Dead-angle-free cleaning antibacterial toothbrush head, multifunctional antibacterial toothbrush head, nano toothbrush

A toothbrush head and cleaning technology, applied in the fields of nano toothbrushes and multi-functional antibacterial toothbrush heads, can solve the problems of increasing recycling, waste of resources, bacterial growth, etc., reducing the difficulty of recycling and degradation, saving manufacturing costs, Improve the effect of tightening action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

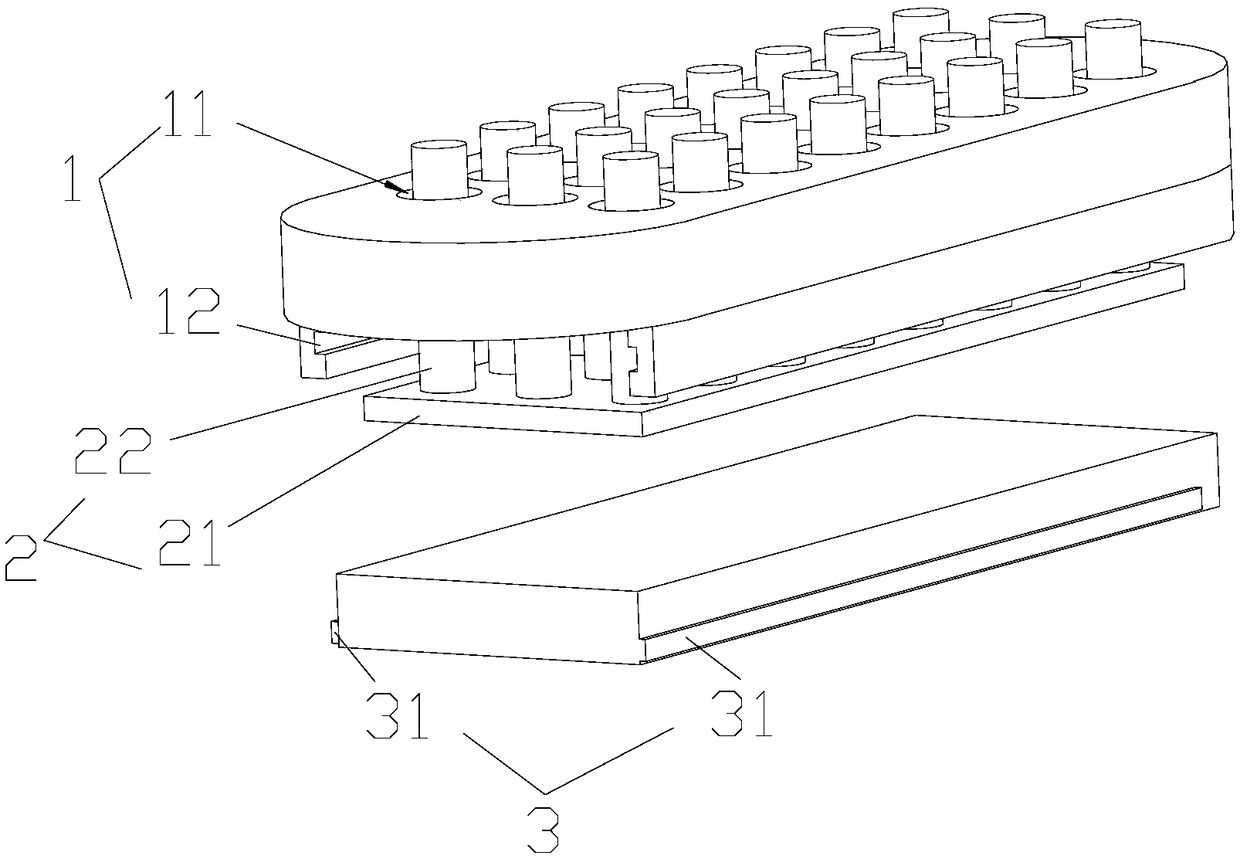

[0053] Such as Figure 1-2 As shown, this embodiment discloses a clean antibacterial toothbrush head without dead angle, which includes a cover plate 1 , a bristle body 2 , and a chassis 3 . A plurality of toothbrush filament through holes 11 are opened on the cover plate 1 , and the bristle body 2 includes a supporting plate 21 and toothbrush filaments 22 , and a plurality of toothbrush filaments 22 are implanted on the supporting plate 21 . The chassis 3 can be mated with the cover plate 1 to clamp the supporting plate 21 between the chassis 3 and the cover plate 1 , and the toothbrush wire 22 can be extended out of the toothbrush wire through hole 11 .

[0054] When the toothbrush head of the present invention needs to be used, insert the toothbrush wire 22 in the supporting plate 21 into the corresponding toothbrush wire through hole 11, so that the front of the supporting plate 21 is attached to the back side of the cover plate 1, and then the chassis 3 It is interfitted...

Embodiment 2

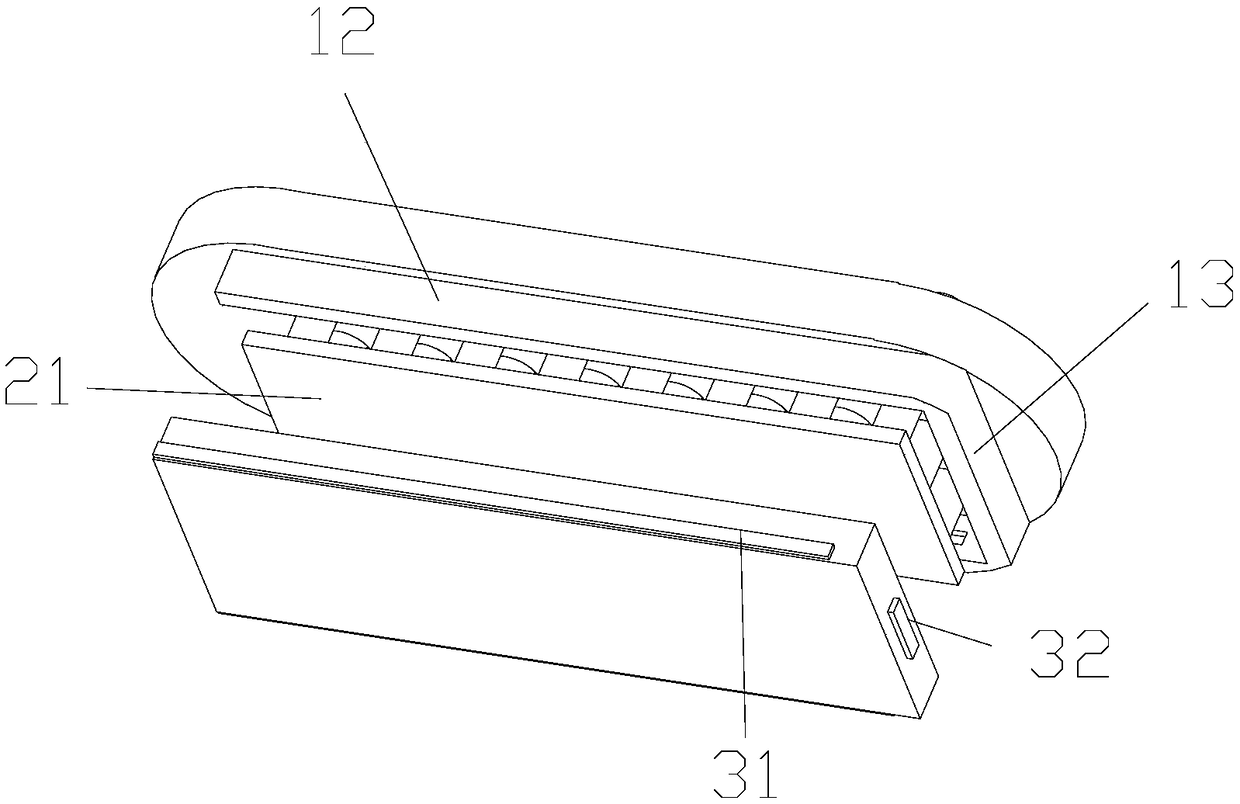

[0058] Such as Figure 1-2As shown, the difference between this embodiment and the above-mentioned embodiments is that: the two long sides of the back of the cover plate 1 are provided with slide grooves 12 , and one of the short sides is provided with a slot 13 . Both sides of the chassis 3 are provided with protrusions 31 , and one end surface is provided with a tenon 32 , the protrusions 31 can slide into the corresponding slide grooves 12 and cause the tenons 32 to be inserted into the slots 13 .

[0059] The present invention adopts a fast plug-in method to realize the interfitting between the cover plate 1 and the chassis 3 , so that the combination or separation of the cover plate 1 and the chassis 3 can be quickly realized. When assembling, the protrusions 31 on both sides of the chassis 3 are opposed to the two slide grooves 12 on the back of the cover plate 1, and the chassis 3 is slid until the tenons 32 are inserted into the corresponding slots 13 to complete the a...

Embodiment 3

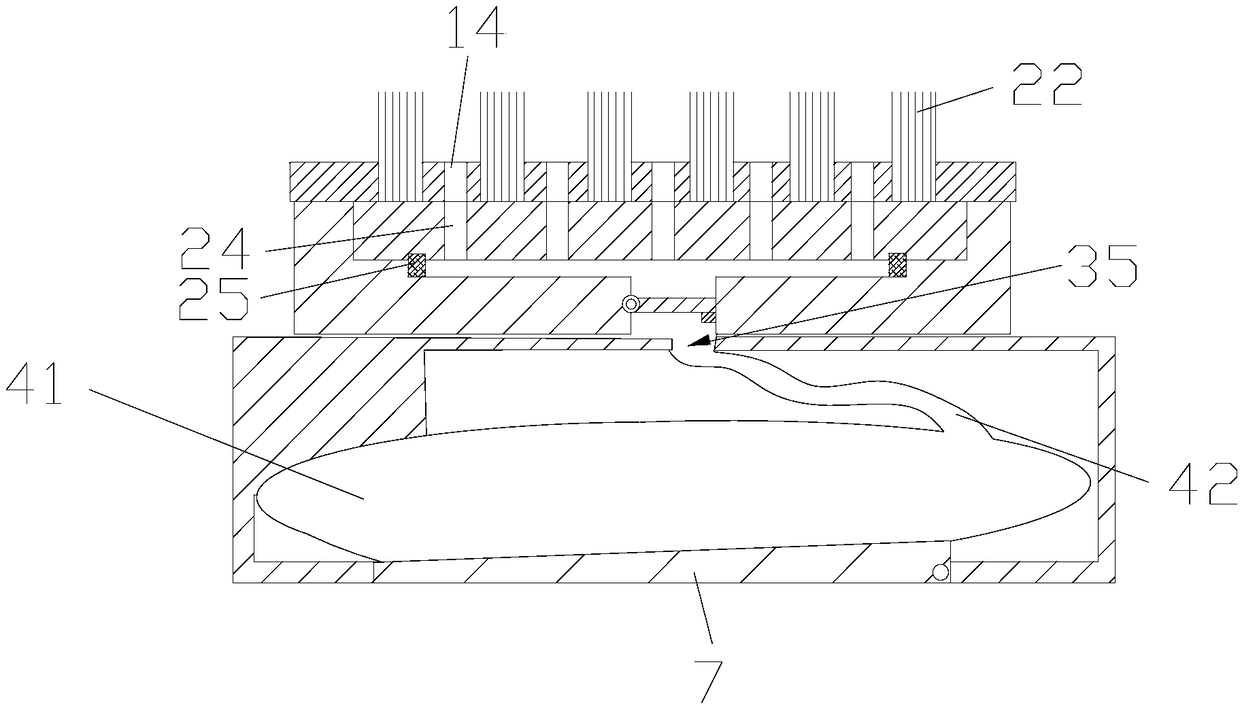

[0061] Such as image 3 , 4 , 8, and 9, the difference between this embodiment and the above-mentioned embodiments is that a functional box 4 is also connected to the chassis 3 . A plurality of toothbrush filament through holes 11 correspond to a plurality of toothbrush filaments 22 one by one, or a plurality of toothbrush filaments 22 protrude from each toothbrush filament through hole 11 . A plurality of outlets 14 are opened on the cover plate 1 , and the outlets 14 are located in the gaps between the through holes 11 of adjacent toothbrush filaments. The support plate 21 is provided with a plurality of feeding ports 24, and the feeding ports 24 are located in the gaps between adjacent bundles of toothbrush filaments 22. The feeding port 24 is in one-to-one correspondence with the discharging port 14 . A ring sealing structure 25 is also provided on the back of the supporting plate 21 , and a plurality of feeding ports 24 are all limited in the sealing structure 25 . A ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com