Fruits and vegetables temperature control storage and transportation dedicated plastic pass box unit with hold-over plate for insulating truck

The technology of a plastic turnover box and a cold storage plate is applied in the field of temperature control boxes, which can solve the problems of the quality decline of fruits and vegetables, high cost of heat preservation vehicles, high energy consumption, etc., and achieve the effects of preventing cold damage of fruits and vegetables, large loading space, and uniform temperature distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with drawings and embodiments.

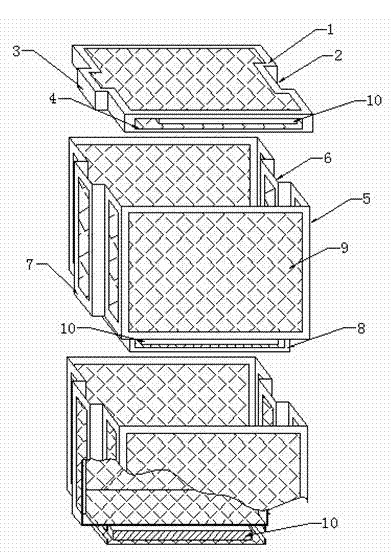

[0012] Such as figure 1 Shown, the present invention comprises a plurality of identical casings 5 and a casing cover 1; All have casing grooves 6 perpendicular to respective casing bottom surfaces at the same central position on one side of a plurality of identical casings 5, the casings The body groove 6 is until the bottom surface of each box body 5, and a box body convex groove 7 perpendicular to the bottom surface of the box body is formed at the same center position on the other side of the same box body 5, and the box body convex groove 7 reaches the bottom surface of each box body. The bottom surface of the body, the box groove 6 is the same size as the box convex groove 7, and there is a layer under the bottom surface of the box in each box groove 6 and box convex groove 7, which can be put into the four sides of the cold storage plate 10. Cool storage frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com