Lithium-sulfur battery flexible electrode material and preparation method and application thereof

A lithium-sulfur battery and flexible electrode technology, applied in the field of lithium-sulfur battery flexible electrode materials and their preparation, can solve the problems of not easy to scale up production, limited sulfur binding capacity, loss of active material, etc., achieve excellent cycle stability, improve binding The effect of increasing power and conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] A flexible electrode material for lithium-sulfur batteries, including single-walled carbon nanotube-wound VO x nano hollow spheres, the VO x The nano hollow sphere is coated with sulfur element.

[0063] Its preparation method is as follows:

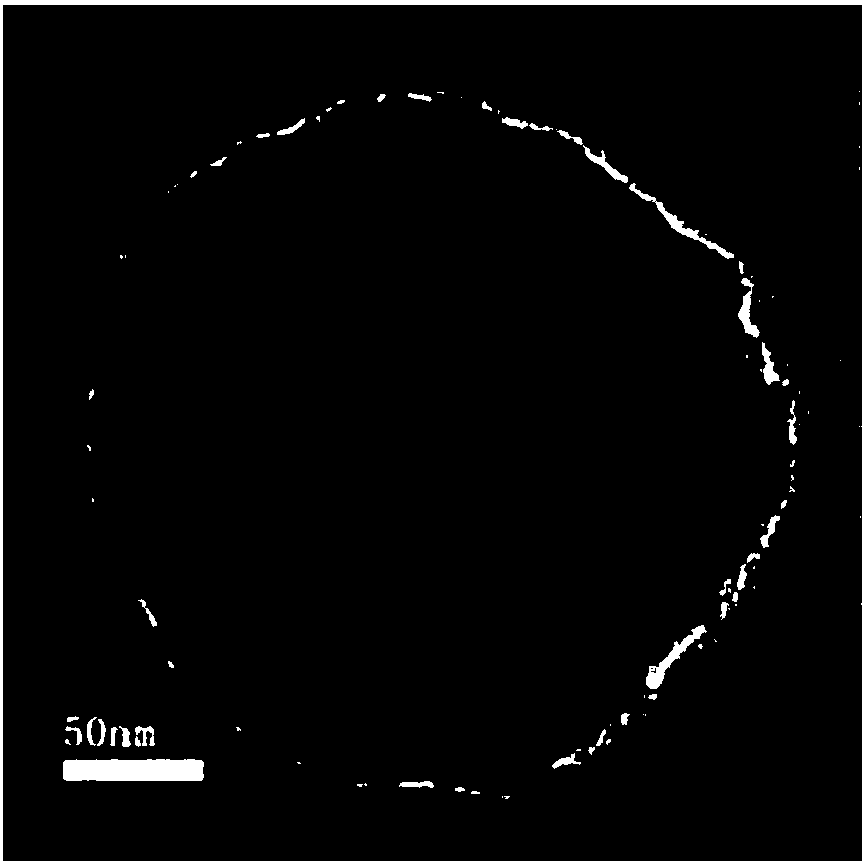

[0064] (1) Dissolve 0.05g of vanadyl acetylacetonate into 20mL of N-N dimethylformamide solution, stir at room temperature for 2h, transfer the solution to a polytetrafluoroethylene reactor, then transfer the reactor to a drying oven to raise the temperature To 200 ℃, keep 21h, then naturally cool to room temperature. Take out the suspension in the reaction kettle, centrifuge at 8000r / min for 5min, collect the precipitate, wash with absolute ethanol for 3 times, then dry at 50°C for 10h, and collect VO with a particle size of about 200nm x Hollow balls, such as figure 1 , figure 2 shown.

[0065] (2) will VO x Mix hollow spheres with sulfur powder at a mass ratio of 1:2, put them into a sealed glass container with a cover ...

Embodiment 2

[0068] The only difference from Example 1 is that the mass of vanadyl acetylacetonate is 0.1 g.

[0069] As a result, step (1) collects VO with a particle size of about 400nm x Hollow balls, such as Figure 4 , Figure 5 shown;

[0070] Step (2) to get VO x Solid spheres complexed with sulfur, such as Image 6 As shown, through elemental analysis, it is found that the core of the obtained solid sphere is sulfur element, and the shell is VO x . The resulting flexible film product is denoted VHS-400@S / SWCNT.

Embodiment 3

[0072] The only difference from Example 1 is that the mass of vanadyl acetylacetonate is 0.3g.

[0073] As a result, step (1) collects VO with a particle size of about 900nm x Hollow balls, such as Figure 7 , Figure 8 shown;

[0074] Step (2) to get VO x Solid spheres complexed with sulfur, such as Figure 9 As shown, through elemental analysis, it is found that the core of the obtained solid sphere is sulfur element, and the shell is VO x . The resulting flexible film product is denoted VHS-900@S / SWCNT.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com