Extrusion device and 3D printer

A technology of extrusion device and extrusion arm, applied in the direction of coating device, 3D object support structure, manufacturing tools, etc., can solve the problems of low efficiency and cumbersome operation, and achieve convenient operation, high efficiency of feeding operation, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

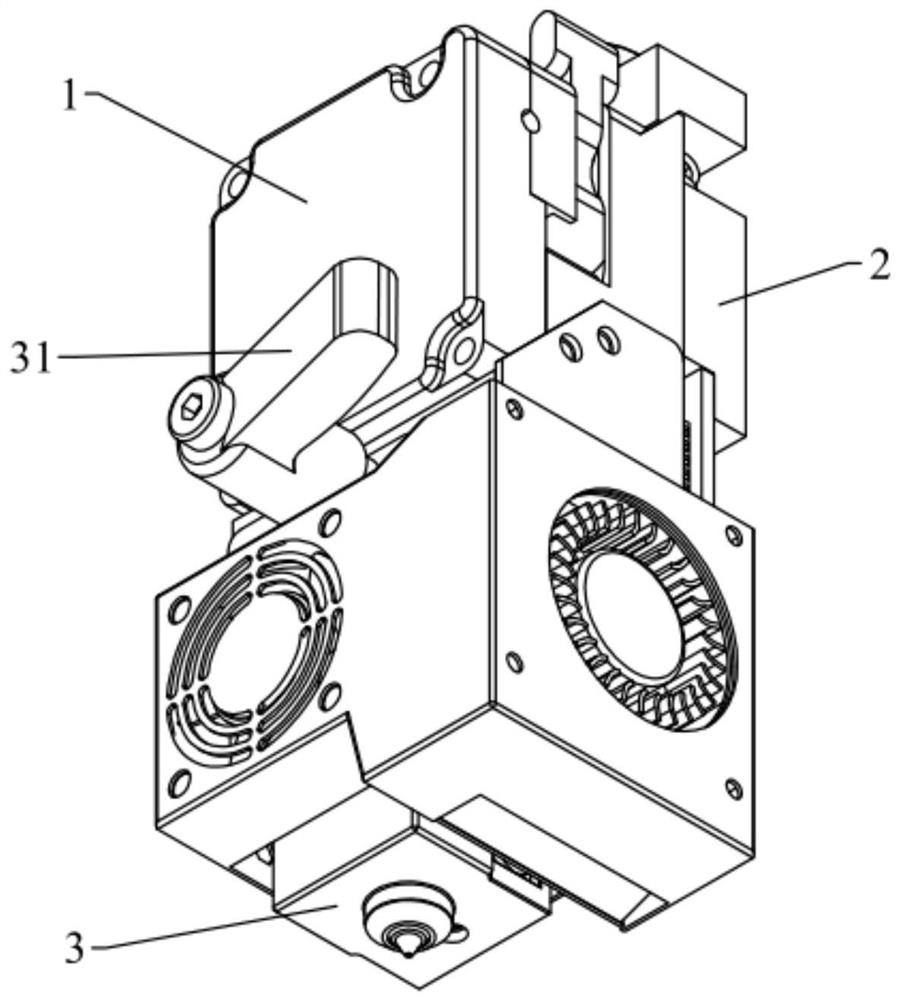

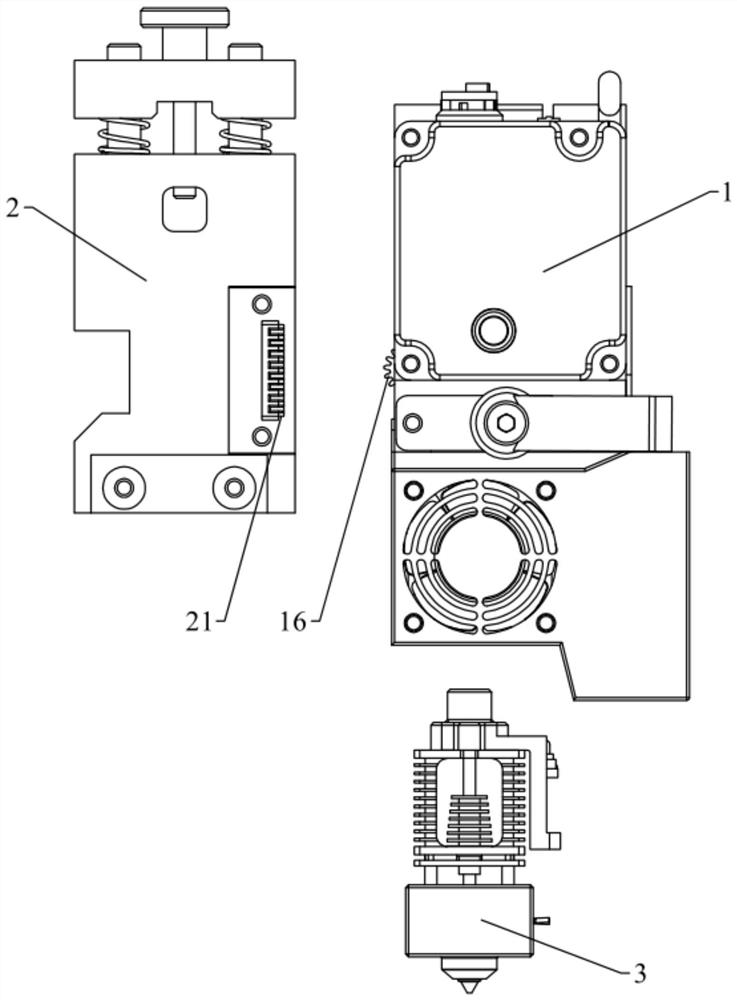

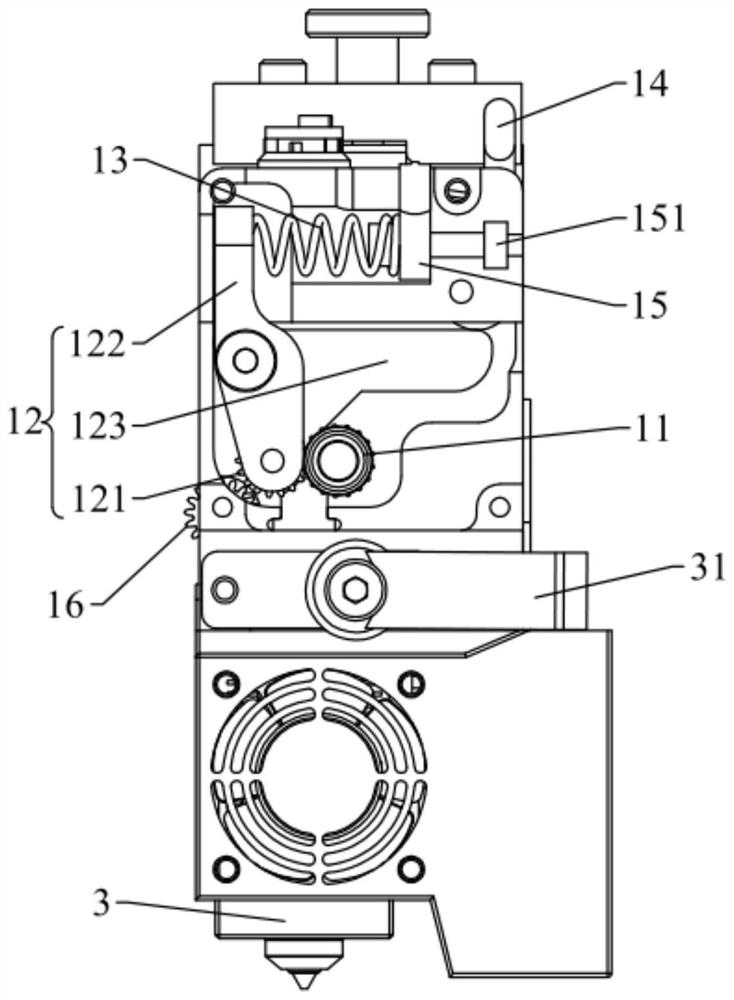

[0035] like Figure 1-Figure 7 As shown, this embodiment provides an extrusion device for a 3D printer, the extrusion device includes an extrusion body 1 and a feeding wrench 14, and the extrusion body 1 is rotatably provided with an extrusion fixed wheel 11 and an extrusion arm 12. On the extrusion arm 12, there is an extrusion moving wheel 121 that can selectively approach or move away from the extrusion fixed wheel 11. Consumables can be extruded through the approaching extrusion fixed wheel 11 and the extrusion moving wheel 121. The extrusion arm One end of 12 is in elastic contact with the extrusion body 1 through the elastic member 13, so as to drive the extrusion driving wheel 121 close to the extrusion fixed wheel 11; set and abut against one end of the extrusion arm 12 , and turn the feeding wrench 14 to drive the extrusion moving wheel 121 away from the extrusion fixed wheel 11 .

[0036] By setting the extrusion fixed wheel 11 and the extrusion moving wheel 121 on ...

Embodiment 2

[0050] This embodiment discloses a 3D printer, which includes a printing drive device and an extrusion device as described in Embodiment 1 arranged on the print drive device. The structure is simple, the operation is simple when replenishing consumables, and the efficiency is high; the extrusion force can be adjusted Large; can be quickly disassembled, easy to adjust and replace.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com