Fluoroplastic extrusion equipment

A technology of extrusion equipment and fluoroplastics, which is applied in the field of wire and cable manufacturing, can solve the problems of low efficiency of extrusion equipment, limited extrusion performance, and affecting the quality of extrusion insulation, so as to ensure the quality of extrusion insulation and avoid residence time Excessive length, the effect of relieving thermal cross-linking phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following is attached Figures 1 to 4 Examples of the present invention are given to further illustrate the specific implementation of the fluoroplastic extrusion equipment of the present invention. The fluoroplastic extrusion equipment of the present invention is not limited to the description of the following examples.

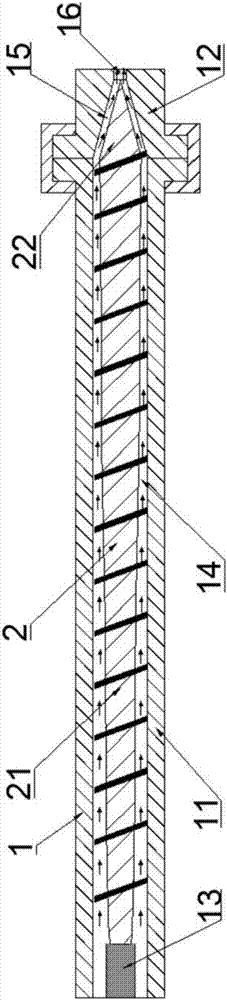

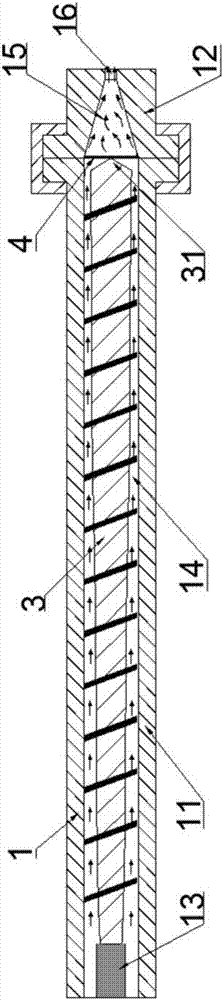

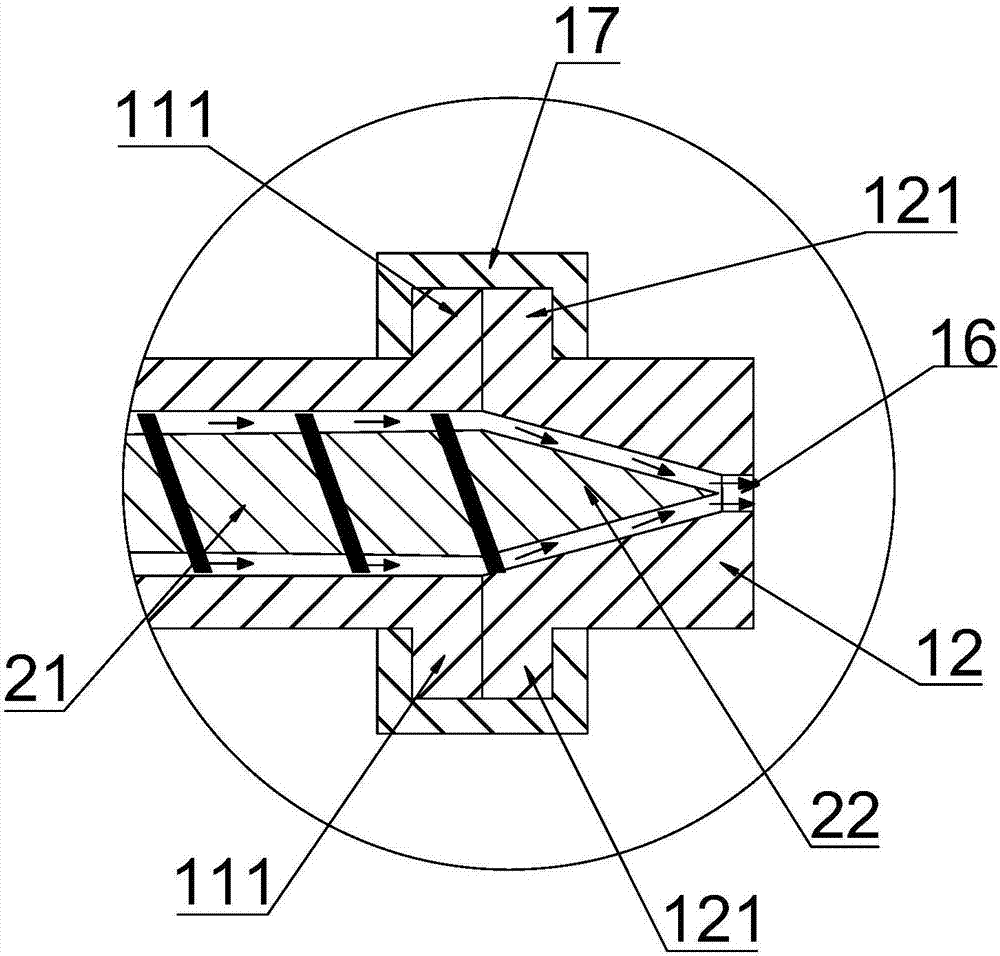

[0022] Such as figure 1 As shown, the fluoroplastic extrusion equipment of the present invention includes an extruder 1, and a cavity is provided inside the extruder 1, and the cavity includes a connected fuselage cavity 14 and a head cavity 15 for The first screw rod 2 extruding the XETFE material is rotatably installed in the cavity and arranged opposite to the extrusion hole 16 of the extruder 1. The first screw rod 2 includes a rod body 21 and a head 22 connected end to end, so The rod body 21 and the head 22 are located in the fuselage cavity 14 and the head cavity 15 respectively so as to form a streamlined channel without dead ends, so th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com