Insulation pipe type busbar three-layer coextrusion continuous vulcanization production equipment and production process

A three-layer co-extrusion and production equipment technology, which is applied in the direction of conductor/cable insulation, electrical components, circuits, etc., can solve the problem of no insulating tubular busbar production equipment and production process, short length of single conductor tube, conductor tube load Large flow and other problems, to reduce production costs and labor intensity of workers, achieve diversity, improve the effect of insulation strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] This embodiment is carried out on the premise of the technical solutions of the above inventions, and detailed implementation methods and specific operation processes are given, but the scope of protection of the present invention is not limited to the following embodiments.

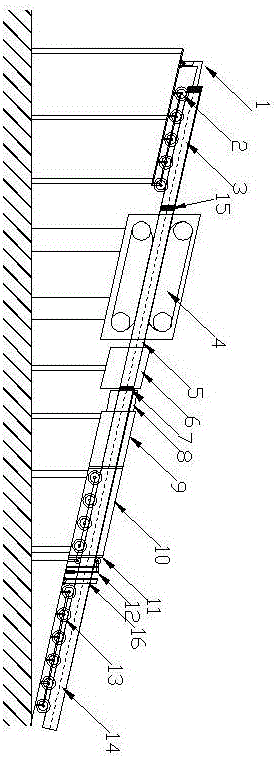

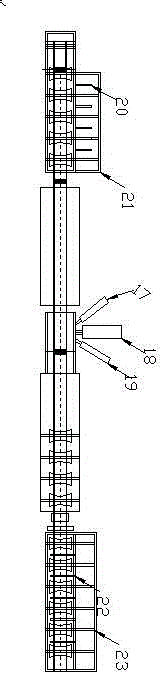

[0032] Such as figure 1 As shown, a three-layer co-extrusion continuous vulcanization production equipment for pipe bus includes: conductor pipe connection auxiliary push car 1, conductor pipe connection platform 2, conductor pipe 3, pneumatic crawler pusher 4, conductor pipe 5, three-layer co-extrusion Machine head 6, conductor pipe connection pin 7, upper sealer 8, vulcanization pipe 9, cooling pipe 10, lower sealer 11, pneumatic pressing device 12, stripping and cutting platform 13, extrusion pipe busbar 14, conductor pipe connection pin 15. Stripping and cutting machine 16, first extruder 17, second extruder 18, third extruder 19, manipulator 20, conductor tube placement platform 21, manipulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com