Lifting logistical trolley

A trolley and logistics technology, which is applied in the field of trolleys, can solve the problems of lifting difficult materials to the designated handling position, and achieve the effect of improving handling capacity, convenient handling and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

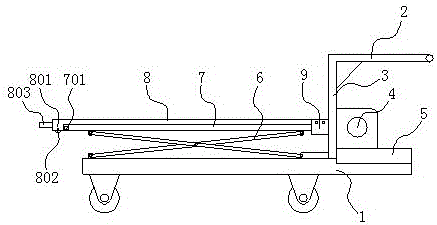

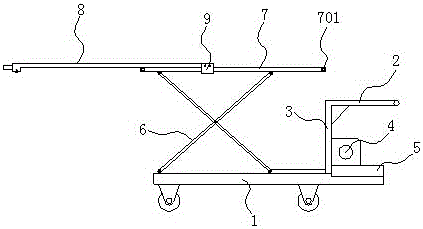

[0013] Now in conjunction with accompanying drawing, the present invention is described as follows.

[0014] Such as figure 1 , figure 2 As shown, the lifting logistics trolley includes a car floor 1, a carrier plate 7, a slide plate 8, a push handle 2, and a lifting mechanism. The lifting mechanism includes a hydraulic cylinder 5, a hydraulic pump 4, a power supply, a controller, and a scissor bracket 6. Promptly lifting mechanism is the scissor type lifting mechanism of prior art. The bottom of the vehicle floor 1 is provided with rollers, and the upper part is provided with a vertical plate 3 vertically fixed to the vehicle floor 1. The support surface of the vehicle floor 1 is divided into two parts by the vertical plate 3. One part supports the scissor bracket 6, the carrier plate 7, and the skateboard. 8. The other part supports the power supply, hydraulic pump 4, hydraulic cylinder 5, and the top of the riser 3 is fixedly connected to the push handle 2. The carrier ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com