Production system for polyethylene glass fiber winding structured wall pipe products and production method

A technology for structural wall pipes and production systems, applied to tubular objects, other household appliances, household appliances, etc., can solve problems such as increasing the diameter of skeleton pipes, uneven mixing of glass fiber materials, and affecting product performance, so as to improve uniformity of mixing The effect of improving the rigidity of the pipe and improving the performance of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

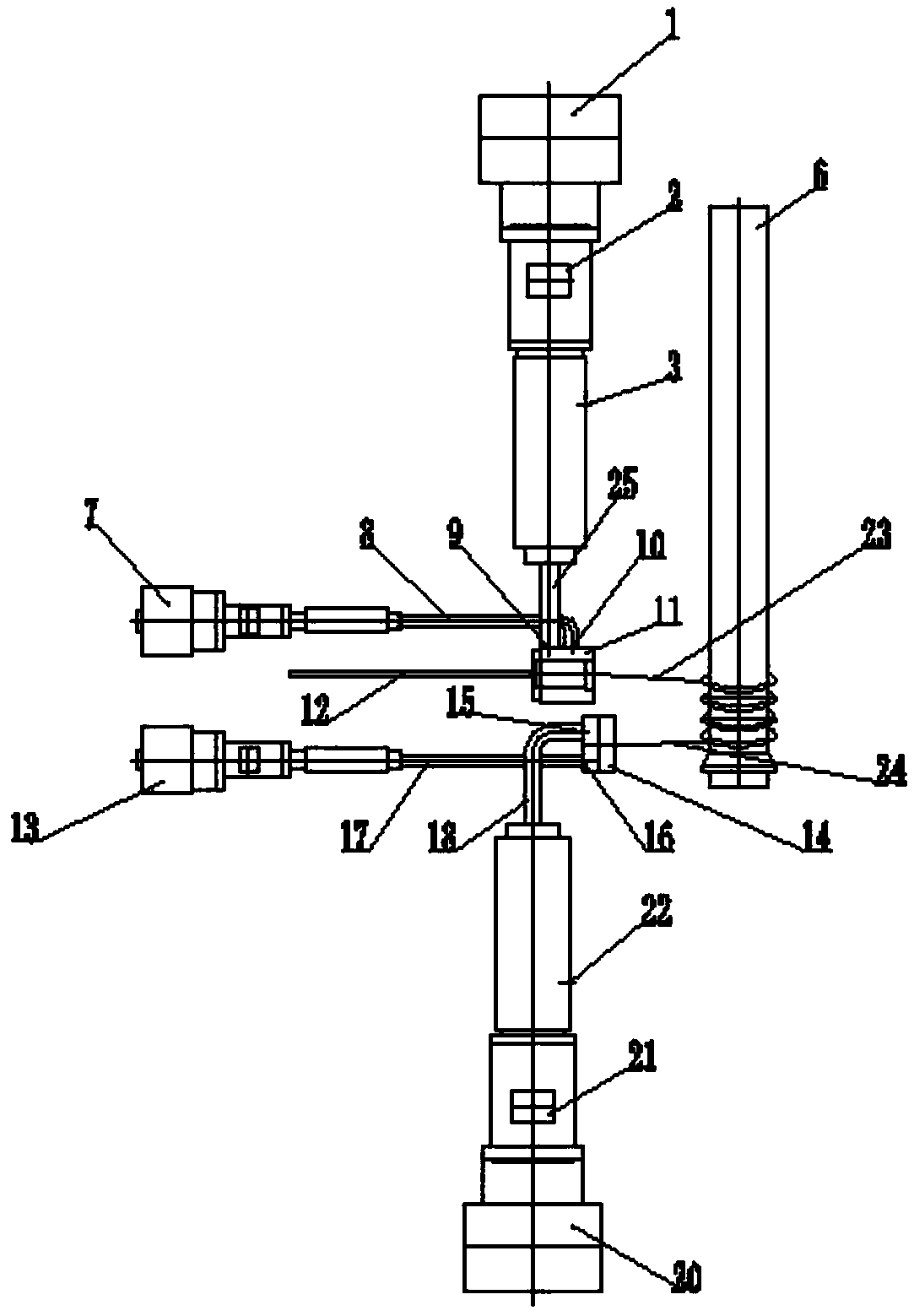

[0029] A polyethylene glass fiber wound structural wall pipe production system, such as figure 1 As shown in , it includes a sheet-shaped inner wall layer belt extrusion unit and a tubular outer wall layer belt extrusion unit, and the sheet-shaped inner wall layer belt extrusion unit includes the first twin-screw extruder 20, the first single-screw extruder 13 and Sheet strip extruder head 14, the first twin-screw extruder is provided with a main feeding port 21 and a side feeding port 22, the discharge port of the first twin-screw extruder is connected to the sheet through the first flow channel 18 The first flow channel port 15 of the strip extruder head; the discharge port of the first single-screw extruder is connected to the second flow channel port 16 of the sheet strip extrusion head through the second flow channel 17 .

[0030] The extruding unit of the tubular outer wall layer band comprises a second twin-screw extruder 1, a second single-screw extruder 7 and a tubula...

Embodiment 2

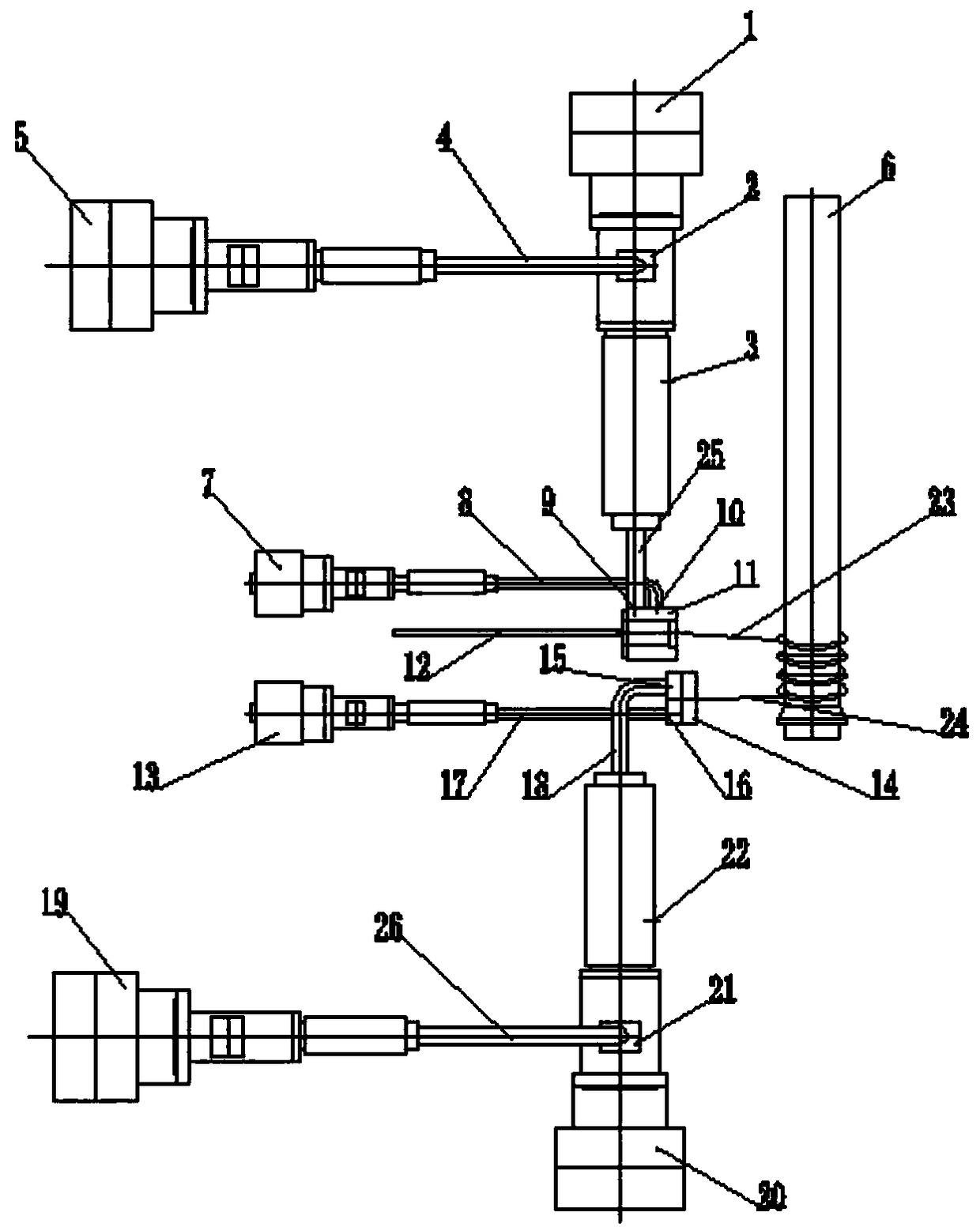

[0032] Such as figure 2 As shown, the extrusion unit of the sheet-shaped inner wall layer belt also includes a first pressurized single-screw extruder 19, which is arranged at the feed end of the first twin-screw extruder, that is, the first pressurized single-screw extruder 19. The feed port of a pressurized single screw extruder is connected to the main feed port of the first twin screw extruder through a fifth runner 26 .

[0033] The extrusion unit of the tubular outer wall layer belt also includes a second pressurized single-screw extruder 5, which is arranged at the feed end of the second twin-screw extruder, that is, the second pressurized unit The discharge port of the screw extruder is connected to the main feed port of the second twin-screw extruder through the sixth channel 4 . Others are the same as in Example 1.

Embodiment 3

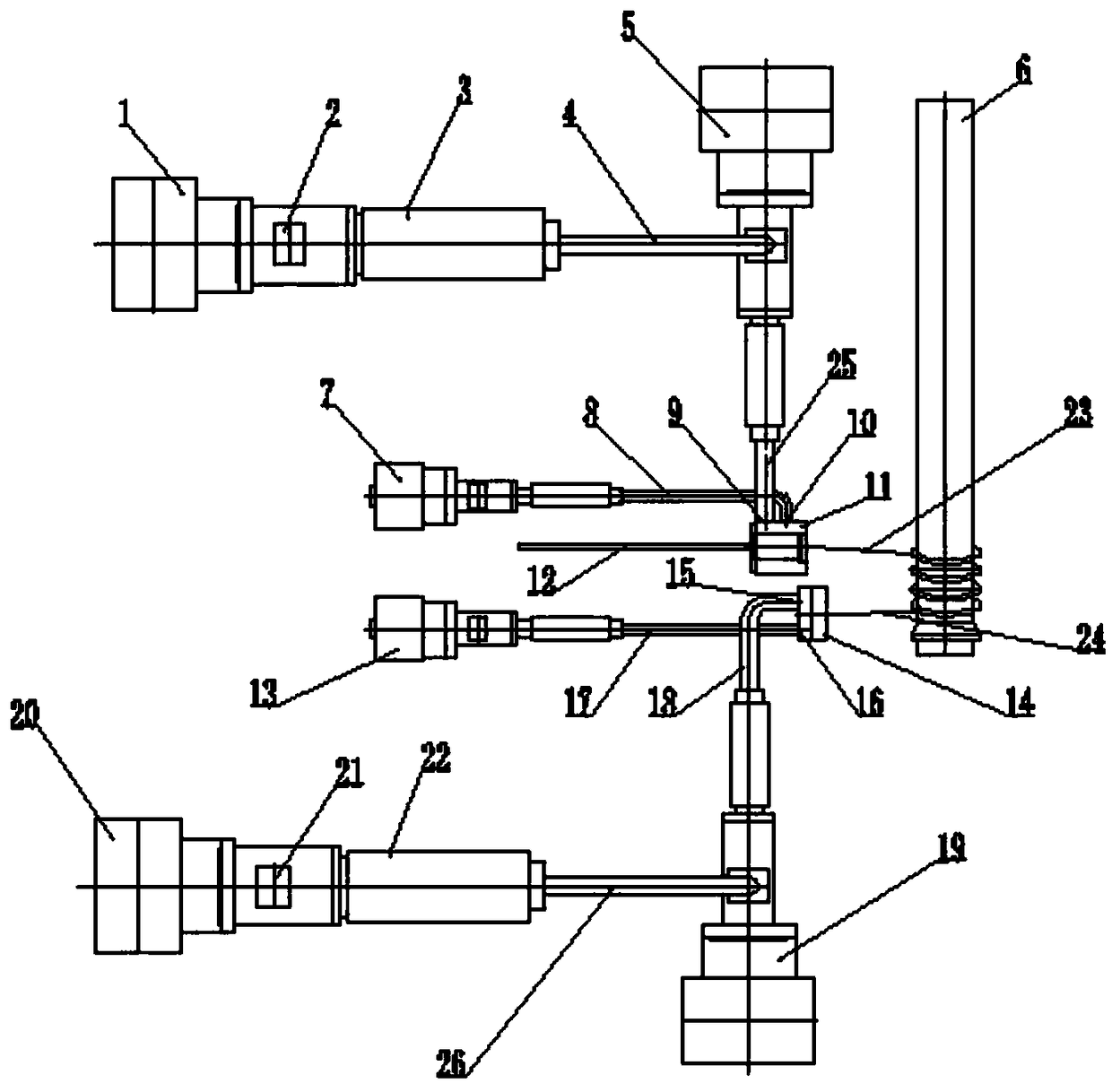

[0035] Such as image 3 As shown, the extrusion unit of the sheet-shaped inner wall layer belt also includes a first pressurized single-screw extruder 19, which is arranged at the discharge end of the first twin-screw extruder, that is, the first pressurized single-screw extruder 19. The feed port of a pressurized single-screw extruder is connected to the discharge port of the first twin-screw extruder through the fifth flow channel 26, and the discharge port of the first pressurized single-screw extruder passes through the first flow channel 18 Connects to the first runner port of the sheet strip extrusion head.

[0036] The extrusion unit of the tubular outer wall layer belt also includes a second pressurized single-screw extruder 5, which is arranged at the discharge end of the second twin-screw extruder, that is, the second pressurized unit The feed port of the screw extruder is connected to the discharge port of the second twin-screw extruder through the sixth flow channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com