A combined flat honeycomb ceramic membrane and its preparation method

A honeycomb ceramic and combined technology, which is applied in the field of membrane separation, can solve the problems of increased difficulty in the preparation of ceramic membrane separation layers, insufficient overall strength of ceramic membranes, and increased cost of ceramic membranes, so as to reduce membrane pollution, facilitate replacement, and reduce fractures. effect of possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

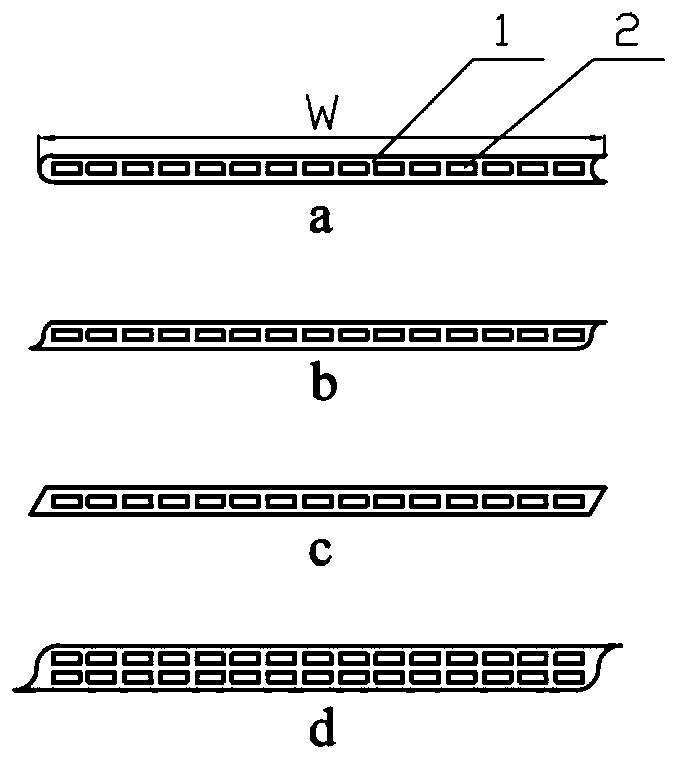

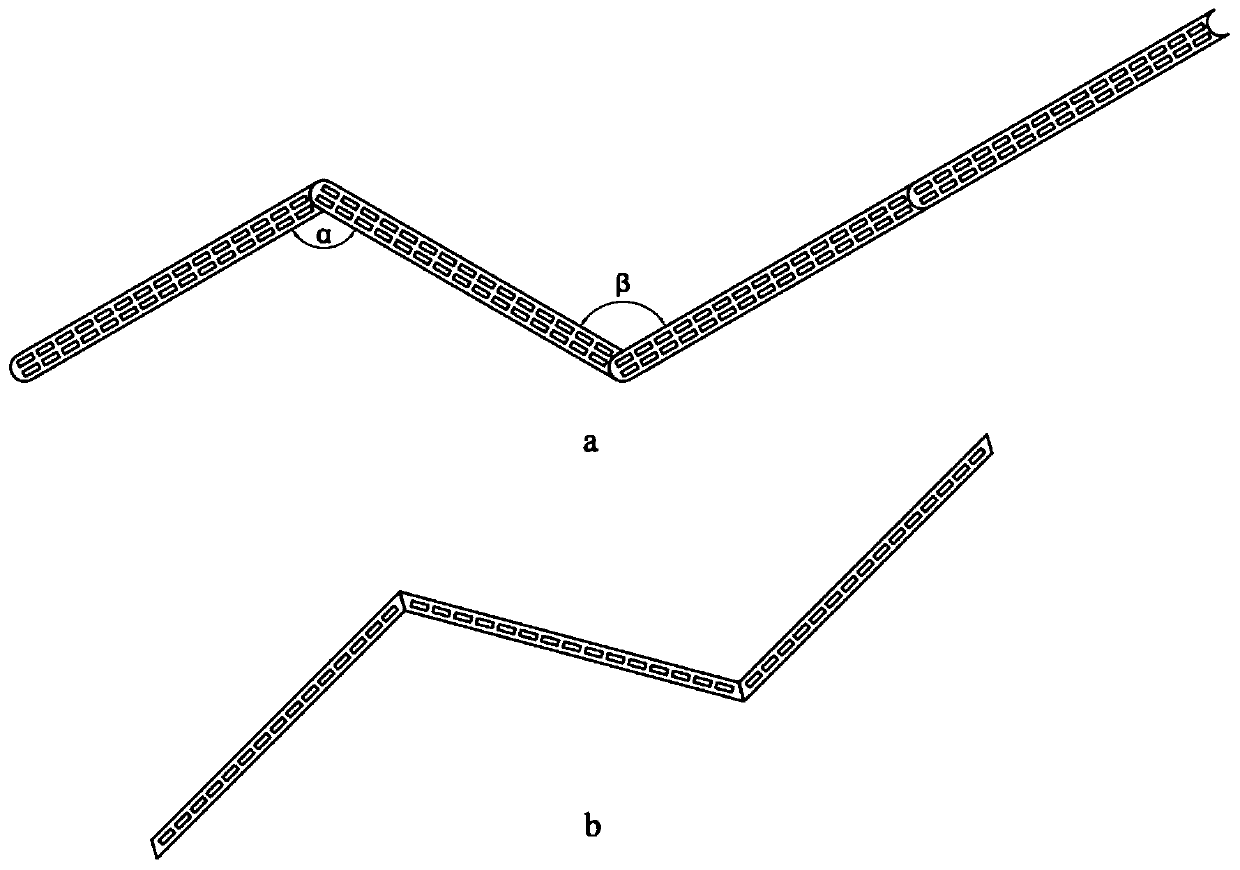

[0037] figure 1 and figure 2 Shown is an embodiment of a combined flat honeycomb ceramic membrane of the present invention, which is composed of flat honeycomb ceramic membrane units. Such as figure 1As shown, the flat-shaped honeycomb ceramic membrane unit is in the shape of a narrow plate with a width W of 7-15 cm and a length of 1-1.2 m, and the edge shapes on both sides are center-rotationally symmetrical. The cross-sectional shape of the edge of the side is one of straight lines, arcs, curves, folded lines or a combination thereof.

[0038] The flat-shaped honeycomb ceramic membrane unit is composed of a support body 1 and separation membrane layers located on the upper and lower surfaces of the support body. Such as figure 1 As shown, the support body 1 has single or double rows of permeate channels 2 in the middle, and the width of a single permeate channel 2 is 3 mm and the height is 1 mm. For the flat-shaped honeycomb ceramic membrane unit with a single row of p...

Embodiment 2

[0042] In this embodiment, a method for preparing a combined flat honeycomb ceramic membrane is composed of the flat honeycomb ceramic membrane units of Embodiment 1, wherein the preparation of the flat honeycomb ceramic membrane unit is as follows:

[0043] (1) Extrusion molding method to prepare the support body of flat honeycomb ceramic membrane unit

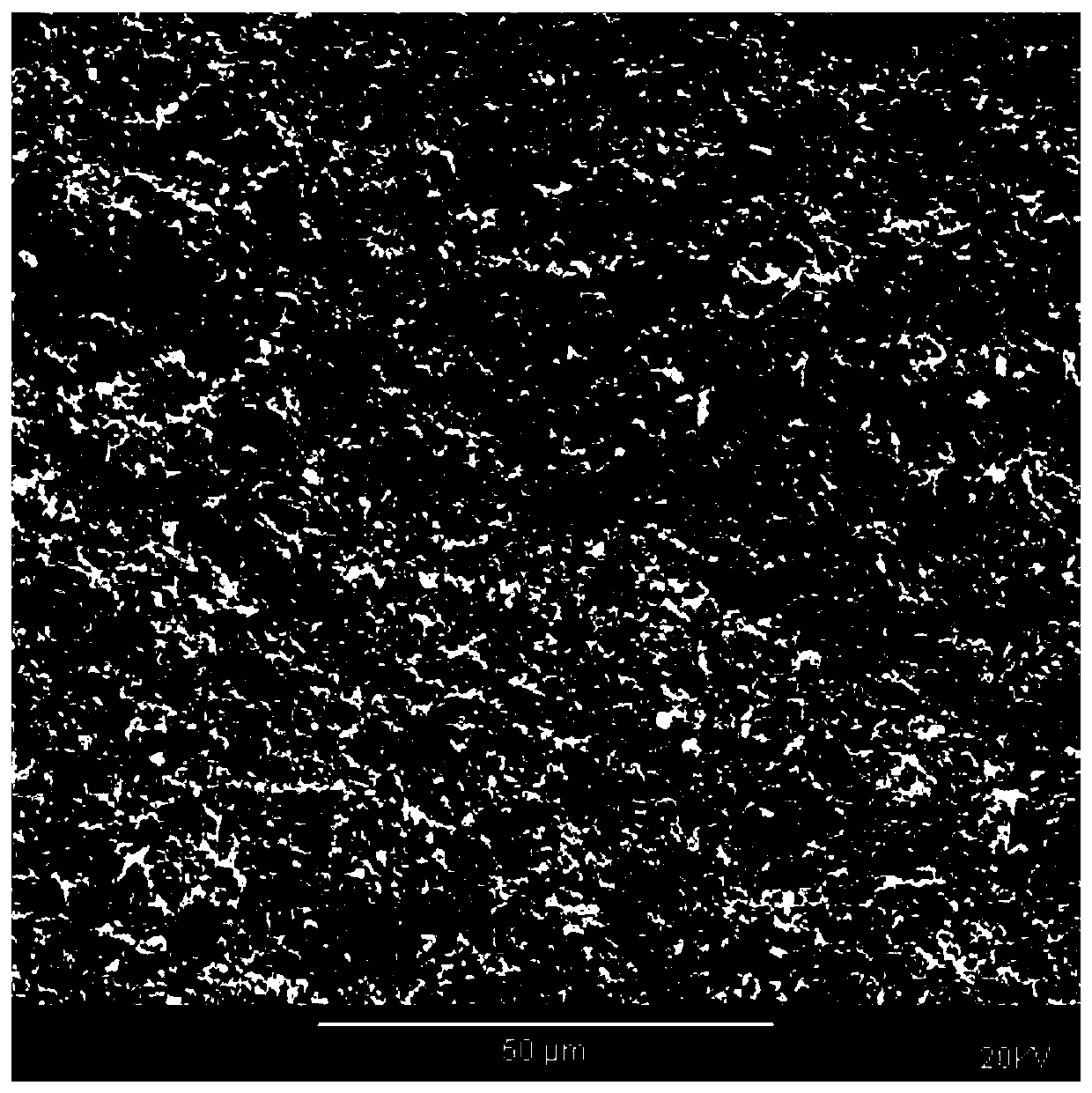

[0044] After mixing 50kg of alumina powder (average particle size of 40μm), 4kg of starch, and 2.5kg of hydroxypropyl methylcellulose in a mixer, add 2kg of glycerin, 0.5kg of polyvinyl alcohol, and 9kg of water in a kneader. Knead into mud in medium, after stale for 1 week, extrude into shape through horizontal extruder, then dry in constant temperature and humidity drying box (temperature is 80°C, humidity is 90%) for 24h, and calcined at 1650°C for 4h to get the average The support body of the flat-shaped honeycomb ceramic membrane unit with a pore size of 4.2 μm and center-rotational symmetry at both ends;

[0045] (2) I...

Embodiment 3

[0049] The preparation method of a combined flat-plate honeycomb ceramic membrane in this embodiment is different from Example 1 in that the preparation of the flat-shaped honeycomb ceramic membrane unit is as follows:

[0050] (1) Extrusion molding method to prepare the support body of flat honeycomb ceramic membrane unit

[0051] After mixing 50kg of alumina powder (average particle size of 10μm), 4kg of starch, and 3.0kg of hydroxypropyl methylcellulose in a mixer, add 2kg of glycerin, 0.75kg of polyvinyl alcohol, and 9kg of water in a kneader. Knead into mud in medium, after stale for 2 weeks, extrude into shape by horizontal extruder, then dry in constant temperature and humidity drying box (temperature is 80°C, humidity is 90%) for 24h, and calcined at 1550°C for 4h to get the average The support body of the flat-shaped honeycomb ceramic membrane unit with a pore size of 1.2 μm and center-rotational symmetry at both ends;

[0052] (2) Inkjet printing method to prepare t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com