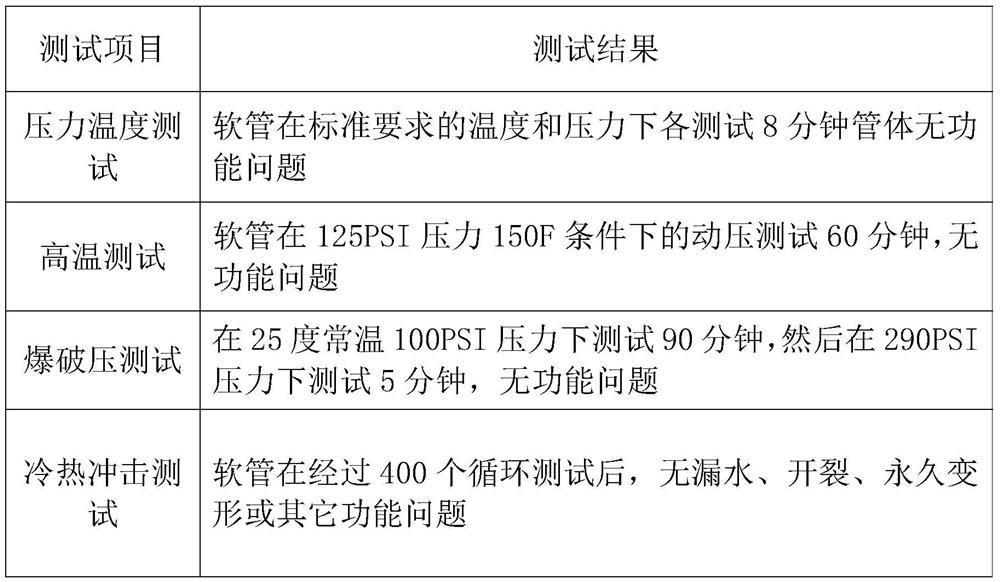

Food-grade hose and preparation method thereof

The invention relates to a food-grade hose which comprises a hose body; the hose body is prepared from a plastic composite material, and the plastic composite material is composed of the following components in parts by mass: 24-30 parts of resin powder, 9.58-13.5 parts of a plasticizer DOTP, 2.24-3.58 parts of calcium carbonate, 0.191-0.287 part of processing aid, 0.31-0.43 part of a stabilizer,0.04-0.07 part of toner and 0.34-0.57 part of an antibacterial agent. The food-grade hose has the advantages that the hardness and toughness of the whole material are adjusted by the plasticizer DOTP,and the hardness and toughness of the whole plastic composite material are improved, so that the prepared pipe body has high stability, durability and corrosion resistance, is less influenced by environmental temperature change, can effectively prevent harmful substances in the pipe body from being separated out in the use process, so as to reduce the harm to human body caused in the process of use and meet the requirements of environmental protection. In addition, the invention further discloses a preparation method of the food-grade hose, wherein the preparation method is used for preparingthe food-grade hose.

Owner:ZHEJIANG KAIYUE PLASTIC IND CO LTD

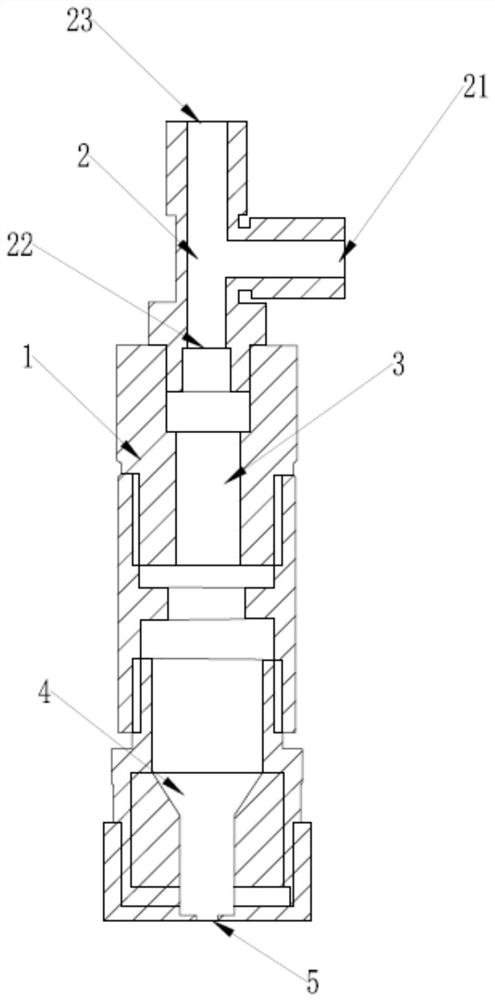

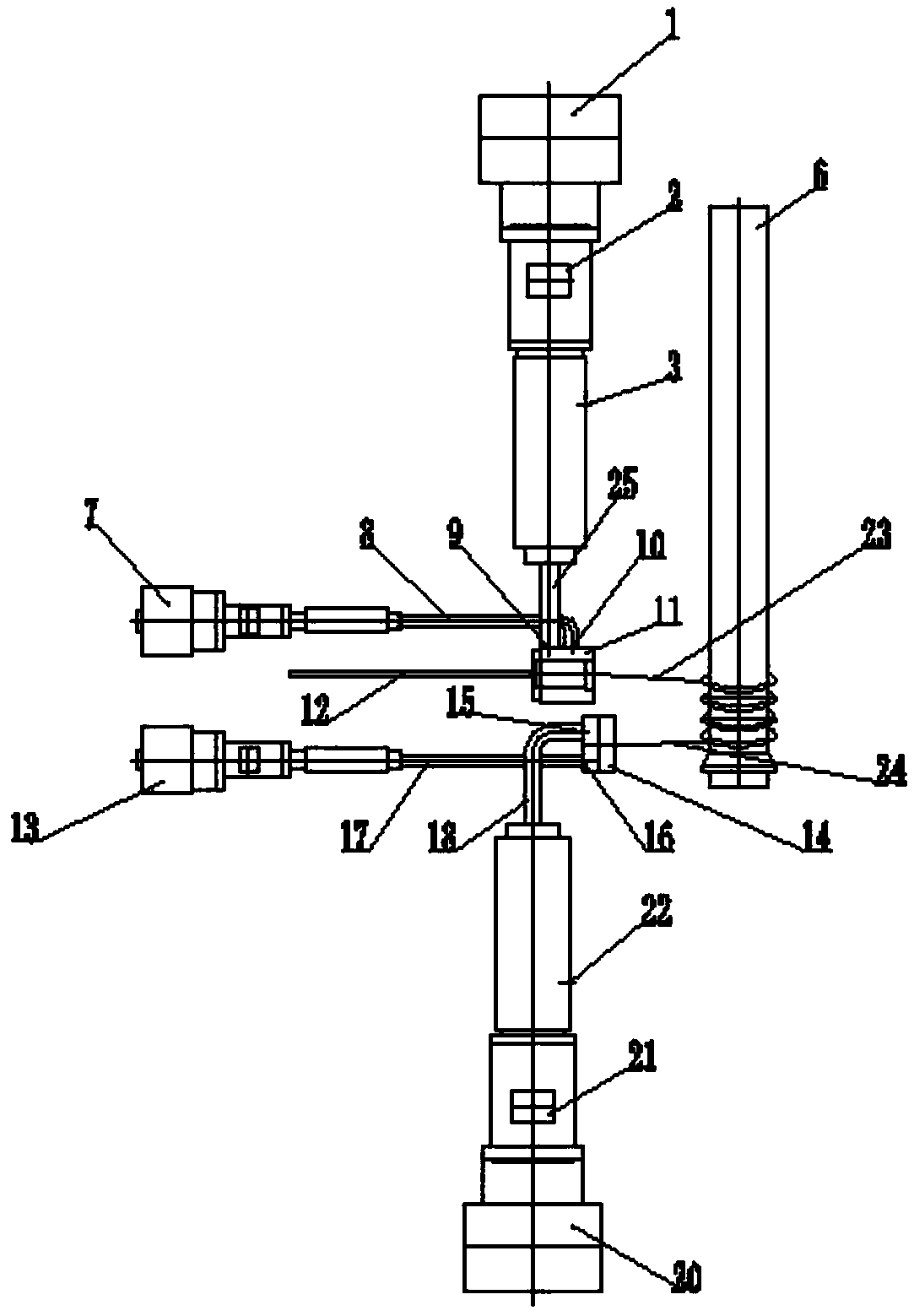

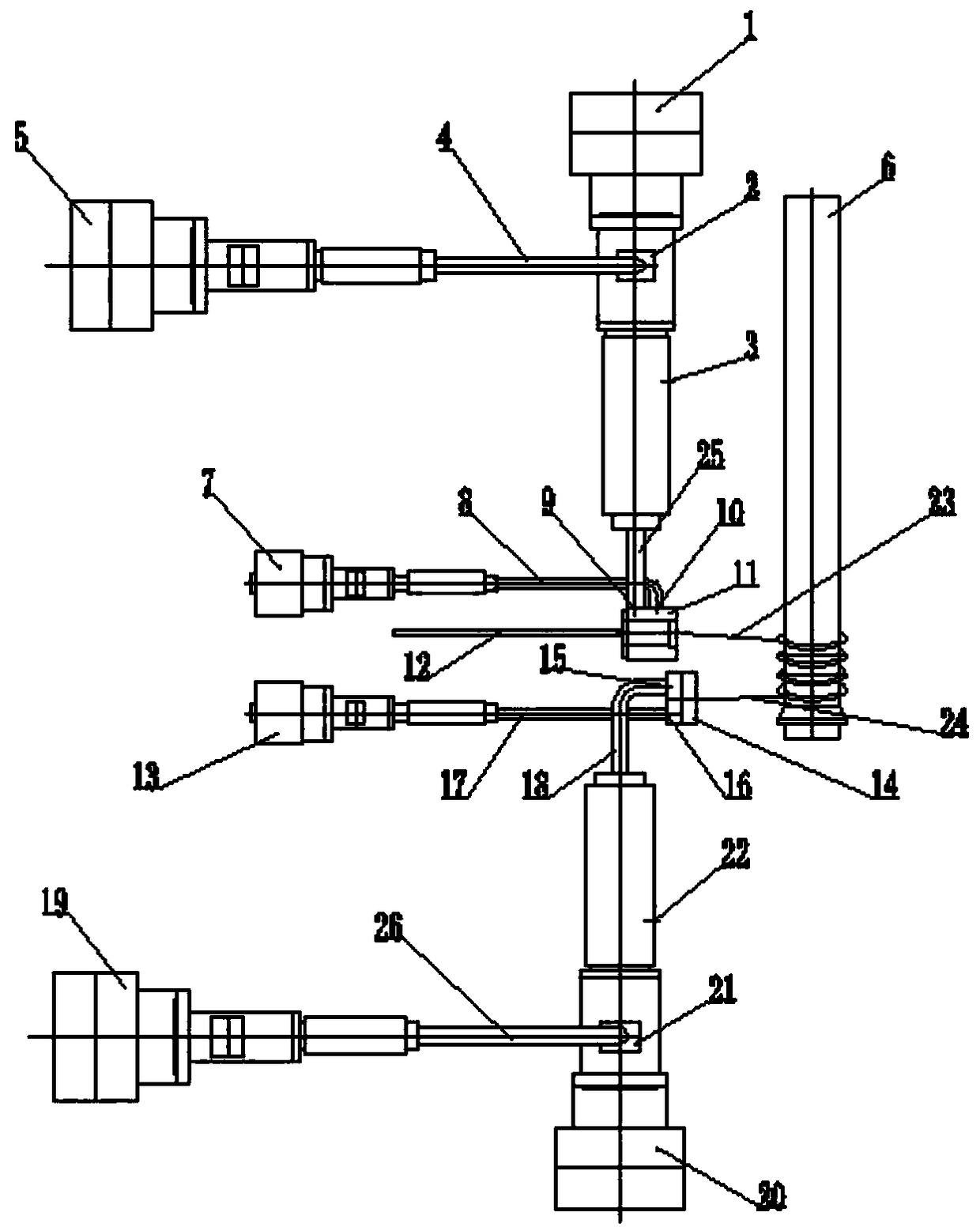

A Pneumatic Single Droplet Generator

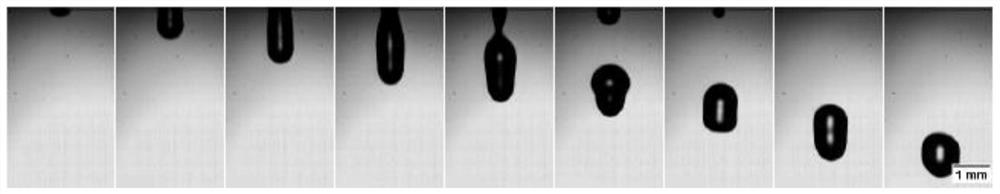

The invention discloses a pneumatic single droplet generator, belonging to the technical field of fluid mechanics, comprising a generator body, a joint, a connecting piece and a liquid chamber; the joint includes a gas inlet, a communication port and a gas outlet; the connecting piece The lower end is connected to the liquid chamber, and the bottom of the liquid chamber is provided with a pinhole; the pulse gas is passed into the gas inlet, and the pulse gas enters the liquid chamber along the connector through the connecting piece, and the liquid in the liquid chamber is impacted by the pulse gas After being extruded from the pinhole, the pulse gas is discharged from the gas outlet to generate a negative pressure in the liquid cavity, and then the liquid is sucked back into the liquid cavity to realize the extrusion of a single droplet. In the present invention, the liquid is extruded from the pinhole under the impact by feeding the pulse gas, and at the same time, the pulse gas is discharged to generate a negative pressure in the liquid container, and the liquid is sucked back into the liquid cavity to realize the extrusion of a single droplet; and through The electromagnetic valve is controlled to realize the reasonable adjustment of the pulse gas pressure and pulse gas action time in the generator.

Owner:HUAZHONG UNIV OF SCI & TECH

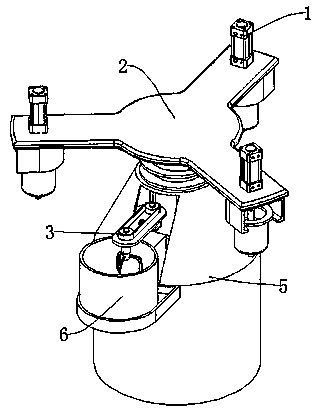

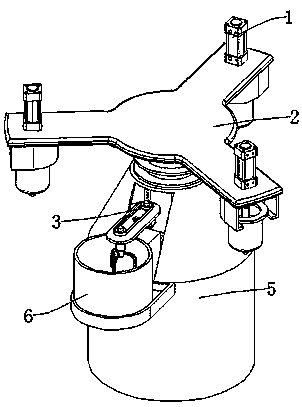

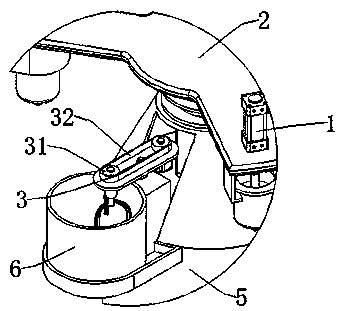

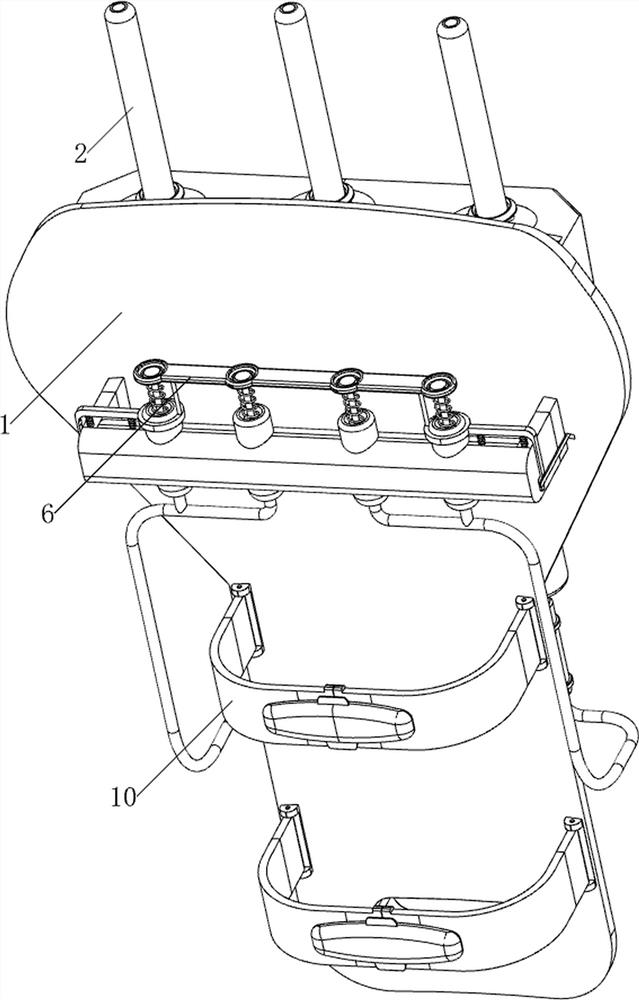

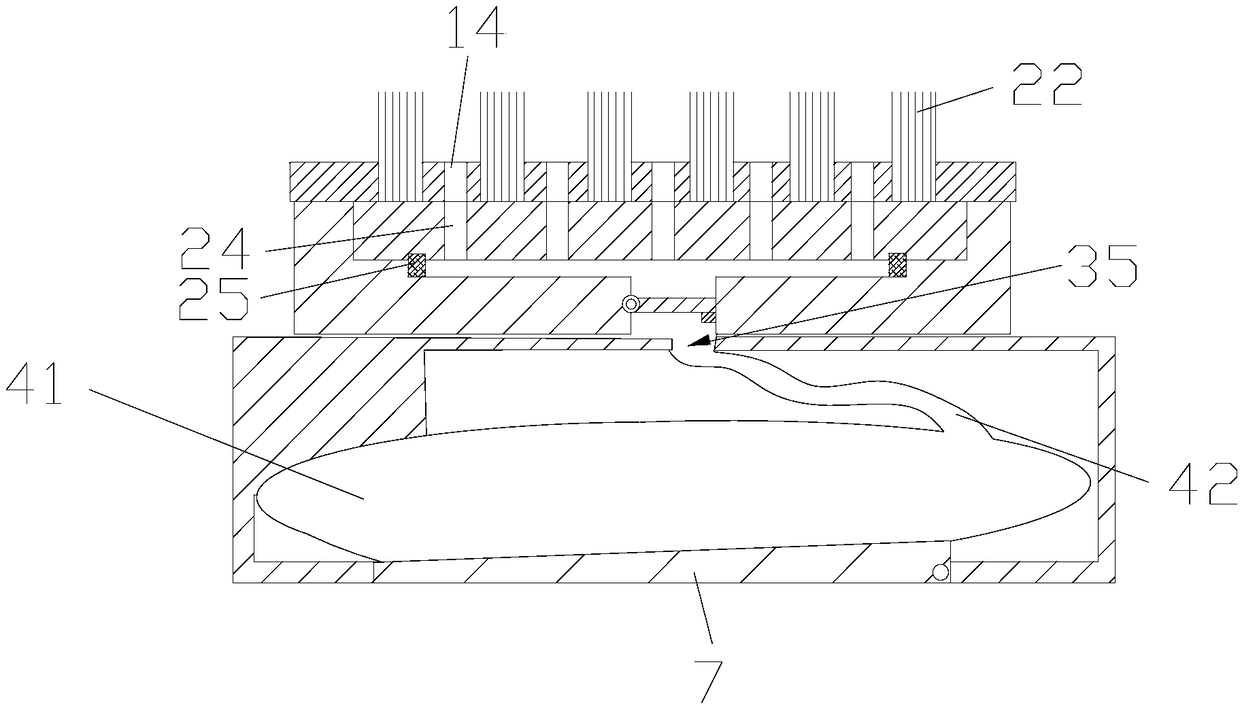

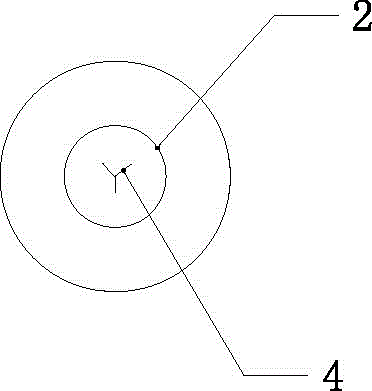

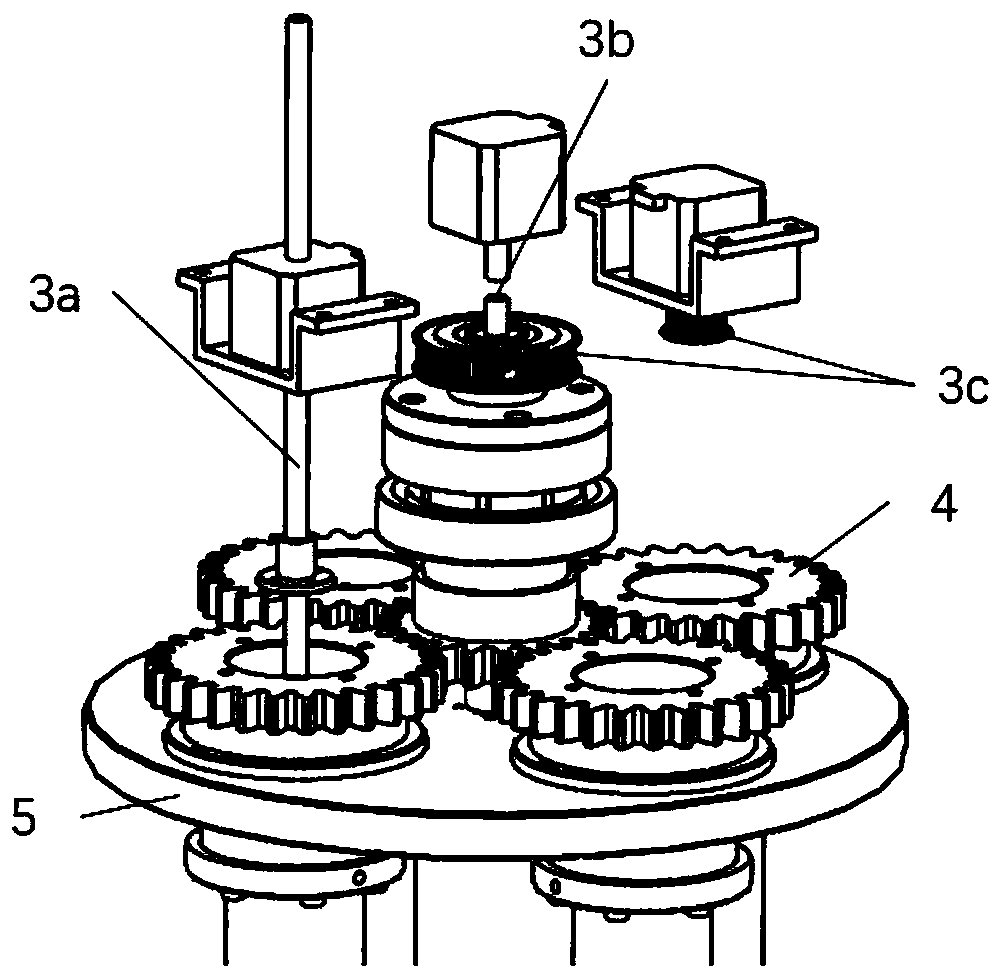

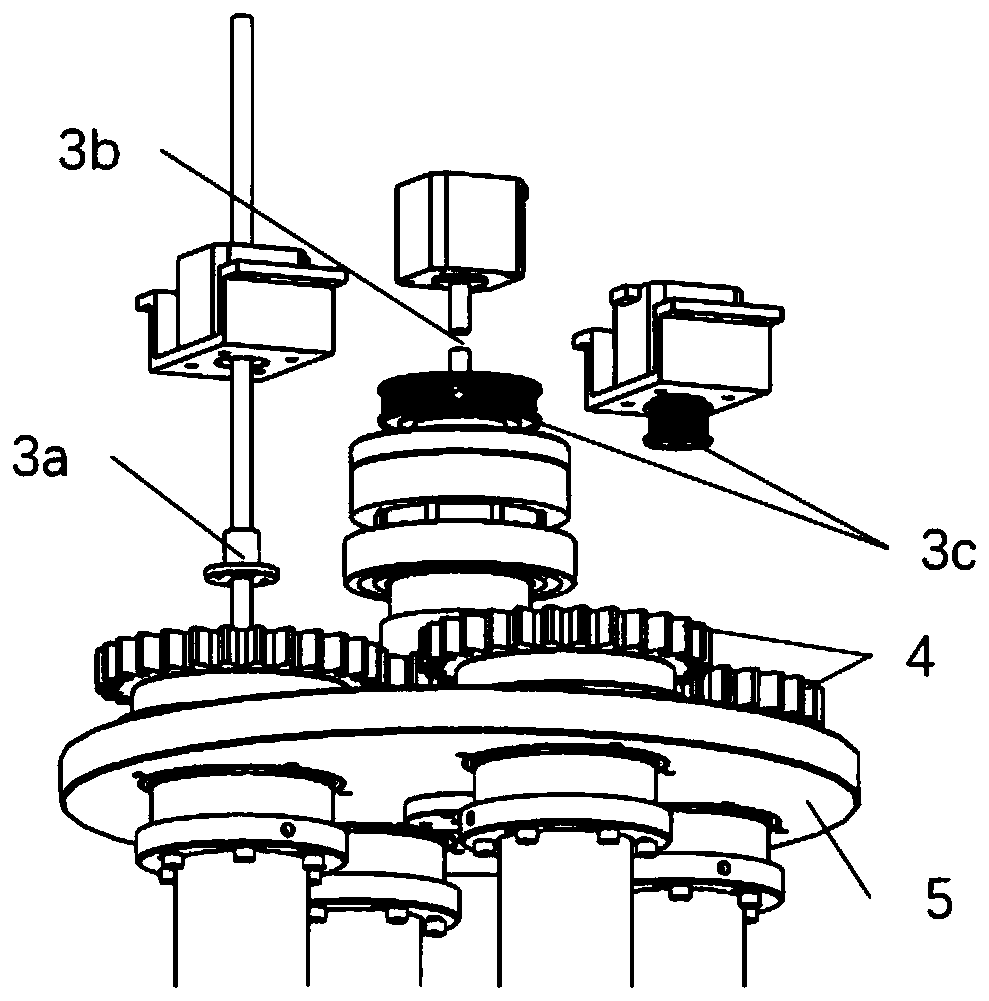

Multi-color automatic piping head

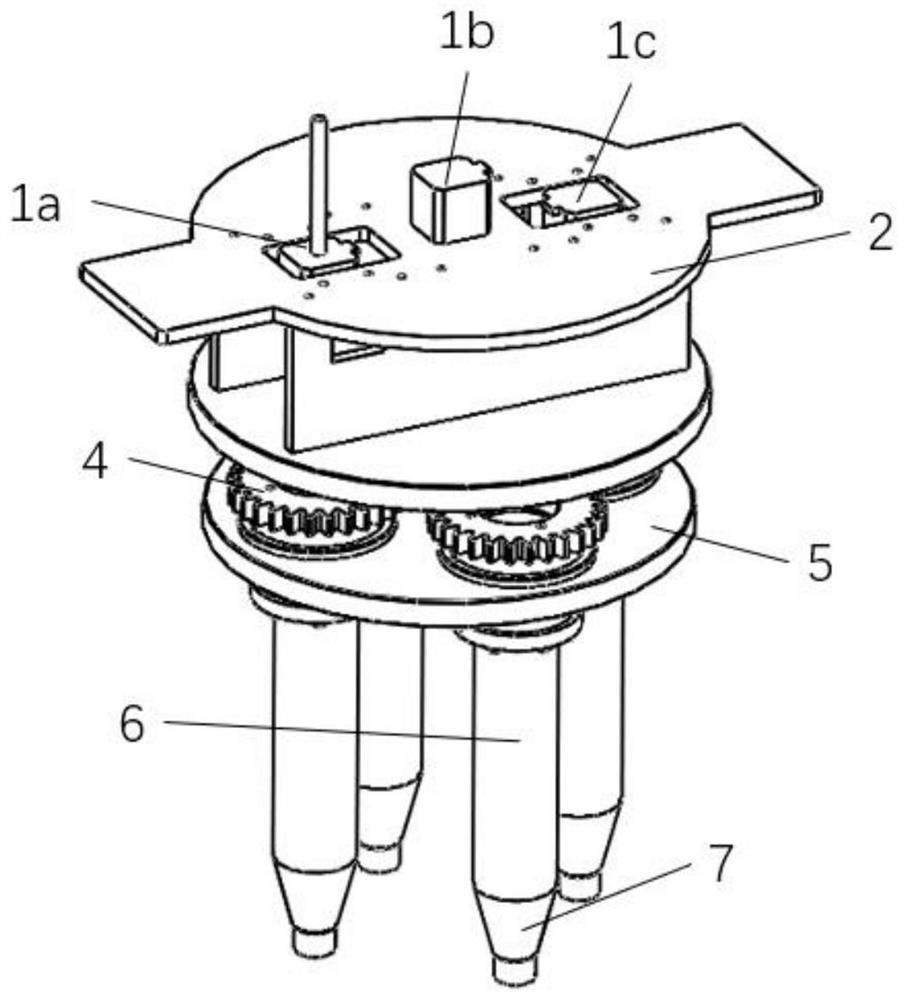

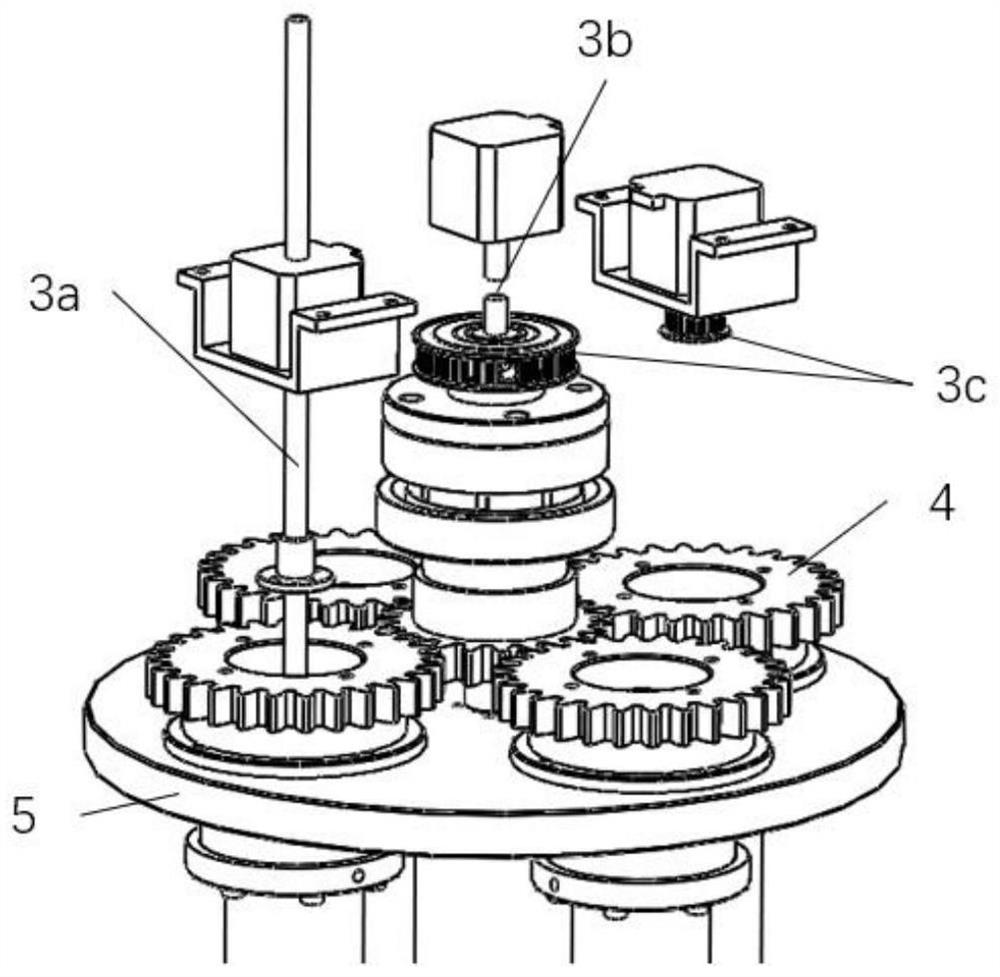

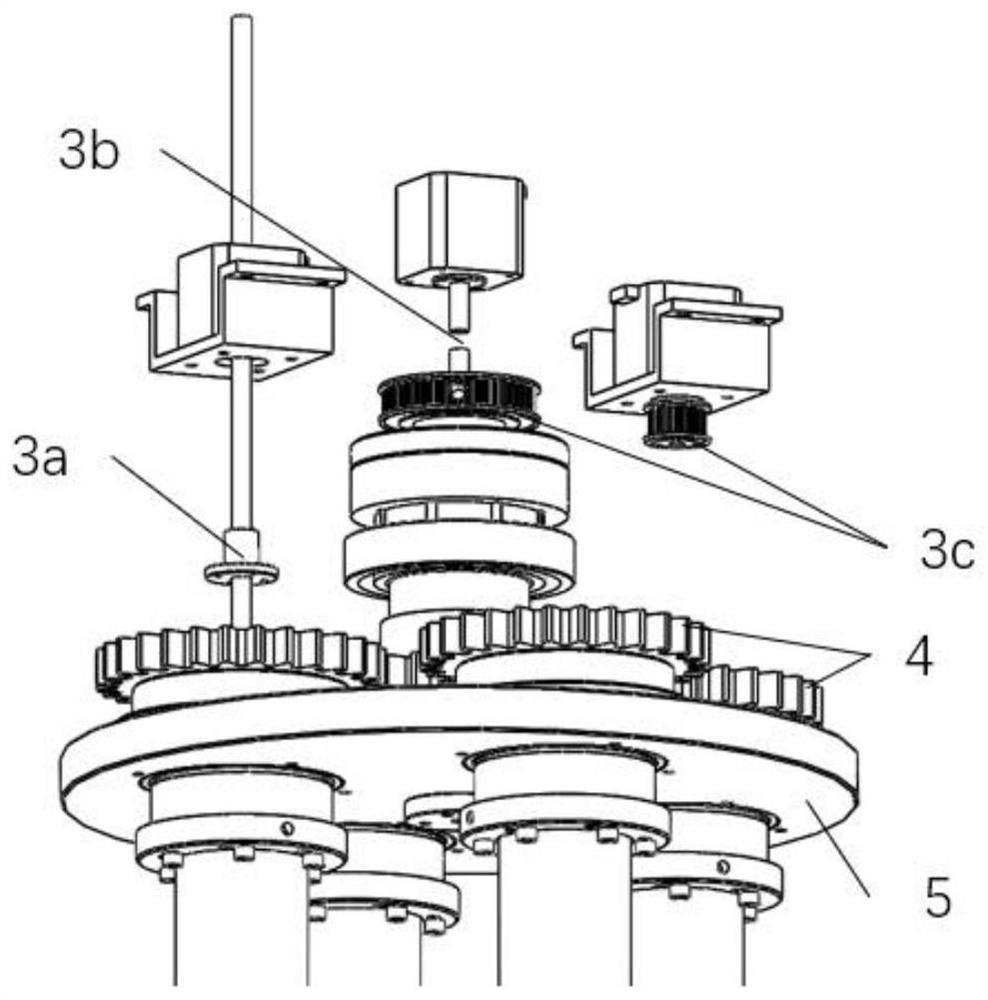

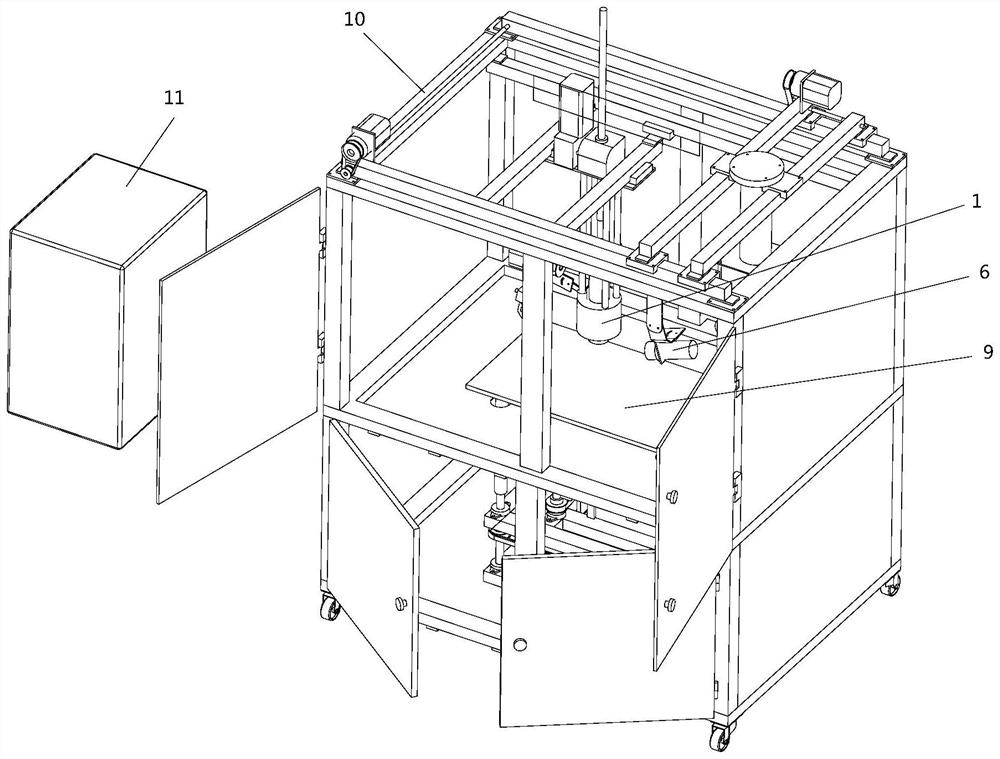

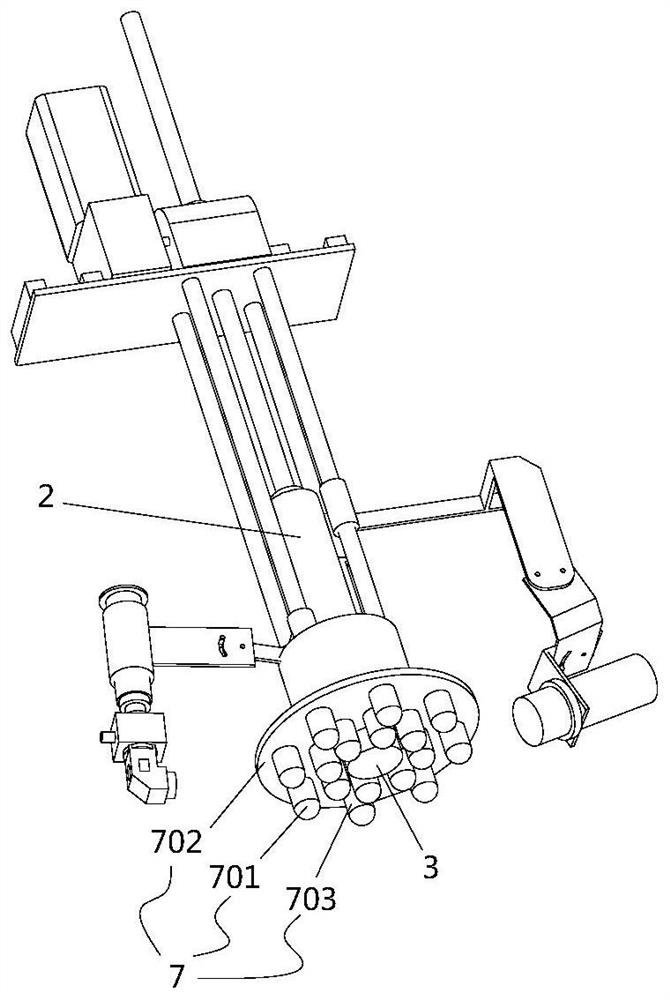

The invention relates to an automatic multi-color pattern mounting head based on motor control. The pattern mounting head comprises motors, a driving device, a standard mounting plate connected with automated equipment, a planet disc provided with a transmission mechanism, multiple material cylinders and pattern mounting nozzles, and the material cylinders and the pattern mounting nozzles are connected with the planet disc. The three motors are installed on the mounting plate, the motors separately control the planet disc through transmission mechanisms to drive the multiple material cylindersto conduct orbital revolution, the gear transmission mechanisms control rotation of the material cylinders, and a linear stepping motor drives a feeding shaft to control feeding of the material cylinders. The planet disc is provided with a center drive gear and multiple driven gear mechanisms, and each driven gear is connected with one set of material cylinders and pattern mounting nozzles; the multiple driven gears, material cylinders and pattern mounting nozzles form a multi-color material bin, and the material bin is rotated to or away from the lower end of the feeding shaft through orbital revolution. The material cylinders and the pattern mounting nozzles are connected through standard connection parts, and the number of the material cylinders and the colors of coatings placed in thematerial cylinders can be set by a user. According to the automatic multi-color pattern mounting head, the number and colors of the material cylinders can be self-defined, and the working efficiencyof pattern mounting is effectively improved.

Owner:BEIJING UNIV OF POSTS & TELECOMM

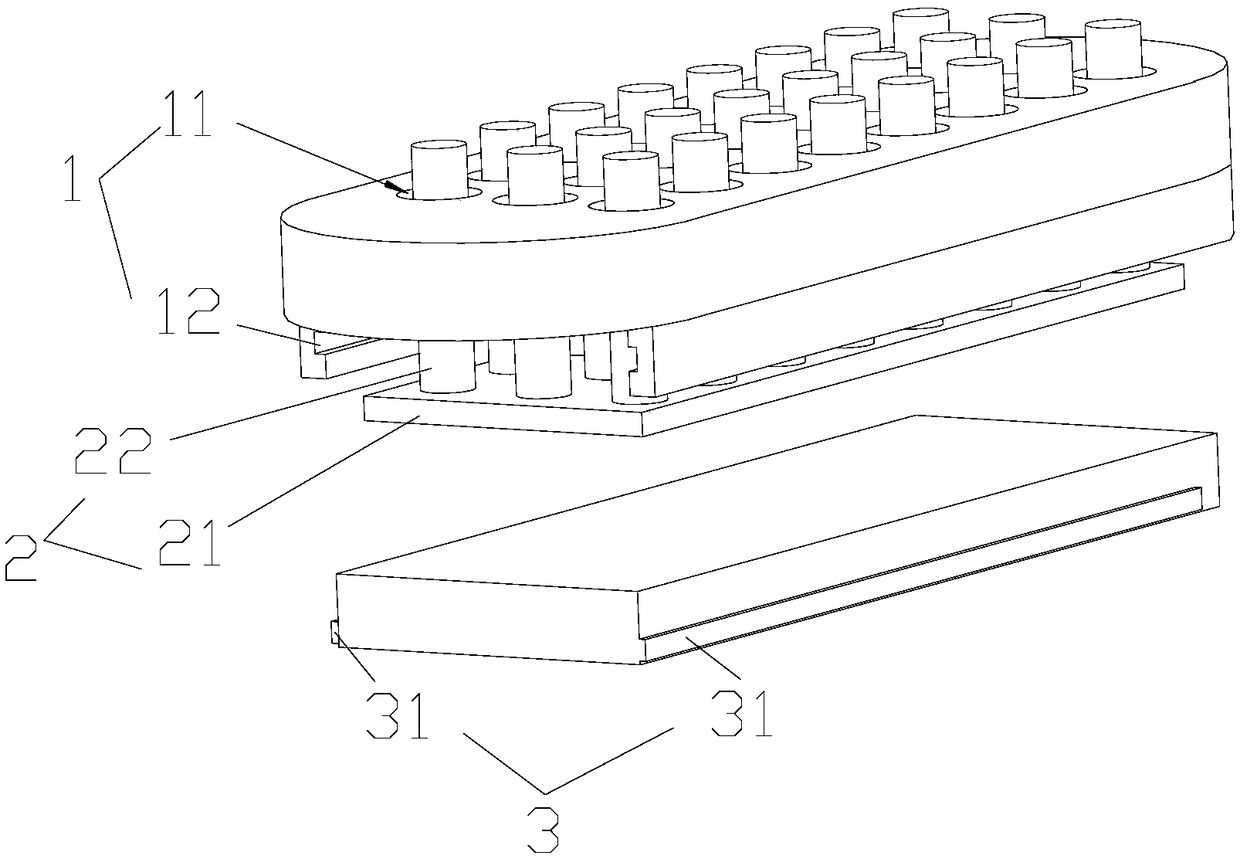

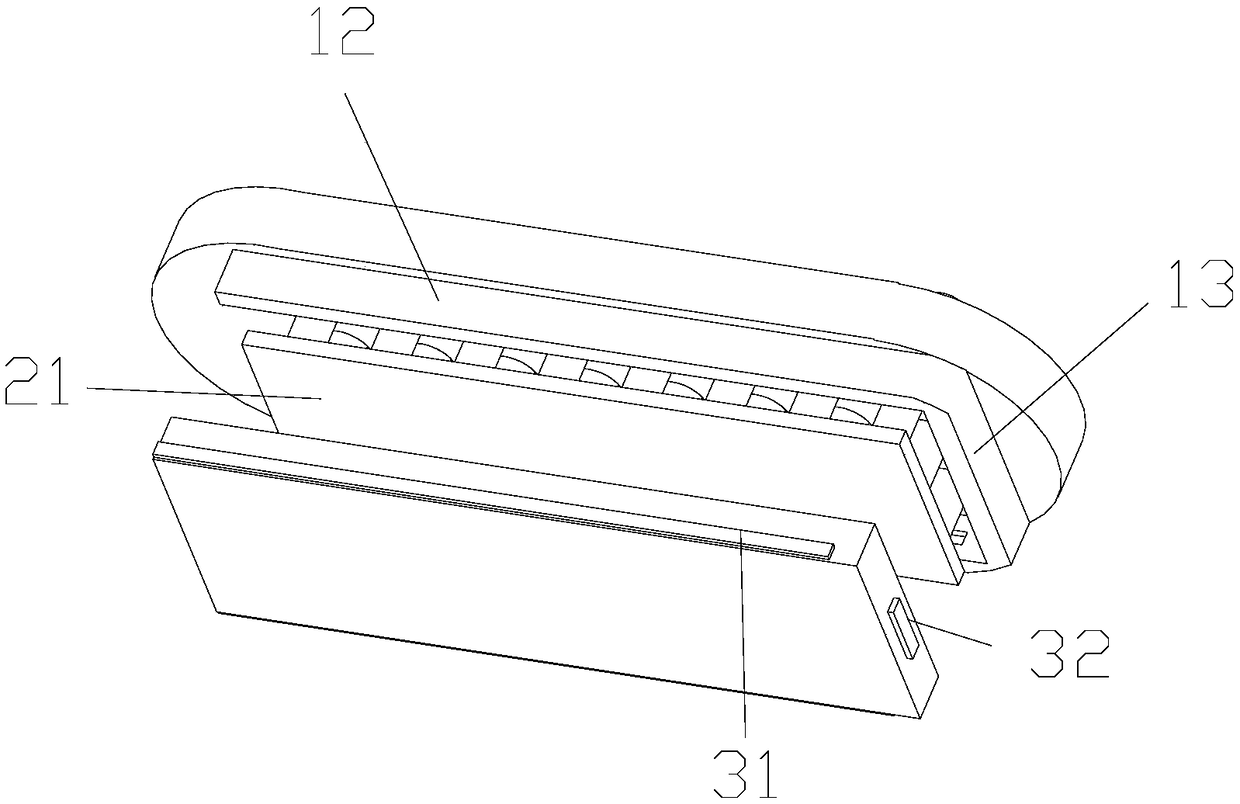

Dead-angle-free cleaning antibacterial toothbrush head, multifunctional antibacterial toothbrush head, nano toothbrush

The invention discloses a dead-angle-free cleaning antibacterial toothbrush head, which comprises a cover plate, a bristle body and a chassis. The cover plate is provided with a plurality of toothbrush wire through holes, and the bristle body comprises a support plate and toothbrush wires, and a plurality of bundles of the toothbrush wires are implanted on the support plate; the chassis can be interposed with the cover plate to sandwich the support plate between the chassis and the cover plate, and the toothbrush thread can be protruded from the toothbrush thread through hole. The invention also discloses a self-contained toothpaste type antibacterial toothbrush head, a multifunctional antibacterial toothbrush head and a nanometer toothbrush. The toothbrush head has the advantages that thetoothbrush head can be cleaned omni-directionally and without dead angles, and bacteria can be prevented from growing.

Owner:广东三椒口腔健康产业研究院有限公司 +1

Tomato sauce bottle beneficial to sauce taking

InactiveCN105380549AEasy to take outAchieve deformationKitchen equipmentBiomedical engineeringPlastic bottle

The invention discloses a tomato sauce bottle beneficial to sauce taking. The tomato sauce bottle comprises a plastic bottle body and a sealed cover. The opening of the plastic bottle body is detachably connected with the sealed cover. The sealed cover comprises a cover body. A through hole is formed in the upper end of the cover body. A sealed film is arranged at the through hole. A discharge seam is formed in the sealed film. An upper cover for sealing the through hole is arranged on the cover body. The plastic bottle body comprises a flexible plastic part and a hard flexible part. In order to solve the technical problem, the tomato sauce bottle which prevents sauce from being splashed and is beneficial to sauce taking is provided.

Owner:CHONGQING ZUIBASHI AGRI PROD

Production system for polyethylene glass fiber winding structured wall pipe products and production method

The invention relates to a production system for polyethylene glass fiber winding structured wall pipe products. The production system comprises a flaky inner wall layer strip extrusion unit and a tubular outer wall layer strip extrusion unit; the flaky inner wall layer strip extrusion unit comprises a first double-screw extruder, a first single-screw extruder and a flaky strip extruder head; thefirst double-screw extruder is provided with a main feed port and a side feed port; discharge ports of the first double-screw extruder and the first single-screw extruder are connected to a first runner port and a second runner port of the flaky strip extruder head through runners; the tubular outer wall layer strip extrusion unit comprises a second double-screw extruder, a second single-screw extruder and a tubular strip extruder head; the second double-screw extruder is provided with a main feed port and a side feed port; and discharge ports of the second double-screw extruder and the secondsingle-screw extruder are connected to a first runner port and a second runner port of the tubular strip extruder head through runners. The production system can effectively improve the mixing uniformity of glass fiber materials, and improves the product rigidity.

Owner:天津业和科技有限公司

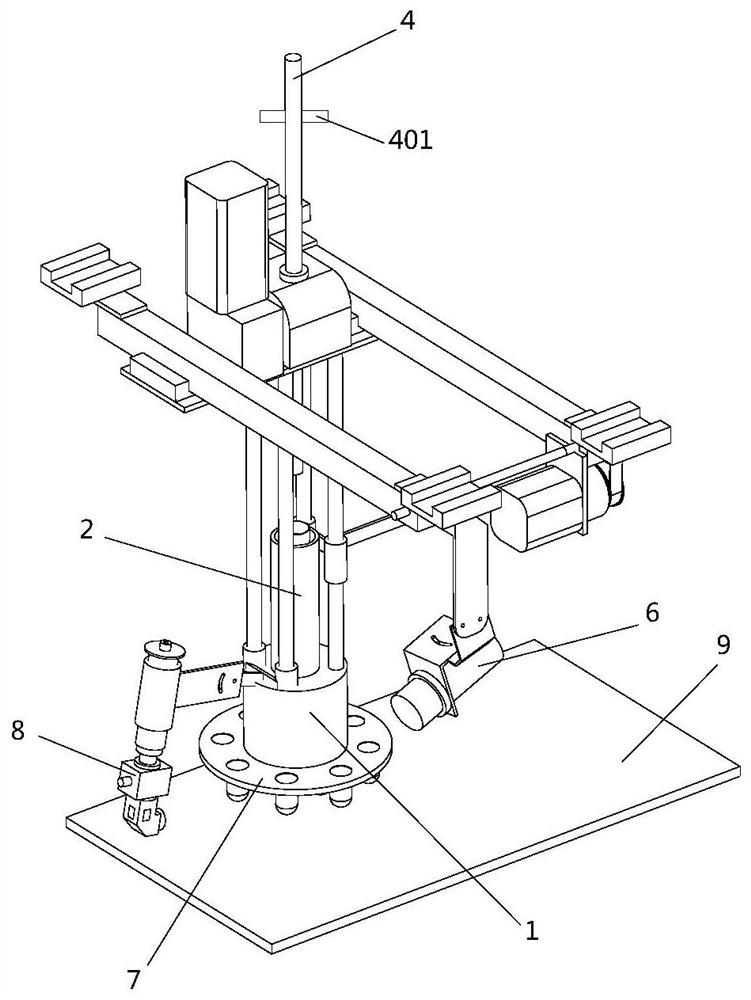

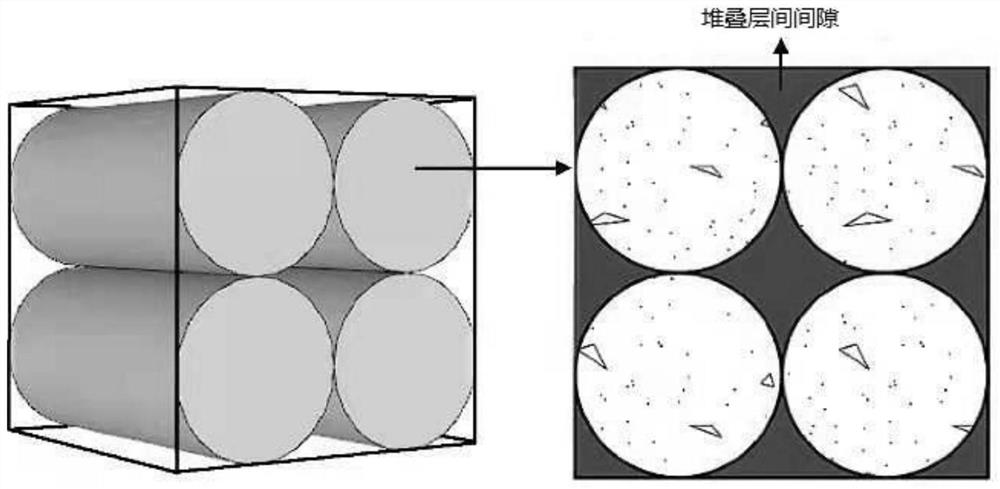

Quick forming device for ultra-high molecular weight polymer

PendingCN112388969AAdapt to a wide range of temperature rangesStrong environmental adaptabilityManufacturing platforms/substratesManufacturing heating elementsSpray nozzlePolymer chemistry

The invention discloses a quick forming device for an ultra-high molecular weight polymer. The quick forming device comprises a stock bin, a spray nozzle arranged at the bottom of the stock bin, a heating module and a rolling assembly. The heating module forms a heating area with the temperature gradually increasing from the top of the stock bin to the side, with the spray nozzle, of the bottom ofthe stock bin, and the rolling assembly is used for compacting the ultra-high molecular weight polymer extruded out of the spray nozzle. According to the quick forming device for the ultra-high molecular weight polymer, the ultra-high molecular weight polymer is heated to be in the molten state and subjected to extrusion forming; the device has the advantages of being large in adaptive temperature interval span, high in environmental adaptability and flexible and variable in printing forming structure; because three feeding chambers are formed in the stock bin, preheating, shrinkage temperature rise and small hole shrinkage accelerated extrusion of the solid or the powdery ultrahigh molecular weight polymer in the stock bin are implemented; and the rolling assembly is additionally is arranged to roll the ultra-high molecular weight polymer for solid bonding, and the problem that the ultra-high molecular weight polymer is poor in viscosity, and layers are not bonded good is solved.

Owner:INST OF CHEM CHINESE ACAD OF SCI

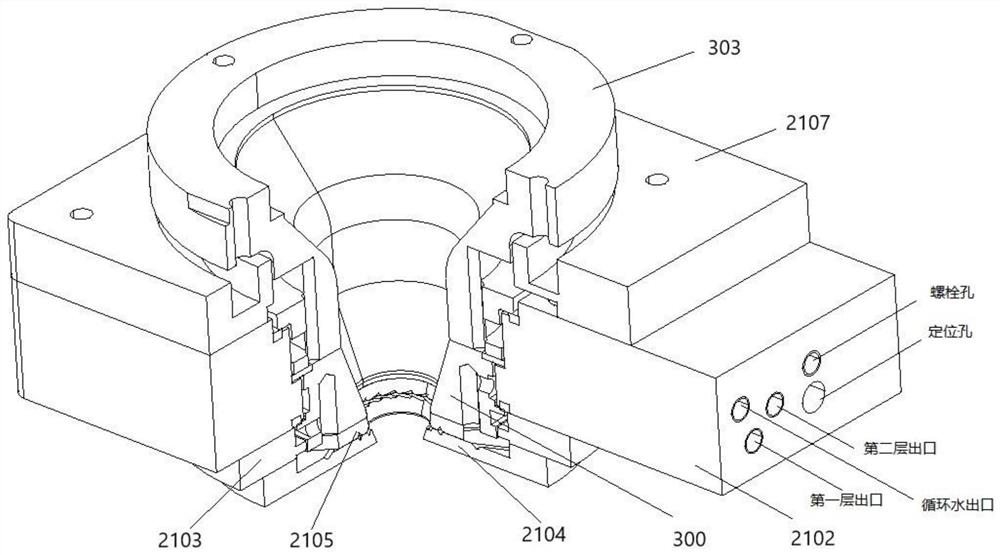

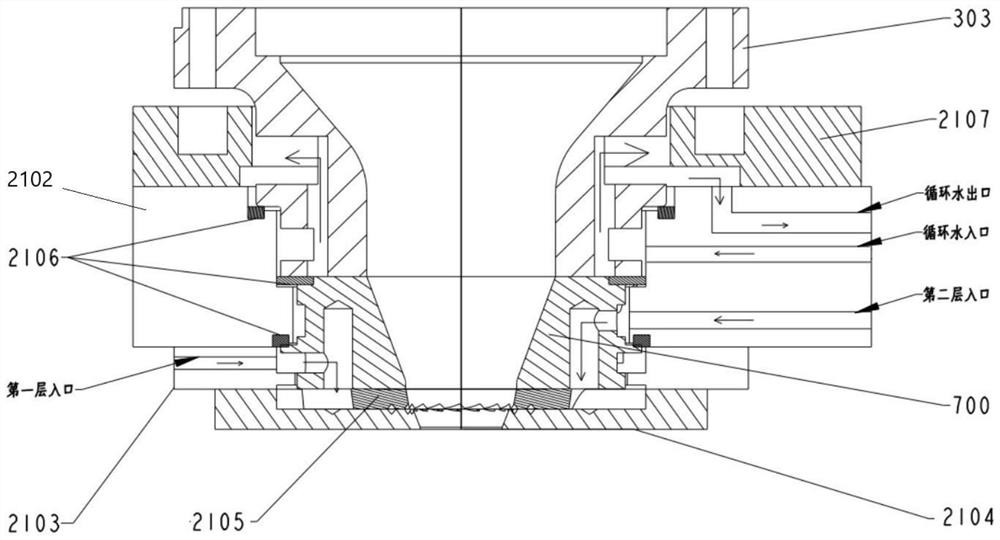

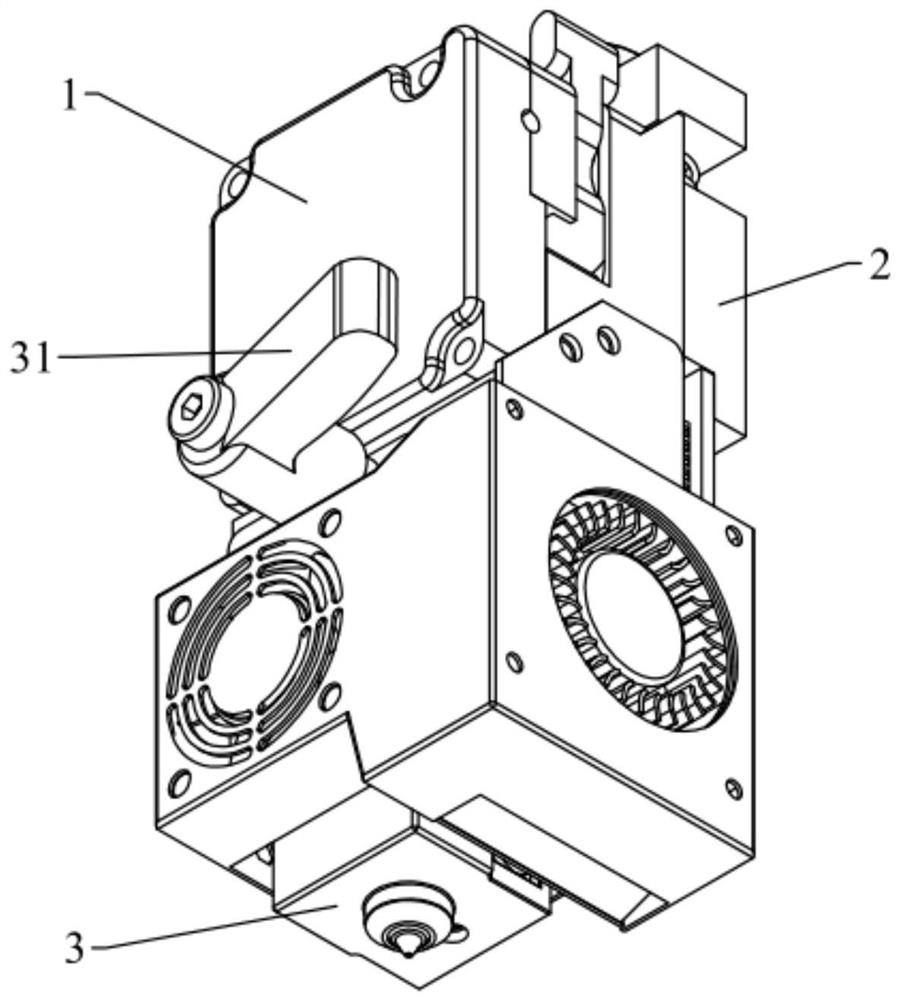

3D printer interlayer reinforced composite material adding device and 3D printer nozzle

ActiveCN113183278BActiveApply evenly and stablyAdditive manufacturing apparatusFeeding arrangmentsComputer printingEngineering

The present invention relates to the technical field of 3D printing equipment, and provides a 3D printer interlayer reinforced composite material adding device and a 3D printer nozzle. The board is set outside the bottom drum and the spatula mouth of the 3D printer; the circulating water inlet and the circulating water outlet are set on the constant temperature water integrated board, and a constant temperature water circulation is set between the constant temperature water integrated board and the bottom drum Passage; the grinding plate is provided with a roller ring, the grinding plate is arranged at the outlet of the spatula mouth of the 3D printer, and the roller ring is docked with the outlet of the spatula mouth; between the sealing backing plate and the grinding plate and the spatula mouth The first layer of slurry channel is set; the second layer of slurry channel is set between the constant temperature water integration plate, the grinding plate and the spatula nozzle; the first layer of slurry channel and the second layer of slurry channel are independent of each other. The invention can evenly spread the reinforced composite material slurry on the surface of the extruded 3D printed concrete.

Owner:大连学庆铭锋数控技术有限公司

Quantitative toothpaste squeezing device

ActiveCN111591577AAchieve persistenceAvoid cleaning hassleFlexible containersPliable tubular containersToothpasteMechanical engineering

The invention discloses a quantitative toothpaste squeezing device which comprises a toothpaste box and a quantitative sleeve installed on the toothpaste box; a partition plate is fixed to the inner wall of the quantitative sleeve; a feeding hole is formed in the upper end of the partition plate in a penetrating manner; a check valve is fixed in the feeding hole; a push plate is connected to the bottom of the partition plate through a reset spring; a connecting rod penetrating through the partition plate is fixed to the upper end of the push plate; a transfer box is fixed to the upper end of the partition plate; a closed hole is formed in the upper wall of the transfer box in the penetrating manner; and a closing plate, arranged right below the closed hole, is fixed at the upper end of theconnecting rod. The quantitative toothpaste squeezing device has the advantages that by arranging the push plate, the push plate is pushed firstly when toothpaste is squeezed, the closing plate is driven by the push plate to block the closed hole, and the situation that the subsequent toothpaste cannot enter the transfer box from the closed hole after passing through the feeding hole is guaranteed, so that the toothpaste cannot be directly output from a conveying pipe to an output pipe for discharging, temporary retention after squeezing of the toothpaste is realized, and the trouble of cleaning due to the fact that the toothpaste flows out by accident is avoided.

Owner:江苏罗来雅实业股份有限公司

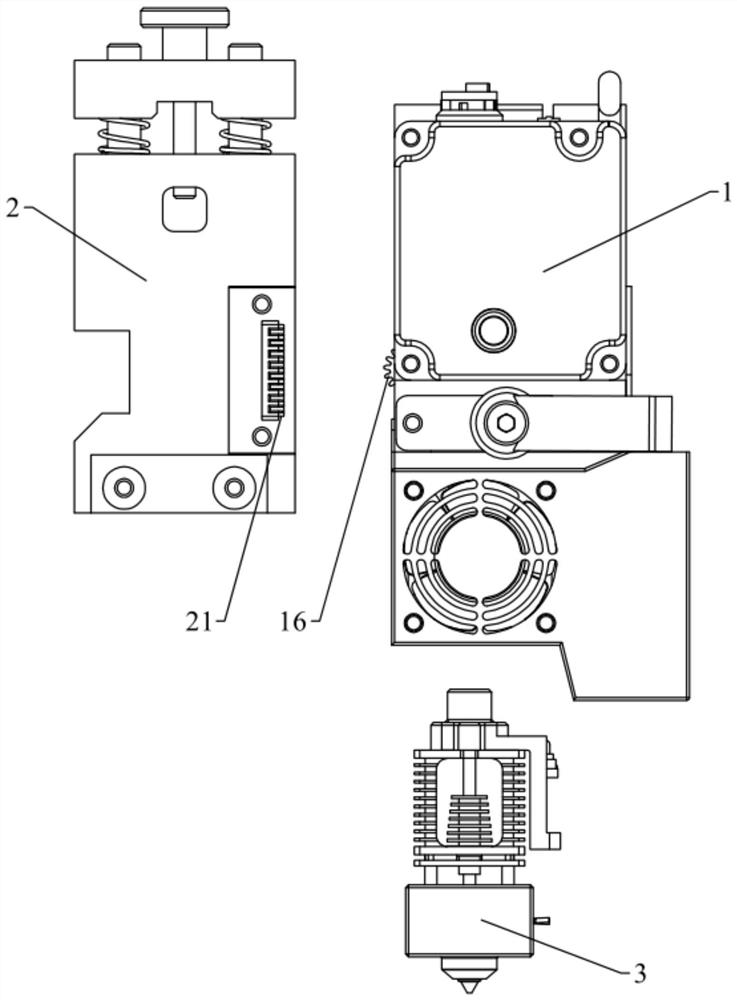

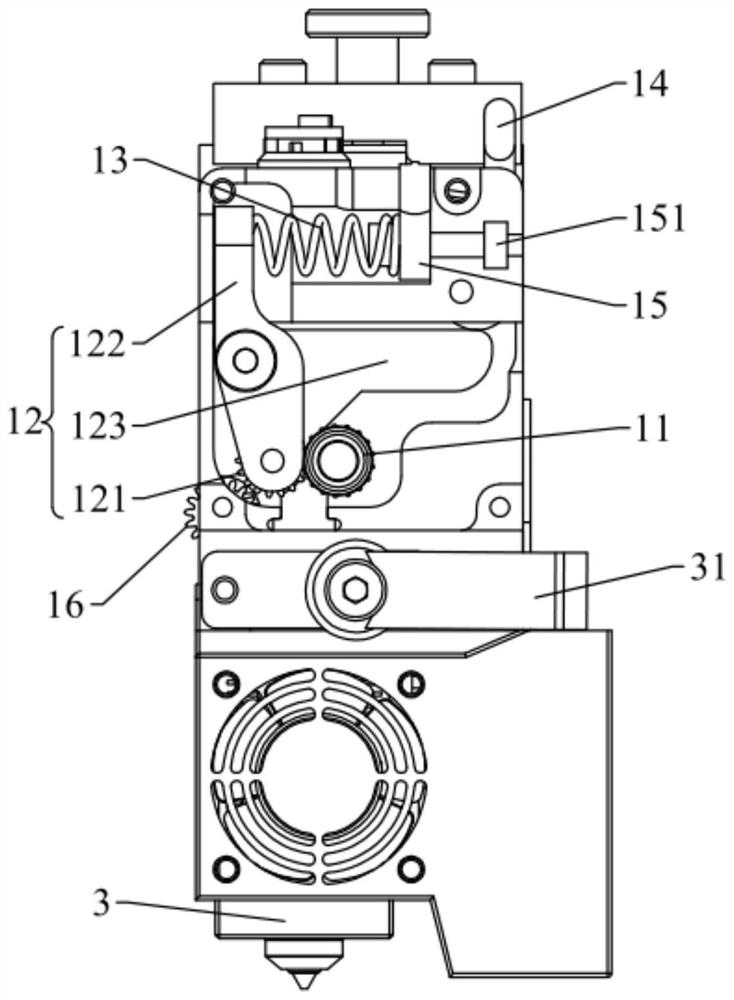

Extrusion device and 3D printer

PendingCN112936868ASimple structureEasy to operate3D object support structuresApplying layer meansWrenchEngineering

The invention relates to the technical field of 3D printers, and discloses an extrusion device and a 3D printer. The extrusion device comprises an extrusion body and a feeding wrench; an extrusion fixed wheel and an extrusion arm are rotationally arranged on the extrusion body, an extrusion movable wheel which can be selectively close to or away from the extrusion fixed wheel is rotationally arranged on the extrusion arm, consumables can be extruded out through the extrusion fixed wheel and the extrusion movable wheel which are close to each other, and one end of the extrusion arm elastically abuts against the extrusion body through an elastic piece so as to drive the extrusion movable wheel to be close to the extrusion fixed wheel; the feeding wrench is rotationally arranged on the extrusion body, one end of the feeding wrench is arranged in a reducing mode and abuts against one end of the extrusion arm, and the feeding wrench is rotated to drive the extrusion movable wheel to be away from the extrusion fixed wheel. When the feeding wrench is rotated, the extrusion movable wheel can be close to or away from the extrusion fixed wheel so as to feed or extrude materials, and the extrusion device is simple in structure, convenient to operate and high in feeding operation efficiency.

Owner:SHENZHEN CREALITY 3D TECH CO LTD

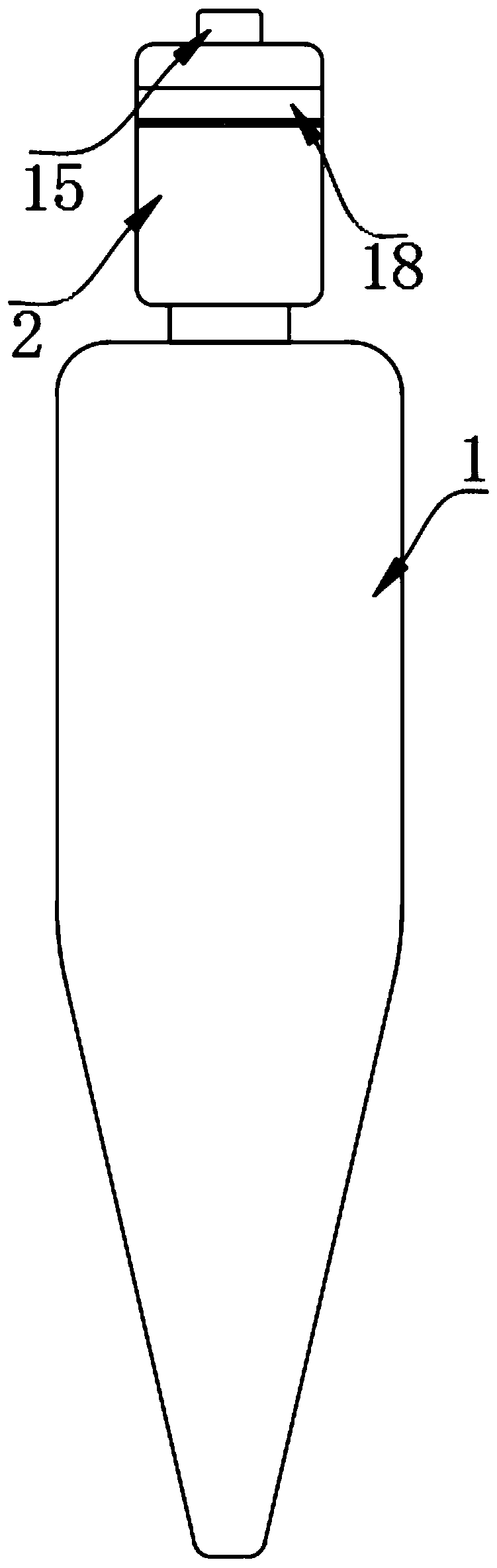

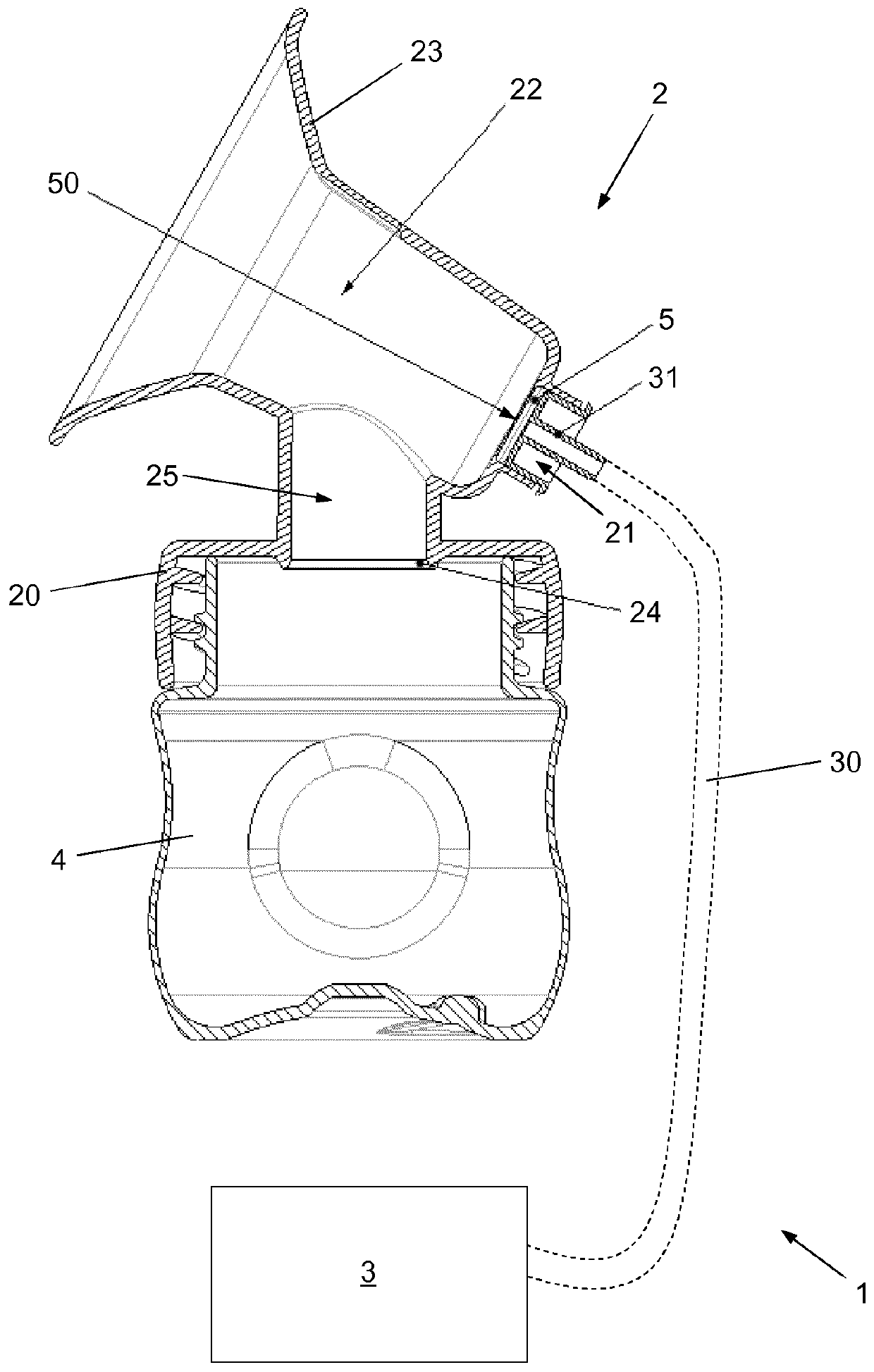

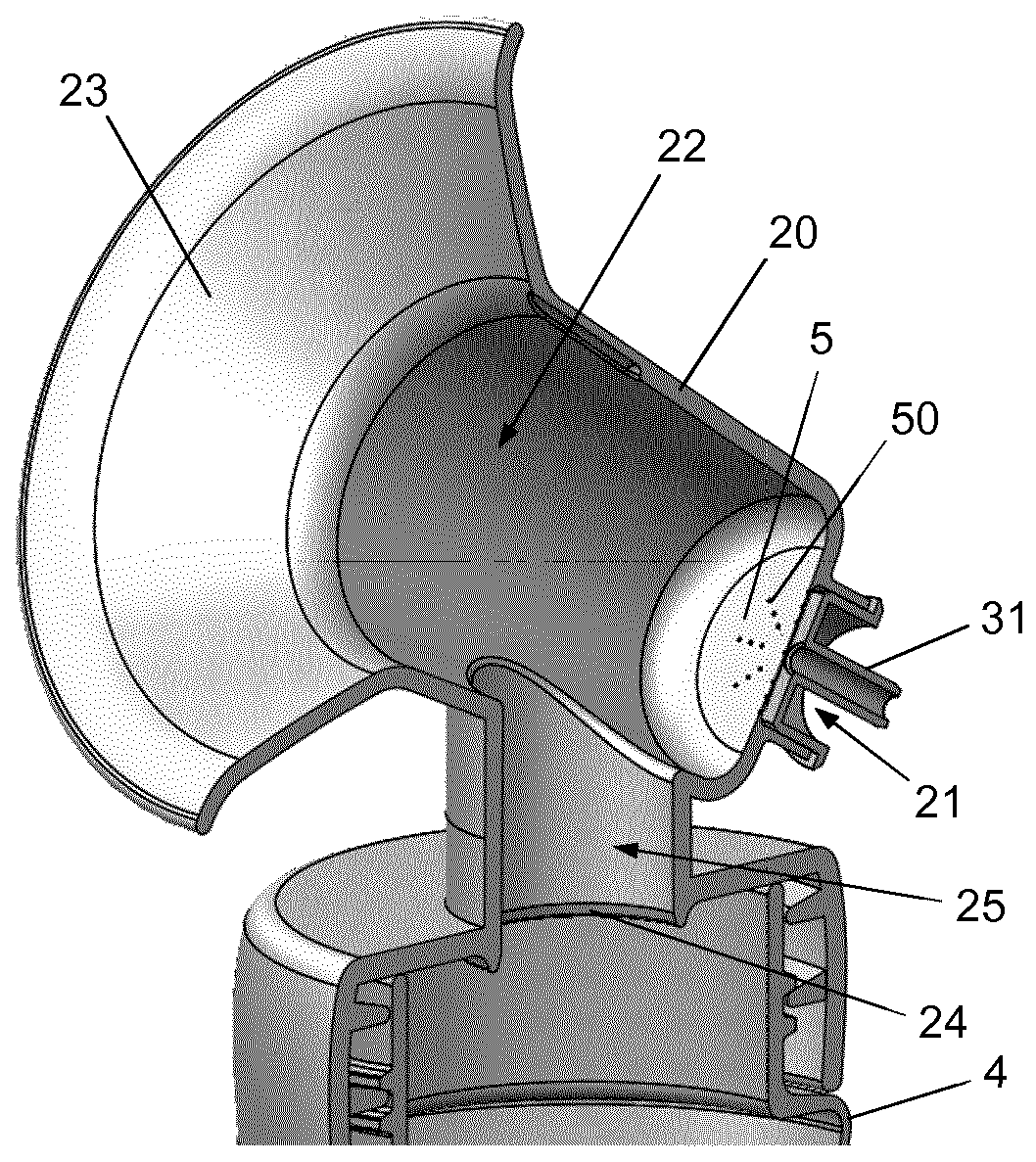

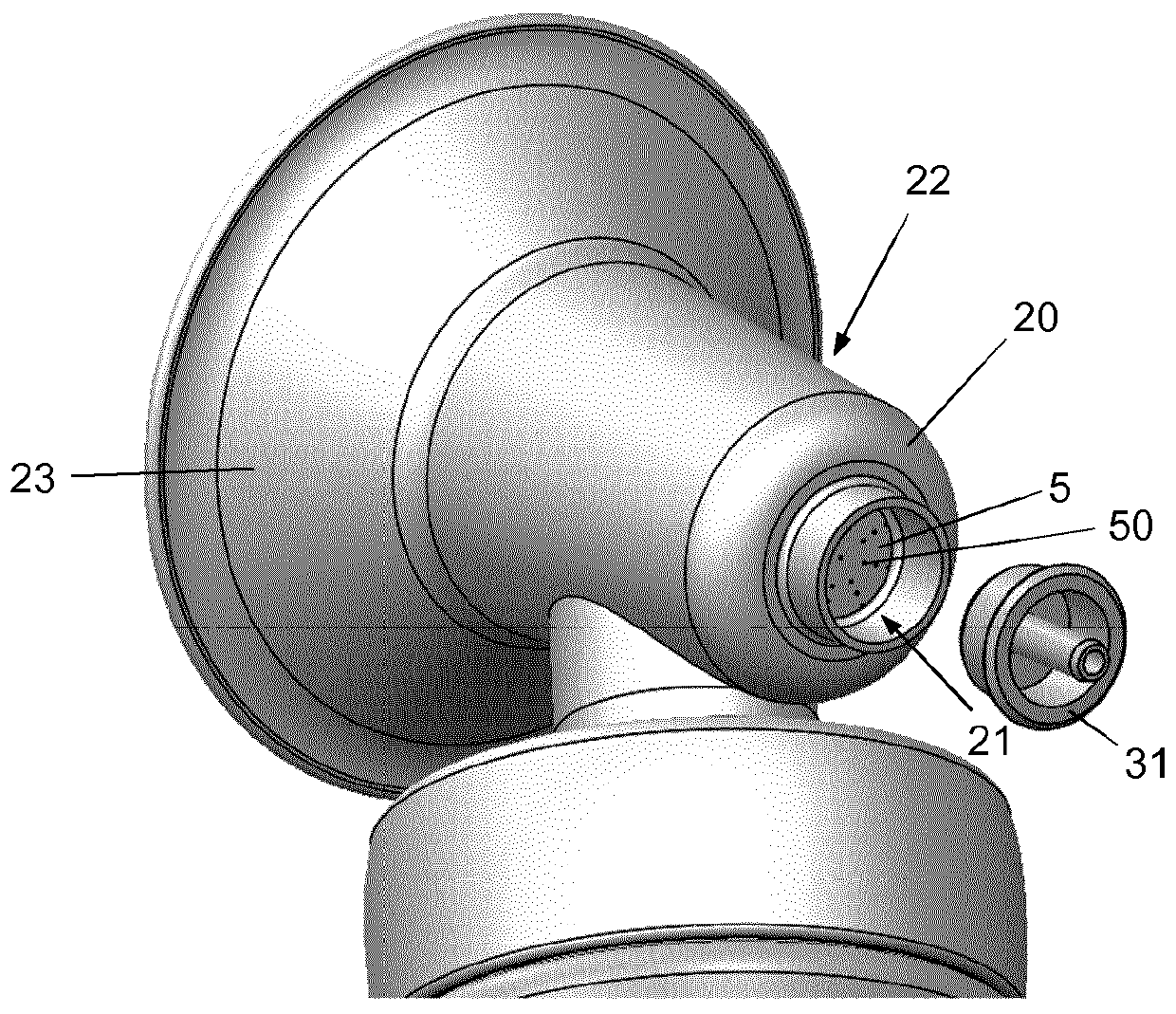

Expression kit for breast pump device

Owner:KONINKLJIJKE PHILIPS NV

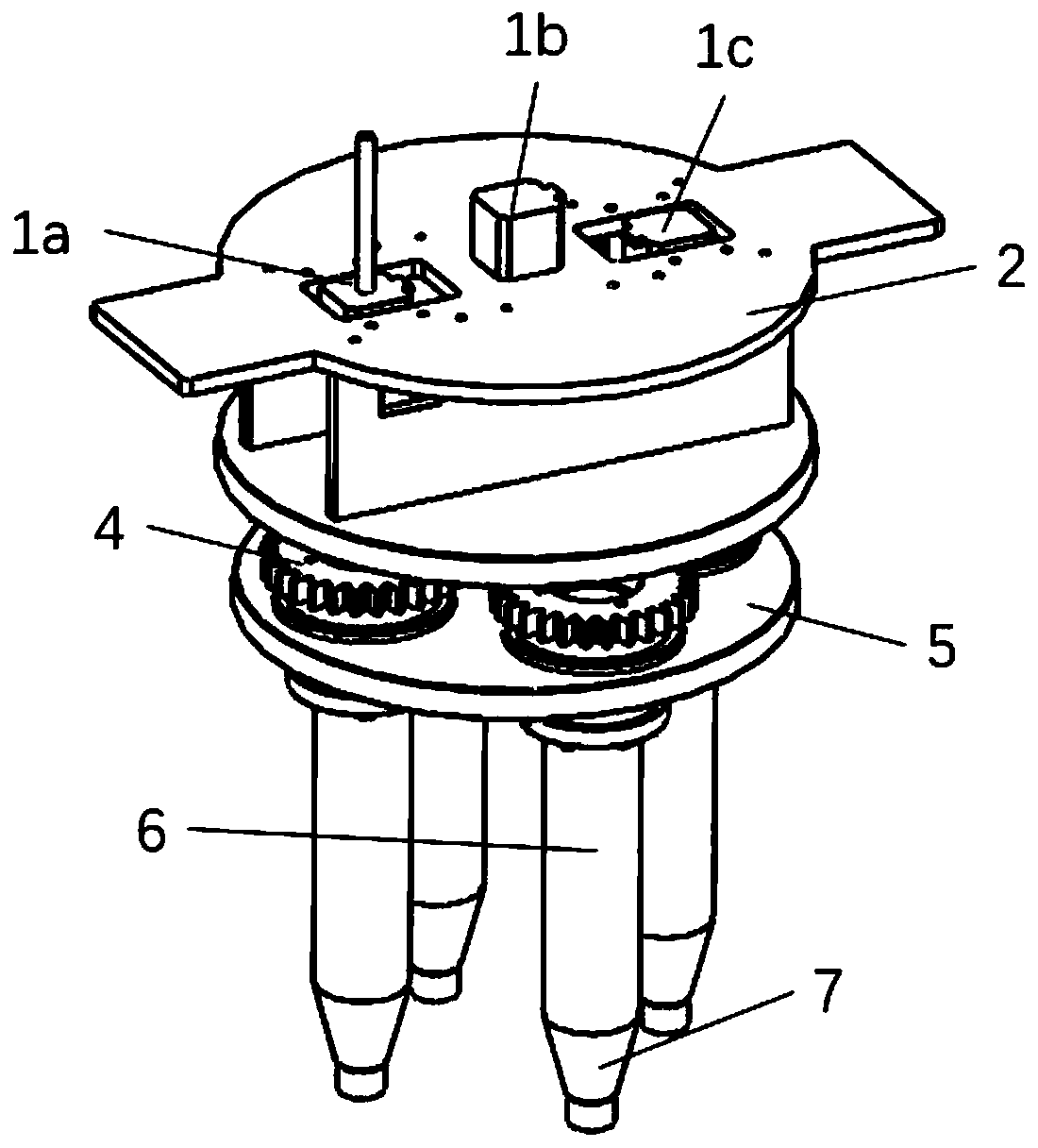

Automatic multi-color pattern mounting head

The invention relates to an automatic multi-color pattern mounting head based on motor control. The pattern mounting head comprises motors, a driving device, a standard mounting plate connected with automated equipment, a planet disc provided with a transmission mechanism, multiple material cylinders and pattern mounting nozzles, and the material cylinders and the pattern mounting nozzles are connected with the planet disc. The three motors are installed on the mounting plate, the motors separately control the planet disc through transmission mechanisms to drive the multiple material cylindersto conduct orbital revolution, the gear transmission mechanisms control rotation of the material cylinders, and a linear stepping motor drives a feeding shaft to control feeding of the material cylinders. The planet disc is provided with a center drive gear and multiple driven gear mechanisms, and each driven gear is connected with one set of material cylinders and pattern mounting nozzles; the multiple driven gears, material cylinders and pattern mounting nozzles form a multi-color material bin, and the material bin is rotated to or away from the lower end of the feeding shaft through orbital revolution. The material cylinders and the pattern mounting nozzles are connected through standard connection parts, and the number of the material cylinders and the colors of coatings placed in thematerial cylinders can be set by a user. According to the automatic multi-color pattern mounting head, the number and colors of the material cylinders can be self-defined, and the working efficiencyof pattern mounting is effectively improved.

Owner:BEIJING UNIV OF POSTS & TELECOMM

Novel toothpaste tube

InactiveCN109552747AExtrusion realizationEasy extrusionFlexible containersPliable tubular containersToothpasteEngineering

The present invention relates to the field of industry, in particular to a novel toothpaste tube, comprising a toothpaste tube body, wherein a toothpaste extrusion piston is pre-arranged inside the toothpaste tube body, the bottom of the toothpaste extrusion piston is connected with a rotating rod, the bottom of the rotating rod is exposed at the bottom of the toothpaste tube body, a rotating handle is arranged at the bottom end of the rotating rod, granular protrusions are arranged on the upper end surface of the toothpaste extrusion piston, an arc-shaped scraper is arranged around the piston, and the tail end of the scraper is a free end. The toothpaste can be extruded by upward pushing of the toothpaste extrusion piston, so that the problem that a dead angle is easy to produce when thetoothpaste is squeezed out by hand is avoided at first, and it is easier to extrude the toothpaste by rotating the rotating handle directly by hand. Since the toothpaste extruding piston is provided with the granular protrusions, the toothpaste can be pressed to be extruded better, and the scraper is arranged to ensure that no toothpaste residue exists at the edge of the toothpaste tube body.

Owner:周昌琼

Foodstuff extruding device

ActiveCN102178333BExtrusion realizationEasy to manufacturePreservation by coatingKitchen equipmentEngineeringMechanical engineering

Owner:NINGBO YINRUI ORGANO SILICON TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com