A kind of flame retardant antistatic rubber floor composition and its preparation method and application

A flame-retardant, anti-static, rubber floor technology, applied in the field of synthetic rubber, can solve the problems that the anti-static effect is not long-term, must be maintained regularly, and is unfavorable for long-term use, and achieves excellent anti-static, production cost control, and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

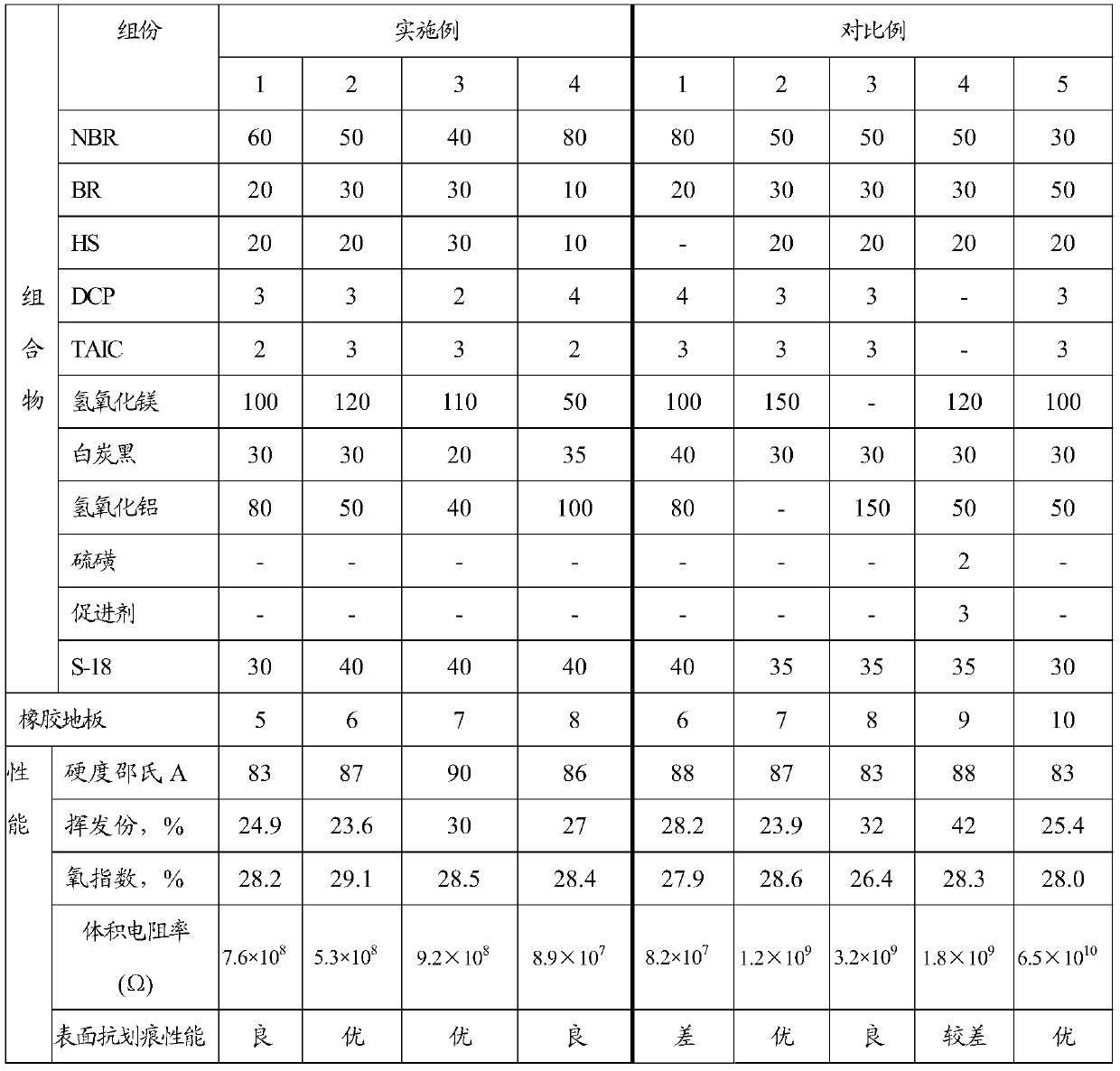

[0048] Example 1 Composition for flame retardant antistatic rubber floor

[0049] The composition of the composition and the parts by weight of each component are shown in Table 1, wherein 1 part by weight=1 kg.

Embodiment 2

[0050] Example 2 Composition for flame retardant antistatic rubber floor

[0051] The composition of the composition and the parts by weight of each component are shown in Table 1, wherein 1 part by weight=1 kg.

Embodiment 3

[0052] Example 3 Composition for flame retardant antistatic rubber floor

[0053] The composition of the composition and the parts by weight of each component are shown in Table 1, wherein 1 part by weight=1 kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com