Three-cavity sterile bag and preparation method thereof

A three-chamber sterile bag and three-chamber bag technology are applied in the field of infusion bags, which can solve the problems of high production cost, difficulty, high production and use costs, and achieve the effects of stable and guaranteed quality, simple structure, and avoidance of waste.

Active Publication Date: 2011-06-15

SICHUAN KELUN PHARMA CO LTD

View PDF10 Cites 25 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, "sterility" is an absolute concept by definition, but unfortunately, in today's highly developed science and technology, absolute sterility can neither be achieved nor verified.

Above, this hybrid approach increases the chances of drug products being contaminated with microbiological risks

At the same time, due to the high construction and operating costs of the sterile dispensing room, it is difficult to establish a sterile dispensing room for general hospitals

At the same time, it also hinders the promotion of mixed infusion methods with therapeutic advantages

Moreover, taking the medicine multiple times will result in multiple punctures of the rubber stopper, which may cause the risk of particle contamination of the infusion product due to repeated friction between the rubber stopper and the insertion needle, and at the same time, the production and use costs are relatively high

But now the medical multi-cavity bag mixed liquid bag that has been used has a complicated manufacturing process. Generally, a single-layer film is folded into double parts, and the infusion tube mouth is welded to make a bag, and then through the side or back, the A variety of different liquid medicines are poured into each chamber in the bag, and sealed into a multi-chamber bag by high-temperature welding

There are also many production processes, and the inner layer in contact with the liquid medicine is directly exposed to the air during bag making, which affects the stability of the final product quality

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

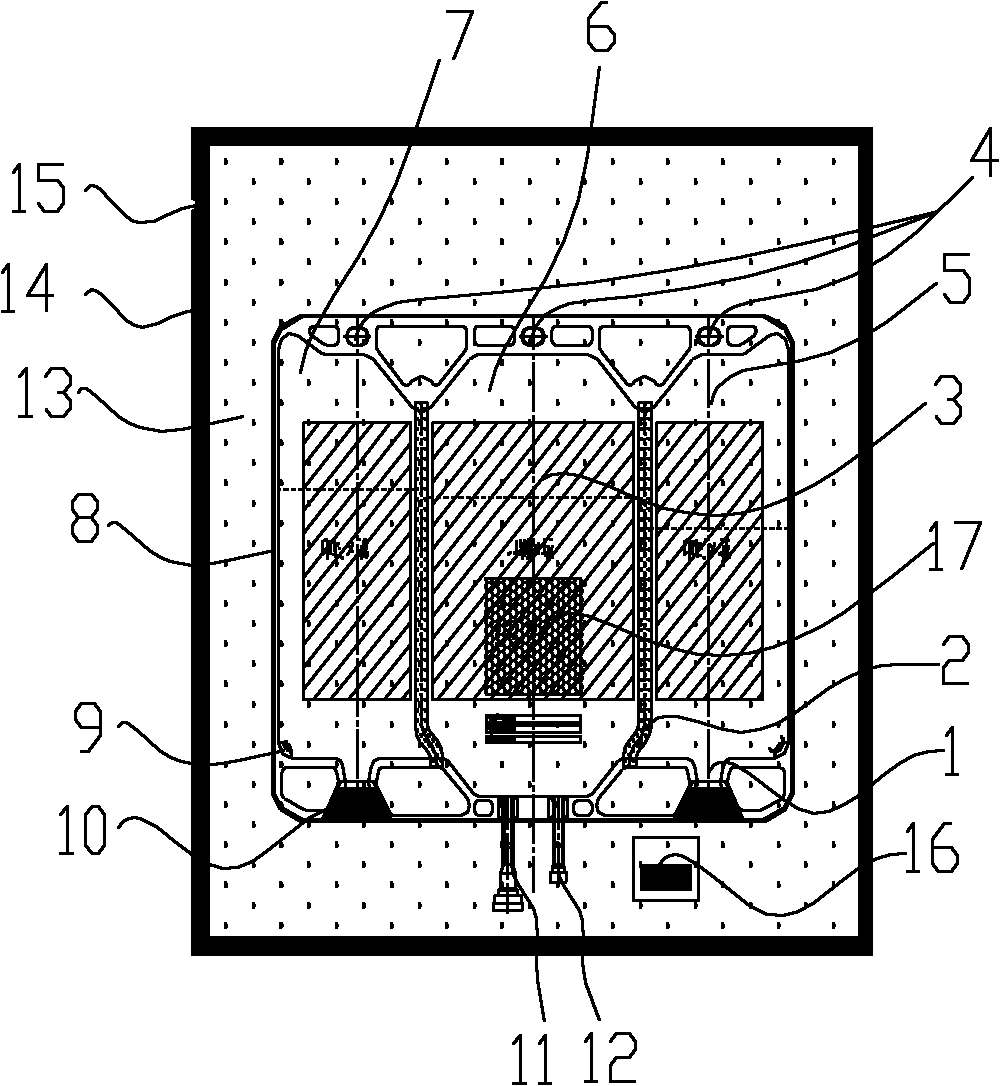

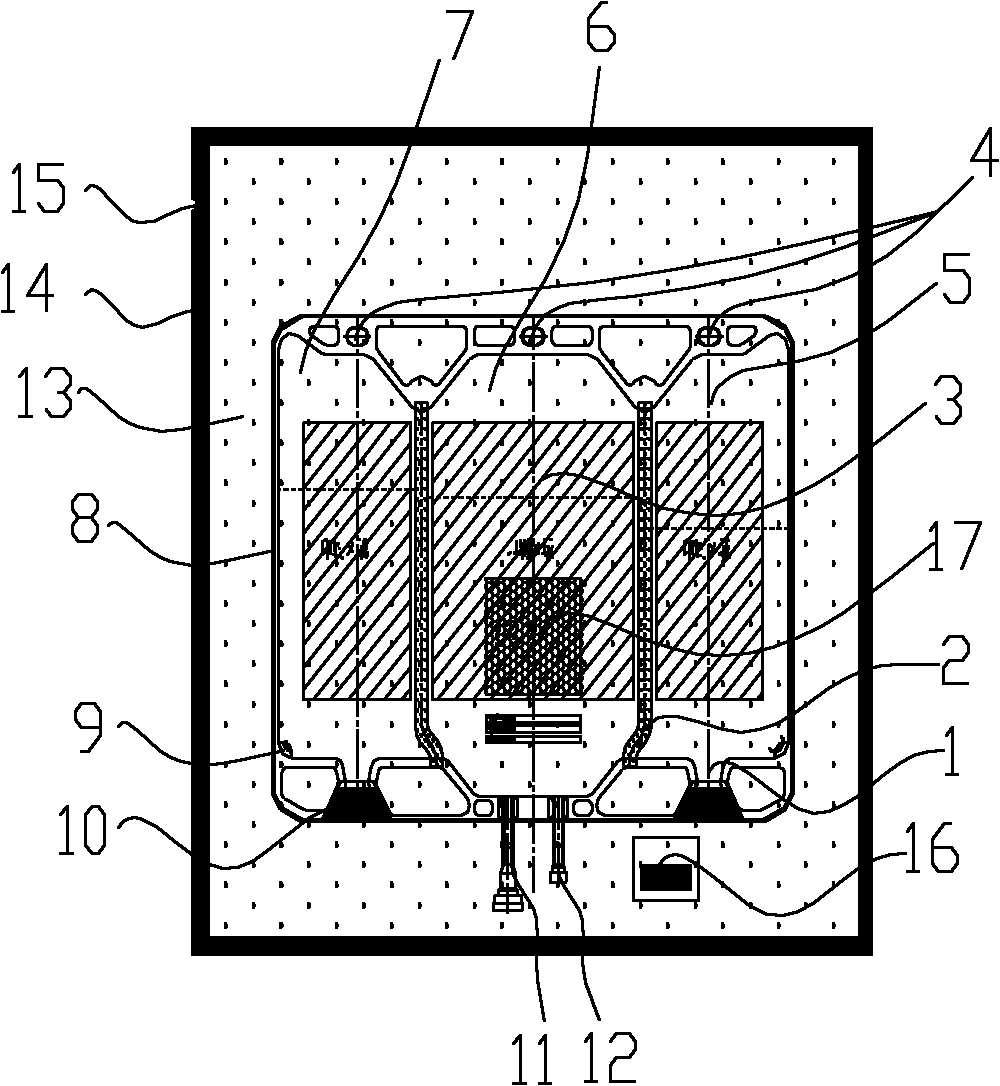

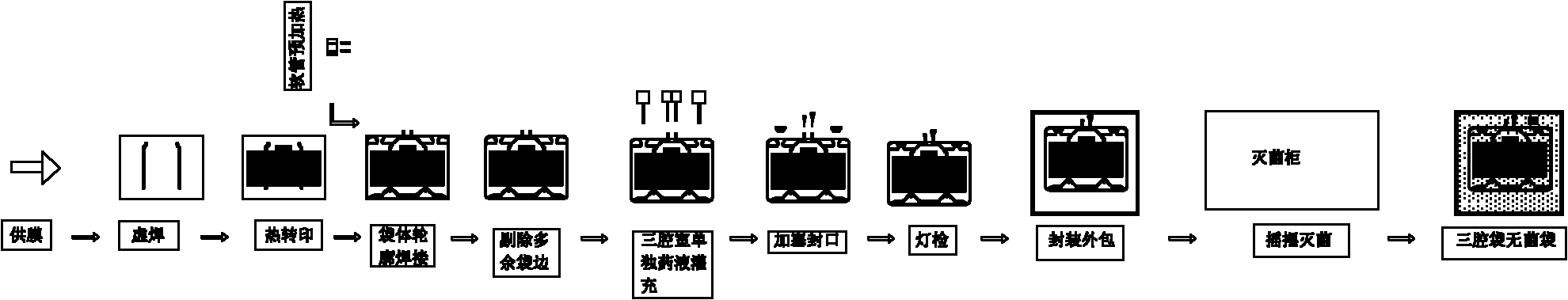

The invention discloses a three-cavity sterile bag and a preparation method thereof. The square sterile bag consists of a double-cavity inner bag and an outer packaging bag, wherein the double-cavity inner bag is formed by welding horn-shaped liquid filling ports, arc-shaped insufficient soldering strips with opening points, thermal transfer with independent cavities, hanging holes, an A liquid medicament cavity, an intermediate liquid medicament cavity, a C liquid medicament cavity, three-cavity bag sides, three-cavity bag corners, straight-strip sealing grids, a medicament delivery plug and a medicament feeding plug into a whole through heat seal; and one side of the outer packaging bag is provided with an outer packaging bag welding edge and an outer packaging bag opening mouth. The preparation method of the sterile bag comprises the steps of bag molding, preparation of filling junctions of the bag, filling, lamp inspection, packaging and sterilization. The three-cavity sterile bag is simple in structure and easy to operate; and for the insufficient soldering of the bag, scientific external force opening points are designed, so that the insufficient soldering of the bag is more operable.

Description

A three-chamber aseptic bag and its manufacturing method technical field The invention relates to an infusion bag, in particular to a three-cavity aseptic bag and its manufacturing method Background technique In clinical practice, if a patient needs to infuse multiple different infusions at the same time, it is generally adopted to mix a variety of single different products before use. Different single varieties are taken out and mixed evenly, and then the mixed medicinal liquid is input into the human body. However, "sterility" is an absolute concept by definition, but unfortunately, in today's highly developed science and technology, absolute sterility can neither be achieved nor verified. Above, this method of mixing increases the chances of the drug being contaminated with microorganisms. At the same time, due to the high construction and operating costs of the aseptic dispensing room, it is difficult to establish a sterile dispensing room in general hospitals. Simu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A61J1/10A61J1/14

Inventor 谭鸿波朱仲强吴小愚吴帅辉罗雅兵崔兵

Owner SICHUAN KELUN PHARMA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com