Double-stage parallel-connection rigid power transmission system for auxiliary transport vehicle under low type coal mine

A power transmission system, auxiliary transportation technology, applied in vehicle parts, transportation and packaging, axles, etc., can solve the problems of limited use, hinder the reduction of the height of the hopper or U-shaped frame, etc., to increase the loading space, save the loading space, Stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In conjunction with accompanying drawing, the specific embodiment of the present invention is described further:

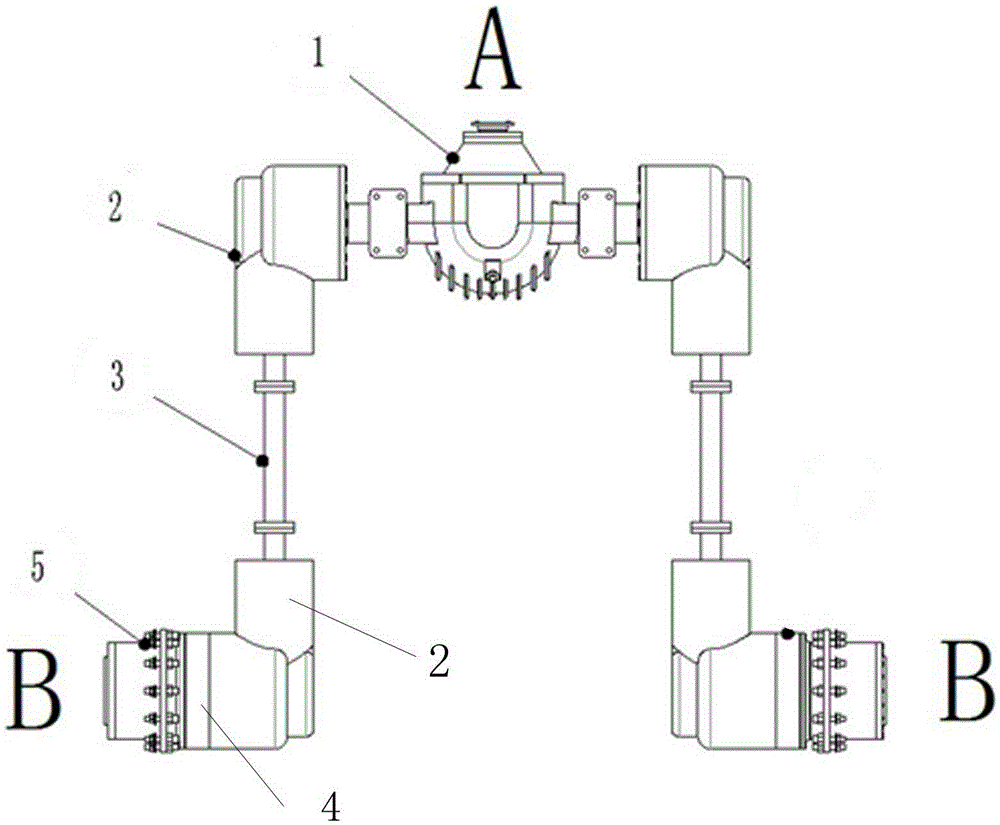

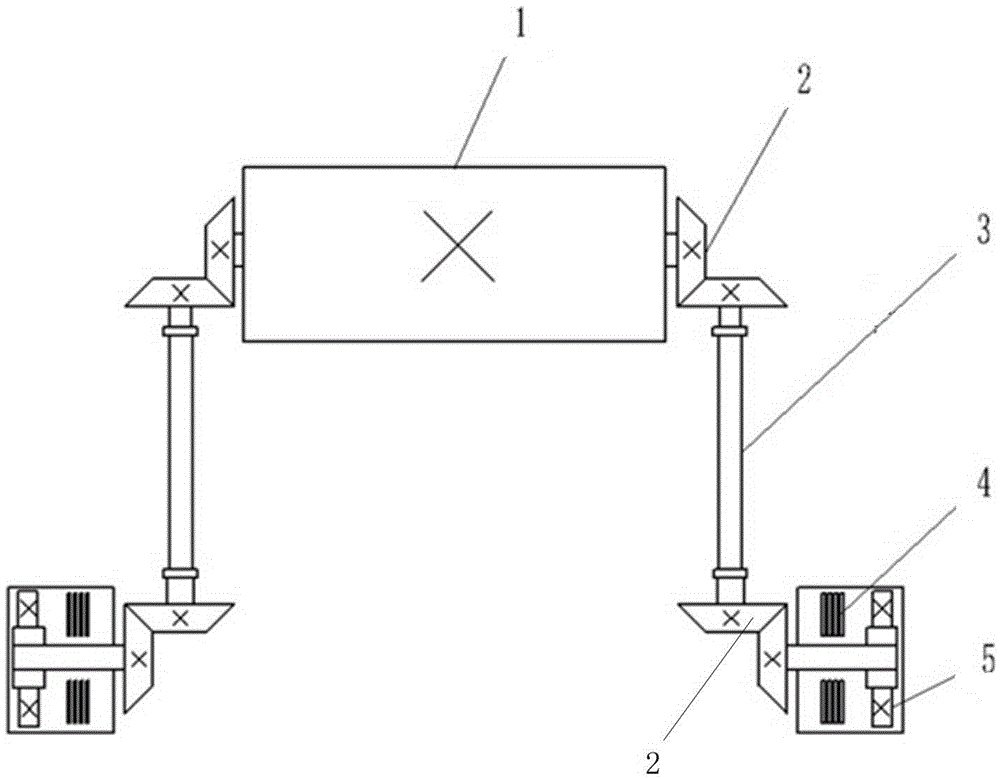

[0018] Such as figure 1 , 2 The shown double-stage parallel rigid power transmission system for a low-profile coal mine auxiliary transport vehicle includes a drive axle main body 1 and two sets of wheel brakes, the wheel brakes are integrated by a wet safety brake 4 and a wheel reducer 5, The two groups of wheel brakes are respectively arranged in parallel on both sides of the rear of the drive axle main body 1 through a transmission mechanism with a transmission ratio of 1; the transmission mechanism includes two transmission boxes 2 rigidly connected by a transmission shaft 3, one of which is The transmission box 2 is connected with the middle half shaft of the drive axle main body 1 through its spline shaft, and the other transmission box 2 is connected with the sun gear in the wheel brake through its spline shaft.

[0019] The transmission box 2 adop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com