Multi-color automatic piping head

A mounting head, automatic technology, applied in baking, food science, baked food processing, etc., can solve the problems of complex mounting head structure, unsatisfactory mounting head replacement, etc., and achieve high-precision results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiment of the present invention is described in further detail below in conjunction with accompanying drawing:

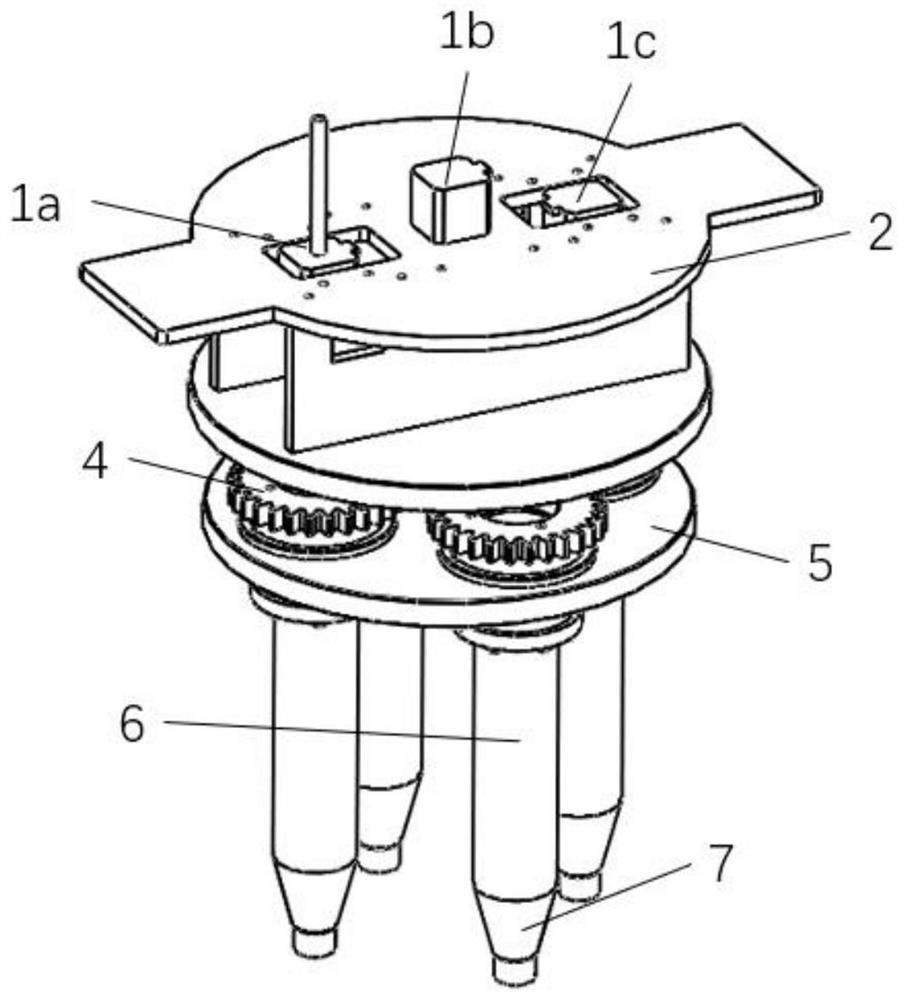

[0032] 1. If figure 1 As shown, the new multi-color automatic mounting head structure includes three servo motors 1a, 1b, 1c, a standard mounting plate 2, a planetary disc 5, a gear structure 4 installed on the planetary disc, and a barrel 6 installed on the planetary disc. And piping nozzle 7.

[0033] 2. If figure 1 As shown, the standard mounting plate 2 of the multi-color automatic mounting head can be connected with an industrial mechanical arm, a Cartesian robot, etc. in an automated production line, so that the motion of the mounting head in the normal direction of the processing surface is controlled by the mechanical arm during processing.

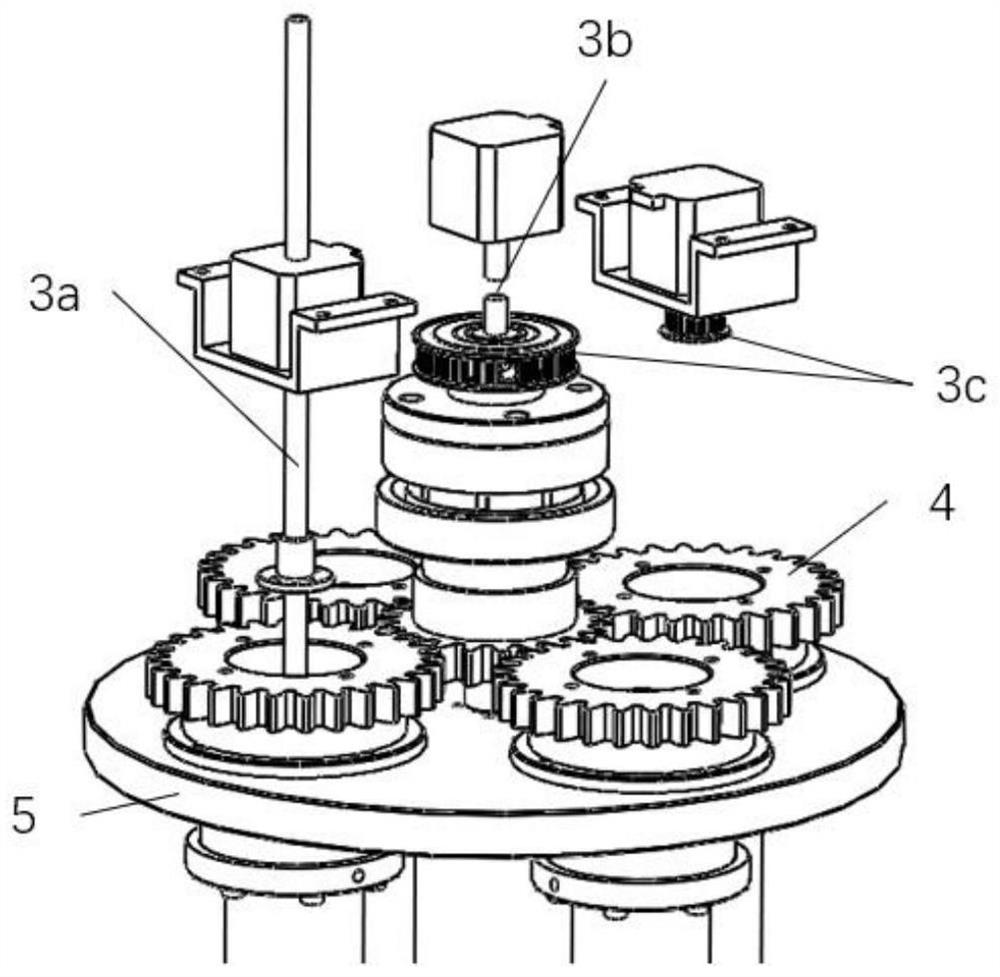

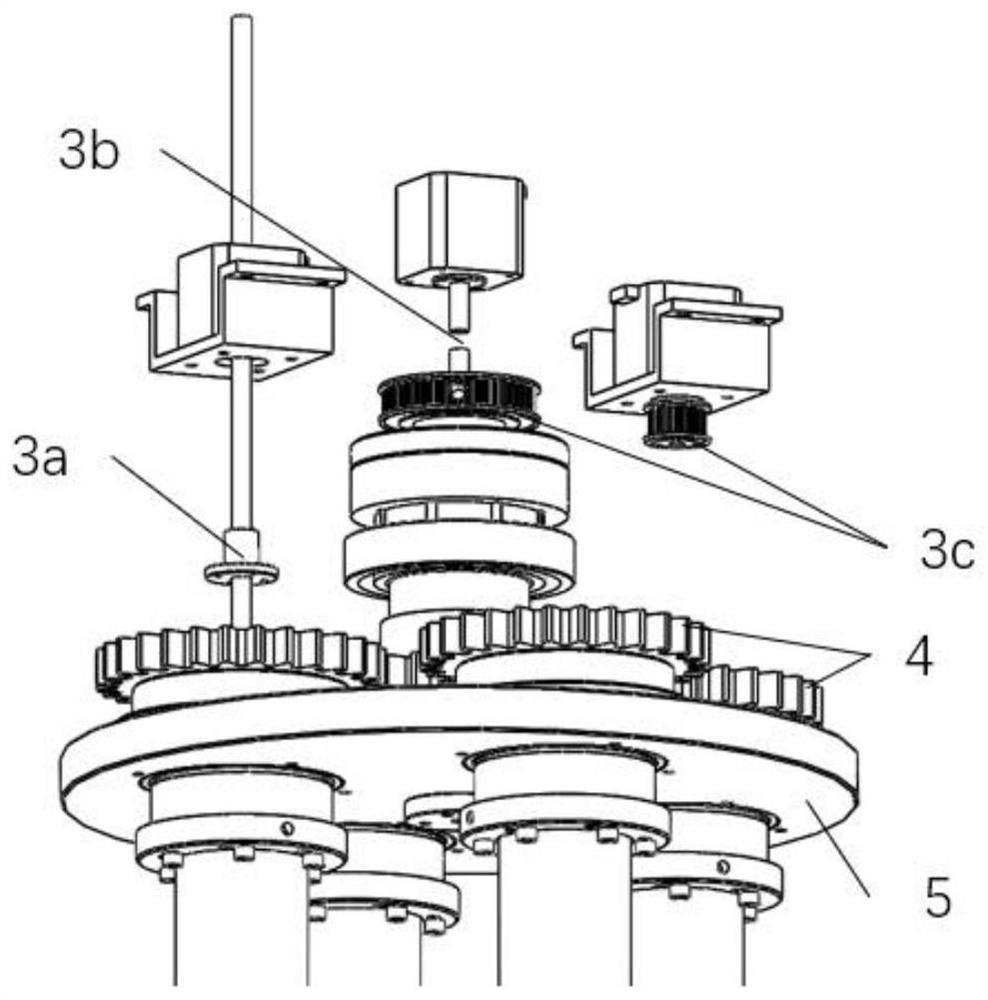

[0034] 3. If figure 2 — Figure 4 , Figure 10 — Figure 14 As shown, the linear motor 1a controls the structure 3a installed on the planetary disc 5 to move up and down in a straight line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com